华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (2): 47-53.doi: 10.12141/j.issn.1000-565X.220136

所属专题: 2023年机械工程

低温差斯特林发动机热力学分析

吴上生 黄铁祥

- 华南理工大学 机械与汽车工程学院,广东 广州 510640

Thermodynamic Analysis of Low Temperature Differential Stirling Engine

WU Shangsheng HUANG Tiexiang

- School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510640,Guangdong,China

摘要:

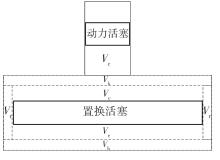

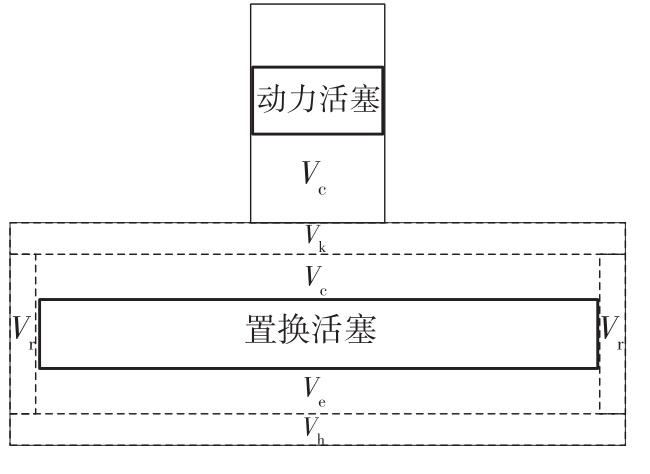

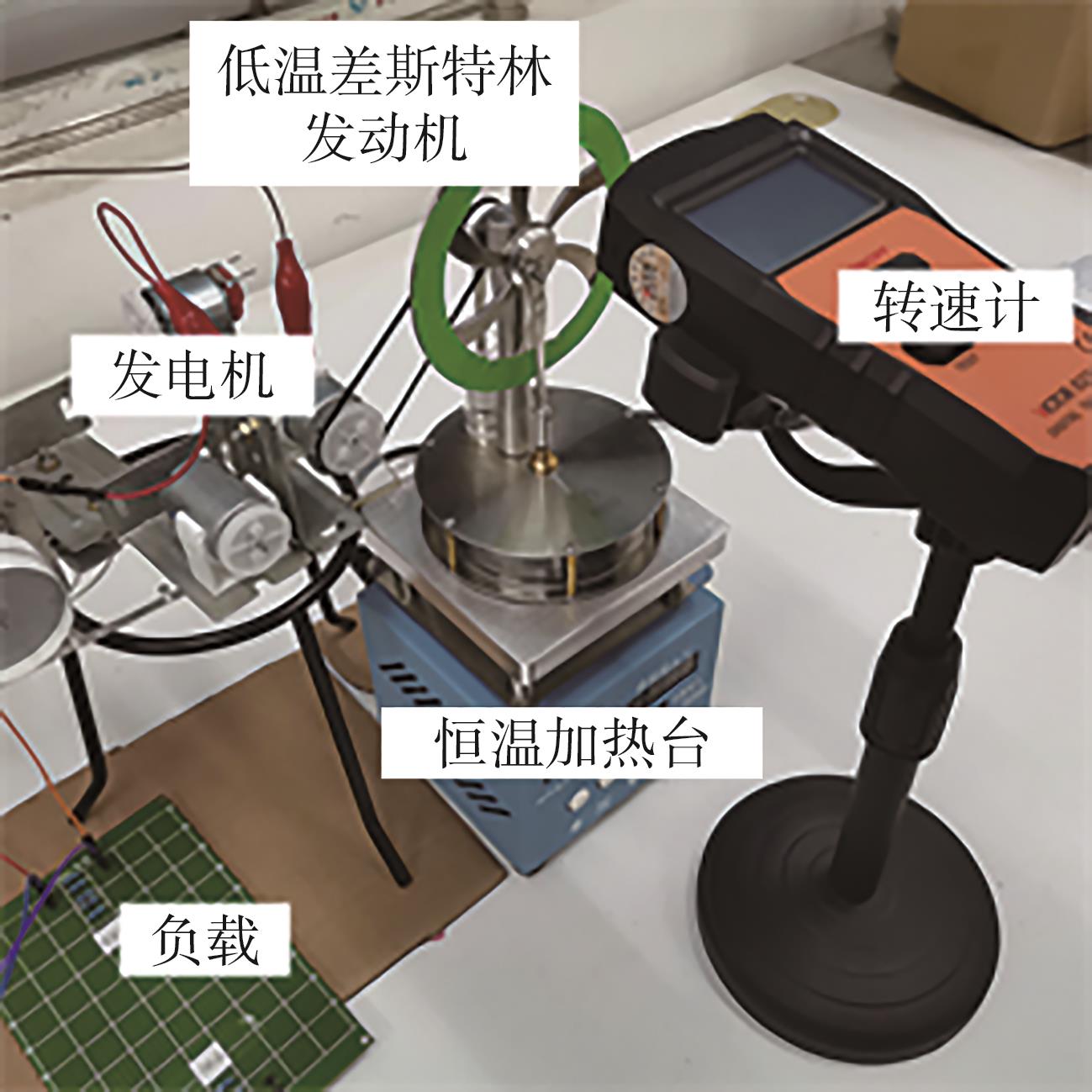

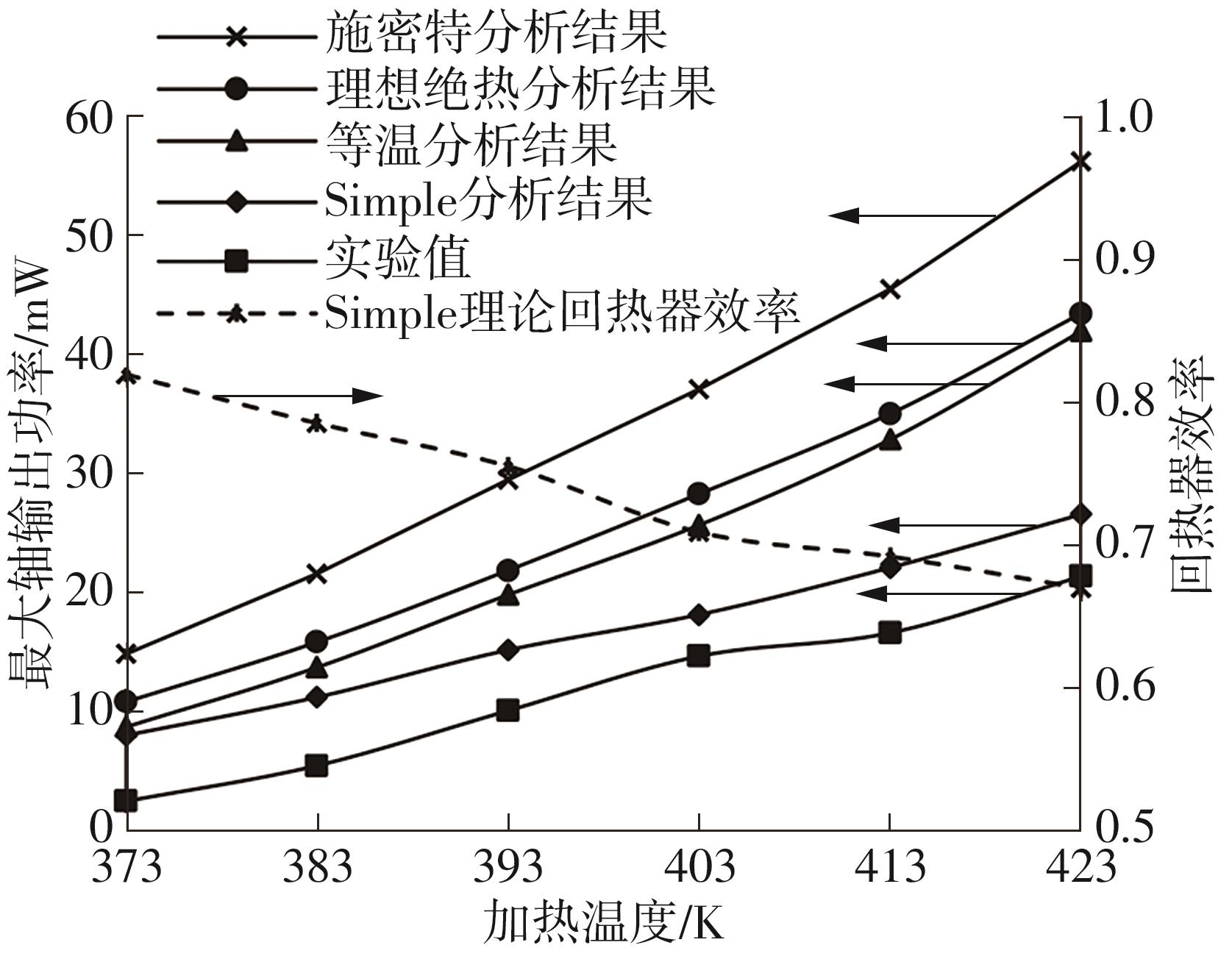

在低温差斯特林发动机的功率预测和参数优化分析中,传统的分析方法并不实用。为了快速准确地预估低温差斯特林发动机的输出功率,文中研究二阶Simple模型在低温差斯特林发动机的热力学循环分析中的应用。描述了低温差斯特林发动机的简化结构模型与内部工质的温度特性,基于Simple模型推导低温差斯特林发动机中非理想换热器的实际换热方程式,分析发动机的回热损失、泵送损失和换热器实际换热量。通过实例计算说明低温差斯特林发动机系统内部工质的温度、压力和能量随曲柄转角的变化,分析低温差斯特林发动机的理论输出功率。将低温差斯特林发动机在不同加热温度下的实际输出功率与Simple模型的计算功率对比,对比结果显示,Simple模型计算的输出功率与实际输出功率之间的误差较小,表明Simple模型与低温差斯特林发动机的实际循环吻合较好。为了研究低温差斯特林发动机中回热器对发动机性能的影响,文中优化了低温差斯特林发动机的回热器结构,将回热器优化后的实际输出功率和Simple模型计算功率,与回热器优化前的实际输出功率和Simple模型计算功率对比。对比结果显示,优化回热器后的低温差斯特林发动机的实际输出功率与Simple模型计算功率均提高20%,表明优化回热器结构是提高低温差斯特林发动机性能的切实有效的方法。

中图分类号: