华南理工大学学报(自然科学版) ›› 2025, Vol. 53 ›› Issue (4): 61-71.doi: 10.12141/j.issn.1000-565X.240208

表面微功能结构铝板传热性能研究

李勇1, 王慧攀1, 何嘉斌2, 江克俊2, 陈昕宇1

- 1.华南理工大学 机械与汽车工程学院,广东 广州 510640

2.中国移动通信集团终端有限公司,北京 102206

Study on Heat Transfer Characteristics of Aluminum Plates with Different Surface Micro-Functional Structures

LI Yong1, WANG Huipan1, HE Jiabin2, JIANG Kejun2, CHEN Xinyu1

- 1.School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510640,Guangdong,China

2.China Mobile Communication Group Terminal Co. ,Ltd. ,Beijing 102206,China

摘要:

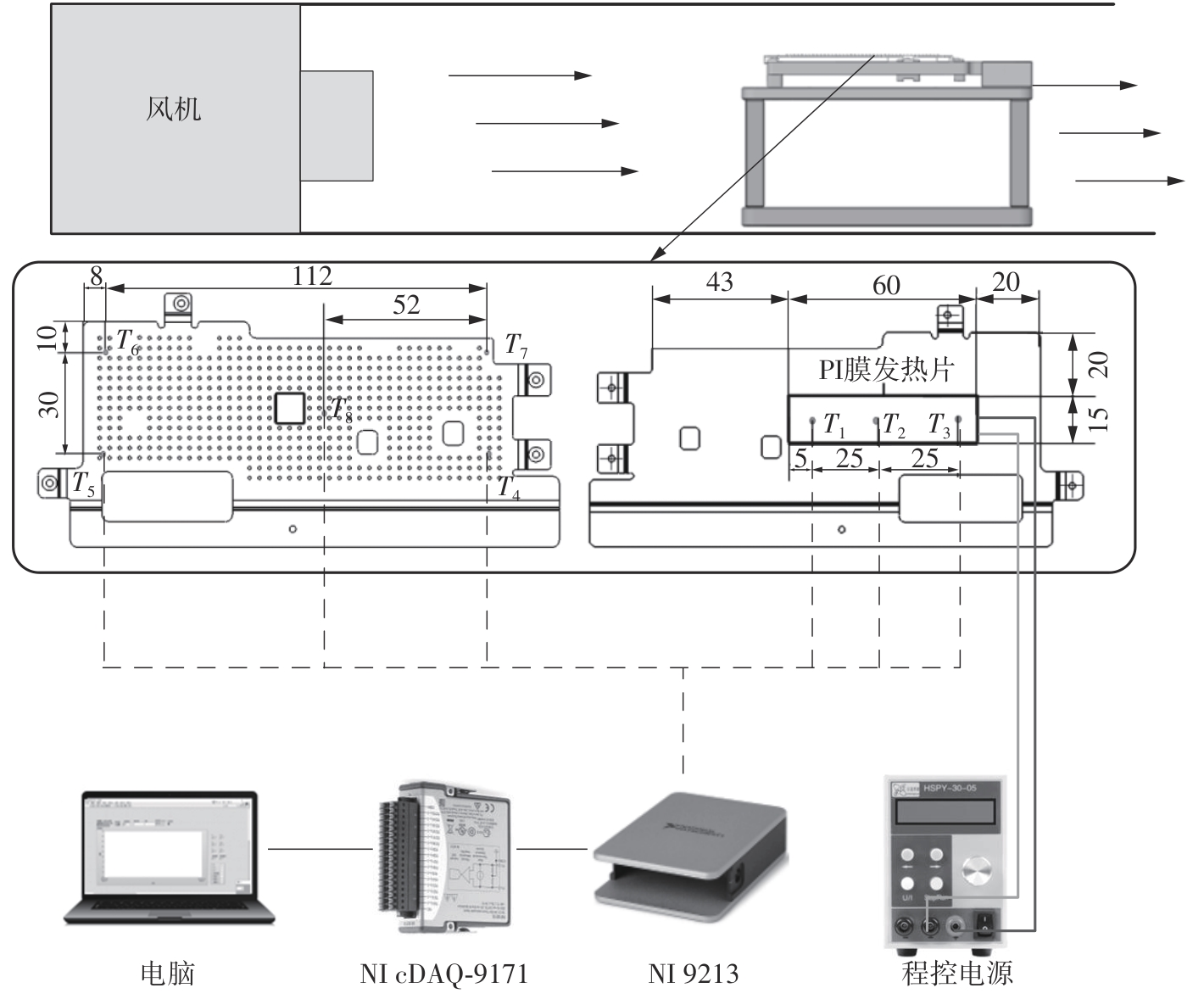

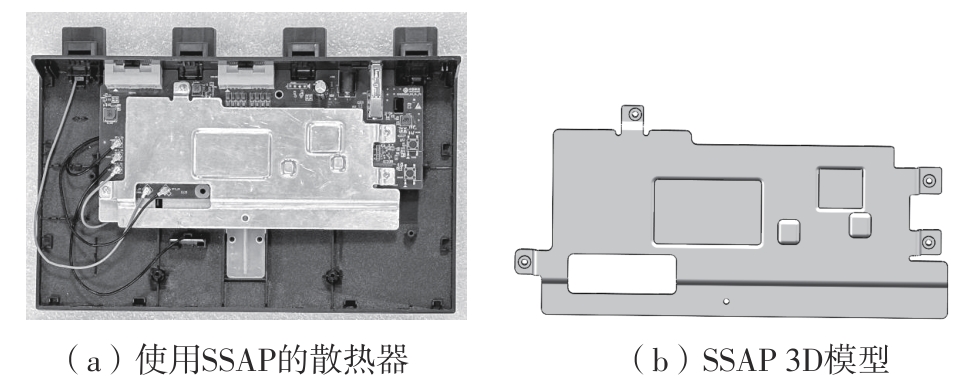

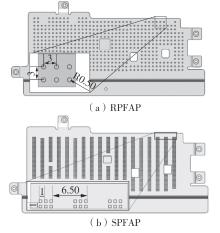

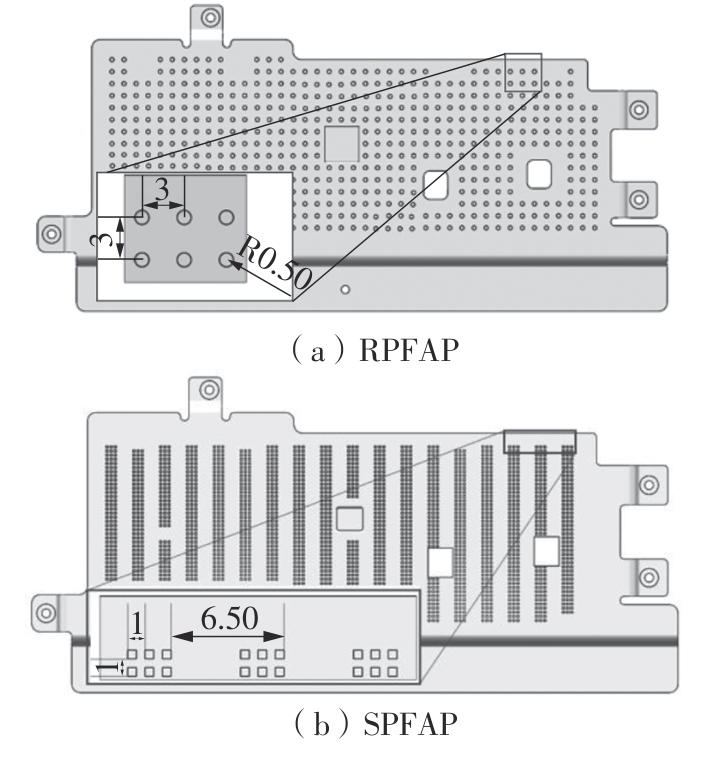

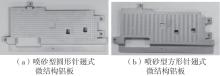

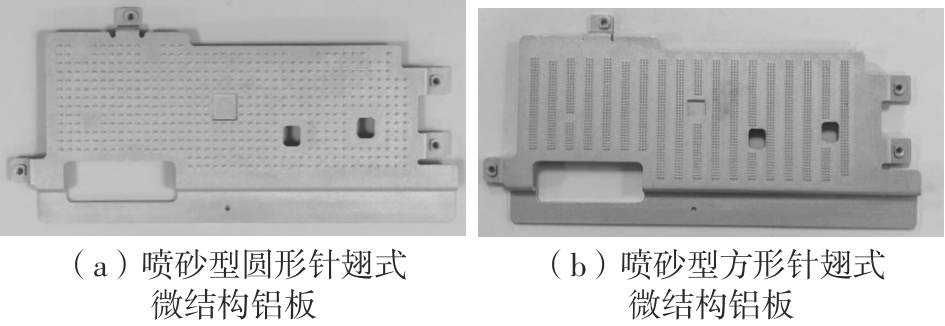

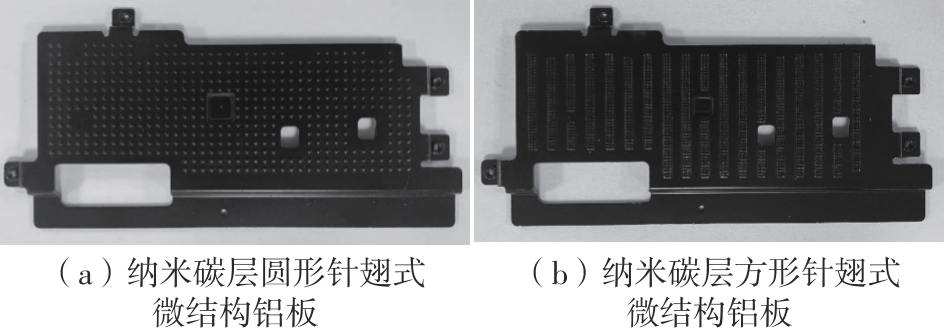

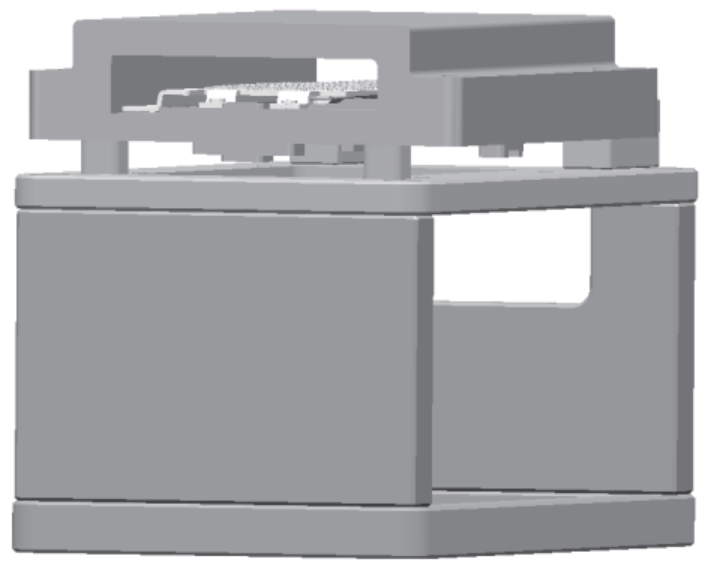

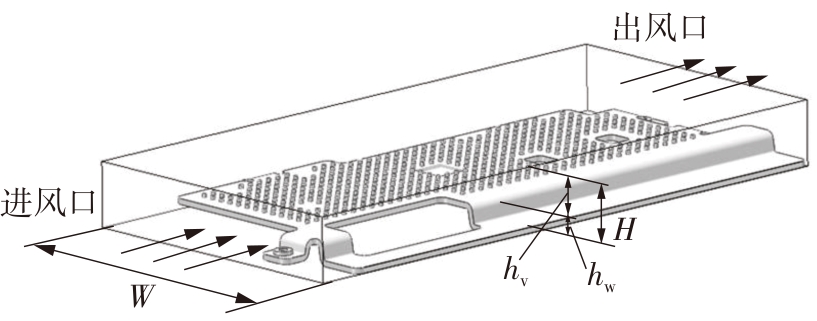

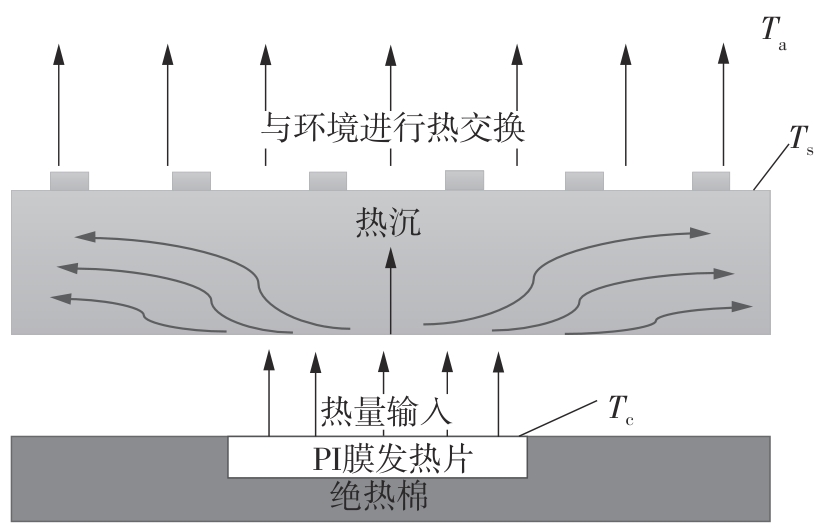

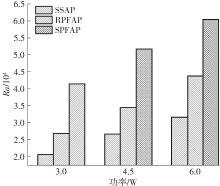

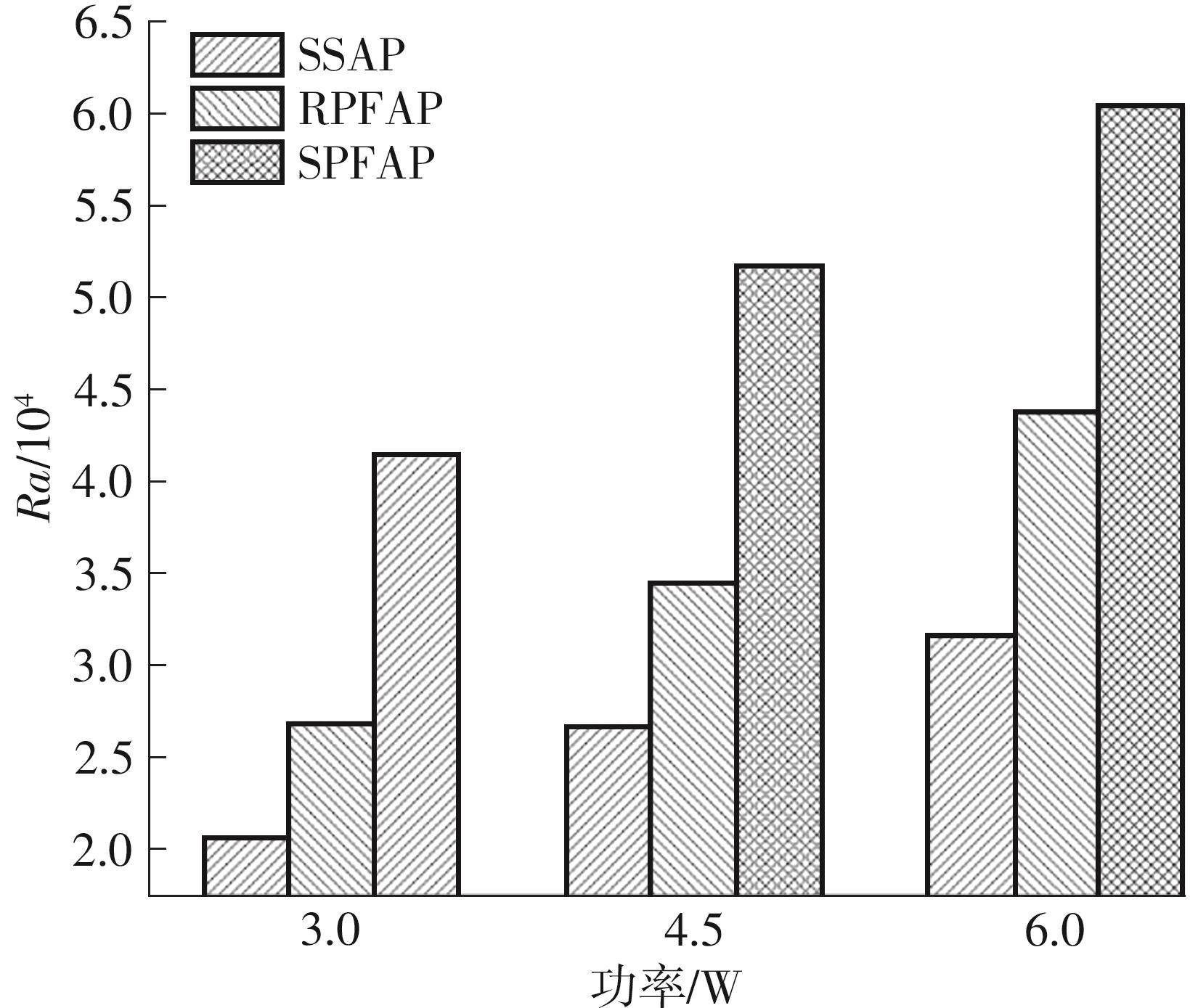

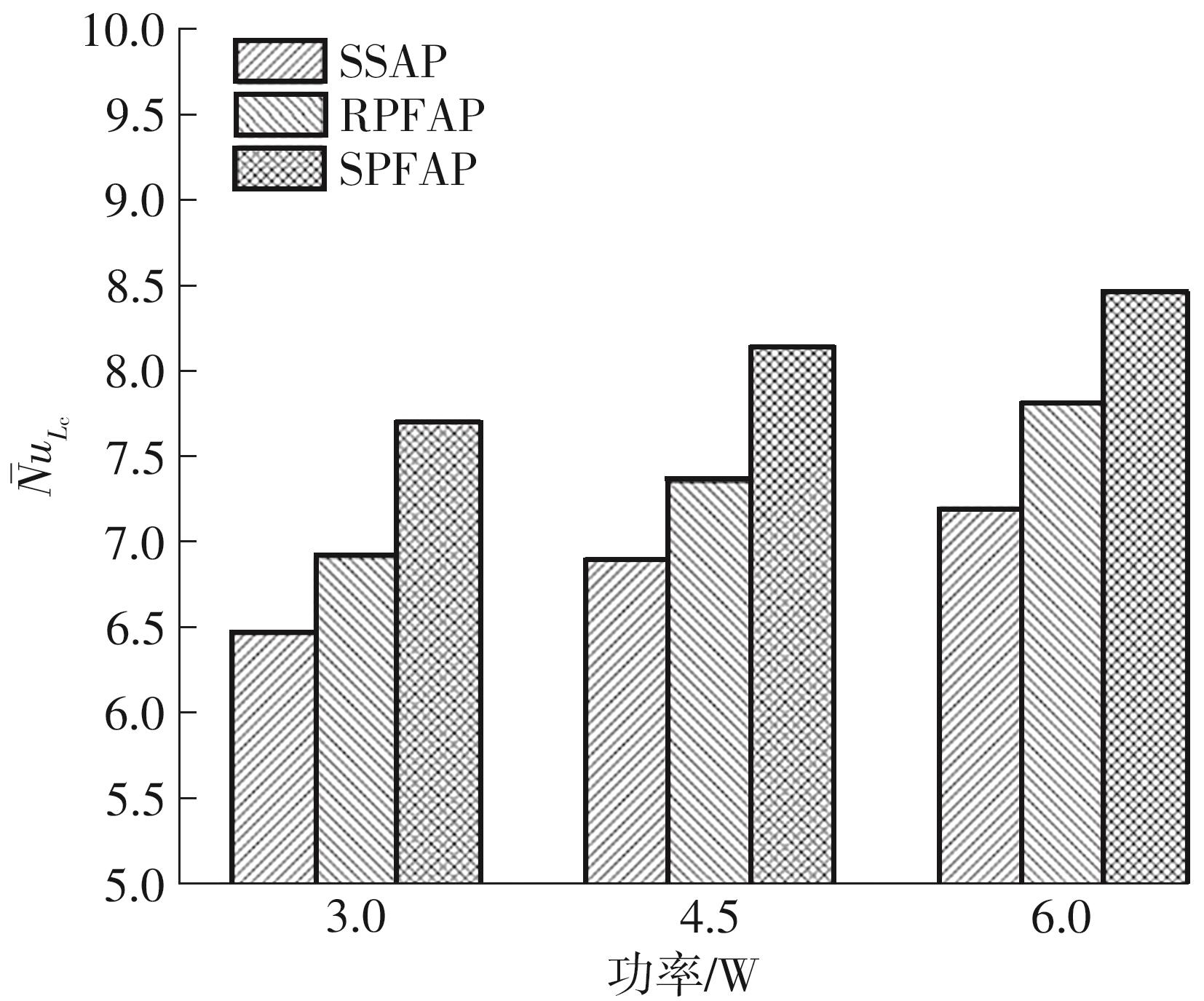

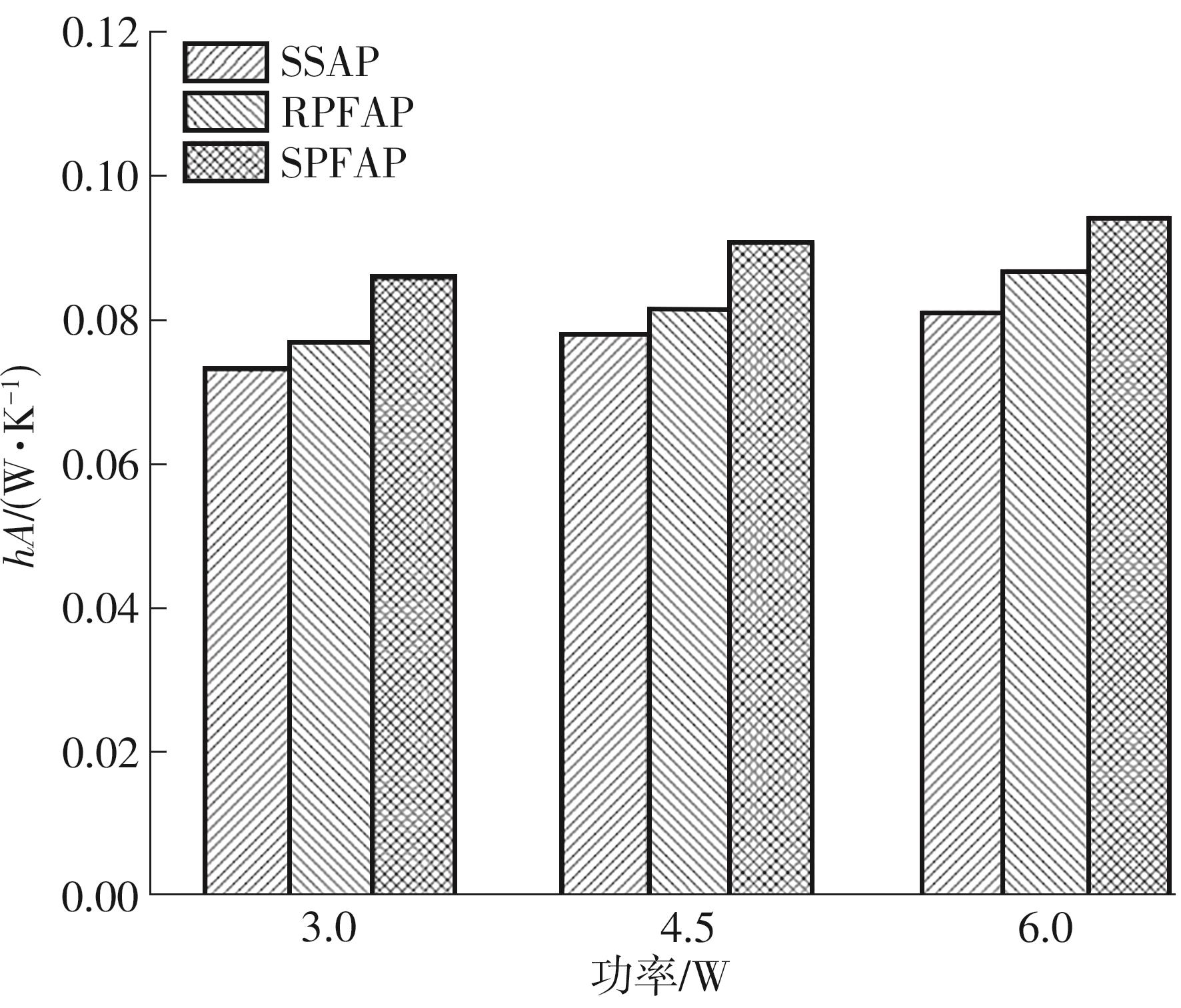

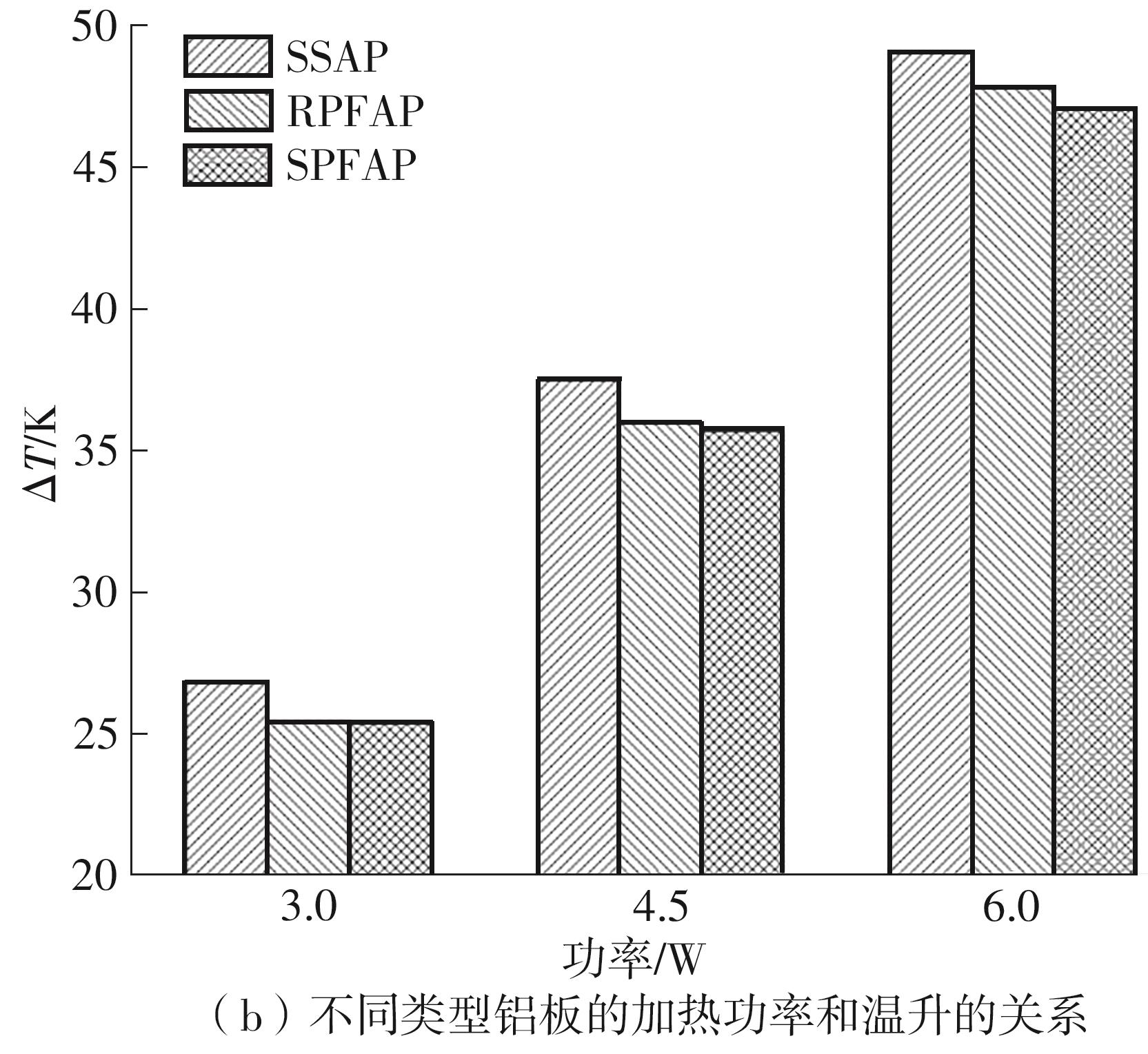

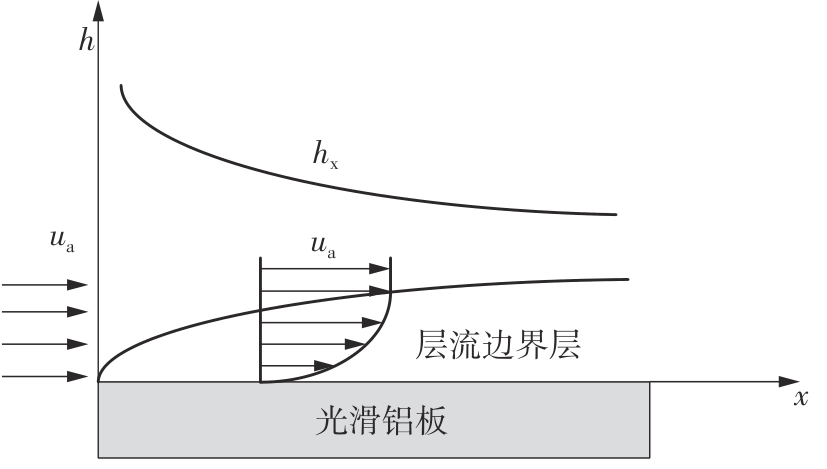

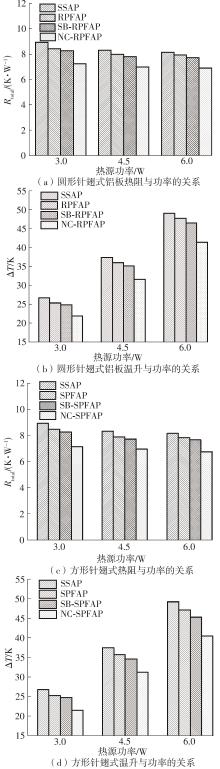

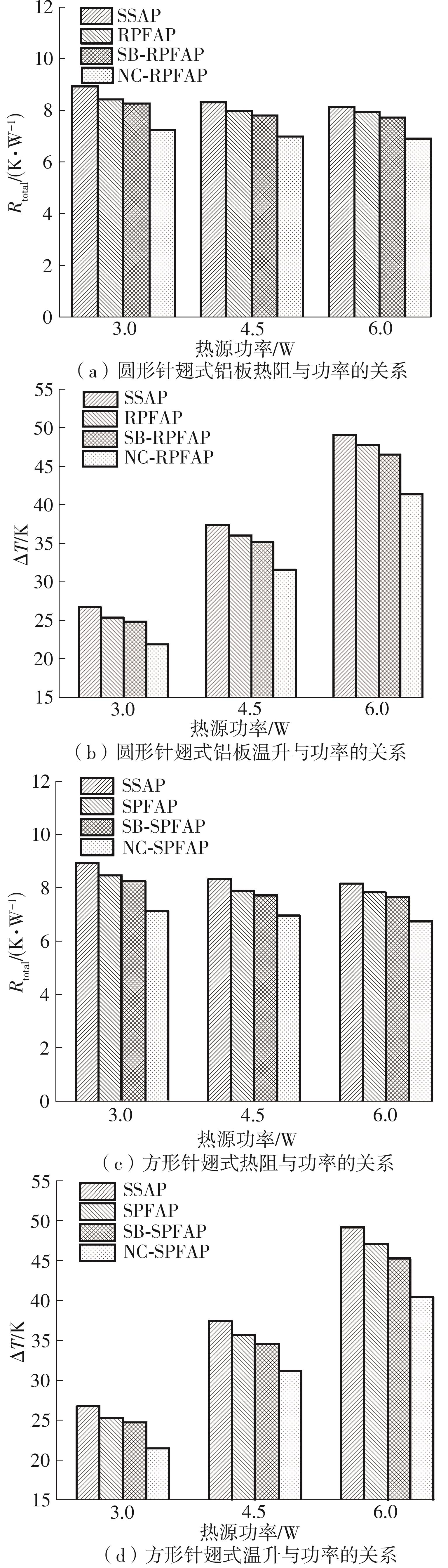

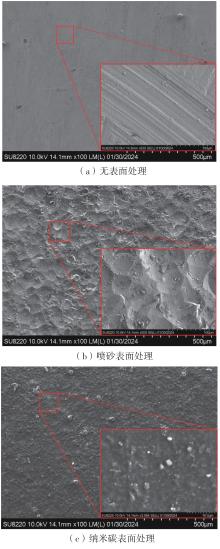

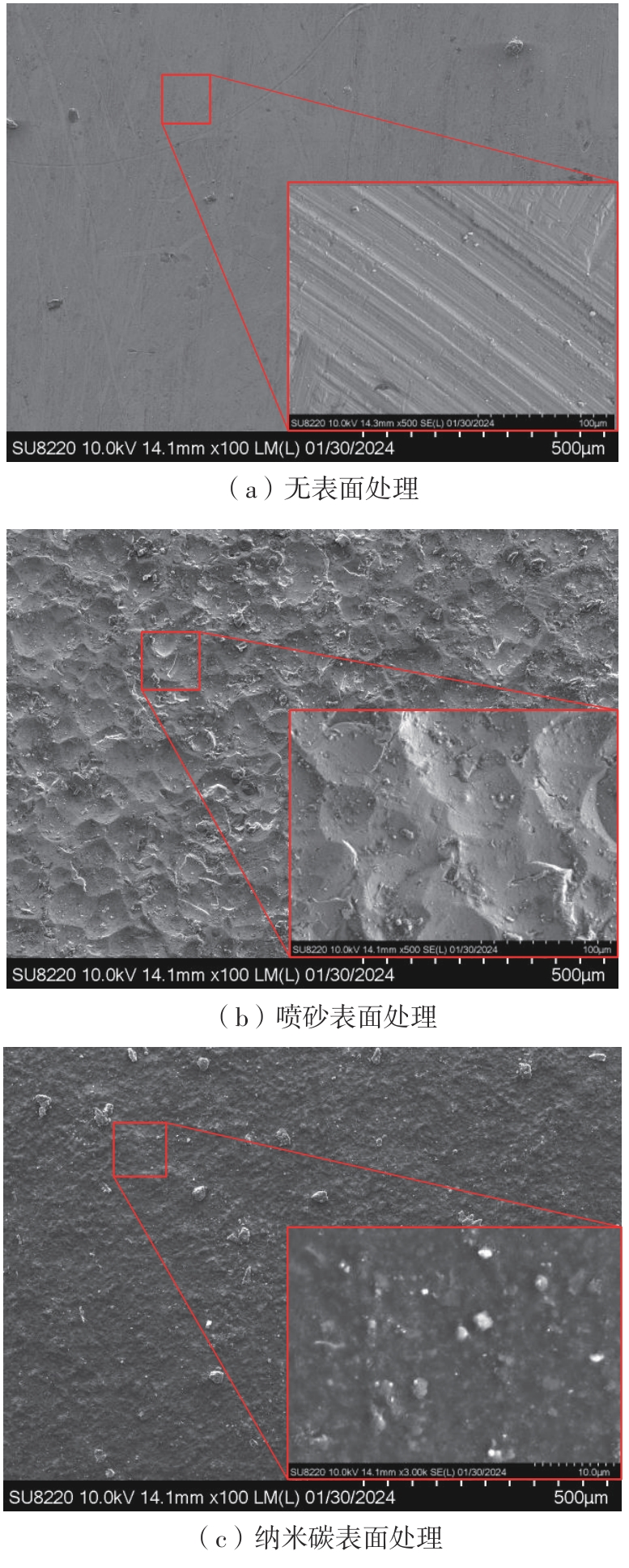

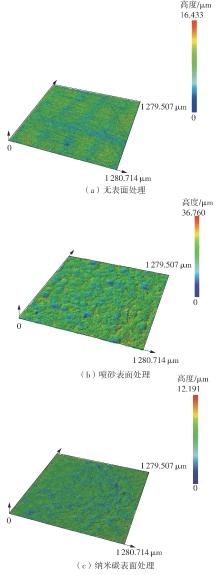

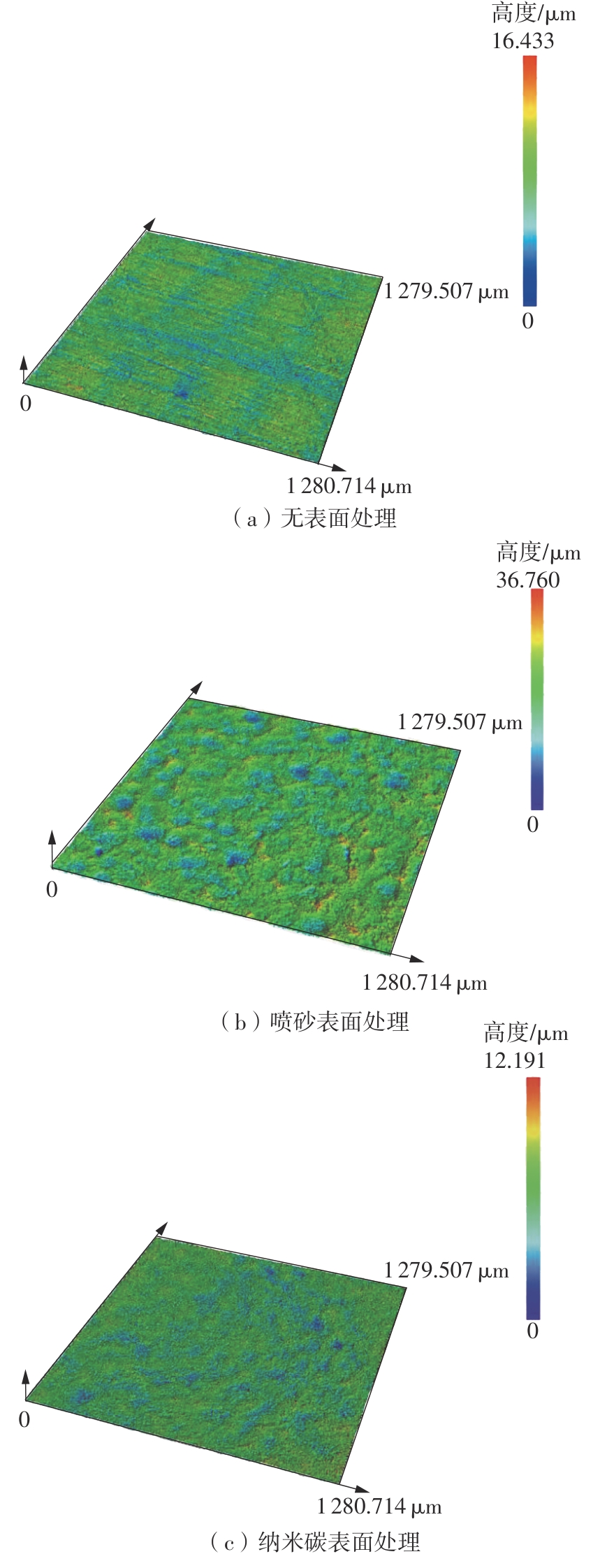

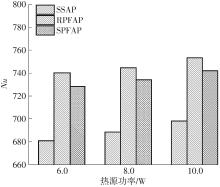

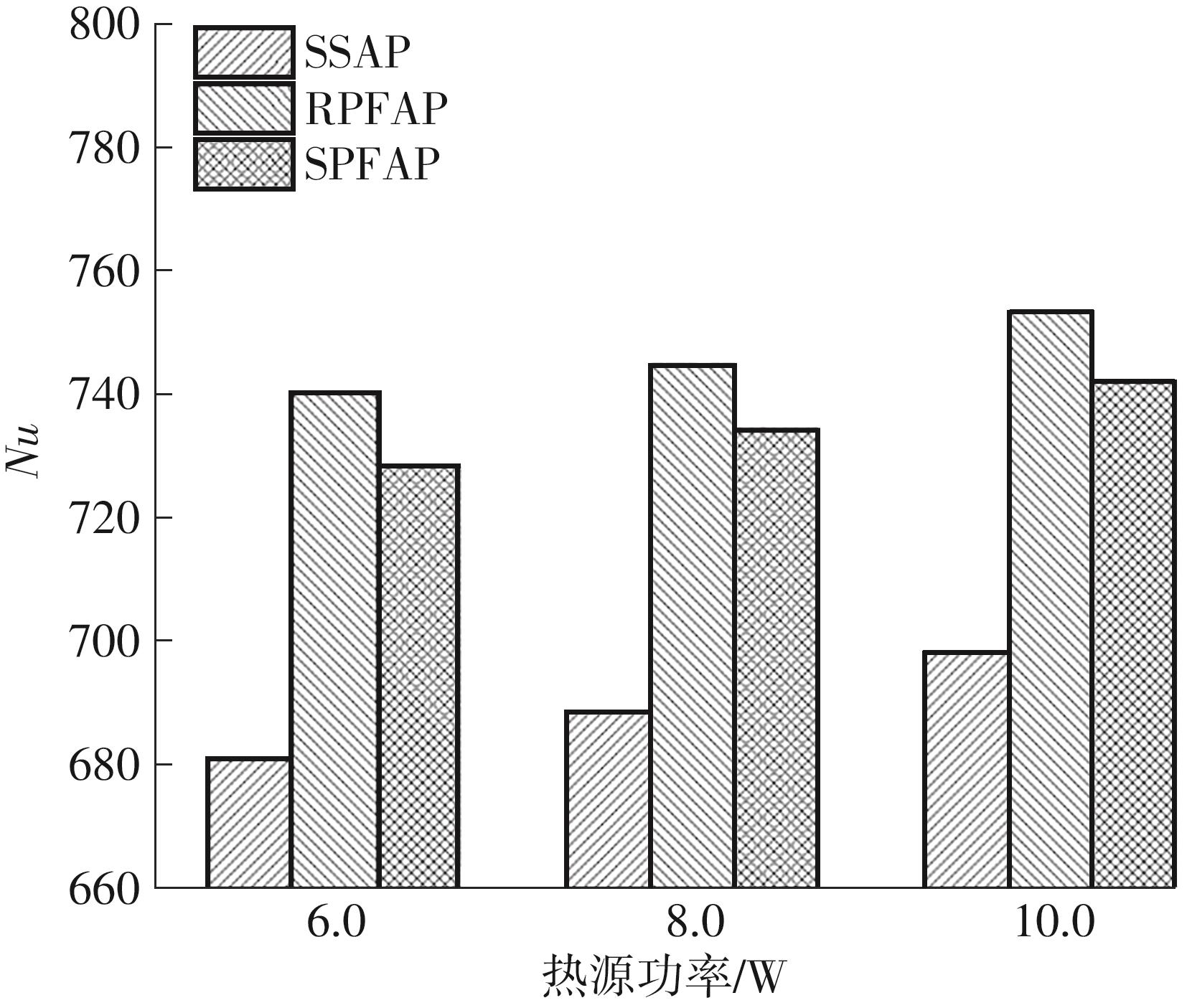

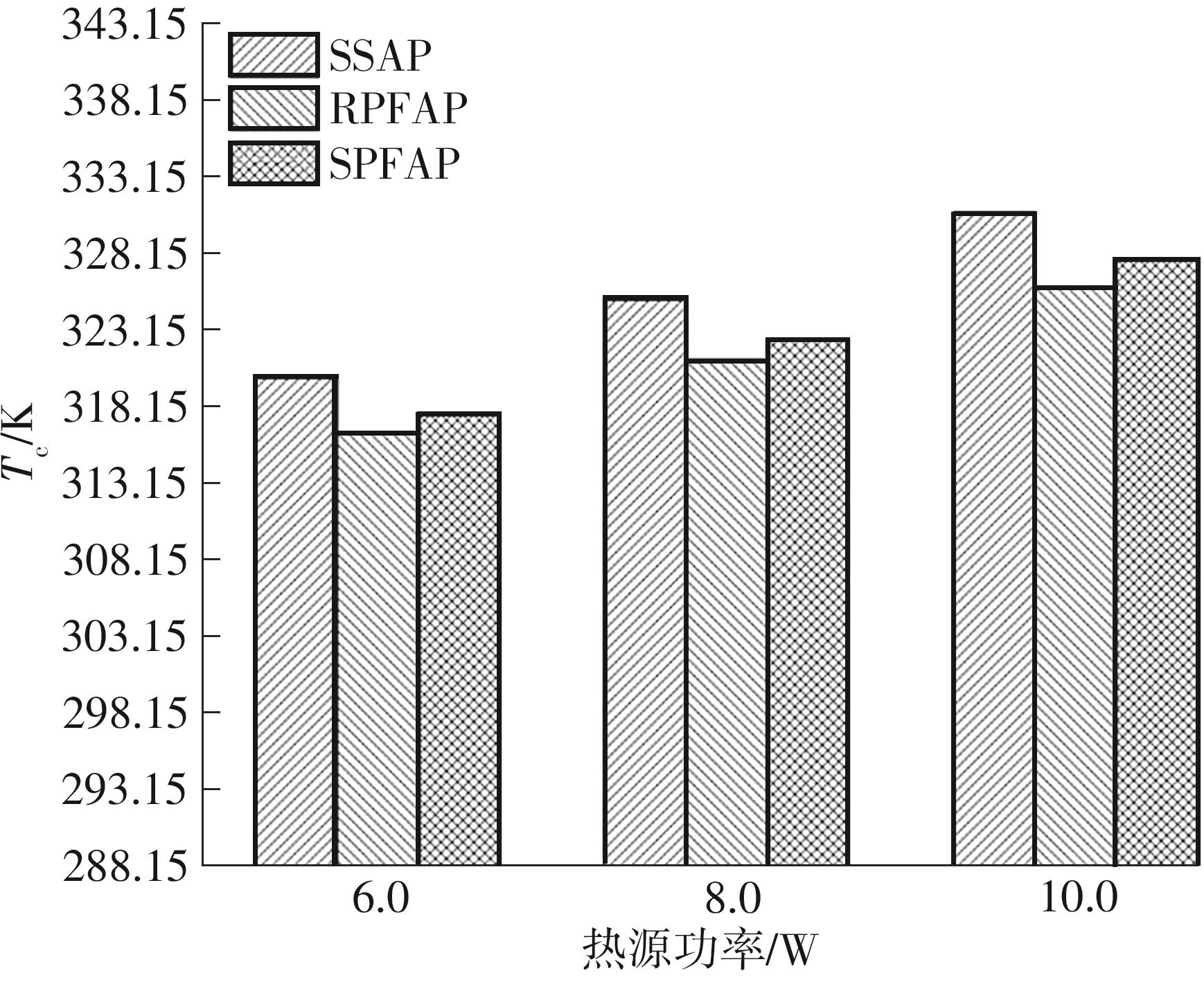

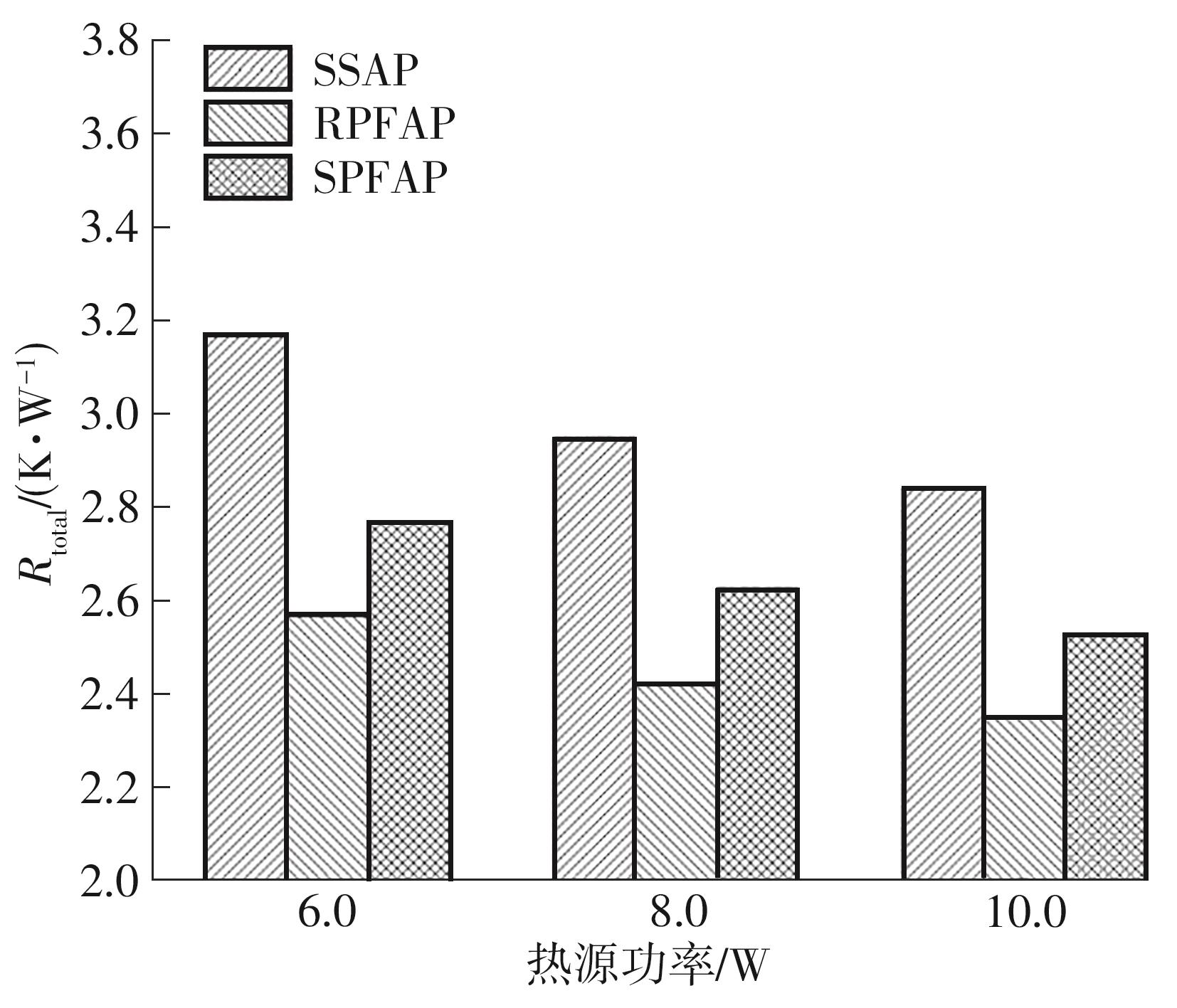

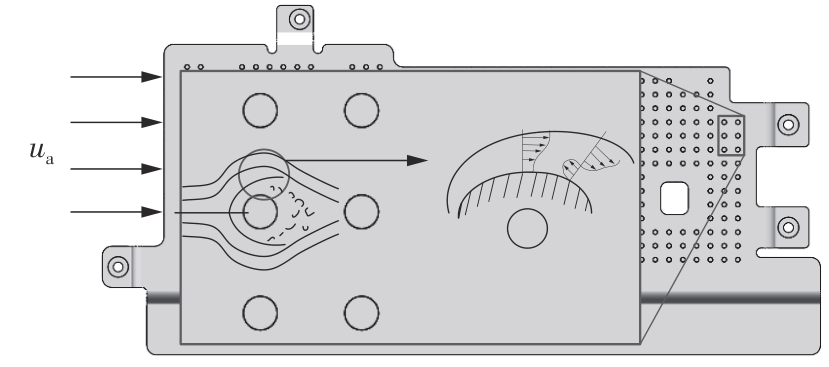

电子产品微型化、轻薄化、低成本的发展需求,给散热模组的设计制造带来极大挑战。为解决轻薄型高性能路由器以及小型电子器件散热难题,在光滑铝板散热器基础上设计了6种具有表面微功能结构的铝板散热器,并根据新设计的铝板散热器搭建实验测试平台,分别在自然对流和微对流工况下,对比分析所设计的6种新型铝板散热器相对于光滑铝板散热器散热性能的提升效果。结果表明:自然对流工况下,热源功率在3.0~6.0 W时,方形针翅式铝板散热性能最优,相比于光滑表面铝板,平均努塞尔数提高约18%,传热系数与传热面积乘积提高约17%,热源温度降低约2.0 K;圆形针翅式铝板相较于光滑表面铝板,平均努塞尔数提高7%,传热系数与传热面积乘积提高约5%,热源降低约1.3 K;表面处理后,喷砂型方形针翅式铝板可使热源温度降低2.0~3.9 K,纳米碳层方形针翅式铝板可使热源温度降低5.3~8.6 K;喷砂型圆形针翅式铝板可使热源温度降低1.9~2.5 K,纳米碳层圆形针翅式铝板可使热源温度降低4.9~7.7 K。在风速2 m/s微对流工况下,圆形针翅式铝板散热性能最优,相比于光滑表面铝板,平均努塞尔数提高约8%,热源在6.0 W时温度可降低3.6 K,热阻降低18%;方形针翅式铝板,相比于光滑表面铝板,平均努塞尔数提高约6%,热源在6.0 W时温度可降低2.4 K,热阻降低11%。热源功率越高,具有表面微功能结构铝板相较于光滑表面铝板散热性能越好。

中图分类号: