华南理工大学学报(自然科学版) ›› 2025, Vol. 53 ›› Issue (6): 12-24.doi: 10.12141/j.issn.1000-565X.240061

典型接触条件下双层螺旋曲杆束的弯曲特性

王荣辉1( ), 刘锡月1, 赵勇霖1, 甄晓霞1(

), 刘锡月1, 赵勇霖1, 甄晓霞1( ), 张卓杰2,3

), 张卓杰2,3

- 1.华南理工大学 土木与交通学院,广东 广州 510640

2.道路与铁道工程安全保障教育部重点实验室 石家庄铁道大学,河北 石家庄 050043

3.河北省风工程和风能利用工程技术创新中心,河北 石家庄 050043

Bending Characteristics of 2-Layer Spiral Strand Under Typical Contact Conditions

WANG Ronghui1( ), LIU Xiyue1, ZHAO Yonglin1, ZHEN Xiaoxia1(

), LIU Xiyue1, ZHAO Yonglin1, ZHEN Xiaoxia1( ), ZHANG Zhuojie2,3

), ZHANG Zhuojie2,3

- 1.School of Civil Engineering and Transportation,South China University of Technology,Guangzhou 510640,Guangdong,China

2.Ministry of Education Key Laboratory of Roads and Railway Engineering Safety Control,Shijiazhuang Tiedao University,Shijiazhuang 050043,Hebei,China

3.Innovation Center for Wind Engineering and Wind Energy Technology of Hebei Province,Shijiazhuang 050043,Hebei,China

摘要:

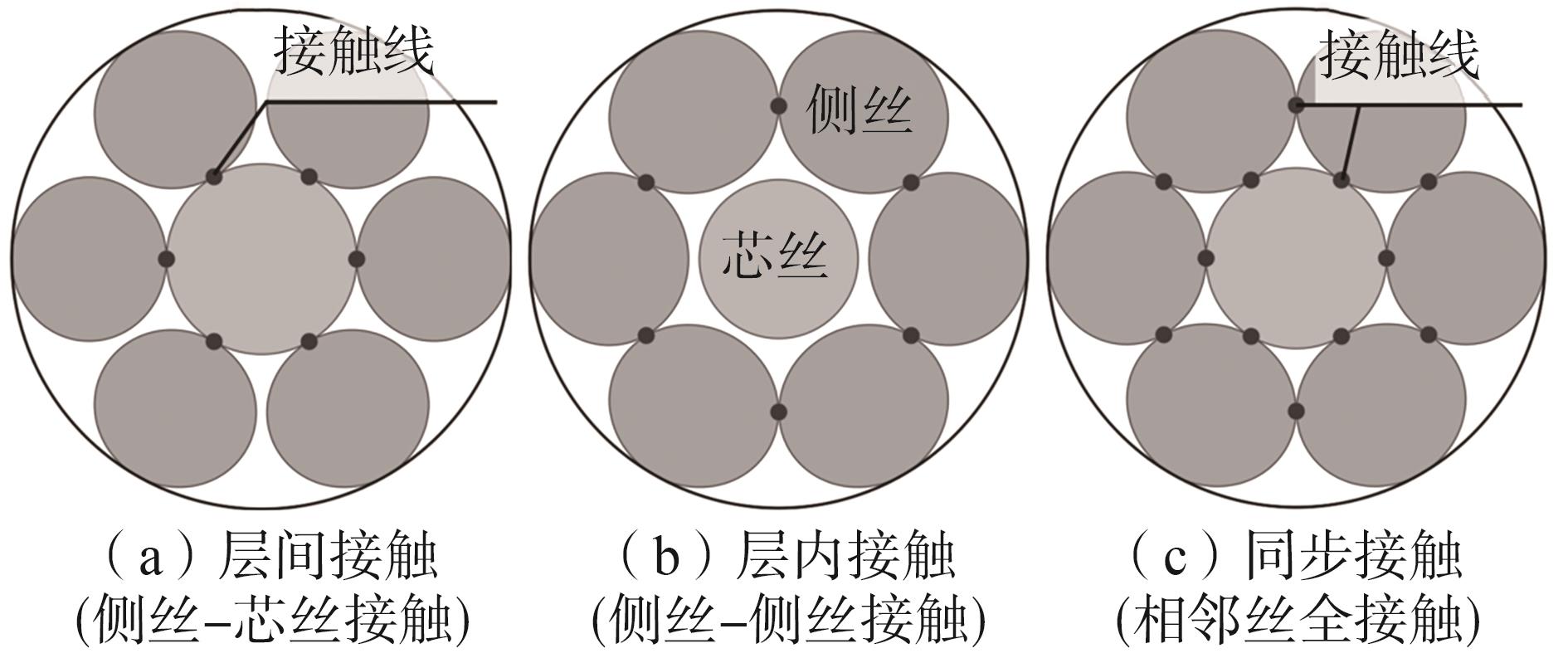

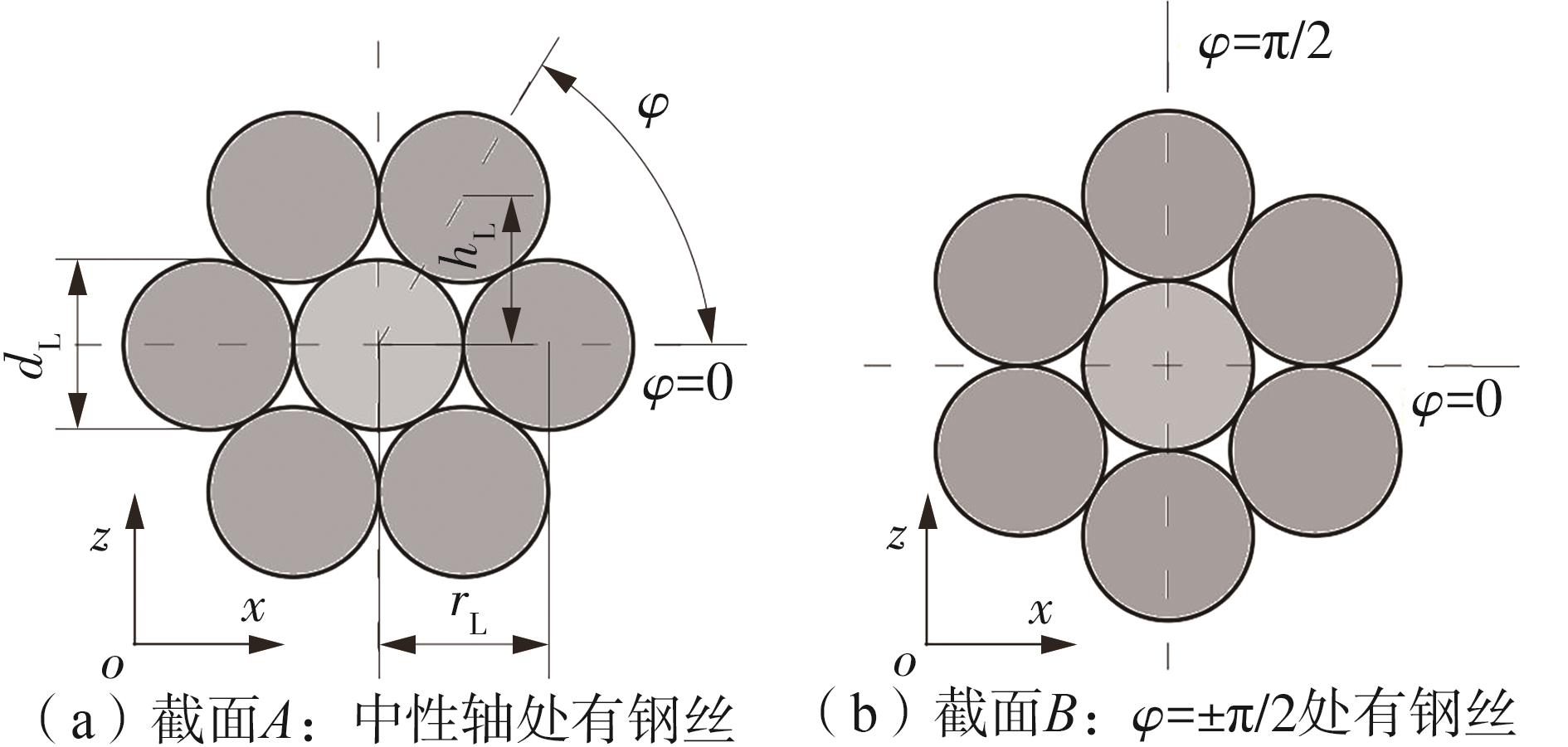

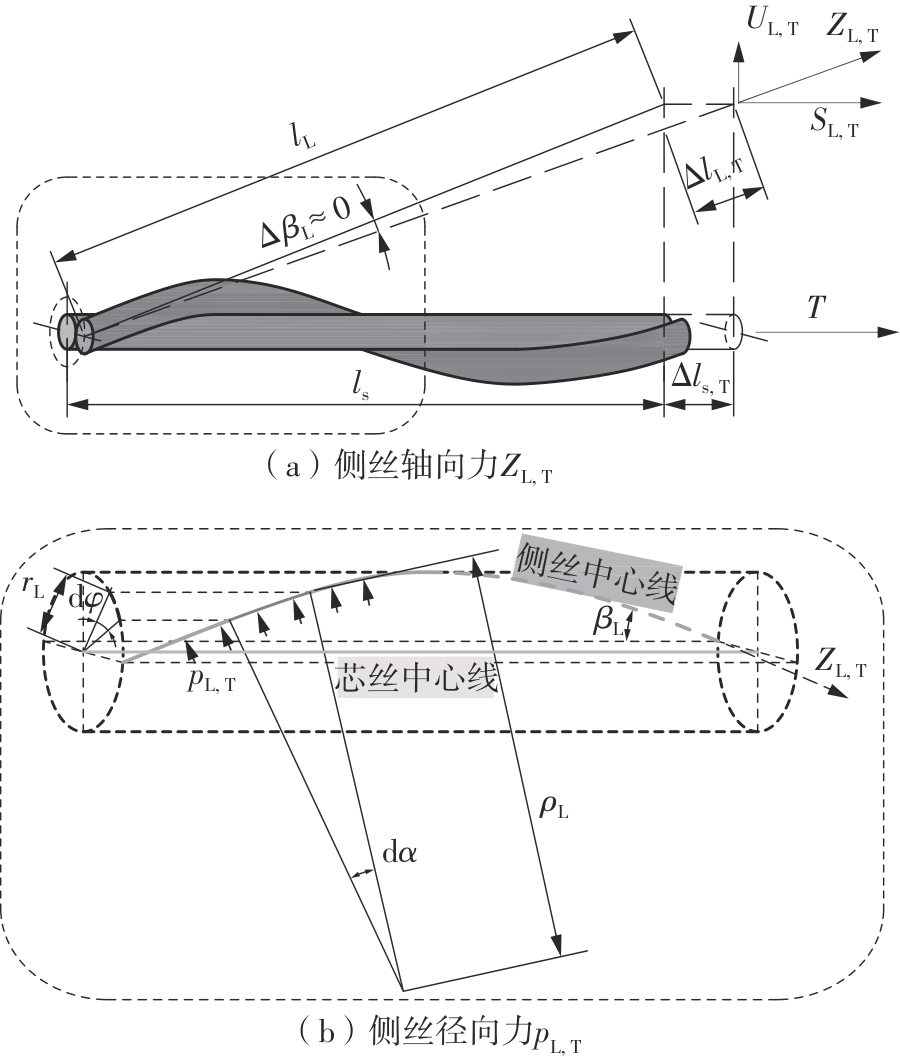

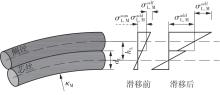

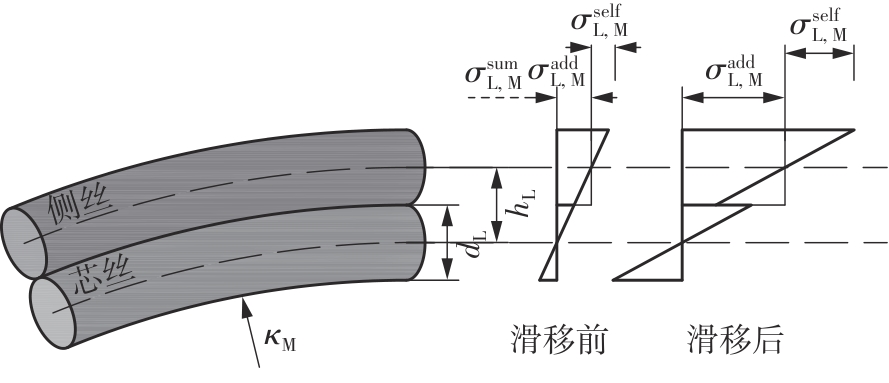

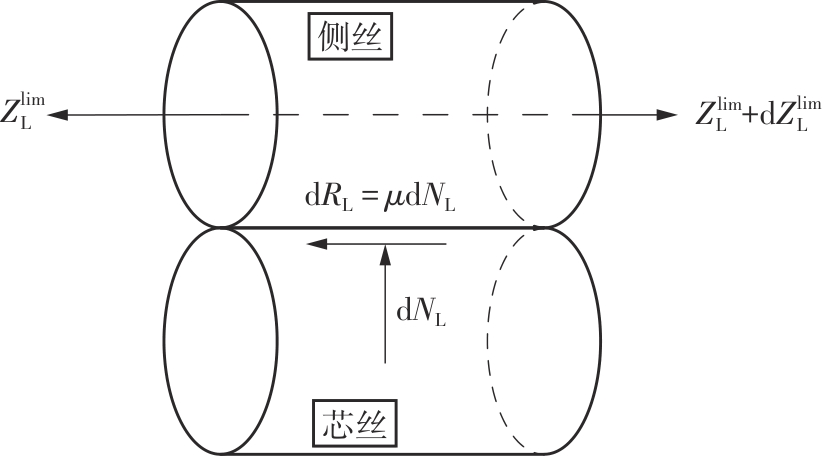

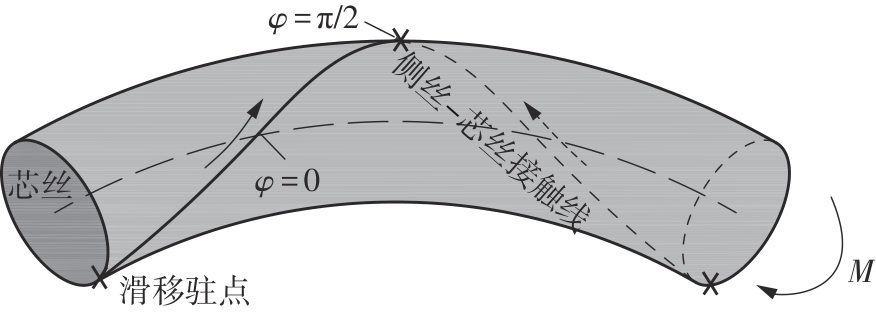

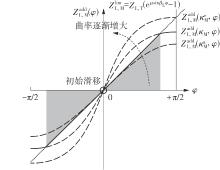

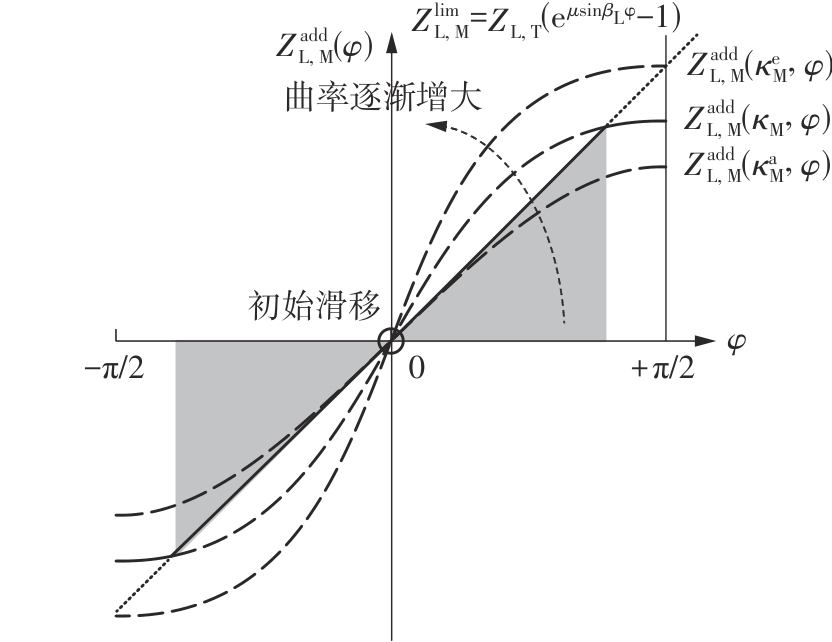

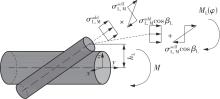

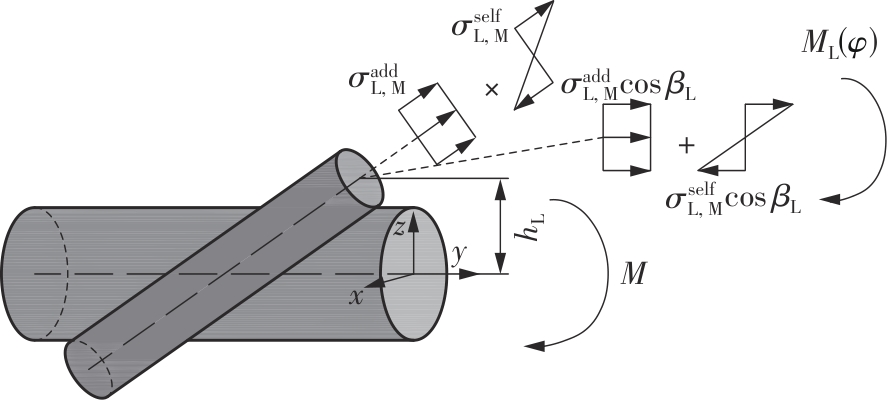

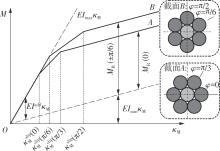

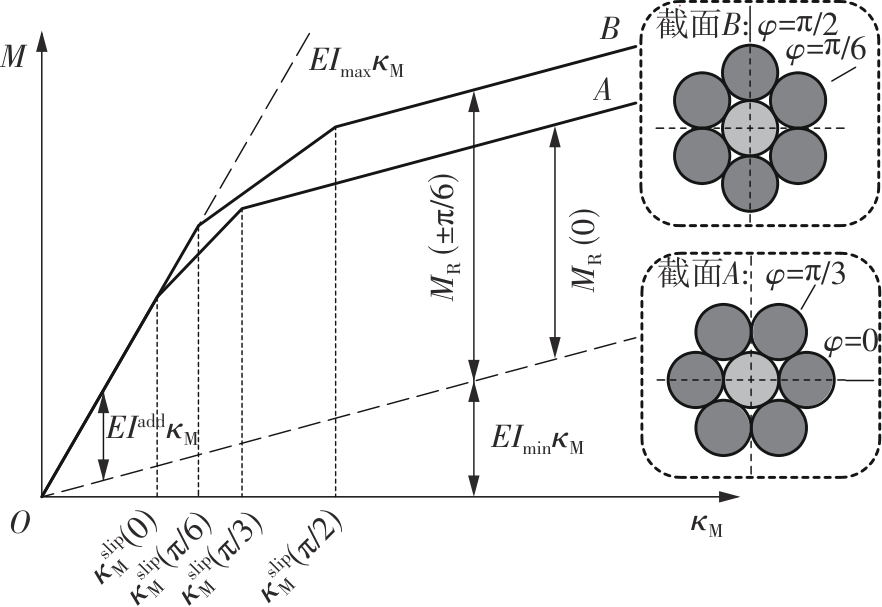

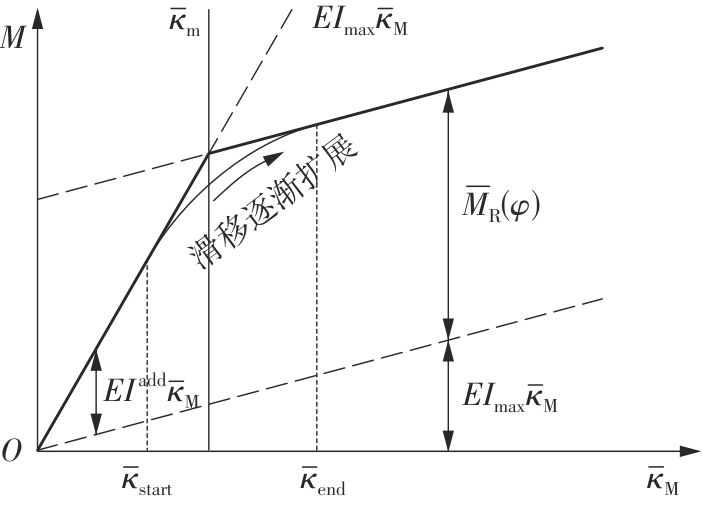

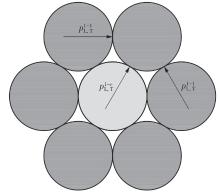

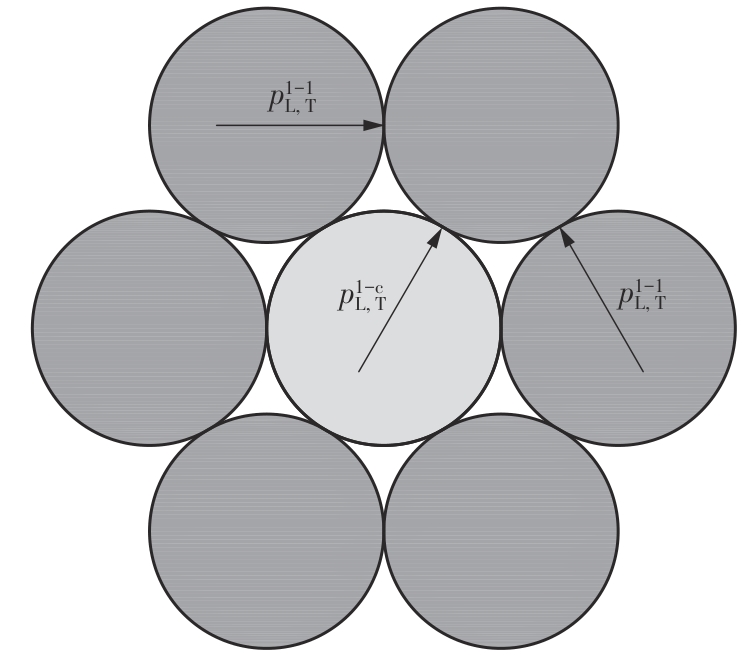

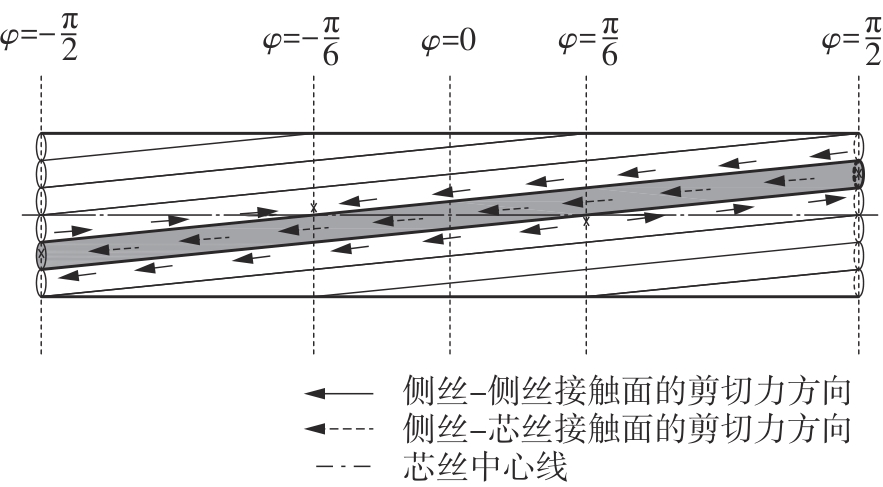

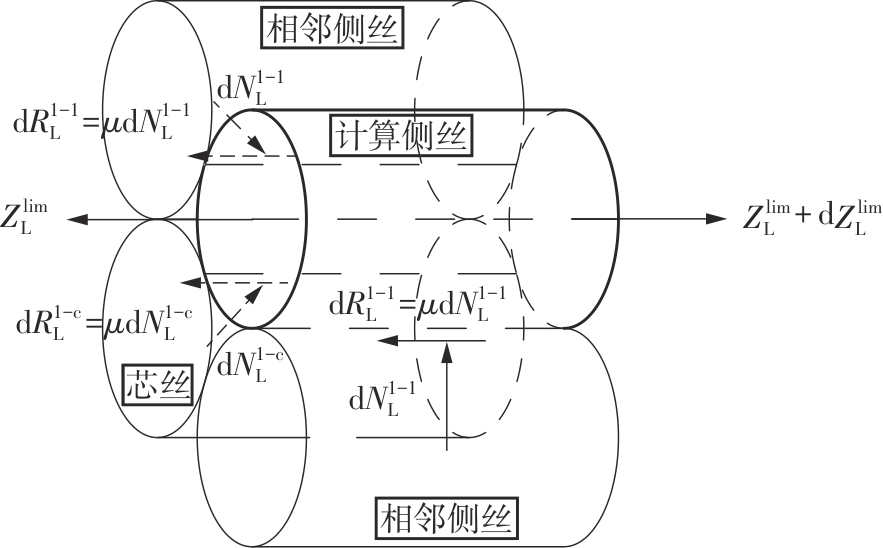

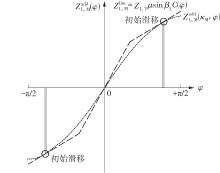

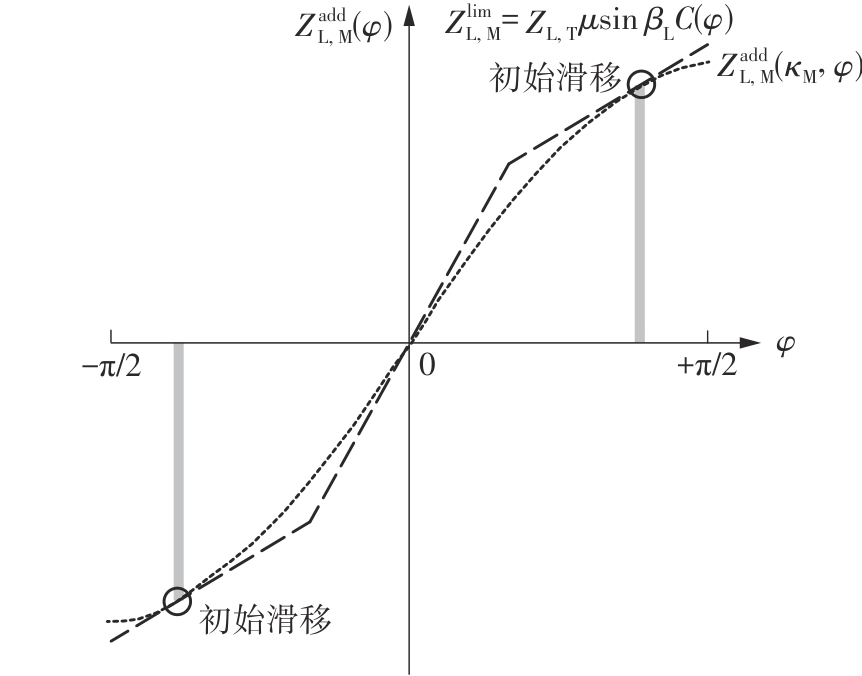

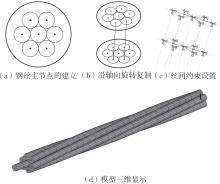

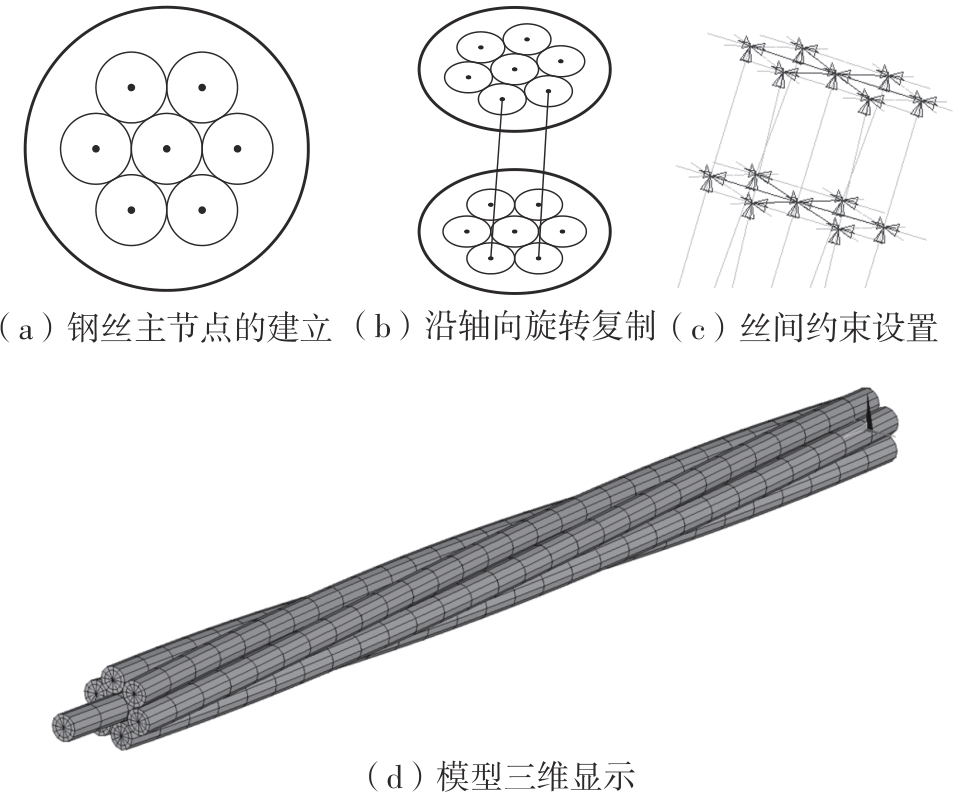

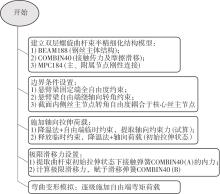

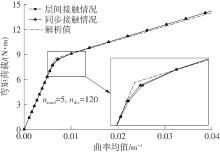

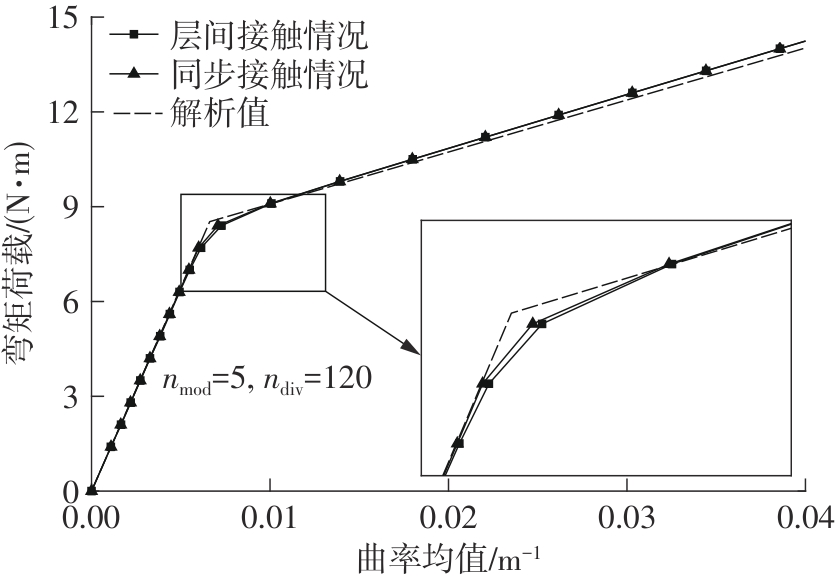

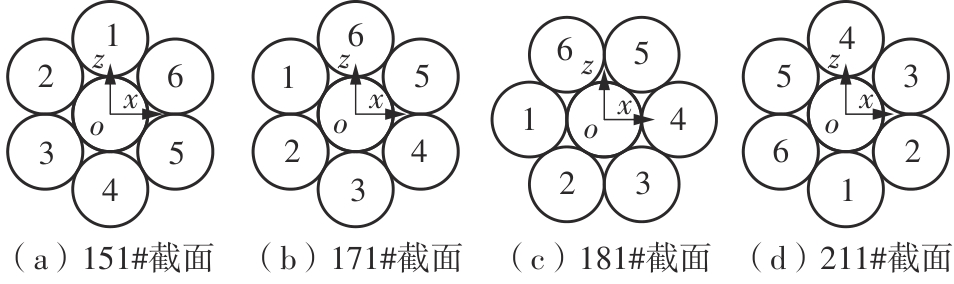

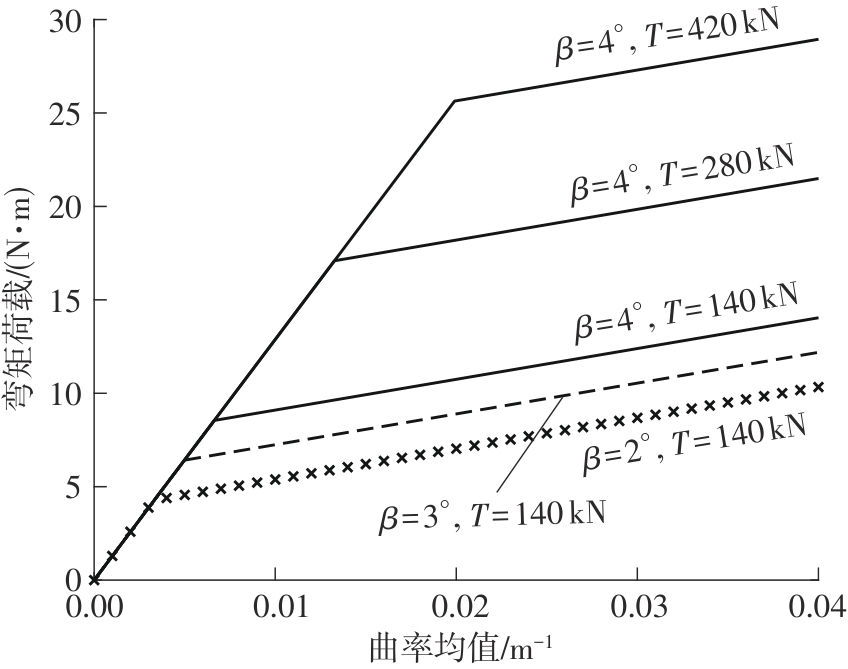

为研究双层螺旋曲杆束在拉-弯耦合作用下的力学行为及其内部钢丝协同工作机理,考虑丝间摩擦滑移,建立了层间接触、同步接触两类典型条件下的侧丝微段静力平衡关系并进行了解析推导,同步提出一种改进的半精细化有限元模型进行数值模拟和结果对比。由弯曲变形时侧丝所受剪切力的分布规律获得了两类接触条件下的丝间相对滑移方向,并在此基础上根据平衡方程推导得到侧丝滑移后的轴力限值;通过对各丝贡献的弯矩求和得到在拉-弯耦合作用下曲杆束各截面的弯矩-局部曲率关系式,并提出一种简化的弯矩-曲率均值关系式描述其整体弯曲行为。结果表明:由于侧丝沿曲杆束整体轴向周期旋转,相邻丝之间接触面有滑移驻点,且驻点两侧相对滑移方向相反;侧丝-侧丝、侧丝-芯丝接触面的滑移驻点、初始滑移位置不同;忽略内部滑移扩展过程,两类接触条件下双层螺旋曲杆束具有相同的弯矩-曲率均值关系式,函数图像呈双折线;半精细化有限元模型滑移前后的弯曲变形结果与解析值的相对误差小于4%,且提取的丝间相对滑移结果规律与分析结论相符。

中图分类号: