华南理工大学学报(自然科学版) ›› 2025, Vol. 53 ›› Issue (5): 130-138.doi: 10.12141/j.issn.1000-565X.240222

立式上行管内正四面体颗粒群的运动分布特性

彭德其1, 周靖强1, 冯源1, 黄治中2, 谭卓伟1, 唐明成3, 彭建国3, 陈莹1

- 1.湘潭大学 机械工程与力学学院,湖南 湘潭 411105

2.湘潭通用离心机有限公司,湖南 湘潭 411200

3.株洲宏大高分子材料有限公司,湖南 株洲 412007

Motion Distribution Characteristics of Regular Tetrahedral Particle Population in Vertical Uppipe

PENG Deqi1, ZHOU Jingqiang1, FENG Yuan1, HUANG Zhizhong2, TAN Zhuowei1, TANG Mingcheng3, PENG Jianguo3, CHEN Ying1

- 1.School of Mechanical Engineering and Mechanics,Xiangtan University,Xiangtan 411105,Hunan,China

2.Xiangtan General Centrifuge Co. ,Ltd. ,Xiangtan 411200,Hunan,China

3.Zhuzhou Hongda Polymer Materials Co. ,Ltd. ,Zhuzhou 412007,Hunan,China

摘要:

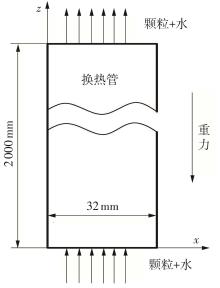

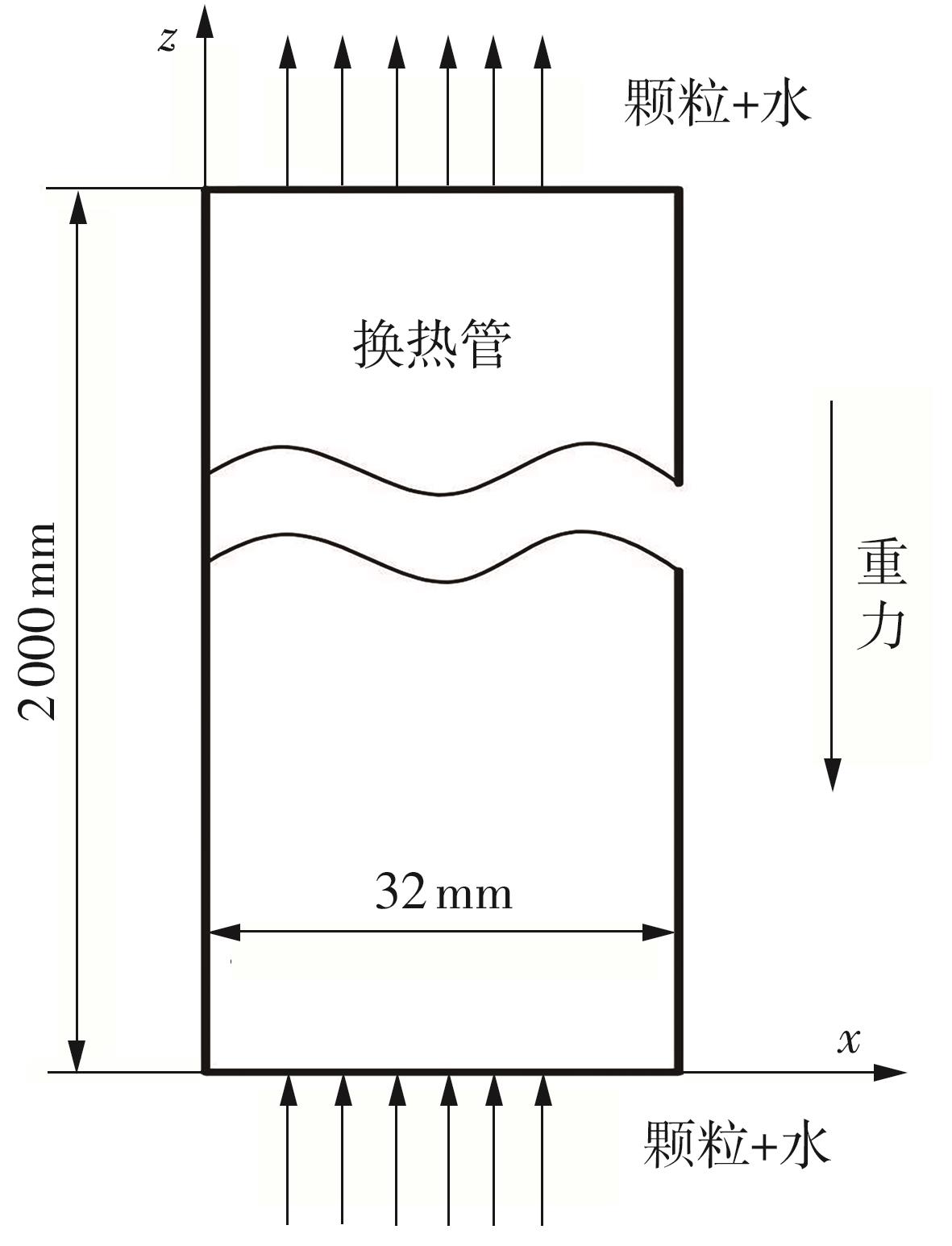

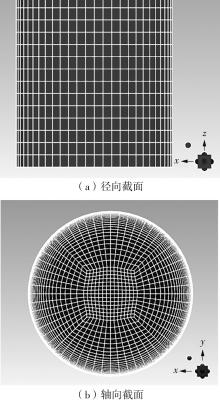

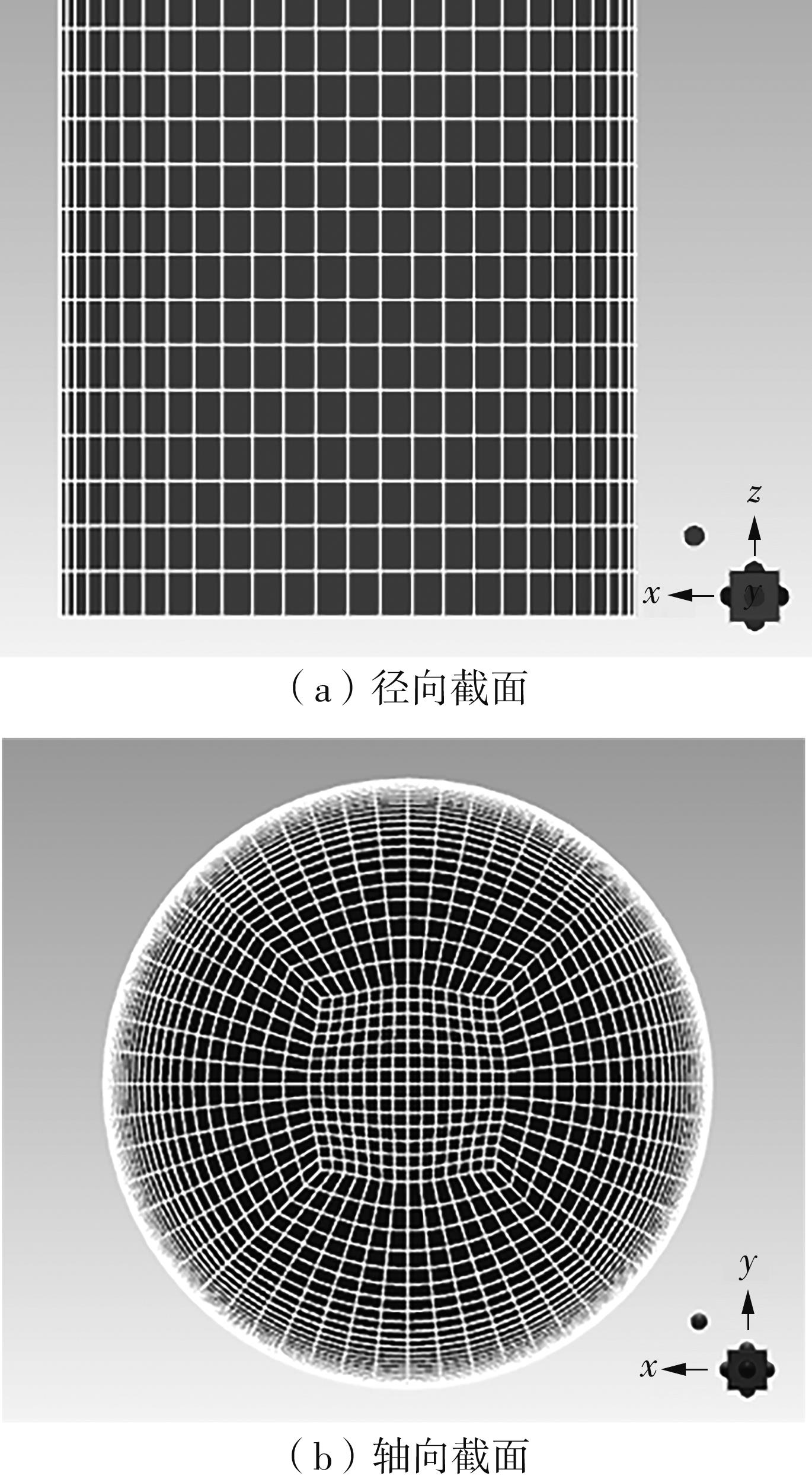

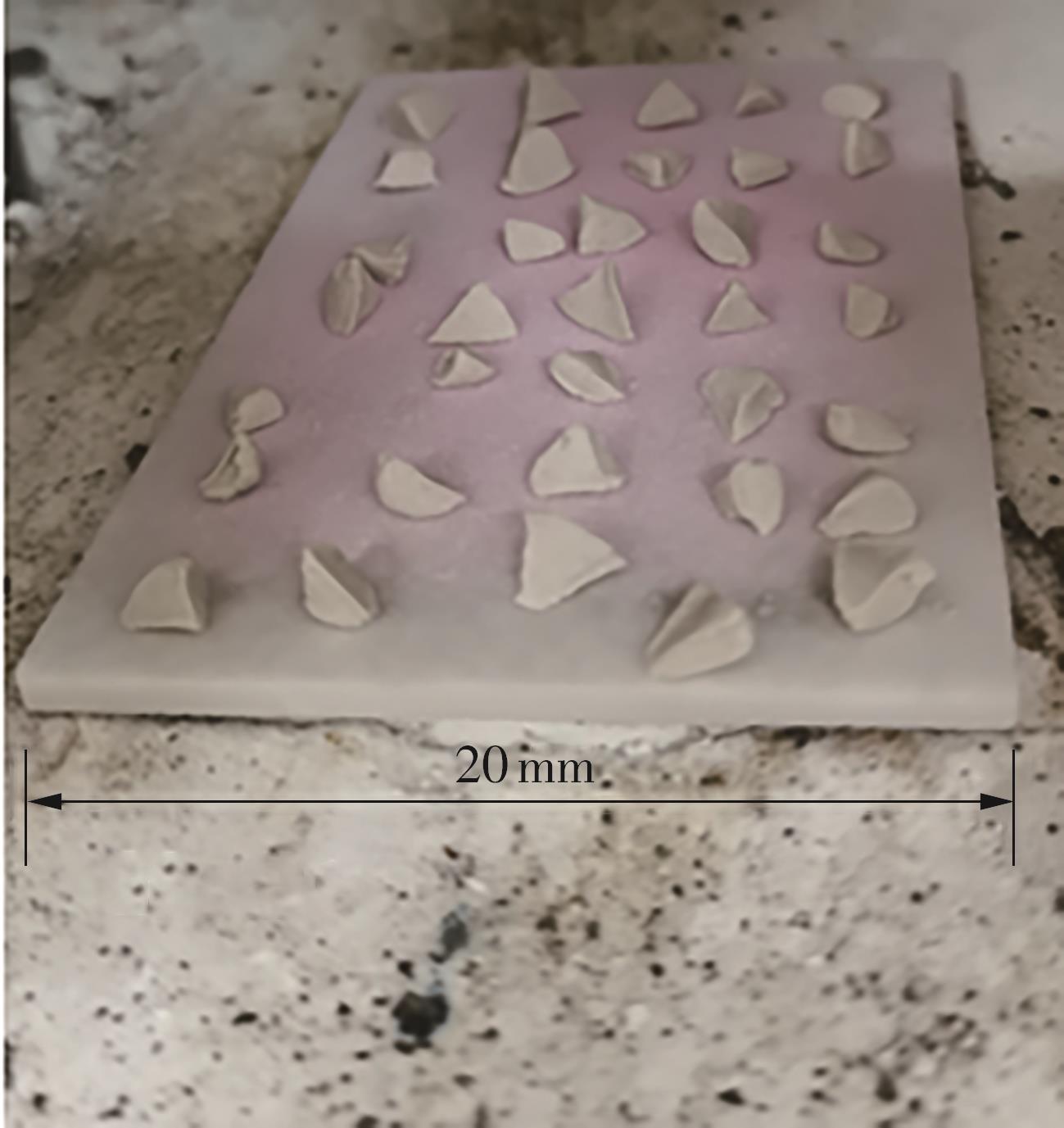

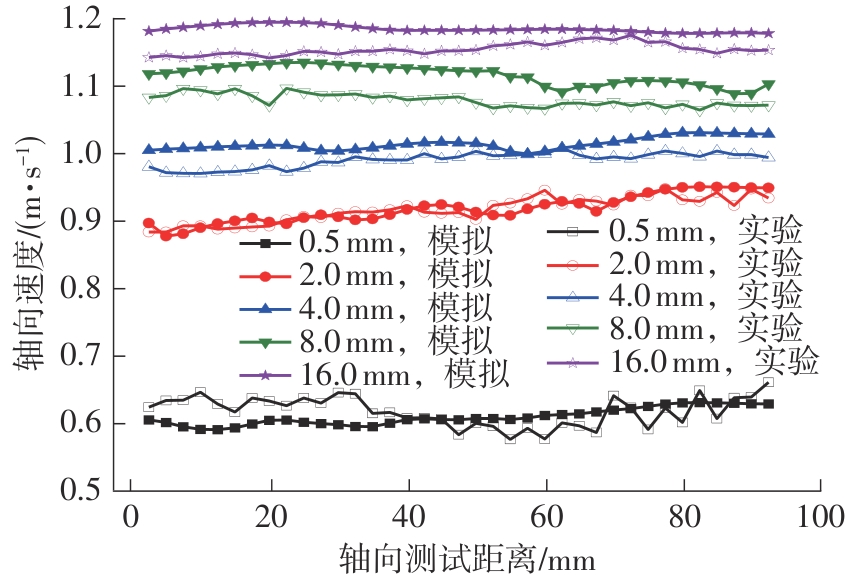

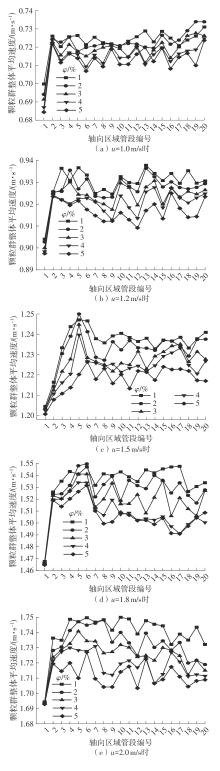

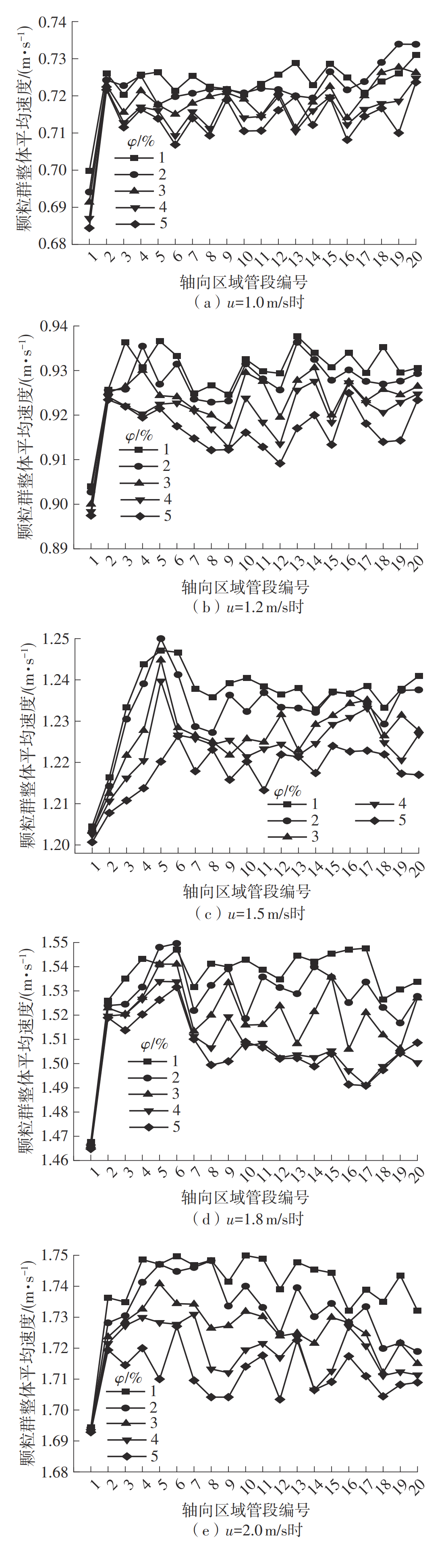

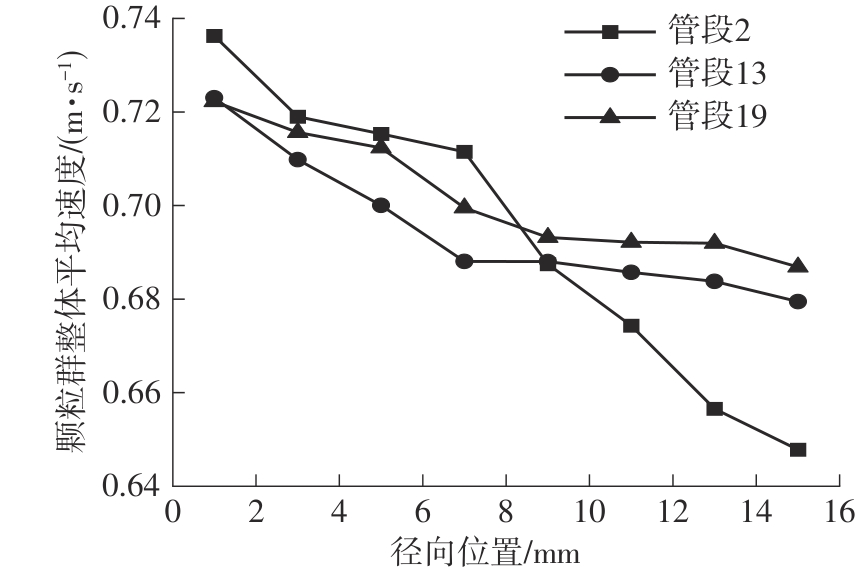

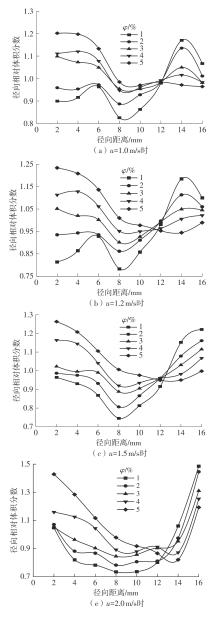

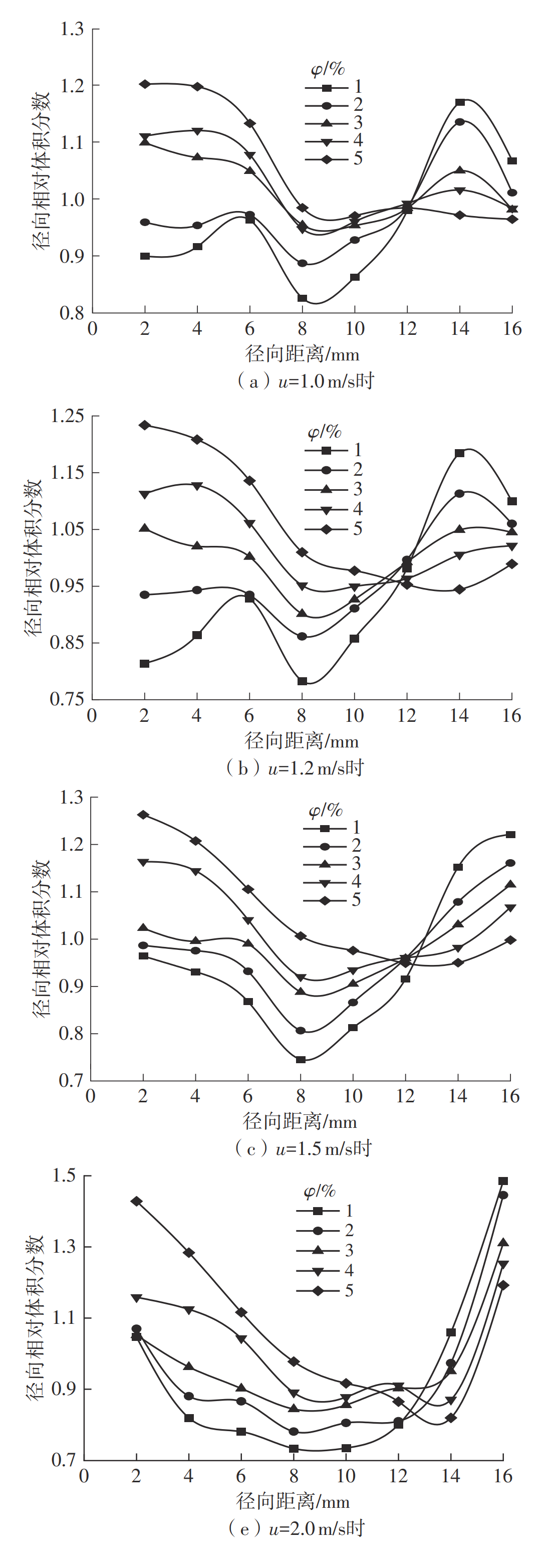

液固两相流技术广泛应用于换热器的强化传热设计,其关键在于引导低体积分数颗粒运动至壁面以扰动并破坏附近的热边界层,进而实现强化传热效果。颗粒的运动行为是深入解析传热强化机理的关键因素,其中非球形颗粒因其形状的各向异性而具有更佳的扰动效果以及更为复杂的运动行为。该文以正四面体颗粒群为研究对象,为分析其在立式上行管内液固两相流中的运动分布规律,基于CFD-DEM(计算流体动力学-离散单元模型)耦合方法模拟研究颗粒进口体积分数(1%、2%、3%、4%、5%)和液相进口流速(1.0、1.2、1.5、1.8、2.0 m/s)对管内颗粒群平均速度和颗粒群相对体积分数分布的影响,并通过PIV(粒子图像测速技术)实验验证数值模拟的准确性。结果表明:在研究参数范围内,颗粒群平均速度沿轴向波动,波动幅度随进口流速的增大而加剧,沿径向由中心至管壁递减,分布随流体轴向的充分发展而越发集中;颗粒群相对体积分数沿径向遵循管中心区域和近壁面较高、过渡区域较低的双峰规律;颗粒进口体积分数为1%、液相进口流速为2.0 m/s时,管壁附近的颗粒体积分数最高。

中图分类号: