| 1 |

李继军,聂晓梦,李根生,等 .平板显示技术比较及研究进展[J].中国光学,2018,11(5):695-710.

|

|

LI Ji-jun, NIE Xiao-meng, LI Gen-sheng,et al .Comparison and research progress of flat panel display technology[J].Chinese Optics,2018,11(5):695-710.

|

| 2 |

WANG L, ZHANG K, SONG Z,et al .Ceria concentration effect on chemical mechanical polishing of optical glass[J].Applied Surface Science,2007,253(11):4951-4954.

|

| 3 |

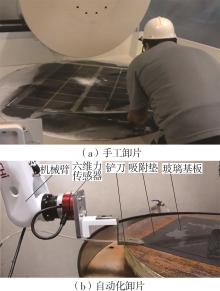

王恒升,章壮,杨会义,等 .一种平板显示玻璃起爪装置、起爪机械臂、自动上下料装置及起爪装置的使用方法:CN108726174A[P].2018-11-02.

|

| 4 |

AYDINOGLU A, PRECIADO V M, POSA M .Contact-aware controller design for complementarity systems[C]∥Proceedings of the IEEE International Conference on Robotics and Automation.Paris:IEEE,2020:1525-1531.

|

| 5 |

POSA M, CANTU C, TEDRAKE R .A direct method for trajectory optimization of rigid bodies through contact[J].The International Journal of Robotics Research,2014,33(1):69-81.

|

| 6 |

MU X, WU Q .On impact dynamics and contact events for biped robots via impact effects[J].IEEE Transactions on Systems,Man,and Cybernetics,Part B (Cyberne-tics),2006,36(6):1364-1372.

|

| 7 |

KOLBERT R, CHAVAN-DAFLE N, RODRIGUEZ A .Experimental validation of contact dynamics for in-hand manipulation[C]∥Proceedings of the International Symposium on Experimental Robotics.Tokyo:IEEE,2016:633-645.

|

| 8 |

EREZ T, TASSA Y, TODOROV E .Simulation tools for model-based robotics:comparison of Bullet,Havok,MuJoCo,ODE and PhysX[C]∥Proceedings of the IEEE International Conference on Robotics and Automation.Washington DC:IEEE,2015:4397-4404.

|

| 9 |

郭胤,王家序,李峰,等 .弹性体摩擦的黏滞疲劳理论及实验研究[J].摩擦学学报,2013,33(5):443-448.

|

|

GUO Yin, WANG Jia-xu, LI Feng,et al .Theory of adhesion hysteresis-fatigue of elastomeric tribology and experimental demonstration[J].Tribology,2013,33(5):443-448.

|

| 10 |

FULLER D D .Theory and practice of lubrication for engineers[M].New York:Wiley,1984.

|

| 11 |

KOSHY C S, FLORES P, LANKARANI H M .Study of the effect of contact force model on the dynamic response of mechanical systems with dry clearance joints:computational and experimental approaches[J].Nonlinear Dynamics,2013,73(1):325-338.

|

| 12 |

FICUCIELLO F, MIGLIOZZI A, COEVOET E,et al .FEM-based deformation control for dexterous manipulation of 3D soft objects[C]∥Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems.Madrid:IEEE,2018:4007-4013.

|

| 13 |

NAGABANDI A, KONOLIGE K, LEVINE S,et al .Deep dynamics models for learning dexterous manipulation[C]∥Proceedings of the Conference on Robot Learning.Cambridge:[s. n.],2020:1101-1112.

|

| 14 |

BAUZA M, RODRIGUEZ A .A probabilistic data-driven model for planar pushing[C]∥Proceedings of the IEEE International Conference on Robotics and Automation.Singapore:IEEE,2017:3008-3015.

|

| 15 |

LI Y, WU J, TEDRAKE R,et al .Learning particle dynamics for manipulating rigid bodies,deformable objects,and fluids[C]∥Proceedings of the International Conference on Learning Representations.New Orleans:[s. n.],2019.

|

| 16 |

FAZILI N, KOLBERT R, TEDRAKE R,et al .Para-meter and contact force estimation of planar rigid-bodies undergoing frictional contact[J].International Journal of Robotics Research,2017,36(13):1437-1454.

|

| 17 |

AJAY A, WU J, FAZELI N,et al .Augmenting physical simulators with stochastic neural networks:case study of planar pushing and bouncing[C]∥Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems.Madrid:IEEE,2018:3066-3073.

|

| 18 |

GOLTS A, FREEDMAN D, ELAD M .Unsupervised single image dehazing using dark channel prior loss[J].IEEE Transactions on Image Processing,2019,29:2692-2701.

|

| 19 |

CRANMER M, GREYDANUS S, HOYER S,et al .Lagrangian neural networks[EB/OL].(2020-07-30)[2021-10-12]..

|

| 20 |

UTGOFF, PAUL E .Machine learning of inductive bias[M].Boston:Springer Science & Business Media,2012.

|

| 21 |

何彦,凌俊杰,王禹林,等 .基于长短时记忆卷积神经网络的刀具磨损在线监测模型[J].中国机械工程,2020,31(16):1959-1967.

|

|

HE Yan, LING Junjie, WANG Yulin,et al .In-process tool wear monitoring model based on LSTM-CNN[J].China Mechanical Engineering,2020,31(16):1959-1967.

|

| 22 |

PENG X B, ANDRYCHOWICZ M, ZAREMBA W,et al .Sim-to-real transfer of robotic control with dyna-mics randomization[C]∥Proceedings of the IEEE International Conference on Robotics and Automation.Brisbane:IEEE,2018:3803-3810.

|

| 23 |

JOZEFOWICZ R, WOJCIECH Z, ILYA S .An empirical exploration of recurrent network architectures[C]∥Proceedings of the International Conference on Machine Learning.Lile:[s. n.],2015:2342-2350.

|

| 24 |

COUMANS E .Bullet physics simulation[C]∥Proceedings of the ACM SIGGRAPH 2015 Courses.Los Angeles:[s. n.],2015.

|

| 25 |

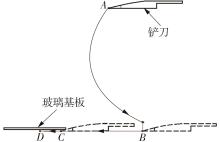

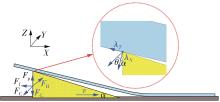

HOU L W, WANG H S, LIU R H .Research on mo-deling and experiment of glass substrate peeling based on adhesion theory[J].Tehnički Vjesnik,2019,26(6):1827-1832.

|

| 26 |

刘润华,王恒升,侯力玮 .玻璃基板无损剥离的建模与分析[J].制造业自动化,2020,42(2):36-41.

|

|

LIU Run-hua, WANG Heng-sheng, HOU Li-wei .Mo-deling and analysis of nondestructive peeling of glass substrate[J].Manufacturing Automation,2020,42(2):36-41.

|

| 27 |

JANNER M, FU J, ZHANG M,et al .When to trust your model:model-based policy optimization[C]∥Proceedings of the Conference in Advances in Neural Information Processing Systems.Vancouver:[s.n.],2019:12519-12530.

|

| 28 |

FUNABASHI S, OGASA S, ISOBE T,et al .Variable in-hand manipulations for tactile-driven robot hand via CNN-LSTM[C]∥Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems.Las Vegas:IEEE,2020:9472-9479.

|