Journal of South China University of Technology(Natural Science) >

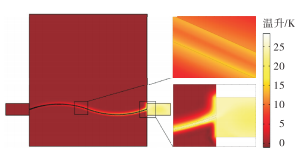

Multiphysics Coupling Simulation of ECM Temperature Based on Different Turbulence Models

Received date: 2021-04-16

Revised date: 2021-06-23

Online published: 2021-08-27

Supported by

Supported by the National Natural Science Foundation of China(51775161,51775158)and the Natural Science Foundation of Anhui Province(2008085QE278)

CHEN Yuanlong, LIN Hua, CHEN Peixuan, et al . Multiphysics Coupling Simulation of ECM Temperature Based on Different Turbulence Models[J]. Journal of South China University of Technology(Natural Science), 2022 , 50(3) : 88 -94,126 . DOI: 10.12141/j.issn.1000-565X.210219

/

| 〈 |

|

〉 |