| 1 |

任民,王志德,牟建民,等 .我国烟草种质资源的种类与分布概况[J].中国烟草科学,2009,30(S1):8-14.

|

|

REN Min, WANG Zhide, MU Jianmin,et al .Overview of species and distribution of tobacco germplasm resources in China[J].Chinese Tobacco Science,2009,30(S1):8-14.

|

| 2 |

张骞方,叶鹏盛,代顺冬,等 .烟草生产废弃物资源化利用现状及建议[J].现代农业科技,2020(3):181,183.

|

|

ZHANG Qianfang, YE Pengsheng, DAI Shundong,et al .Current situation and suggestions on the resource utilization of tobacco waste[J].Modern Agricultural Science and Technology,2020(3):181,183.

|

| 3 |

徐晓铭,张洋,司成,等 .烟草提取物的药理作用研究进展[J].山东医药,2023,63(11):112-115.

|

|

XU Xiaoming, ZHANG Yang, SI Cheng,et al .Research progress on the pharmacological effects of tobacco extracts[J].Shandong Medical Journal,2023,63(11):112-115.

|

| 4 |

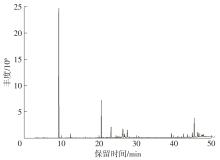

高宏建,张献忠,钟建军,等 .水蒸汽蒸馏法提取烟草精油的研究[J].食品工业科技,2011,32(10):388-390.

|

|

GAO Hong-jian, ZHANG Xian-zhong, ZHONG Jian-jun,et al .Research on extraction tobacco essential oils by steam distillation[J].Science and Technology of Food Industry,2011,32(10):388-390.

|

| 5 |

ZHANG X, GAO H, ZHANG L,et al .Extraction of essential oil from discarded tobacco leaves by solvent extraction and steam distillation,and identification of its chemical composition[J].Industrial Crops and Products,2012,39:162-169.

|

| 6 |

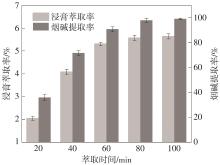

刘春波,于昊辰,李易丞,等 .从烟叶中提取烟碱的工艺条件优化[J].辽宁化工,2019,48(1):24-26.

|

|

LIU Chun-bo, YU Hao-chen, LI Yi-cheng,et al .Optimization of extraction process of nicotine from tobacco leaves[J].Liaoning Chemical Industry,2019,48(1):24-26.

|

| 7 |

BANOŽIĆ M, BANJARI I, FLANJAK I,et al .Optimization of MAE for the separation of nicotine and phenolics from tobacco waste by using the response surface methodology approach[J].Molecules,2021,26(14):1-14.

|

| 8 |

王莹,杨海朝,刘凤霞,等 .微波和超声波辅助萃取废弃烟叶及烟杆中烟碱的研究[J].农产品加工,2019(10):1-5.

|

|

WANG Ying, YANG Haichao, LIU Fengxia,et al .Study on extraction of nicotine from discarded tobacco leaves and stems by microwave and ultrasonic assisted extraction[J].Farm Products Processing,2019(10):1-5.

|

| 9 |

MÖCK D M J, RIEGERT C, RADTKE S,et al .Process optimization and extraction of acids,syringols,guaiacols,phenols and ketones from beech wood slow pyrolysis liquids with supercritical carbon dioxide at different densities[J].The Journal of Supercritical Fluids,2023,199:105937/1-13.

|

| 10 |

PEREIRA G S L, MAGALHÃES R D S, FRAGA S,et al .Extraction of bioactive compounds from Butia capitata fruits using supercritical carbon dioxide and pressurized fluids[J].The Journal of Supercritical Fluids,2023,199:105959/1-7.

|

| 11 |

PINTO M B C, VARDANEGA R, NÁTHIA-NEVES G,et al .Novel Brazilian hop (Humulus lupulus L.) extracts through supercritical CO2 extraction:enhancing hop processing for greater sustainability[J].Food Research International,2023,172:1-12.

|

| 12 |

PAN Z, WANG X, LI Q,et al .Supercritical extraction technique of agarwood essential oil induced by plant hormones[J].BioResources,2023,18(4):6741-6760.

|

| 13 |

MATEUS L S, DUTRA J M, FAVARETO R,et al .Optimization studies and compositional oil analysis of pequi (caryocar brasiliense cambess) almonds by supercritical CO2 extraction[J].Molecules,2023,28(3):1-13.

|

| 14 |

赵丹,尹洁 .超临界流体萃取技术及其应用简介 [J].安徽农业科学,2014,42(15):4772-4780.

|

|

ZHAO Dan, YIN Jie .Overview of supercritical fluid extraction and its application[J].Journal of Anhui Agricultural Sciences,2014,42(15):4772-4780.

|

| 15 |

吴芳,李雄山,陈乐斌 .超临界流体萃取技术及其应用[J].广州化工,2018,46(2):21-23.

|

|

WU Fang, LI Xiong-shan, CHEN Le-bin .Application of supercritical fluid extraction[J].Guangzhou Chemical Industry,2018,46(2):21-23.

|

| 16 |

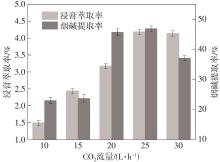

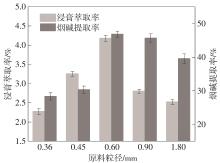

邱运仁,俞晓惠,杜吉华 .超临界CO2萃取烟叶中的烟碱[J].烟草科技,2006(8):21-24.

|

|

QIU Yun-ren, YU Xiao-hui, DU Ji-hua .Extraction of nicotine in tobacco with supercritical carbon dioxide fluid[J].Tobacco Science & Technology,2006(8):21-24.

|

| 17 |

杨靖,陈芝飞,孙志涛 .超临界CO2流体萃取烟叶中烟碱工艺研究[J].香料香精化妆品,2010(1):17-18.

|

|

YANG Jing, CHEN Zhifei, SUN Zhitao .Extraction technology on nicotine from tobacco by supercritical CO2 [J].Flavour Fragrance Cosmetics,2010(1):17-18.

|

| 18 |

DJAPIC N .Supercritical carbon dioxide extraction of nicotiana tabacum leaves:optimization of extraction yield and nicotine content[J].Molecules,2022,27(23):1-11.

|

| 19 |

DONG Z B, SHAO W Y, LIANG Y R .Isolation and characterization of essential oil extracted from tangerine peel [J].Asian Journal of Chemistry,2014,26(16):4975-4978.

|

| 20 |

阳元娥,谭伟,李桂锋 .超临界CO2萃取废次烟叶中烟碱工艺优化[J].化学与生物工程,2008,25(6):74-76.

|

|

YANG Yuan-e, TAN Wei, LI Gui-feng .Optimization of extraction technology of nicotine from waste tobacco leaves by supercritical CO2 [J].Chemistry and Bioengineering,2008,25(6):74-76.

|

| 21 |

RAJPUT S, KAUR S, PANESAR P S,et al .Supercritical fluid extraction of essential oils from Citrus reticulata peels:optimization and characterization studies[J].Biomass Conversion and Biorefinery,2023,13(16):14605-14614.

|