| 1 |

HE B, YUAN X, QIAN S S, et al .Carbon neutrality: a review [J].Journal of Computing and Information Science in Engineering, 2023, 23: 060809/1-23.

|

| 2 |

SAMUEL S, MICHAEL R M, TIMOTHY D A .The promise and peril of carbon neutrality goals [J].Review of Environmental Economics and Policy, 2024,18(1):88-95.

|

| 3 |

袁佳双,张永香 .气候变化科学与碳中和[J].中国人口资源与环境,2022,32(9):47-52.

|

|

YUAN Jiashuang, ZHANG Yongxiang .Climate change science and carbon neutrality [J].China Population Resources & Environment,2022,32(9):47-52.

|

| 4 |

中华人民共和国国家统计局 .中国能源统计年鉴[G].北京: 中国统计出版社,2016.

|

| 5 |

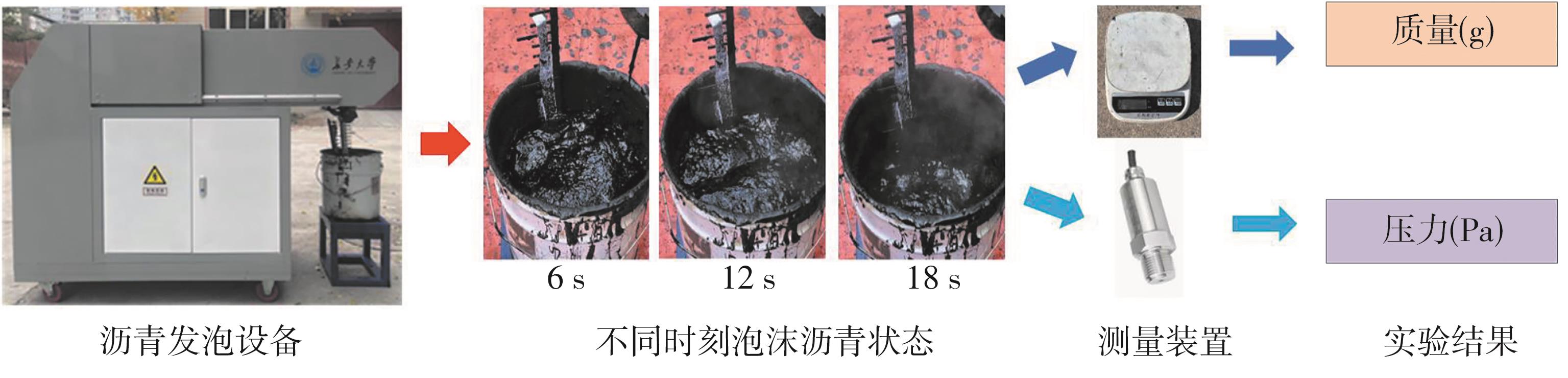

陶卓辉,沈士蕙,孙杨,等 .表面活性泡沫沥青发泡工艺及流变特性研究[J].华南理工大学学报(自然科学版),2024,52(3):41-49.

|

|

TAO Zhuohui, SHEN Shihui, SUN Yang, et al .Foaming technology and rheological characteristics of surfactant additive-foamed asphalt [J].Journal of South China University of Technology (Natural Science Edition), 2024, 52(3): 41-49.

|

| 6 |

RODGERS B M .Investigation of foamed bitumen mixes using reclaimed asphalt pavement materials for cold recycling technology [J].International Journal of Pavement Research & Technology, 2022, 15(1):98-110.

|

| 7 |

马涛,栾英成,何亮,等 .乳化沥青与泡沫沥青冷再生技术发展综述[J].交通运输工程学报, 2023,23(2):1-23.

|

|

MA Tao, LUAN Ying-cheng, HE Liang, et al .Review on cold recycling technology development of emulsified asphalt and foamed asphalt [J].Journal of Traffic and Transportation Engineering, 2023, 23(2): 1-23.

|

| 8 |

郝培文,李万军,韩钰祥,等 .基于OT试验的乳化沥青冷再生面层混合料抗反射裂缝性能研究[J].材料导报, 2021,35(Z2):150-157.

|

|

HAO Peiwen, LI Wanjun, HAN Yuxiang, et al .Crack resistance of cold recycled mixture with emulsified asphalt for surface course based on OT test [J].Materials Reports, 2021, 35(Z2): 150-157.

|

| 9 |

MA W Y, WEST R, TRAN N, et al .Optimising water content in cold recycled foamed asphalt mixtures [J].Road Materials and Pavement Design, 2017,18(4):58-78.

|

| 10 |

LIANG X M, YU X, XU B, et al .Storage stability and compatibility in foamed warm-mix asphalt containing recycled asphalt pavement binder [J].Journal of Materials in Civil Engineering, 2024, 36(5):04024062/1-15.

|

| 11 |

MYUNGJEONG M, KIM S, SHEN J N .Laboratory evaluation of foamed asphalt mixtures with 100% RAP and rejuvenator [J].Australian Journal of Civil Engineering, 2021,19(1):46-57.

|

| 12 |

CHENG P J, YI J Y, CHEN Z, et al .Influence factors of strength and performance of foamed asphalt cold recycled mixture [J].Road Materials and Pavement Design, 2022, 23(2): 461-476.

|

| 13 |

BISWAJIT K B, MD A H, RAFIQUL A T .Effects of asphalt foaming on damage characteristics of foamed warm mix asphalt [J].Transportation Research Record, 2021, 2675(8): 318-331.

|

| 14 |

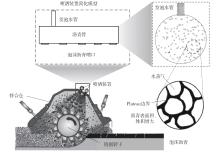

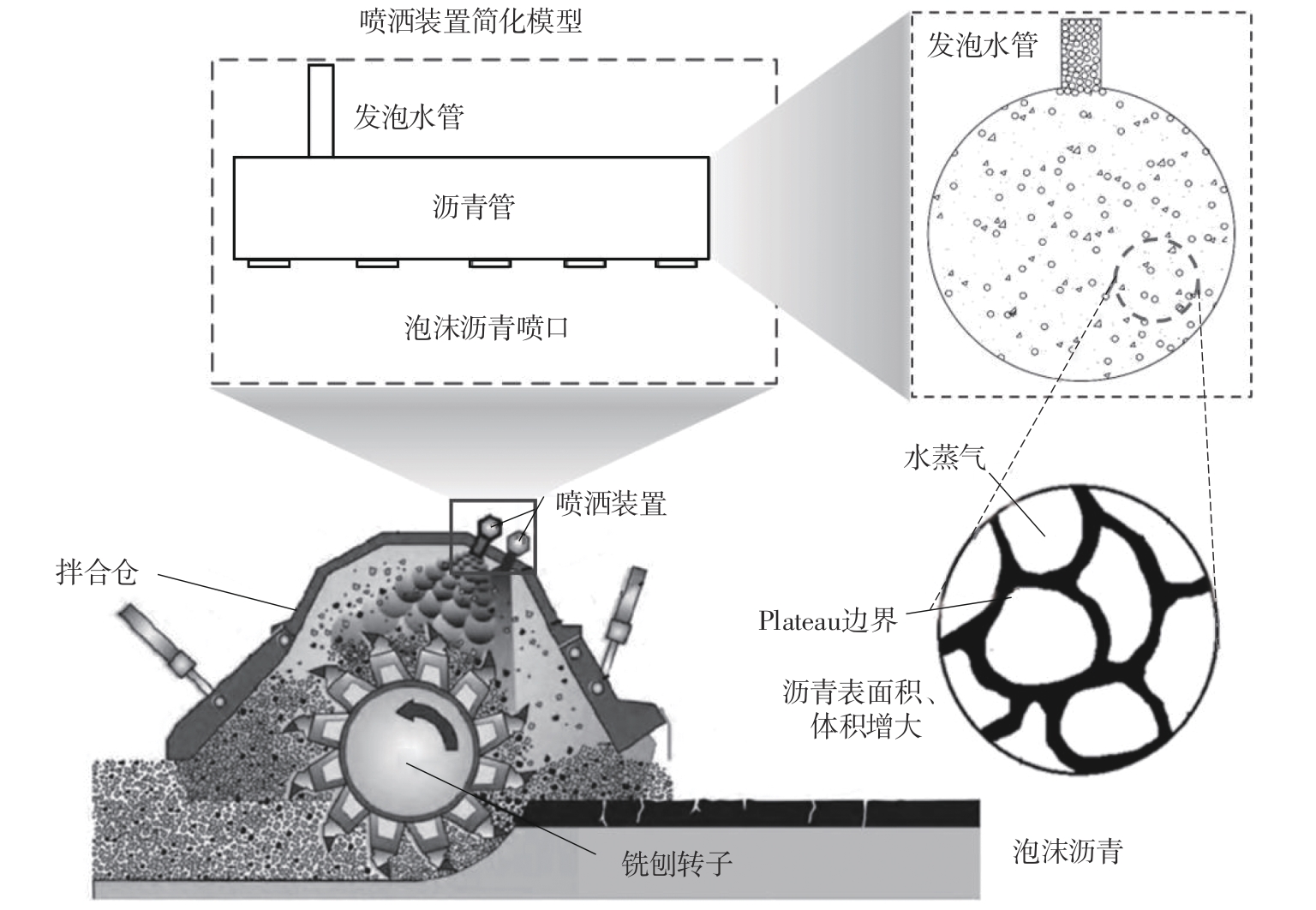

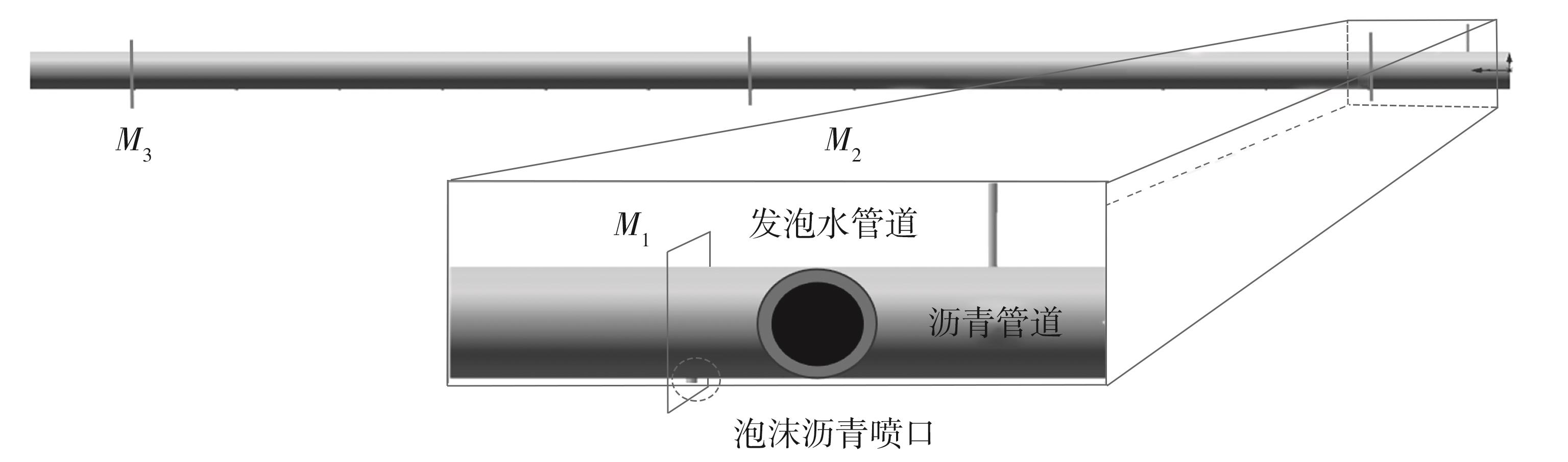

程海鹰,贾磊 .Fluent在泡沫沥青流量控制研究中的应用[J].机械设计与制造,2015,9(4):123-125.

|

|

CHENG Hai-ying, JIA Lei .The application of fluent in the study of foamed bitumen flow control [J].Machinery Design & Manufacture, 2015, 9(4):123-125.

|

| 15 |

CHENG H Y, LUO Z, ND S .A study of foam bitumen preparation for effective recycling of pavement layers [J].Sustainability, 2022,14(15): 9375/1-22.

|

| 16 |

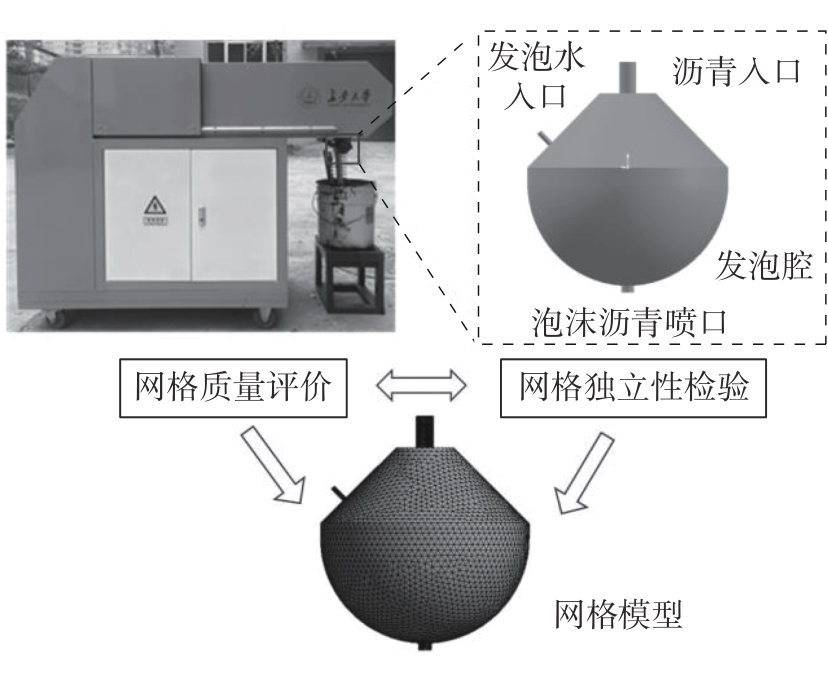

程海鹰,陈文岩,杨忠义,等 .沥青发泡腔结构参数对腔内流场的影响[J].过程工程学报, 2016,16(1):18-25.

|

|

CHENG Hai-ying, CHEN Wenyan, YANG Zhong-yi,et al .Effects of structural parameters of asphalt foaming chamber on its inner flow field [J].The Chinese Journal of Process Engineering, 2016, 16(1):18-25.

|

| 17 |

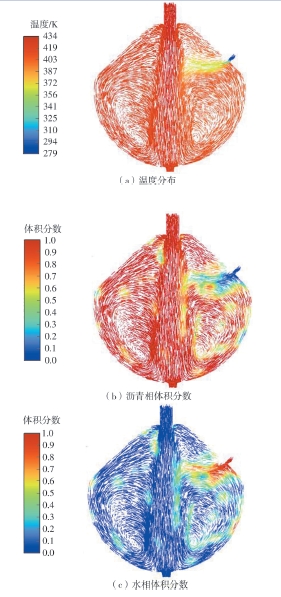

LIU F M, WANG A L, FU Z S .Evaluation for VOF simulation of flow field in asphalt foaming chamber based on volume fraction [J].Journal of Testing and Evaluation, 2018, 46(4): 1391-1398.

|

| 18 |

MULBAH C, KANG C, MAO N, et al .A review of VOF methods for simulating bubble dynamics [J].Progress in Nuclear Energy, 2022, 154:104478/1-20.

|

| 19 |

WANG J H, LUO J, HUANG S X, et al .Numerical simulation of single aluminum droplet evaporation based on VOF method [J].Case Studies in Thermal Engineering, 2022, 34(3): 102008/1-10.

|

| 20 |

寇元德 .基于沥青特性的有限空间内沥青加热研究 [D].西安:长安大学, 2022.

|

| 21 |

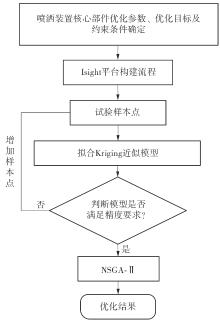

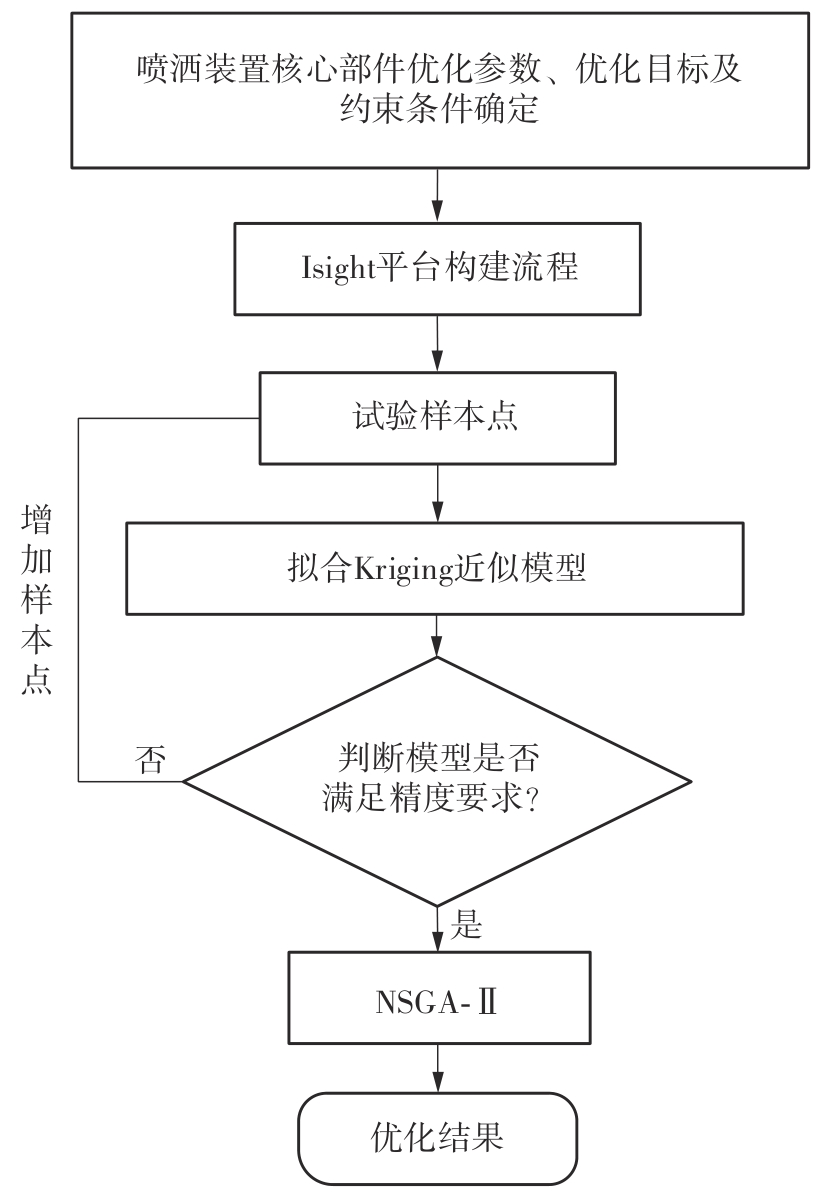

ZHANG X B, XIE Y D, HAN J Z, et al .Design of control valve with low energy consumption based on Isight platform [J].Energy,2022,239(5):122328/1-13.

|

| 22 |

WANG W, MO R, ZHANG Y .Multi-objective aerodynamic optimization design method of compressor rotor based on Isight [J].Procedia Engineering,2011, 15(1): 3699-3703.

|

| 23 |

RAMÓN G, VÍCTOR L, CECILIA C .An overview of kriging and cokriging predictors for functional random fields [J].Mathematics, 2023, 11(15): 3425/1-22.

|

| 24 |

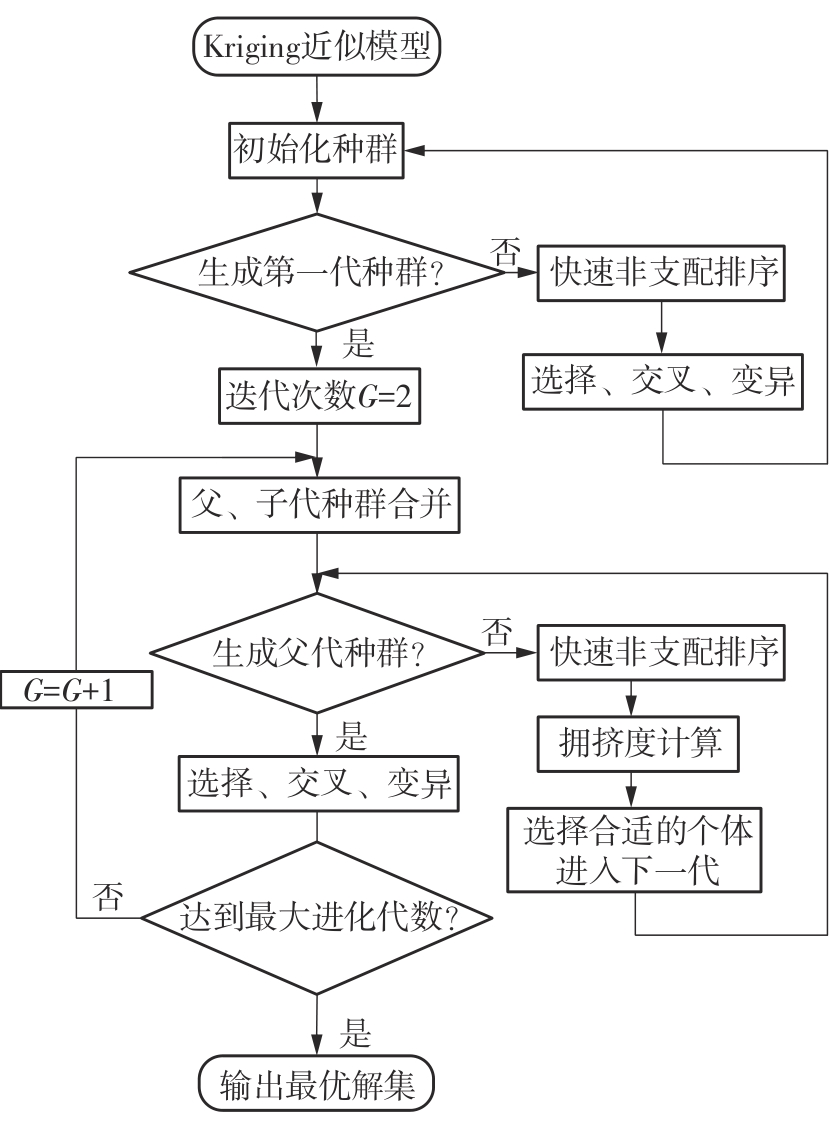

SHI S Y, XIONG H G .Solving the multi-objective job shop scheduling problems with overtime consideration by an enhanced NSGA-Ⅱ [J].Computers & Industrial Engineering, 2024, 190(3):110001/1-15.

|

| 25 |

WANG L, WANG T G, LUO Y .Improved non-dominated sorting genetic algorithm (NSGA)-Ⅱ in multi-objective optimization studies of wind turbine blades [J].Applied Mathematics and Mechanics(English Edition), 2011, 32(6):739-748.

|

| 26 |

SANCHEZ T, CONCIATORI D, BEN-FTIMA M,et al .Terrestrial laser scanning for structural inspection with Kriging interpolation [J].Structure & Infrastructure Engineering: Maintenance, Management,Life-Cycle Design & Performance, 2022, 18(3):429-438.

|