华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (9): 19-29.doi: 10.12141/j.issn.1000-565X.220693

高水基液压马达配流机构的研究

于鸣泉1,2 赵继云1,2 满家祥3 郜青文1

- 1.中国矿业大学 机电工程学院,江苏 徐州 221110

2.中国矿业大学 矿山机电设备江苏省重点实验室,江苏 徐州 221116

3.徐州工程学院 机电工程学院,江苏 徐州 221110

Study of Distribution Structure for High Water-Based Hydraulic Motor

YU Mingquan1,2 ZHAO Jiyun1,2 MAN Jiaxiang3 GAO Qingwen1

- 1.School of Mechanical and Electrical Engineering,China University of Mining and Technology,Xuzhou 221110,Jiangsu,China

2.Jiangsu Key Laboratory of Mine Mechanical and Electrical Equipment,China University of Mining and Technology,Xuzhou 221116,Jiangsu,China

3.School of Mechanical and Electrical Engineering,Xuzhou Institute of Engineering,Xuzhou 221110,Jiangsu,China

摘要:

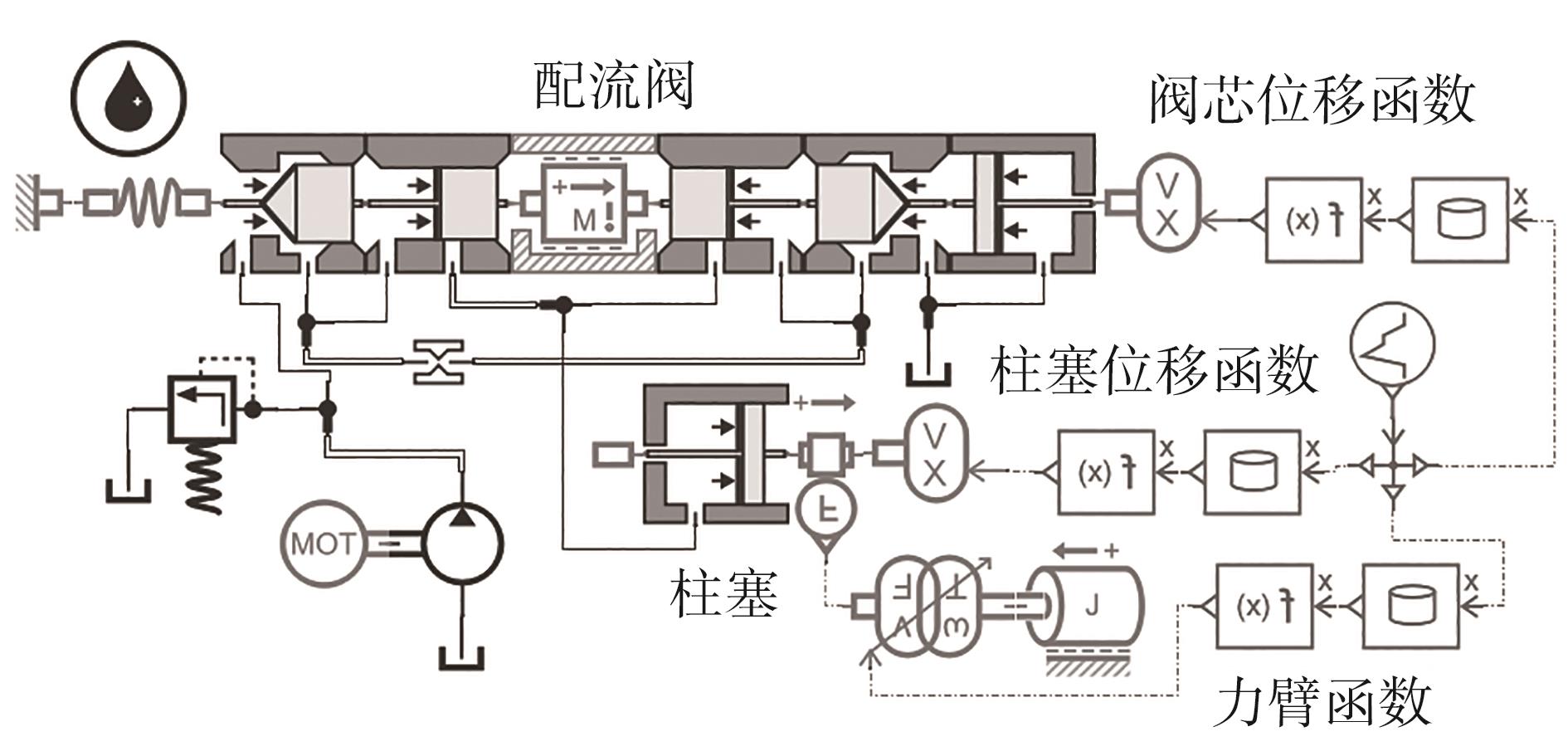

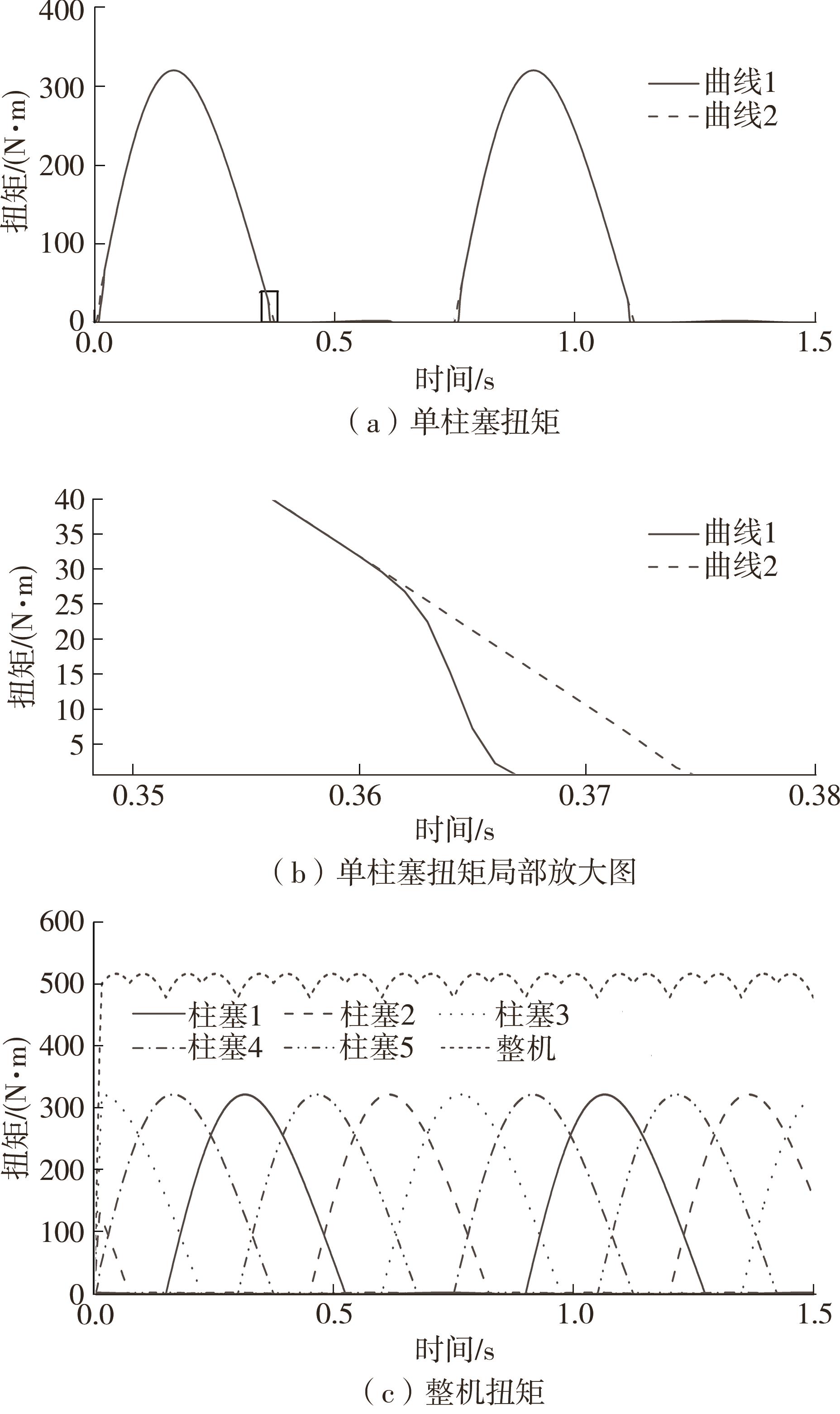

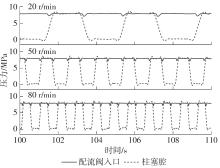

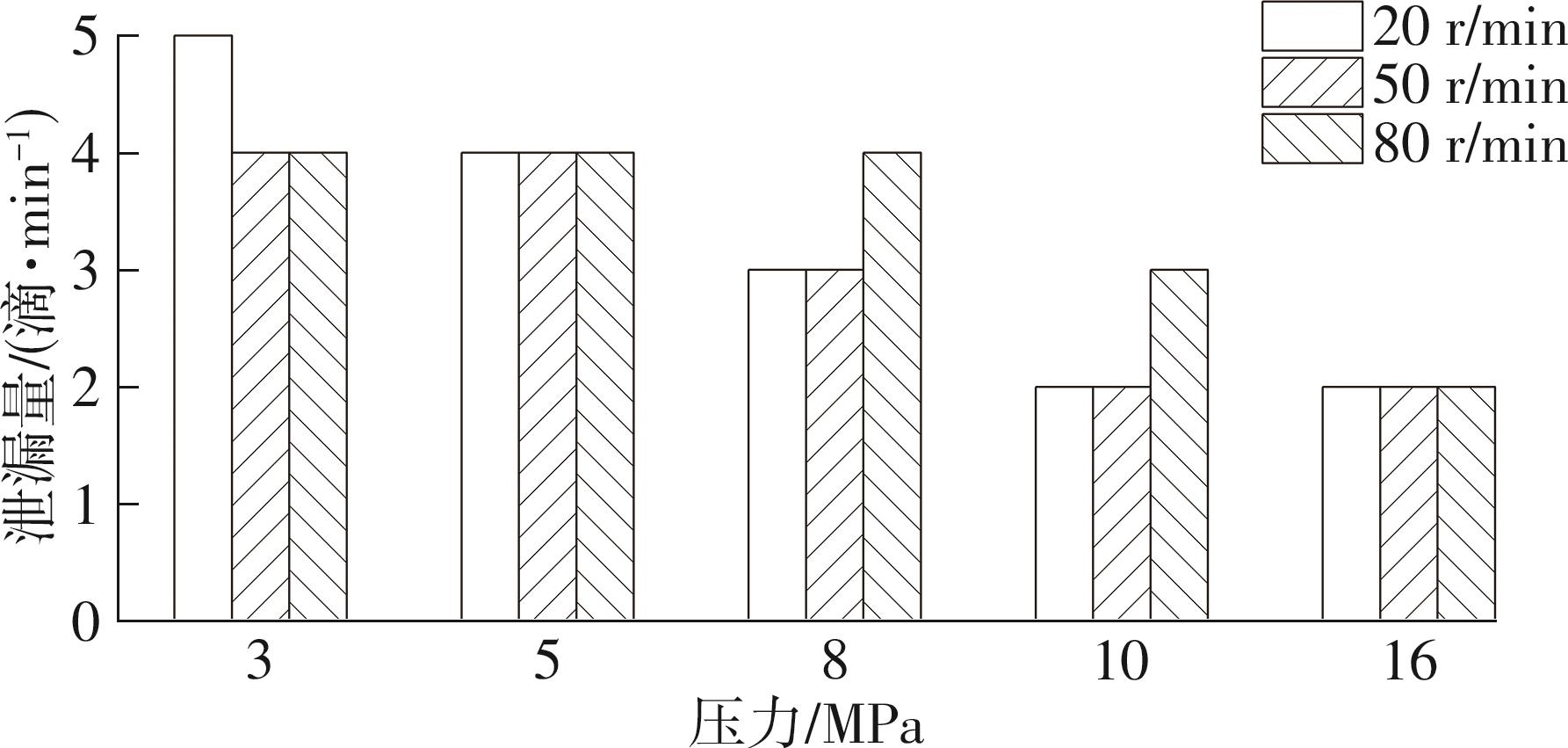

高水基液压马达由于其介质友好性可用于煤矿、食品、水下作业等领域,但目前水马达仍沿用油马达结构,仅将介质更换为高水基乳化液。马达的传统轴、盘配流机构在低速、高压、高水基工况下会产生严重泄漏、锈蚀现象,且阀配流机构存在的问题是一个柱塞需要配备两个单向配流阀,导致马达体积较大,同时配流阀间需准确配合,否则会出现窜、困液现象。针对以上问题提出了一种阀配流机构来控制马达配流,其由梭阀和凸轮组成,其中凸轮驱动顶杆实现柱塞的进排液过程。文中首先对配流阀进行结构设计和理论分析,揭示其配流原理;其次在AMESim中分析其参数的动态响应特性,选择正弦加速度函数曲线控制的凸轮来驱动阀芯,并选取压力和流量波动小的直径0.6 mm的阀芯通流孔,优化了配流结构。对马达整机性能进行仿真,整机扭矩波动为7.39%,验证了该机构良好的配流性能。运用Fluent仿真优化阀内流场,选用压降小、速度分布均匀的豁槽结构,并在此基础上进行样机制备和实验分析。在16 MPa工况下,柱塞腔可建压迅速,配流阀入口的压力波动率为12.5%,且泄漏量仅为2 滴/min。可知此配流梭阀应用于高水基液压马达后,可以实现稳定配流。

中图分类号: