Journal of South China University of Technology(Natural Science Edition) ›› 2025, Vol. 53 ›› Issue (3): 97-104.doi: 10.12141/j.issn.1000-565X.230489

• Materials Science & Technology • Previous Articles Next Articles

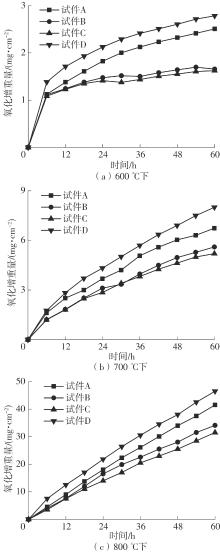

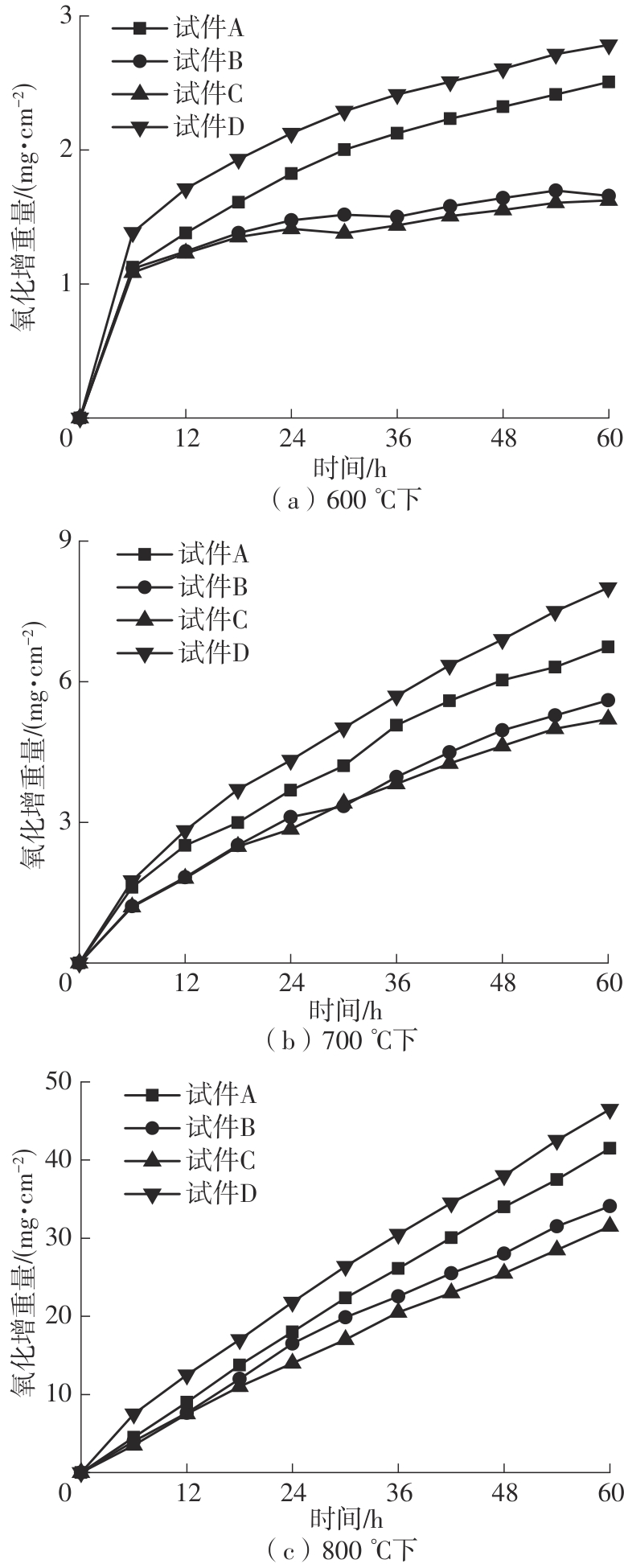

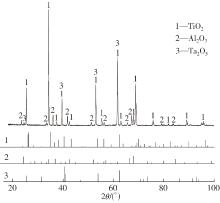

Preparation and Performance Analysis of High Temperature Oxidation Cladding Coating on TC4 Surface

ZHENG Lijuan( ), XIE Yinkai, ZHANG Kuo, FU Yuming(

), XIE Yinkai, ZHANG Kuo, FU Yuming( )

)

- School of Mechanical Engineering,Yanshan University,Qinhuangdao 066004,Hebei,China

-

Received:2023-07-19Online:2025-03-10Published:2024-10-25 -

Contact:FU Yuming E-mail:ydzlj@ysu.edu.cn;mec9@ysu.edu.cn -

Supported by:the Natural Science Foundation of Hebei Province(E2021203218)

CLC Number:

Cite this article

ZHENG Lijuan, XIE Yinkai, ZHANG Kuo, FU Yuming. Preparation and Performance Analysis of High Temperature Oxidation Cladding Coating on TC4 Surface[J]. Journal of South China University of Technology(Natural Science Edition), 2025, 53(3): 97-104.

share this article

| 1 | LIU Z, ZHANG D C, GONG L J,et al .Microstructures and mechanical properties of in situ TiC-β-Ti-Nb composites with ultrafine grains fabricated by high-pressure sintering[J].Scientific Reports,2018,8:9496/1-9. |

| 2 | 付宇明,马顺芯,刘绍峰,等 .TC4表面激光熔覆硬质复合涂层组织与性能[J].华南理工大学学报(自然科学版),2024,52(3):10-17. |

| FU Yuming, MA Shunxin, LIU Shaofeng,et al .Microstructure and properties of laser cladding hard composite coating on TC4 surface [J].Journal of South China University of Technology (Natural Science Edition),2024,52(3):10-17. | |

| 3 | ZHANG D C, MAO Y F, YAN M,et al .Superelastic behavior of a β-type titanium alloy[J].Journal of the Mechanical Behavior of Biomedical Materials,2013,20:29-35. |

| 4 | SONG R, LI J, SHAO J Z,et al .Microstructural evolution and wear behaviors of laser cladding Ti2Ni/α(Ti) dual-phase coating reinforced by TiB and TiC[J].Applied Surface Science,2015,355:298-309. |

| 5 | GUO S Q .Densification of ZrB2-based composites and their mechanical and physical properties:a review[J].Journal of the European Ceramic Society,2009,29(6):995-1011. |

| 6 | LI Z, GOBBI S, NORRIS I,et al .Laser welding techniques for titanium alloy sheet[J].Journal of Materials Processing Technology,1997,65:203-208. |

| 7 | XU X, YU Y, HUANG H .Mechanisms of abrasive wear in the grinding of titanium (TC4) and nickel (K417)alloys[J].Wear,2003,255:1421-1426. |

| 8 | QIN Y, XIONG D, LI J .Tribological properties of laser surface textured and plasma electrolytic oxidation duplex-treated Ti6Al4V alloy deposited with MoS2 film[J].Surface and Coatings Technology,2015,269:266-272. |

| 9 | KUMAR S A, RAMAN S G S, NARAYANAN T S N S, et al .Influence of counterbody material on fretting wear behaviour of surface mechanical attrition treated Ti-6Al-4V[J].Tribology International,2013,57:107-114. |

| 10 | 覃鑫,祁文军,左小刚 .TC4钛合金表面激光熔覆NiCrCoAlY-Cr3C2复合涂层的摩擦和高温抗氧化性能[J].材料工程,2021,49(12):107-114. |

| QIN Xin, QI Wen-jun, ZUO Xiao-gang .Friction and high temperature oxidation resistance of laser cladding NiCrCoAlY-Cr3C2 composite coating on TC4 titanium alloy[J].Journal of Materials Engineering,2021,49(12):107-114. | |

| 11 | 周璇,肖华强,赵欣鑫,等 .TC4合金表面激光熔覆TiAl涂层的高温循环氧化行为[J].中国有色金属学报,2023,33(2):400-412. |

| ZHOU Xuan, XIAO Hua-qiang, ZHAO Xin-xin,et al . High-temperature cyclic oxidation behavior of laser cladding TiAl coating on TC4 alloy surface[J].The Chinese Journal of Nonferrous Metals,2023,33(2):400-412. | |

| 12 | 单晓浩,王存山,于群 .钛合金表面激光熔覆Nb-Al-Ti高温合金涂层组织与性能[J].中国激光,2016,43(8):0802015/1-8. |

| SHAN Xiaohao, WANG Cunshan, YU Qun .Microstructure and property of Nb-Al-Ti high temperature alloy coatings by laser cladding on Ti alloy surfaces[J].Chinese Journal of Lasers,2016,43(8):0802015/1-8. | |

| 13 | 于多,殷杰,张步豪,等 .碳化物超高温陶瓷材料研究进展[J].航空制造技术,2019,62(19):53-64. |

| YU Duo, YIN Jie, ZHANG Buhao,et al .Recent research progresses on ultrahigh temperature carbide ceramic materials [J].Aeronautical Manufacturing Technology,2019,62(19):53-64. | |

| 14 | YOO H, KIM H S, HONG B G,et al .Hafnium carbide protective layer coatings on carbon/carbon composites deposited with a vacuum plasma spray coating method [J].Journal of the European Ceramic Society,2016,36(7):1581-1587. |

| 15 | 董天下,孟凡桂,陈红梅,等 .石墨表面TaC涂层的熔盐法制备及表征[J].表面技术,2023,52(2):297-306. |

| DONG Tian-xia, MENG Fan-gui, CHEN Hong-mei,et al . Preparation and characterization of TaC coating on graphite via molten salt method[J].Surface Technology,2023,52(2):297-306. | |

| 16 | GOWTHAM A, CHAITANYA G, KATIYAR J K,et al . Experimental investigations on laser cladding of NiCrBSi+WC coating on SS410[J].Materials Today:Proceedings,2020,27:1984-1989. |

| 17 | MOSTAJERAN A, SHOJA-RAZAVI R, HADI M,et al . Evaluation of the mechanical properties of WC-FeAl composite coating fabricated by laser cladding method[J].International Journal of Refractory Metals and Hard Materials,2020,88:105199/1-10. |

| 18 | YAO J, ZHANG J, WU G,et al .Microstructure and wear resistance of laser cladded composite coatings prepared from pre-alloyed WC-NiCrMo powder with different laser spots [J].Optics and Laser Technology,2018,101:520-530. |

| 19 | 吴腾,师文庆,谢林圯,等 .激光熔覆铁基TiC复合涂层成形质量的控制方法[J].激光技术,2022,46(3):344-354. |

| WU Teng, SHI Wenqing, XIE Linyi,et al .Forming quality control method of laser cladding Fe-based TiC composite coating[J].Laser Technology,2022,46(3):344-354. | |

| 20 | 侯锁霞,赵江昆,李强,等 .对激光熔覆形成缺陷的影响因素的探究[J].材料导报,2022,36(Z1):22030105/1-4. |

| HOU Suoxia, ZHAO Jiangkun, LI Qiang,et al .Study on the influencing factors of laser cladding defects[J].Materials Reports,2022,36(Z1):22030105/1-4. | |

| 21 | 张杰,张群莉,姚建华,等 .激光熔覆工艺参数对IN718合金组织及元素偏析的影响[J].热加工工艺,2022,51(19):30-34,40. |

| ZHANG Jie, ZHANG Qunli, YAO Jianhua,et al .Effect of laser cladding process parameters on microstructure and element segregation of IN718 alloy[J].Hot Working Technology,2022,51(19):30-34,40. | |

| 22 | 赵晖,孙旭,杜春燕,等 .TC4合金表面激光熔覆材料研究进展[J].沈阳理工大学学报,2022,41(1):31-37. |

| ZHAO Hui, SUN Xu, DU Chunyan,et al .Progress in research of laser cladding materials on TC4 alloy surface[J].Journal of Shenyang Ligong University,2022,41(1):31-37. | |

| 23 | 许明三,周春辉,张正,等 .激光熔覆过程中的粉、气、光耦合温度场[J].中国机械工程,2022,33(1):70-77. |

| XU Mingsan, ZHOU Chunhui, ZHANG Zheng,et al . Temperature distribution of powder-gas-optical coupling temperature field in laser cladding processes[J].China Mechanical Engineering,2022,33(1):70-77. | |

| 24 | BARIN I, KNACKE O, KUBASCHEWSKI O .Thermochemical properties of inorganic substances[M]. Berlin/Heidelberg:Springer,1977. |

| 25 | 张伟祥,唐超兰,陈志茹,等 .退火温度对激光选区熔化成形TC4钛合金组织及力学性能的影响[J].金属热处理,2019,44(6):122-127. |

| ZHANG Weixiang, TANG Chaolan, CHEN Zhiru,et al .Effect of annealing temperature on microstructure and mechanical properties of TC4 titanium alloy formed by selective laser melting[J].Heat Treatment of Metals,2019,44(6):122-127. | |

| 26 | 肖振楠,刘婷婷,廖文和,等 .激光选区熔化成形TC4钛合金热处理后微观组织和力学性能[J].中国激光,2017,44(9):0902001/1-9. |

| XIAO Zhennan, LIU Tingting, LIAO Wenhe,et al . Microstructure and mechanical properties of TC4 titanium alloy formed by selective laser melting after heat treatment [J].Chinese Journal of Lasers,2017,44(9):0902001/1-9. | |

| 27 | CHEN Dong, WANG Quansheng, LIU Yanbo,et al .Effect of Ta2O5-Y2O3 dopants on phase structure, fracture toughness and thermophysical properties of zirconia[J].Rare Metal Materials and Engineering,2021,50(6):1890-1895. |

| 28 | 李浩,王松,余艺平,等 .Ta-Hf体系材料研究进展[J].中国陶瓷,2020,56(11):10-18. |

| LI Hao, WANG Song, Yu Yiping .Research progress of Ta-Hf system materials[J].China Ceramics,2020,56(11):10-18. |

| [1] | FU Yuming, LI Changcheng, YAN Maorong, ZHENG Lijuan. Microstructure and High Temperature Deformation Resistance of Nickel-Based Coating on TC4 Surface [J]. Journal of South China University of Technology(Natural Science Edition), 2025, 53(1): 108-117. |

| [2] | FU Yuming, MA Shunxin, LIU Shaofeng, et al. Microstructure and Properties of Laser Cladding Hard Composite Coating on TC4 Surface [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(3): 10-17. |

| [3] | ZHENG Lijuan, HU Zitao, LIU Shaofeng, et al. Preparation and Analysis of Laser Cladding Hard Coating on TC4 Surface [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(6): 146-152. |

| [4] | WANG Qingqing, LIU Zhanqiang, CHENG Yanhai, et al. Hardness Prediction of TC4 Machined Surface Based on the Evolution of Multi-scale Grain Refinement [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(2): 35-46. |

| [5] | KANG Lan, WU Bin, CHEN Zhibang. Mechanical Property of Reworked Part of Locally Corroded Steel Plate Repaired with Laser Cladding Technology [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(5): 137-146. |

| [6] | HE Ya-feng LU Wen-zhuang GAN Wei-min . Electrochemical Corrosion Behaviors of Titanium Alloy in Different Solutions [J]. Journal of South China University of Technology (Natural Science Edition), 2017, 45(6): 124-130. |

| [7] | HE Ya-feng LU Wen-zhuang GAN Wei-min. A Probe into Multi-Physics Coupling in Electrochemical Machining Process of Square Holes in Titanium Alloys [J]. Journal of South China University of Technology (Natural Science Edition), 2016, 44(5): 110-116. |

| [8] | QU Sheng-guan PAN Yu-xiang LI Gang LI Xiao-qiang YANG Chao. Warming-Assisted Burnishing and Fretting Wear Performance of Ti-6Al-4V Alloys [J]. Journal of South China University of Technology (Natural Science Edition), 2016, 44(3): 1-7. |

| [9] | Zhao Wei Wang Sheng-zhang Li Liang Yang Yin-fei. Evaluation of Cutting Tool Performance of End Mills for Titanium Alloy Components [J]. Journal of South China University of Technology (Natural Science Edition), 2015, 43(9): 121-127. |

| [10] | Xu An- yang Liu Zhi- dong Li Wen- pei Qiu Ming- bo Tian Zhong- jun. In- Situ Synthesis of TiN Coating on Titanium Alloy Surface by EDM with Functional Electrode [J]. Journal of South China University of Technology (Natural Science Edition), 2014, 42(1): 11-16. |

| [11] | Li Yuan-yuan Zou Li-ming Yang Chao. Fabrication of Biomedical Titanium Alloys with High Strength and Low Modulus by Means of Powder Metallurgy [J]. Journal of South China University of Technology(Natural Science Edition), 2012, 40(10): 43-50. |

| [12] | Wang Zhen-min Zhang Dong Li Jin Huang Shi-sheng. All-Position Automatic Welding Process for Tube Sheet of Heat Exchanger [J]. Journal of South China University of Technology (Natural Science Edition), 2010, 38(5): 100-104. |

| [13] | Xu Hong-hao Zuo Dun-wen Zhu Xiao-xiao Wang Min . Modification Mechanism of Residual Stress on Milled Surface with Stretching Fixation [J]. Journal of South China University of Technology (Natural Science Edition), 2008, 36(2): 89-93,100. |

| [14] | Li Xiaoqiang Li Yuanyuan Shao Ming. Diffusion Bonding of Titanium Alloy to Stainless Steel Web with a Nickel Interlayer [J]. Journal of South China University of Technology(Natural Science Edition), 2003, 31(6): 51-55. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||