| 1 |

《中国公路学报》编辑部 .中国筑路机械学术研究综述· 2018[J].中国公路学报,2018,31(6):1-164.

|

|

Editorial Department of China Journal of Highway and Transport .Review on China’s road construction machinery research progress:2018[J].China Journal of Highway and Transport,2018,31(6):1-164.

|

| 2 |

李泽军 .液压挖掘机工作装置焊接疲劳寿命分析[D].重庆:重庆交通大学,2013.

|

| 3 |

程珩,白瑞 .挖掘机工作装置疲劳寿命分析[J].振动、测试与诊断,2011,31(4):512-516,538-539.

|

|

CHENG Heng, BAI Rui .Fatigue life prediction of the excavator working mechanism based on load history[J].Journal of Vibration Measurement & Diagnosis,2011,31(4):512-516,538-539.

|

| 4 |

曹露露 .挖掘机工作装置疲劳寿命预测及极小子样下可靠性评估方法研究[D].西安:长安大学,2019.

|

| 5 |

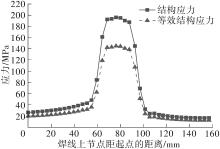

周张义,王雨舟,杨欣 .基于不同应力法的焊接构架纵向角接头疲劳累积损伤评估[J].焊接学报,2018,39(8):18-22,129-130.

|

|

ZHOU Zhangyi, WANG Yuzhou, YANG Xin .Fatigue cumulative damage assessment of longitudinal fillet welded gusset in welded frame based on different stress approaches[J].Transactions of the China welding institution,2018,39(8):18-22,129-130.

|

| 6 |

庞利叶,吕彭民,向清怡,等 .基于热点应力法的液压挖掘机斗杆疲劳寿命评估[J].制造业自动化,2019,41(6):8-11.

|

|

PANG Li-ye, Peng-min LYU, XIANG Qing-yi,et al .Fatigue life evaluation of hydraulic excavator’s bucket rod based on hot spot stress method[J].Manufacturing Automation,2019,41(6):8-11.

|

| 7 |

李俊 .基于热点应力法的挖掘机动臂焊缝的疲劳寿命分析[D].成都:电子科技大学,2015.

|

| 8 |

WANG B, LI K, LU P .Research on welding structure with transition changing faces at cylinder block on boom of medium excavator by means of hot spot stress approach[J].Journal of Failure Analysis and Prevention,2018,18(5):1127-1132.

|

| 9 |

ZHU Q, LU P, XIANG Q .Fatigue life evaluation of web butt welding structure on boom of excavator by hot spot stress approach[J].Engineering Failure Analysis,2020,113:104547/1-8.

|

| 10 |

ABDELBASET H, CHENG B, TIAN L,et al .Reduce hot spot stresses in welded connections of orthotropic steel bridge decks by using UHPC layer: experimental and numerical investigation[J].Engineering Structures,2020,220:110988/1-16.

|

| 11 |

DONG P .A structural stress definition and numerical implementation for fatigue analysis of welded joints[J].International Journal Fatigue,2001,23:865-876.

|

| 12 |

DONG P .A robust structural stress method for fatigue analysis of offshore/marine structures[J].Journal of Offshore Mechanics and Arctic Engineering,2005,127(1):68-74.

|

| 13 |

DONG P, HONG J K .The master S-N curve approach to fatigue evaluation of offshore and marine structures[C]∥Proceedings of ASME 2004 23rd International Conference on Offshore Mechanics and Arctic Engineering.Vancouver:OMAE,2004:847-855.

|

| 14 |

DONG P, HONG J K .Analysis of recent fatigue data using the structural stress procedure in ASME Div 2 Rewrite[J].Journal of Pressure Vessel Technology,2007,129(3):355-362.

|

| 15 |

HONG T K .Fatigue prediction of spot welded joints using equivalent structural stress[J].Materials & Design,2007,28(3):837-843.

|

| 16 |

刘俊卿,马岩,曹书文 .基于等效结构应力法的塔吊焊接节点疲劳寿命评估[J].沈阳工业大学学报,2021,43(5):522-528.

|

|

LIU Jun-qing, MA Yan, CAO Shu-wen .Fatigue life analysis on welded joints of tower crane based on equivalent structural stress method[J].Journal of Shenyang University of Technology,2021,43(5):522-528.

|

| 17 |

陈江义,吕海勇,罗琳丽 .基于Verity方法的起重机箱型主梁疲劳寿命分析[J].制造业自动化,2014,36(2):6-9.

|

|

CHEN Jiang-yi, LV Hai-yong, LUO Lin-li .Fatigue life analysis for box girder of crane by Verity method[J].Manufacturing Automation,2014,36(2):6-9.

|

| 18 |

谢素明,周晓坤,李向伟,等 .基于美国ASME标准的重载货车车体焊缝疲劳寿命预测[J].计算力学学报,2012,29(1):129-134.

|

|

XIE Su-ming, ZHOU Xiao-kun, LI Xiang-wei,et al .Fatigue life prediction for weld line in heavy freight carbody based on ASME standard[J].Chinese Journal of Computational Mechanics,2012,29(1):129-134.

|

| 19 |

CHEN B, TENG F .Fatigue life evaluation of car body based on master S-N curve method[J].Open Journal of Transportation Technologies,2020,9(4),322-327.

|

| 20 |

KIM S M, KIM M H .Incorporating mesh-insensitive structural stress into the fatigue assessment procedure of common structural rules for bulk carriers[J].International Journal of Naval Architecture and Ocean Engineering,2015,7(1):10-24.

|

| 21 |

杨鑫华,孙屹博,邹丽 .网格不敏感结构应力的焊接疲劳数据分布[J].焊接学报,2015,36(2):11-14,113.

|

|

YANG Xinhua, SUN Yibo, ZOU Li .Data distribution in welding fatigue analysis based on mesh-insensitive structural stress[J].Transactions of the China welding institution,2015,36(2):11-14,113.

|

| 22 |

杨广雪,刘志明,李广全,等 .基于等效结构应力法的焊接构架疲劳损伤评估[J].铁道学报,2020,42(7):73-79.

|

|

YANG Guangxue, LIU Zhiming, LI Guangquan,et al .Fatigue damage assessment of welded frame on equivalent structural stress method[J].Journal of the China Railway Society,2020,42(7):73-79.

|

| 23 |

PARIS P, ERDOGAN F .A critical analysis of crack propagation laws[J].Journal of Basic Engineering,1963,85(4):528-533.

|

| 24 |

FRICKE W, KAHL A .Comparison of different structural stress approaches for fatigue assessment of welded ship structures[J].Marine Structures,2005,18(7/8):473-488.

|

| 25 |

向清怡,吕彭民,王斌华,等 .液压挖掘机工作装置铰点实测载荷特征研究[J].机械强度,2018,40(5):1063-1070.

|

|

XIANG Qingyi, LV Pengmin, WANG Binhua,et al .Research on characteristics of actual hinge joint load of hydraulic excavator working device[J].Journal of Mechanical Strength,2018,40(5):1063-1070.

|

| 26 |

曹蕾蕾,郭城臣,王严,等 .基于实测数据的挖掘机工作装置疲劳寿命评估[J].华南理工大学学报(自然科学版),2021,49(8):122-128,139.

|

|

CAO Leilei, GUO Chengchen, WANG Yan,et al .Fatigue analysis of hydraulic excavator working device based on experiment data[J].Journal of South China University of Technology (Natural Science Edition),2021,49(8):122-128,139.

|

| 27 |

MINER M A .Cumulative damage in fatigue[J].Journal of Applied Mechanics,1945,12(3):A159~A164.

|

| 28 |

向清怡,吕彭民,王斌华,等 .液压挖掘机斗杆台架疲劳试验载荷等效方法[J].中国公路学报,2018,31(6):317-326.

|

|

XIANG Qing-yi, LU Peng-min, WANG Bin-hua,et al .Load equivalent method for fatigue bench test of hydraulic excavator stick[J].China Journal of Highway and Transport,2018,31(6):317-326.

|

| 29 |

向清怡,吕彭民,王斌华,等 .液压挖掘机工作装置载荷谱测试方法[J].中国公路学报,2017,30(9):151-158.

|

|

XIANG Qing-yi, LU Peng-min, WANG Bin-hua,et al .Load spectrum test method of hydraulic excavator working device[J].China Journal of Highway and Transport,2017,30(9):151-158.

|

| 30 |

吴玉文,吕彭民 .液压挖掘机工作装置动态测试与瞬态动力学分析[J].筑路机械与施工机械化,2020,37(Z1):116-120.

|

|

WU Yu-wen, Peng-min LYU .Dynamic test and dynamic analysis of working device of hydraulic excavator[J].Road Machinery & Construction Mechanization,2020,37(Z1):116-120.

|

| 31 |

邵雨虹,吕彭民,向清怡,等 .基于Bayes方法的挖掘机动臂疲劳寿命可靠性评估[J].制造业自动化,2018,40(9):60-65.

|

|

SHAO Yu-hong, Peng-min LYU, XIANG Qing-yi,et al .Reliability assessment of fatigue life of excavator arm based on Bayes method[J].Manufacturing Automation,2018,40(9):60-65.

|