| 1 |

魏海斌,魏东升,蒋博宇,等 .基于IPSO-SVR的盾构下穿既有道路沉降预测分析[J].华南理工大学学报(自然科学版),2023,51(6):62-71.

|

|

WEI Haibin, WEI Dongsheng, JIANG Boyu,et al .Prediction analysis of settlement of existing road under shield tunneling based on IPSO-SVR[J].Journal of South China University of Technology (Natural Science Edition),2023,51(6):62-71.

|

| 2 |

赵晓华,董文慧,李佳,等 .基于驾驶行为的隧道交通标志影响特征及作用机理[J].华南理工大学学报(自然科学版),2023,51(4):88-100.

|

|

ZHAO Xiaohua, DONG Wenhui, LI Jia,et al .Influence characteristics and action mechanism of tunnel traffic signs based on driving behavior[J].Journal of South China University of Technology (Natural Science Edition),2023,51(4):88-100.

|

| 3 |

邓锷,杨伟超,张平平 .软岩力学参数对薄基岩顶板隧道爆破围岩振动的影响[J].华南理工大学学报(自然科学版),2019,47(8):23-30.

|

|

DENG E, YANG Weichao, ZHANG Pingping .Influence of soft rock mechanics parameters on surrounding rock vibration during the tunnel blasting with thin bedrock roof[J].Journal of South China University of Technology (Natural Science Edition),2019,47(8):23-30.

|

| 4 |

蒋望涛,姜海强,马勤国,等 .考虑损伤和不均匀冻胀的寒区隧道弹塑性统一解[J].华南理工大学学报(自然科学版),2022,50(1):69-79,100.

|

|

JIANG Wangtao, JIANG Haiqiang, MA Qinguo, et al .Unified elasto-plastic solution for cold regions tunnel considering damage and non-uniform frost heave[J].Journal of South China University of Technology (Natural Science Edition),2022,50(1):69-79,100.

|

| 5 |

郗艳红,渠述强,毛军,等 .隧道列车火灾玻璃破裂开口火溢流行为特性研究[J].华南理工大学学报(自然科学版),2021,49(5):56-64.

|

|

XI Yanhong, QU Shuqiang, MAO Jun, et al .Research on behavior characteristics of flame ejected from broken glass in tunnel train fire accident[J].Journal of South China University of Technology (Natural Science Edition),2021,49(5):56-64.

|

| 6 |

GREWAL H S, AGRAWAL A, SINGH H .Design and development of high-velocity slurry erosion test rig using CFD[J].Journal of Materials Engineering and Performance,2013,22(1):152-161.

|

| 7 |

RAVELET F, BAKIR F, KHELLADI S,et al .Experimental study of hydraulic transport of large particles in horizontal pipes[J].Experimental Thermal and Fluid Science,2013,45(2):187-197.

|

| 8 |

HASHEMI S A, SADIGHIAN A, SHAH S I A,et al .Solid velocity and concentration fluctuations in highly concentrated liquid-solid (slurry) pipe flows[J].International Journal of Multiphase Flow,2014,66(11):46-61.

|

| 9 |

VLASÁK P, CHÁRA Z, KRUPIČKA J,et al .Experimental investigation of coarse particles-water mixture flow in horizontal and inclined pipes[J].Journal of Hydrology and Hydromechanics,2014,62(3):241-247.

|

| 10 |

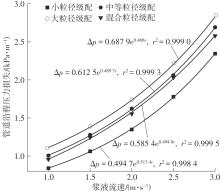

WU D, YANG B, LIU Y .Pressure drop in loop pipe flow of fresh cemented coal gangue-fly ash slurry:experiment and simulation[J].Advanced Powder Technology,2015,26(3):920-927.

|

| 11 |

WU D, YANG B, LIU Y .Transportability and pressure drop of fresh cemented coal gangue-fly ash backfill (CGFB) slurry in pipe loop[J].Powder Technology,2015,284(11):218-224.

|

| 12 |

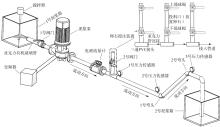

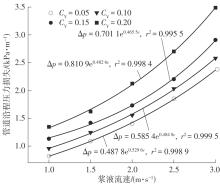

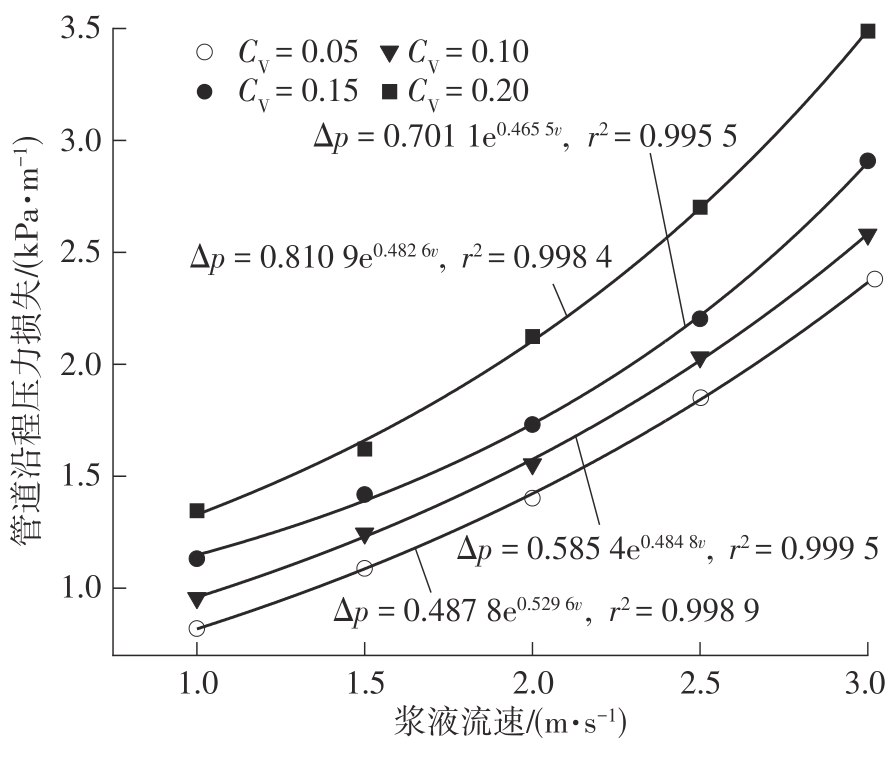

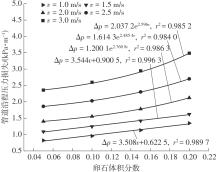

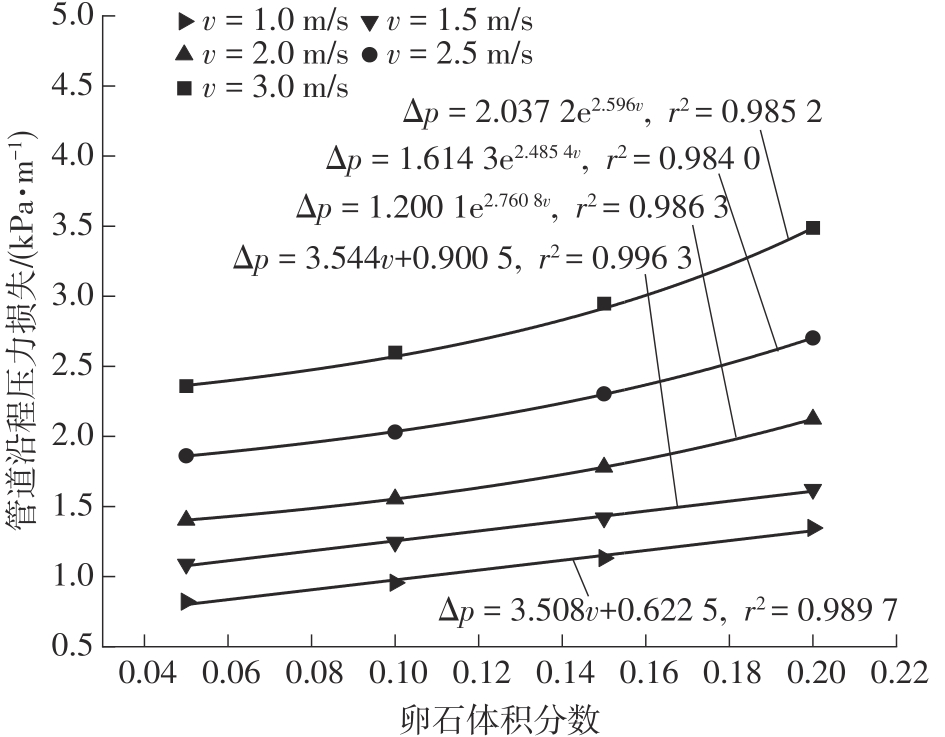

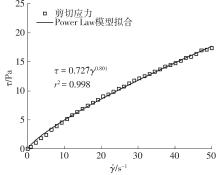

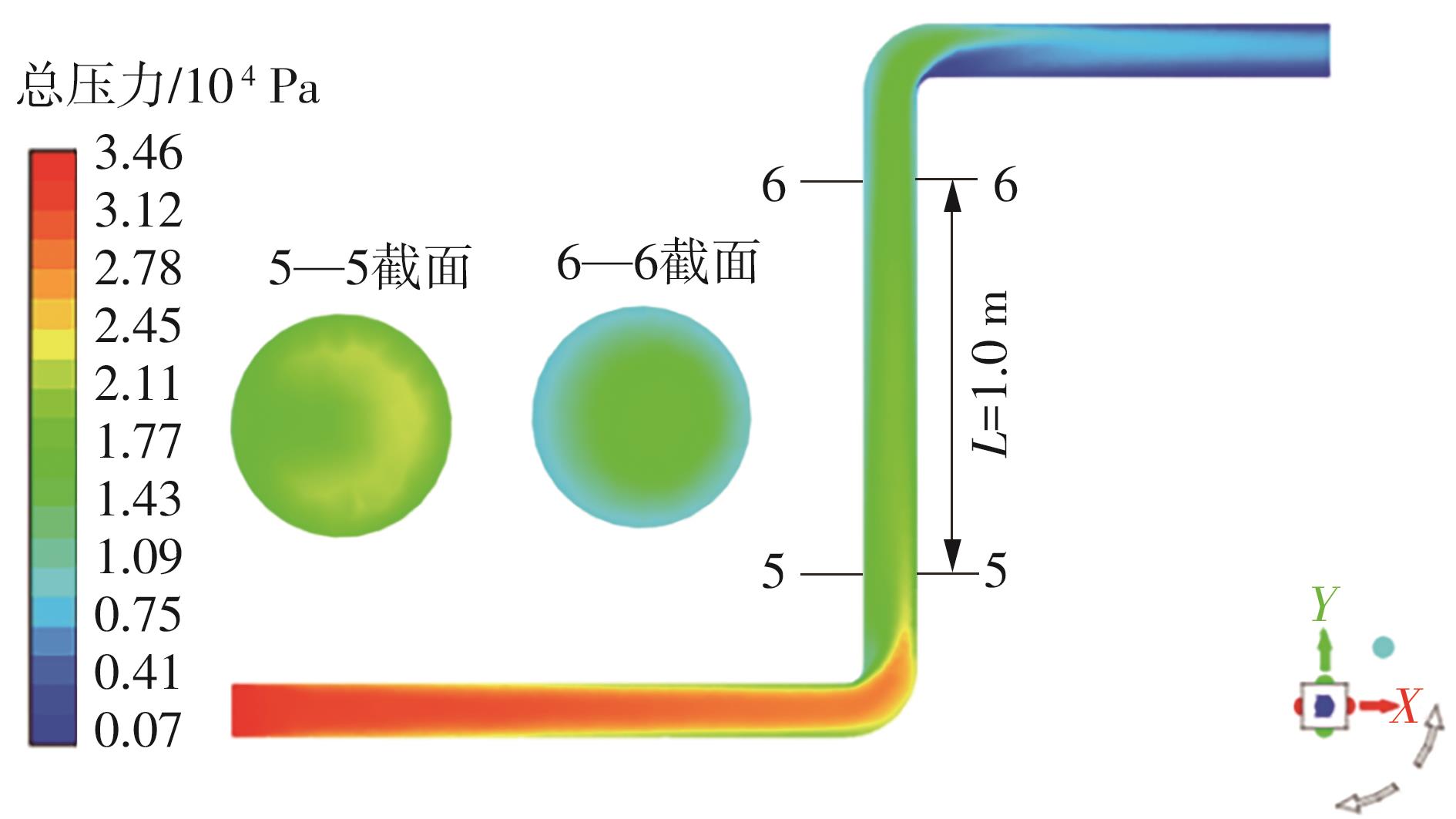

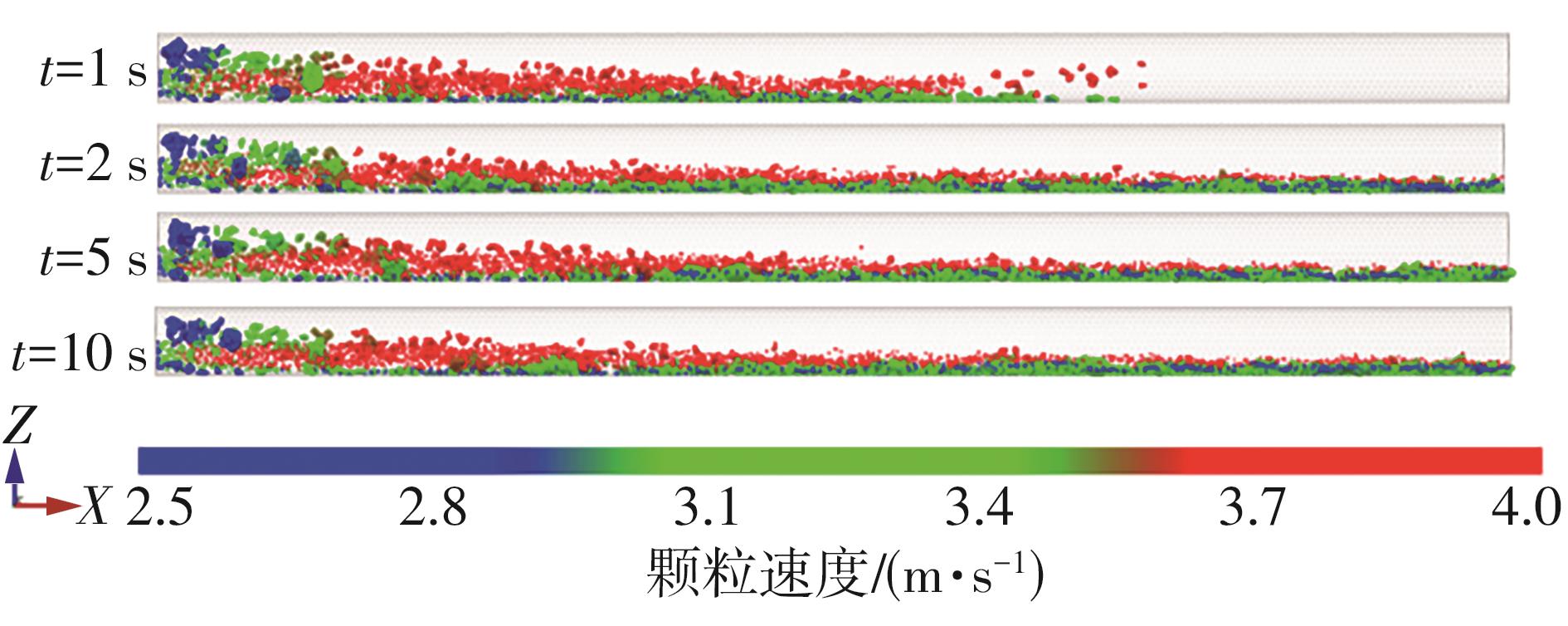

夏毅敏,王洋,吴遁,等 .泥水盾构环流系统管道输送特性[J].中南大学学报(自然科学版),2017,48(11):2889-2896.

|

|

XIA Yimin, WANG Yang, WU Dun,et al .Transport characteristics of shield slurry system[J].Journal of Central South University (Science and Technology),2017,48(11):2889-2896.

|

| 13 |

夏毅敏,姚菁,吴遁,等 .泥水盾构水平直管内石碴起动速度研究[J].隧道建设(中英文),2018,38(3):392-398.

|

|

XIA Yimin, YAO Jing, WU Dun,et al .Study of pickup velocity of pebbles in horizontal straight pipe of slurry shield[J].Tunnel Construction,2018,38(3):392-398.

|

| 14 |

熊庭,张梦达,危卫,等 .泥浆管道输送特性的CFD模拟[J].人民黄河,2018,40(4):19-23.

|

|

XIONG Ting, ZHANG Meng-da, WEI Wei,et al .CFD simulation of characteristics of pipeline slurry transportation[J].Yellow River,2018,40(4):19-23.

|

| 15 |

徐朝辉 .泥水盾构水平直管输碴特性研究[J].山西建筑,2018,44(17):178-180.

|

|

XU Zhaohui .Study on ballast transmission characteristics of the slurry shield horizontal straight pipe[J].Shanxi Architecture,2018,44(17):178-180.

|

| 16 |

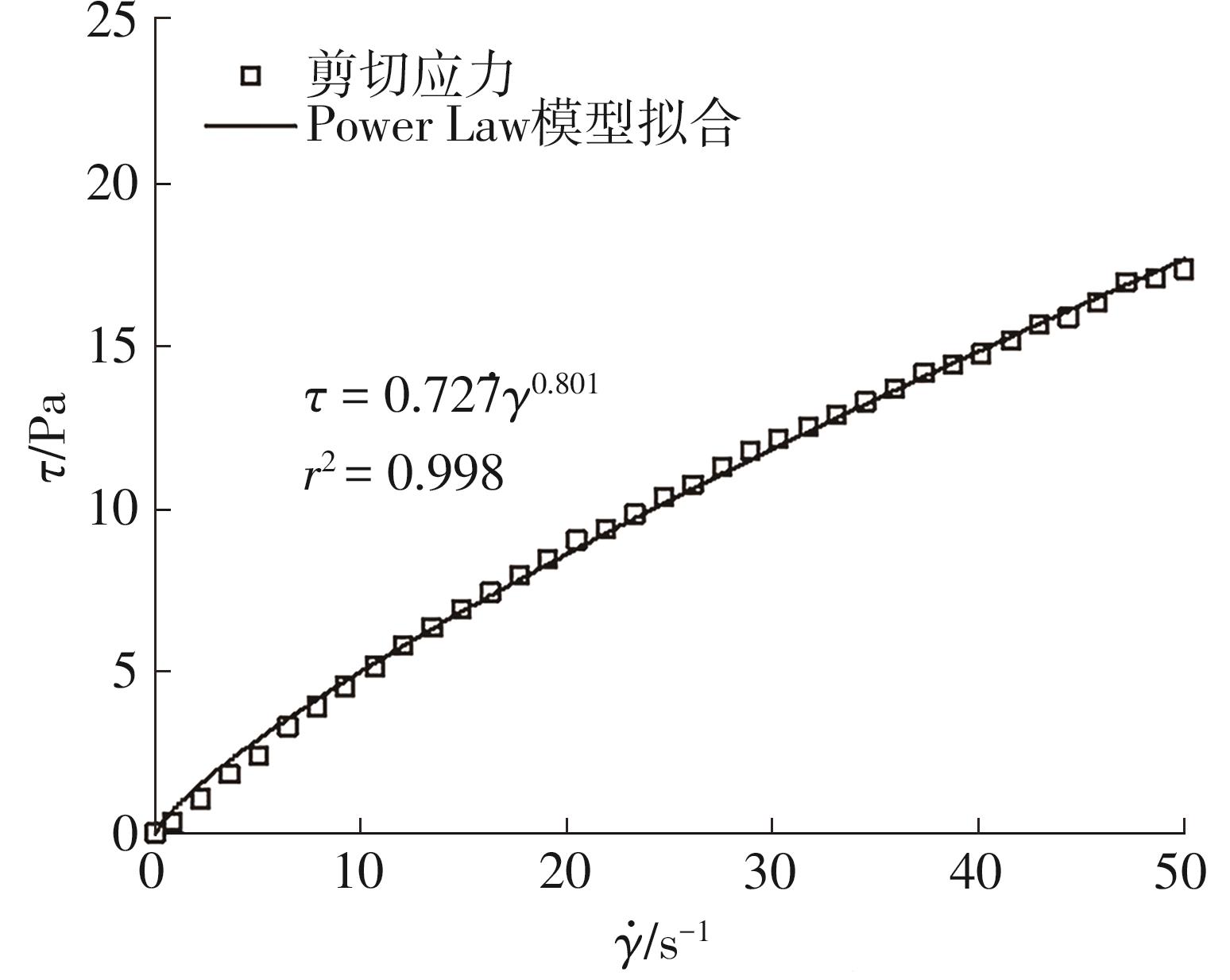

YANG D, XIA Y, WU D,et al .Numerical investigation of pipeline transport characteristics of slurry shield under gravel stratum[J].Tunnelling and Underground Space Technology,2018,71:223-230.

|

| 17 |

WANG Y, XIA Y, XIAO X,et al .Ballast flow characteristics of discharging pipeline in shield slurry system[J].Applied Sciences,2019,9:5402/1-20.

|

| 18 |

吴遁 .卵石地层中泥水盾构管道出渣影响因素研究[J].人民黄河,2020,42(5):157-161.

|

|

WU Dun .Study on the lnfluencing factors of the ballast carrying capacity of the slurry shield pipe under the sandy pebble formation[J].Yellow River,2020,42(5):157-161.

|

| 19 |

JIANG S, CHEN X, CAO G,et al .Optimization of fresh concrete pumping pressure loss with CFD-DEM approach[J].Construction and Building Materials,2021,276:122204/1-15.

|

| 20 |

LAUNDER B E, SPALDING D B .The numerical computation of turbulent flows[J]. Computer Methods in Applied Mechanics and Engineering,1974(3):269-289.

|

| 21 |

CUNDALL P A, STRACK O D L .A discrete numerical model for granular assemblies[J].Geotechnique,1979,29(1):47-65.

|

| 22 |

GUO Y, LI X, JIN D,et al .Assessment on the reverse circulation performance of slurry shield pipeline system assisted with CFD-DEM modeling under sandy cobble stratum[J].Powder Technology,2023,425:118573/1-19.

|