| [1] |

朱彬荣,潘金龙,周震鑫,等 .3D打印高延性水泥基复合材料的单轴受拉和受压行为[J].硅酸盐学报,2021,49(5):844-854.

|

|

ZHU Binrong, PANG Jinlong, ZHOU Zhenxin,et al .Uniaxial tensile and compressive stress-strain behavior of 3D printed engineered cementitious composites[J].Journal of the Chinese Ceramic Society,2021,49(5):844-854

|

| [2] |

叶俊宏,郑怡,余江滔,等 .3D打印纤维增强混凝土材料研究进展[J].硅酸盐学报,2021,49(11):2538-2548.

|

|

YE Junhong, ZHENG Yi, YU Jiangtao,et al .Research progress on 3D printable fiber reinforced concrete[J].Journal of the Chinese Ceramic Society,2021,49(11):2538-2548

|

| [3] |

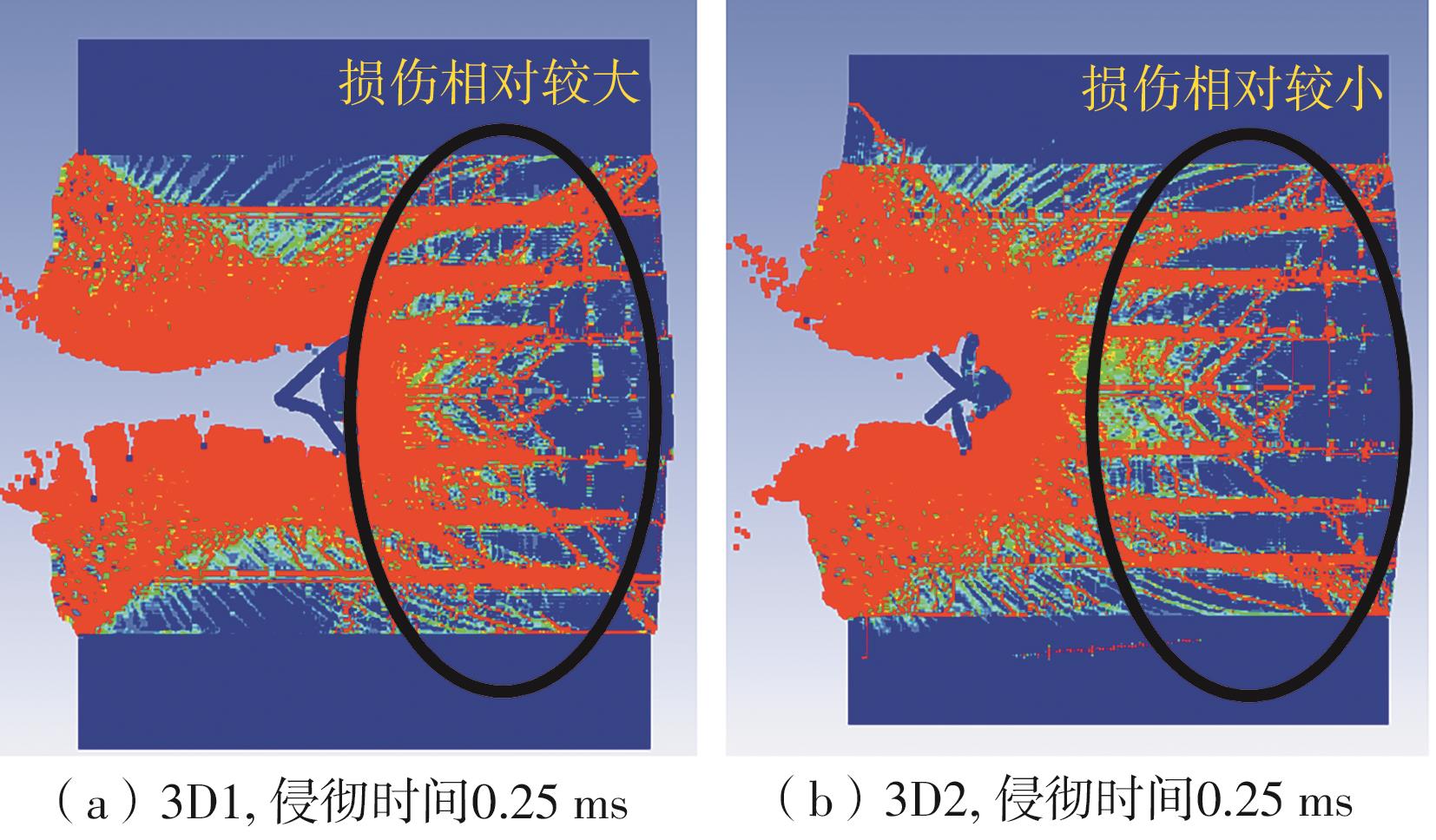

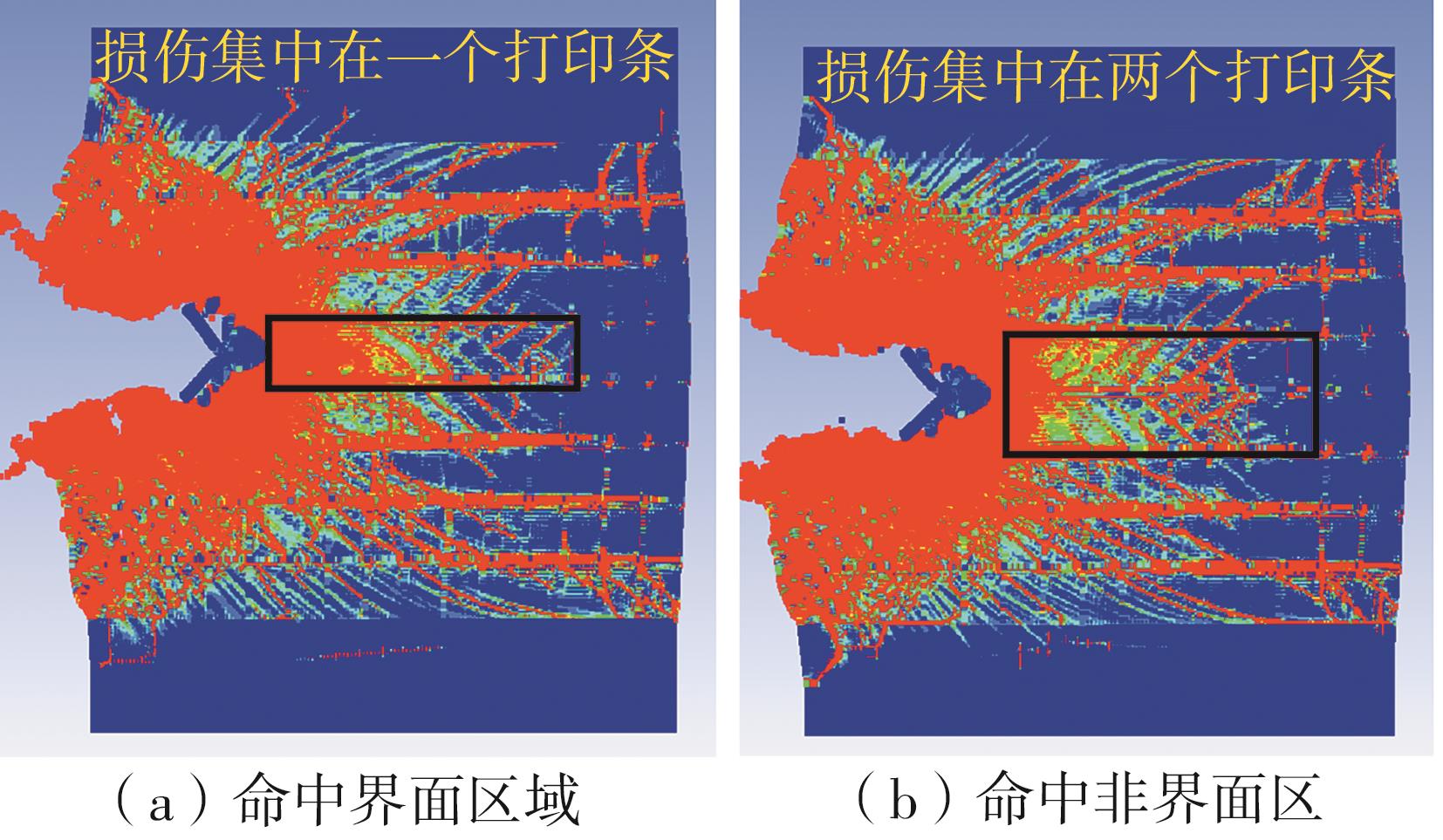

DU L Y, ZHOU J H, LAI J Z .Dynamic damage behavior and anisotropic mechanism of 3D printed reinforced concrete subjected to penetration,[J].Construction and Building Materials,2025,458(10):139559/1-13.

|

| [4] |

YANG Y, WU C, LIU Z .Rate dependent behaviour of 3D printed ultra-high performance fibre-reinforced concrete under dynamic splitting tensile[J].Composite Structures,2023,309:116727/1-25.

|

| [5] |

YANG Y, WU C, LIU Z,et al .Characteristics of 3D-printing ultra-high performance fibre-reinforced concrete under impact loading[J].International Journal of Impact Engineering,2022,164:104205/1-22.

|

| [6] |

MA G, BAI G, WANG L,et al .Explosion resistance of 3D printing ultra-high performance concrete based on contact explosion tests[J].International Journal of Impact Engineering,2022,169:104316/1-15.

|

| [7] |

LIU J, LI S,FOX K,et al .3D concrete printing of bioinspired Bouligand structure: a study on impact resistance[J].Additive Manufacturing,2022,50:102544/1-20.

|

| [8] |

尹雪祥,赖建中,周捷航,等 .超高性能混凝土梯度材料抗超高速侵彻性能数值模拟[J].硅酸盐学报,2021,49(11):2435-2449.

|

|

YIN Xuexiang, LAI Jianzhong, ZHOU Jiehang,et al .Numerical simulation on anti-hypervelocity penetration performance of ultra-high performance concrete gradient material [J].Journal of the Chinese Ceramic Society,2021,49(11):2435-2449

|

| [9] |

KHAN S A,KOC M .Numerical modelling and simulation for extrusion-based 3D concrete printing: the underlying physics, potential, and challenges[J].Results in Materials,2022,16:100337/1-7.

|

| [10] |

NGUYAN-VAN V, LI S, LIU J,et al .Modelling of 3D concrete printing process: a perspective on material and structural simulations[J].Additive Manufacturing,2023,61:103333/1-18.

|

| [11] |

VAN D H M, BESTER F, KRUGER J,et al .Mechanical characterisation for numerical simulation of extrusion-based 3D concrete printing[J].Journal of Building Engineering,2021,44:102944/1-15.

|

| [12] |

CHEN Y, ZHANG Y, XIE Y,et al .Unraveling pore structure alternations in 3D-printed geopolymer concrete and corresponding impacts on macro-properties[J].Additive Manufacturing,2022,59:103137/1-18.

|

| [13] |

DING T, WANG Z, LIU H,et al .Simulation on pull-out performance of steel bar from 3D-printed concrete[J].Engineering Structures,2023,283:115910/1-14.

|

| [14] |

陈虹羽 .3D打印混凝土力学性能及壳体结构抗冲击性能研究[D].长沙:长沙理工大学,2020.

|

| [15] |

岳健广,王健,吴瑶,等 .3D打印碳纤维混凝土断裂力学性能试验研究及数值模拟[J/OL].建筑结构学报.(2023-1-15)[2024-12-14]..

|

|

YUE Jianguang, WANG Jian, WU Yao,et al .Experimental study and numerical simulation of mechanical properties of 3D printed carbon fiber reinforced concrete[J/OL].Journal of Building Structures.(2023-1-15)[2024-12-14]..

|

| [16] |

GENG Z, SHE W, ZUO W,et al .Layer-interface properties in 3D printed concrete:dual hierarchical structure and micromechanical characterization[J].Cement and Concrete Research,2020,138:106220/1-17.

|

| [17] |

WANG L, YANG Y, YAO L,et al .Interfacial bonding properties of 3D printed permanent formwork with the post-casted concrete[J].Cement and Concrete Composites,2022,128:104457/1-15.

|

| [18] |

WENG Y, LI M, ZHANG D,et al .Investigation of interlayer adhesion of 3D printable cementitious material from the aspect of printing process[J].Cement and Concrete Research,2021,143:106386/1-16.

|

| [19] |

DU L, ZHOU J, LAI J,et al .Effect of pore structure on durability and mechanical performance of 3D printed concrete[J].Construction and Building Materials, 2023,400:132581/1-12.

|

| [20] |

孙晓燕,沈俊逸,王海龙,等 .3D打印混凝土永久模板叠合梁抗弯性能研究[J].土木工程学报, 2022,55(10):1-10.

|

|

SUN Xiaoyan, SHEN Junyi, WANG Hailong,et al .Bending behavior of composite beam with 3D printed concrete permanent formwork[J].China Civil Engineering Journal,2022,55(10):1-10.

|

| [21] |

ZHOU J, LAI J, DU L,et al .Effect of directionally distributed steel fiber on static and dynamic properties of 3D printed cementitious composite[J].Construction and Building Materials,2022,318:125948/1-23.

|

| [22] |

张海燕,唐国铭,过民龙,等 .回字形3D打印混凝土受压性能试验及数值模拟[J].硅酸盐通报, 2023,42(6):1980-1986,1995.

|

|

ZHANG Haiyan, TANG Guoming, GUO Minlong,et al .Tests and numerical simulation on compressive properties of 3D printing concrete along rectangular-ambulatory-plane path,[J].Bulletin of Chinese Ceramic Society,2023,42(6):1980-1986,1995.

|

| [23] |

李俊睿 .3D打印水泥基材料基本力学性能与数值模拟[D].南京:东南大学,2022.

|

| [24] |

杨浩若 .侵彻和爆炸下超高性能水泥基复合材料的毁伤效应及数值模拟[D].南京:南京理工大学,2018.

|

| [25] |

董赛阳 .3D打印功能梯度混凝土的制备及性能研究[D].南京:南京理工大学,2020.

|

| [26] |

杨宇杰 .3D打印混凝土材料抗侵彻爆炸性能研究及数值模拟[D].南京:南京理工大学,2021.

|

| [27] |

李宏基 .不同混凝土防护工程材料抗侵彻爆炸性能研究及数值模拟[D].南京:南京理工大学,2020.

|