| 1 |

吴泽宇,李明航,王文斌,等 .车轮踏面粗糙度对基于惯性基准法的钢轨波磨检测结果影响分析[J].振动与冲击,2023,42(15):241-249.

|

|

WU Zeyu, LI Minghang, WANG Wenbin,et al .Influence analysis of wheel tread roughness on rail corrugation detection results based on inertial reference method[J].Journal of Vibration and Shock,2023,42(15):241-249.

|

| 2 |

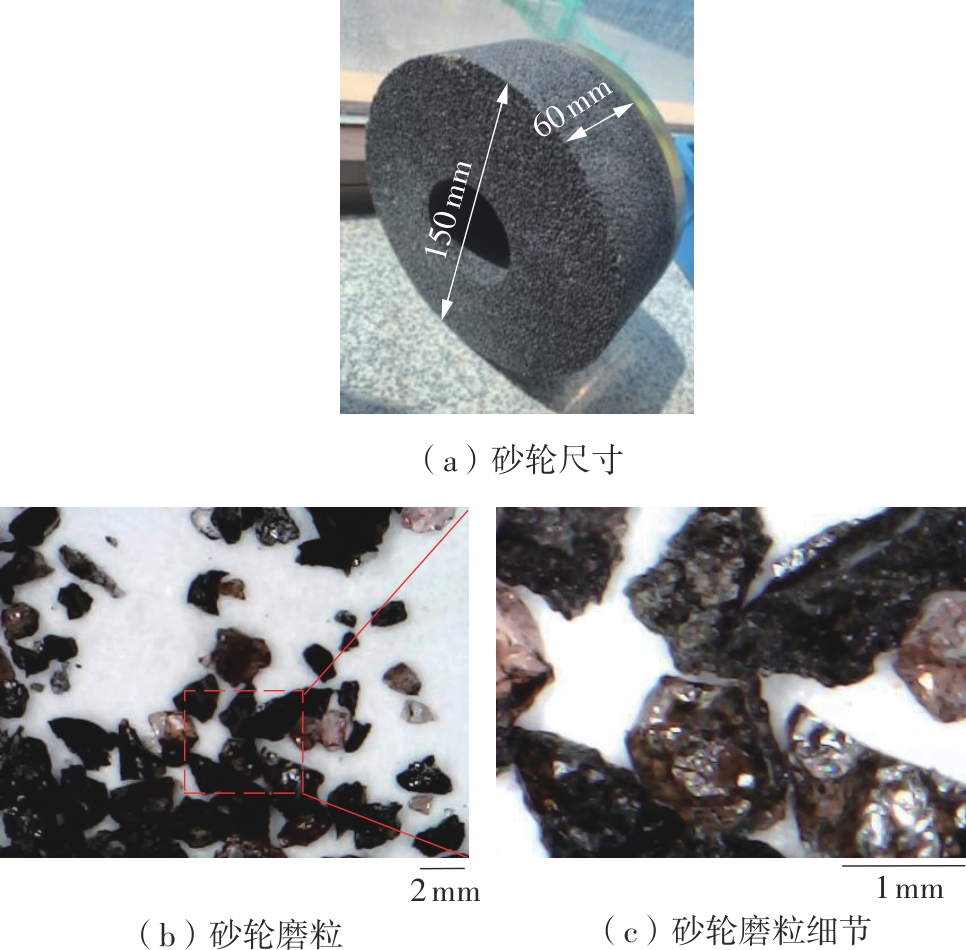

张胜,刘长宝,樊小强,等 .固化工艺对树脂基高速打磨磨石性能影响[J].铁道学报,2024,46(1):137-144.

|

|

ZHANG Sheng, LIU Changbao, FAN Xiaoqiang,et al .Effect of curing process on properties of resin based high speed grinding wheel and its regulation mechanism[J].Journal of the China Railway Society,2024,46(1):137-144.

|

| 3 |

李江,樊文刚,吴志伟,等 .基于槽型接触轮的钢轨砂带打磨材料去除特性[J].中国铁道科学,2023,44(4):75-83.

|

|

LI Jiang, FAN Wengang, WU Zhiwei,et al .Research on material removal characteristics of rail grinding by abrasive belt based on grooved contact wheel[J].China Railway Science,2023,44(4):75-83.

|

| 4 |

HE Z, LI J Y, LIU Y M,et al .Investigation of conditions leading to critical transitions between abrasive belt wear modes for rail grinding[J].Wear,2021,484/485:204048/1-9.

|

| 5 |

樊文刚,刘月明,李建勇 .高速铁路钢轨打磨技术的发展现状与展望[J].机械工程学报,2018,54(22):184-195.

|

|

FAN Wengang, LIU Yueming, LI Jianyong .Development status and prospect of rail grinding technology for high speed railway[J].Journal of Mechanical Engineering,2018,54(22):184-195.

|

| 6 |

D’ADDONA D M, MATARAZZO D, TETI R,et al .Prediction of dressing in grinding operation via neural networks[J].Procedia CIRP,2017,62:305-310.

|

| 7 |

GONZÁLEZ D, ALVAREZ J, SÁNCHEZ J,et al .Deep learning-based feature extraction of acoustic emission signals for monitoring wear of grinding wheels[J].Sensors,2022,22:6911/1-14.

|

| 8 |

张诗语 .SiCf/SiC复合材料磨削中基于声发射信号的砂轮磨损识别[D].长沙:湖南大学,2022.

|

| 9 |

胡天荣,郑红伟,戴士杰 .基于异类信息融合的砂轮磨损状态监测[J].工具技术,2023,57(2):126 -131.

|

|

HU Tianrong, ZHENG Hongwei, DAI Shijie .Grinding wheel wear condition monitoring based on heterogeneous information fusion[J].Tool Engineering,2023,57(2):126 -131.

|

| 10 |

BI G, LIU S, SU S B,et al .Diamond grinding wheel condition monitoring based on acoustic emission signals[J].Sensors,2021,21(4):1054/1-17.

|

| 11 |

于帅 .基于钢轨打磨车的砂带磨损监测系统研究[D].北京:北京交通大学,2021.

|

| 12 |

程灿,李建勇,刘月明,等 .基于磨削声与电流的砂带磨损状态识别[J].振动、测试与诊断,2020,40(2):355-360,422.

|

|

CHENG Can, LI Jianyong, LIU Yueming,et al .Wear identification of abrasive belt based on grinding sound and current[J].Journal of Vibration,Measurement and Diagnosis,2020,40(2):355-360,422.

|

| 13 |

毛聪,孙鹏程,唐伟东,等 .磨削白层特性及其与声发射信号的相关性[J].机械工程学报,2023,59(9):349-359.

|

|

MAO Cong, SUN Pengcheng, TANG Weidong,et al .Features of grinding white layer and its correlation with acoustic emission signal[J].Journal of Mechanical Engineering,2023,59(9):349-359.

|

| 14 |

赵华东,刘勇,朱振伟,等 .金刚石砂轮与金刚石滚轮磨削接触的声发射监测[J].机械设计与制造,2024(2):174-178.

|

|

ZHAO Hua-dong, LIU Yong, ZHU Zhen-wei,et al .Acoustic emission monitoring of grinding contact between diamond wheel and diamond wheel[J].Machi-nery Design & Manufacture,2024(2):174-178.

|

| 15 |

何喆,李建勇,刘月明,等 .砂带虚拟形貌的建模[J].华南理工大学学报(自然科学版),2017,45(12):85-91,105.

|

|

HE Zhe, LI Jian-yong, LIU Yue-ming,et al .Modeling of virtual topography of abrasive belt[J].Journal of South China University of Technology (Natural Science Edition),2017,45(12):85-91,105.

|

| 16 |

程灿 .面向钢轨打磨的砂带磨损状态监测与剩余寿命预测研究[D].北京:北京交通大学,2020.

|

| 17 |

聂磊,张吕凡,徐诗奕,等 .基于相似度特征融合和CNN的滚动轴承剩余寿命预测[J].噪声与振动控制,2023,43(5):115-121.

|

|

NIE Lei, ZHANG Lvfan, XU Shiyi,et al .Remaining life prediction of rolling bearing based on similarity feature fusion and convolutional neural network[J].Noise and Vibration Control,2023,43(5):115-121.

|

| 18 |

刘岚,侯立群 .基于改进一维残差网络的轴承故障诊断[J].仪器仪表用户,2021,28(9):45-50.

|

|

LIU Lan, HOU Liqun .Bearing fault diagnosis method based on improved 1D residual network[J].Instrumentation,2021,28(9):45-50.

|

| 19 |

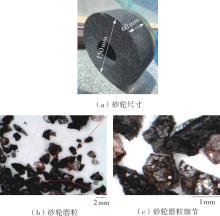

张国文,贺春江,张静,等 .钢轨打磨车砂轮技术标准[J].金刚石与磨料磨具工程,2018,38(4):83-86.

|

|

ZHANG Guowen, HE Chunjiang, ZHANG Jing,et al .Standard of grinding wheel used on rail grinding[J].Diamond and Abrasives Engineering,2018,38(4):83-86.

|

| 20 |

钢轨打磨车砂轮订货技术条件: [S].

|

| 21 |

谭永敏,施展,迟玉伦,等 .基于Shannon熵与声发射信号的CBN砂轮性能监测方法研究[J].机械强度,2023,45(2):321-330.

|

|

TAN Yongmin, SHI Zhan, CHI Yulun,et al .Research on CBN grinding wheel performance monitoring method based on Shannon entropy and acoustic emission signal[J].Journal of Mechanical Strength,2023,45(2):321-330.

|

| 22 |

赵书东,禹晓敏,王文玺,等 .金字塔砂带磨损状态的声信号GA-BP识别方法[J].表面技术,2024,53(3):28-38.

|

|

ZHAO Shudong, YU Xiaomin, WANG Wenxi,et al .GA-BP identification of acoustic signals for wear states of pyramidal abrasive belts[J].Surface Technology,2024,53(3):28-38.

|

| 23 |

黄献聪,来悦,李常胜,等 .超高分子量聚乙烯纤维及其复合材料的热氧老化行为[J].兵工学报,2022,43(12):3211-3220.

|

|

HUANG Xiancong, LAI Yue, LI Changsheng,et al .Thermo-oxidative aging behavior of ultra-high molecular weight polyethylene fiber and its composites[J].Acta Armamentarh,2022,43(12):3211-3220.

|

| 24 |

樊威,李嘉禄 .热氧老化对碳纤维织物增强聚合物基复合材料弯曲性能的影响[J].复合材料学报,2015,32(5):1260-1270.

|

|

FAN Wei, LI Jialu .Effects of thermo-oxidative aging on flexural properties of carbon fiber fabric reinforced polymer matrix composites[J].Acta Materiae Compositae Sinica,2015,32 (5):1260-1270.

|