Journal of South China University of Technology(Natural Science Edition) ›› 2025, Vol. 53 ›› Issue (7): 50-59.doi: 10.12141/j.issn.1000-565X.240278

• Mechanical Engineering • Previous Articles Next Articles

A Contact Fatigue Assessment Model for Gears Considering Residual Stress and Inhomogeneities

LIU Yi1,2, SUN Linlin3, YANG Wenhan1, GUO Hui1, HOU Shengwen2, LIU Geng1

- 1.School of Mechanical Engineering,Northwestern Polytechnical University,Xi’an 710072,Shaanxi,China

2.Key Laboratory of Gear Transmission of Shaanxi Province,Shaanxi Fast Auto Drive Group Co. ,Ltd. ,Xi’an 710119,Shaanxi,China

3.Key Laboratory of Road Construction Technology and Equipment of the Ministry of Education,Chang’an University,Xi’an 710064,Shaanxi,China

-

Received:2024-06-04Online:2025-07-25Published:2025-02-21 -

About author:刘义(1978—),男,博士生,正高级工程师,主要从事齿轮设计与制造研究。E-mail: liuyi@fastgroup.cn -

Supported by:the National Natural Science Foundation of China(52205048);the Key Research and Development Program of Shaanxi Province(2023GXLH-087)

CLC Number:

Cite this article

LIU Yi, SUN Linlin, YANG Wenhan, GUO Hui, HOU Shengwen, LIU Geng. A Contact Fatigue Assessment Model for Gears Considering Residual Stress and Inhomogeneities[J]. Journal of South China University of Technology(Natural Science Edition), 2025, 53(7): 50-59.

share this article

| [1] | BURRELL N .Improved gear life through controlled shot peening[J].Gear Technology,1986(9/10):12-18,64. |

| [2] | WANG Y, ZHANG W, LIU Y .Analysis model for surface residual stress distribution of spiral bevel gear by generating grinding[J].Mechanism and Machine Theory,2018,130:477-490. |

| [3] | WANG G, ZHU D, ZOU S,et al .Simulation and experimental esearch on electrical control anti-backlash based on a novel type of variable tooth thickness involute gear pair[J].Journal of Mechanical Engineering,2022,2:126-140. |

| [4] | WANG C, ZHANG H, XIONG X,et al .Changes in surface integrity of cemented tungsten carbide with shot peening treatment[J].Surface and Coatings Technology,2021,425:127710/1-10. |

| [5] | DALY J .Problems related to stress corrosion cracking reduced by controlled shot peening[J].Industrial Heating,1998,65(5):65-70. |

| [6] | GU Y .Corrosion behavior and residual stress of microarc oxidation coated AZ31 magnesium alloy for biomedical applications[D].Fairbanks:University of Alaska Fairbanks,2012. |

| [7] | THORNTON P A .The influence of nonmetallic inclusions on the mechanical properties of steel:a review[J].Journal of Materials Science,1971,6:347-356. |

| [8] | LIU J, ZHANG M, JIANG F,et al .Numerical simulation for elasto-plastic contact of novel Ti-(SiCf/Al3Ti)- laminated composite with double-layered SiC fiber reinforcements[J].Metals,2019,9(2):165-193. |

| [9] | LEROUX J, FULLERINGER B, NELIAS D .Contact analysis in presence of spherical inhomogeneities within a half-space[J].International Journal of Solids and Structures,2010,47(22/23):3034-3049. |

| [10] | WANG W, LIU H, ZHU C,et al .Evaluation of rolling contact fatigue of a carburized wind turbine gear considering the residual stress and hardness gradient[J].Journal of Tribology,2018,140(6):14-26. |

| [11] | WANG W, LIU H, ZHU C,et al .Effect of the residual stress on contact fatigue of a wind turbine carburized gear with multiaxial fatigue criteria[J].International Journal of Mechanical Sciences,2018,151:263-273. |

| [12] | YOU S, TANG J, ZHOU W,et al .Research on calculation of contact fatigue life of rough tooth surface considering residual stress[J].Engineering Failure Analysis,2022,140:106459/1-14. |

| [13] | CHEN Z, JIANG Y, TONG Z,et al .Residual stress distribution design for gear surfaces based on genetic algorithm optimization[J].Materials,2021,14(2):366/1-17. |

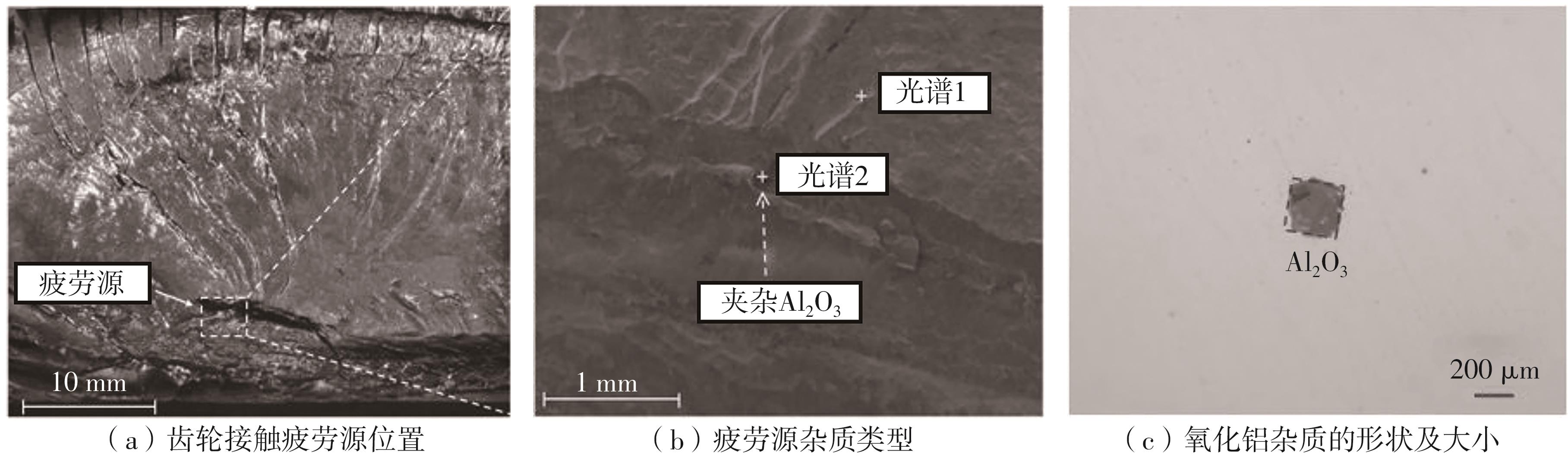

| [14] | HASHIMOTO K, FUJIMATSU T, TSUNEKAGE N,et al .Study of rolling contact fatigue of bearing steels in relation to various oxide inclusions[J].Materials & Design,2011,32(3):1605-1611. |

| [15] | CERULLO M .Sub-surface fatigue crack growth at alumina inclusions in AISI 52100 roller bearings[J].Procedia Engineering,2014,74:333-338. |

| [16] | TIEMENS B L .Performance optimization and computational design of ultra-high strength gear steels[D].Chicago:Northwestern University,2006. |

| [17] | 张文博,刘怀举,朱才朝,等 .夹杂物对齿轮接触疲劳性能影响的仿真分析[J].机械传动,2020,44(11):14-20,52. |

| ZHANG Wenbo, LIU Huaiju, ZHU Caichao,et al .Simulation analysis of the influence of inclusion on contact fatigue performance of gear[J].Mechanical Transmission,2020,44(11):14-20,52. | |

| [18] | LI Z, FREBORG A M, HANSEN B D,et al .Modeling the effect of carburization and quenching on the development of residual stresses and bending fatigue resistance of steel gears[J].Journal of Materials Engineering and Performance,2013,22:664-672. |

| [19] | RAJESH S, MARIMUTHU P, BABU P D,et al .Contact fatigue life estimation for asymmetric helical gear drives[J].International Journal of Fatigue,2022,164:107155/1-11. |

| [20] | NAJJARI M, GUILBAULT R .Modeling the edge contact effect of finite contact lines on subsurface stresses[J].Tribology International,2014,77:78-85. |

| [21] | NAJJARI M, GUILBAULT R .Edge contact effect on thermal elastohydrodynamic lubrication of finite contact lines[J].Tribology International,2014,71:50-61. |

| [22] | JIA X, WANG W, ZHAO Z,et al .A contact fatigue model of helical gear under elastohydrodynamic lubrication[J].Tribology,2014,34(1):8-14. |

| [23] | CAZAN S, DĂNILĂ C, CREŢU S .Tooth contact analysis of helical gears using semi-analytical methods in real gearing situations[J].Tribology International,2023,185:108482/1-16. |

| [24] | ALLEY E S, NEU R W .Microstructure-sensitive modeling of rolling contact fatigue[J].International Journal of Fatigue,2010,32(5):841-850. |

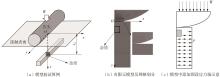

| [25] | WANG Q J, ZHU D .Interfacial mechanics:theories and methods for contact and lubrication[M].[S.l.]:CRC Press,2019:170-190. |

| [26] | WANG Q J, SUN L, ZHANG X,et al .FFT-based methods for computational contact mechanics[J].Frontiers in Mechanical Engineering,2020,6:61/1-22. |

| [27] | CHEN W W, ZHOU K, KEER L M,et al .Modeling elasto-plastic indentation on layered materials using the equivalent inclusion method[J].International Journal of Solids and Structures,2010,47(20):2841-2854. |

| [28] | ESHELBY J D .The determination of the elastic field of an ellipsoidal inclusion,and related problems[J].Proceedings of the Royal Society of London,Series A:Mathematical and Physical Sciences,1957,241(1226):376-396. |

| [29] | LIU S, JIN X, WANG Z,et al .Analytical solution for elastic fields caused by eigenstrains in a half-space and numerical implementation based on FFT[J].International Journal of Plasticity,2012,35:135-154. |

| [30] | ZHANG M, ZHAO N, WANG Z,et al .Efficient numerical method with a dual-grid scheme for contact of inhomogeneous materials and its applications[J].Computational Mechanics,2018,62(5):991-1007. |

| [31] | ZHOU Q, JIN X, WANG Z,et al .Numerical implementation of the equivalent inclusion method for 2D arbitrarily shaped inhomogeneities[J].Journal of Elasticity,2015,118:39-61. |

| [32] | 方宗德 .齿轮轮齿承载接触分析(LTCA)的模型和方法[J].机械传动,1998,22(2):1-3. |

| FANG Zongde .Models and methods of load-bearing contact analysis (LTCA) for gear teeth[J].Mechanical Transmission,1998,22(2):1-3. | |

| [33] | 李雁淮,王飞,吕坚,等 .单丸粒喷丸模型和多丸粒喷丸模型的有限元模拟[J].西安交通大学学报,2007,41(3):348-352. |

| LI Yanhuai, WANG Fei, Jian LÜ,et al .Finite element simulation of single Sshot peening model and multiple shot peening model[J].Journal of Xi’an Jiaotong University,2007,41(3):348-352. | |

| [34] | AGHA S R .Fatigue performance of superfinish hard turned surfaces in rolling contact[D].West Lafayette:Purdue University,2000. |

| [35] | 黄新春,史恺宁 .高温合金磨削残余应力机理及对疲劳寿命的影响研究[J].航空精密制造技术,2021,57(6):1-5. |

| HUANG Xin-chun, SHI Kai-ning .Study of residual stress and its influence on fatigue life in grinding superalloy[J].Aeronautical Precision Manufacturing Technology,2021,57(6):1-5. | |

| [36] | 李康 .湿喷丸强化Ti-6Al-4V合金的微动磨损和微动疲劳行为及其机理研究[D].大连:大连理工大学,2016. |

| [37] | LI S X .Effects of inclusions on very high cycle fatigue properties of high strength steels[J].International Materials Reviews,2012,57(2):92-114. |

| [38] | LIU R, SUN D, HOU J,et al .Fatigue life analysis of wind turbine gear with oxide inclusion[J].Fatigue & Fracture of Engineering Materials & Structures,2021,44(3):776-787. |

| [39] | IBRAHIM I A, MOHAMED F A, LAVERNIA E J .Particulate reinforced metal matrix composites-a review[J].Journal of Materials Science,1991,26:1137-1156. |

| [40] | DANG-VAN K .Macro-micro approach in high-cycle multiaxial fatigue[M]∥ MCDOWELL D L,ELLIS J R.Advances in Multiaxial Fatigue.[S.l.]:ASTM,1993:120-130. |

| [41] | KAROLCZUK A, MACHA E .A review of critical plane orientations in multiaxial fatigue failure criteria of metallic materials[J].International Journal of Fracture,2005,134(3/4):267-304. |

| [42] | DANG-VAN K, CAILLETAUD G, FLAVENOT J F,et al .Criterion for high cycle fatigue failure under multiaxial loading[J].Mechanical Engineering Publications,Biaxial and Multiaxial Fatigue,1989:459-478. |

| [43] | 闻邦椿 .机械设计手册(单行本):疲劳强度与可靠性设计[M].北京:机械工业出版社,2015. |

| [44] | HARRIS T A, YU W K .Lundberg-Palmgren fatigue theory:considerations of failure stress and stressed volume[J].Journal of Tribology,1999,121(1):85-89. |

| [1] | JI Shuting, LI Jiahao, ZHANG Yueming. Active Tooth Surface Design and Performance Optimization of High Reduction Ratio Hypoid Gears [J]. Journal of South China University of Technology(Natural Science Edition), 2025, 53(9): 106-116. |

| [2] | XIA Qinxiang, PENG Chong, LIU Meihua, et al. Research on Material Flow Behavior of Gear Blank with Deep Spoke During Multi Station Close Die Forging [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(9): 35-41. |

| [3] | JIANG Jinke, LI Meng. Loaded Tooth Contact Analysis for Double-Helical Planetary Gear Sets with Floating Components [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(9): 51-61. |

| [4] | CHEN Guohua, XIE Mulin, ZHANG Qiang, et al. Study on Hydrogen Leakage-Explosion and Risk of Hydrogen Bus in Station [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(2): 84-94. |

| [5] | CHANG Lehao, WANG Peilin, HUANG Qidi, et al. Coupled Analysis of Dynamic Contact and Dynamics of Gear System Considering Tooth Back Meshing [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(12): 22-31. |

| [6] | BAI Dalian, YANG Lufeng, YIN Yuqi. Generalized Plastic Hinge Method for Ultimate Strength Analysis of Steel Frames Considering Residual Stress [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(7): 90-99. |

| [7] | LI Junye, TIAN Gongqiang, WANG Xinpeng, et al.. Analysis of Forming Characteristics of Conductive Slip Ring Brush Wire by Finite Element Method [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(11): 140-150. |

| [8] | ZHOU Jianxing, ZHANG Ronghua, ZENG Qunfeng, et al. Dynamic Wear Characteristics of Tooth Profile of RV Reducer for Industrial Robot [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(1): 22-30. |

| [9] | MO Haijun, ZHAO Hang, CHENG Yu, et al. Normal Contact Stiffness Model of Fine Particle Shot Peening Gear [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(9): 90-98. |

| [10] | JIANG Jinke FANG Zongde . Design and Analysis for Actively Modified Gear with Zero Amplitude of Loaded Transmission Error [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(9): 99-108. |

| [11] | ZHANG Junhao, CHENG Xiuquan, XIA Qinxiang, et al. Study on Residual Stress Control of Damaged Aircraft Component Based on Non-uniform Overlap Ratio Laser Shock Peening [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(3): 73-79. |

| [12] | GONG Jingyi, YANG Long, LIU Geng, et al. Quasi-Static Contact Characteristics of Double Gearboxes with Coupling Misalignment [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(10): 114-123. |

| [13] | WANG Yanzhong, XU Zichun, MA Tao, et al. Analysis of Lubrication and Friction Characteristics for Modified Herringbone Gear [J]. Journal of South China University of Technology (Natural Science Edition), 2021, 49(1): 93-102. |

| [14] | JIANG Jinke LIU Zhao PENG Xianlong. Optimization Design of Vibration Reduction for Hypoid Gears with Ease-Off Flank Modification [J]. Journal of South China University of Technology (Natural Science Edition), 2020, 48(5): 134-141,148. |

| [15] | WEN Huiying, WU Jiabin, QI Weiwei, et al. CP-CS Fusion Model for On-Ramp Merging Area on the Highway [J]. Journal of South China University of Technology (Natural Science Edition), 2020, 48(2): 50-57. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||