华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (9): 44-55.doi: 10.12141/j.issn.1000-565X.220651

固-液-温耦合作用下油液特性对大排量柱塞泵流量脉动的影响

夏毅敏1 李正辉1 谭顺辉2 刘伟3 夏士奇1

- 1.中南大学 机电工程学院, 湖南 长沙 410083

2.中铁工程装备集团有限公司, 河南 郑州 450016

3.中国铁建重工集团股份有限公司, 湖南 长沙 410100

Influence of Oil Characteristics on Flow Pulsation of Axial Piston Pump of Large Displacement Under Solid-Liquid-Temperature Coupling

XIA Yimin1 LI Zhenghui1 TAN Shunhui2 LIU Wei3 XIA Shiqi1

- 1.College of Mechaniacal and Electrical Engineering,Central South University,Changsha 410083,Hunan,China

2.China Railway Engineering Equipment Group Co. ,Ltd. ,Zhengzhou 450016,Henan,China

3.China Railway Construction Heavy Industry Corporation Limited,Changsha 410100,Hunan,China

摘要:

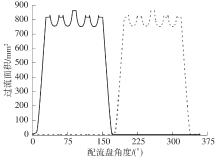

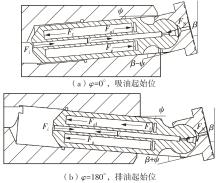

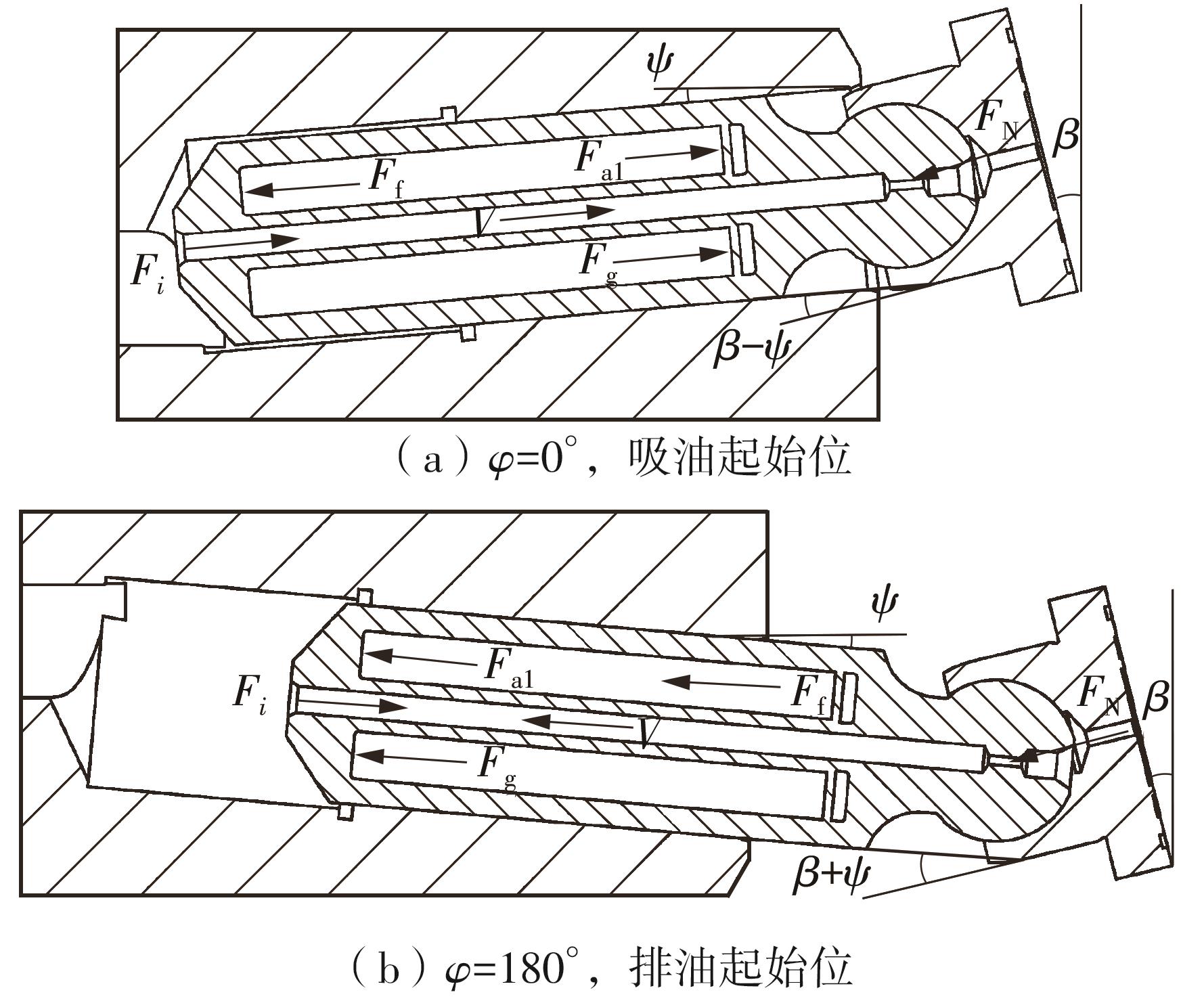

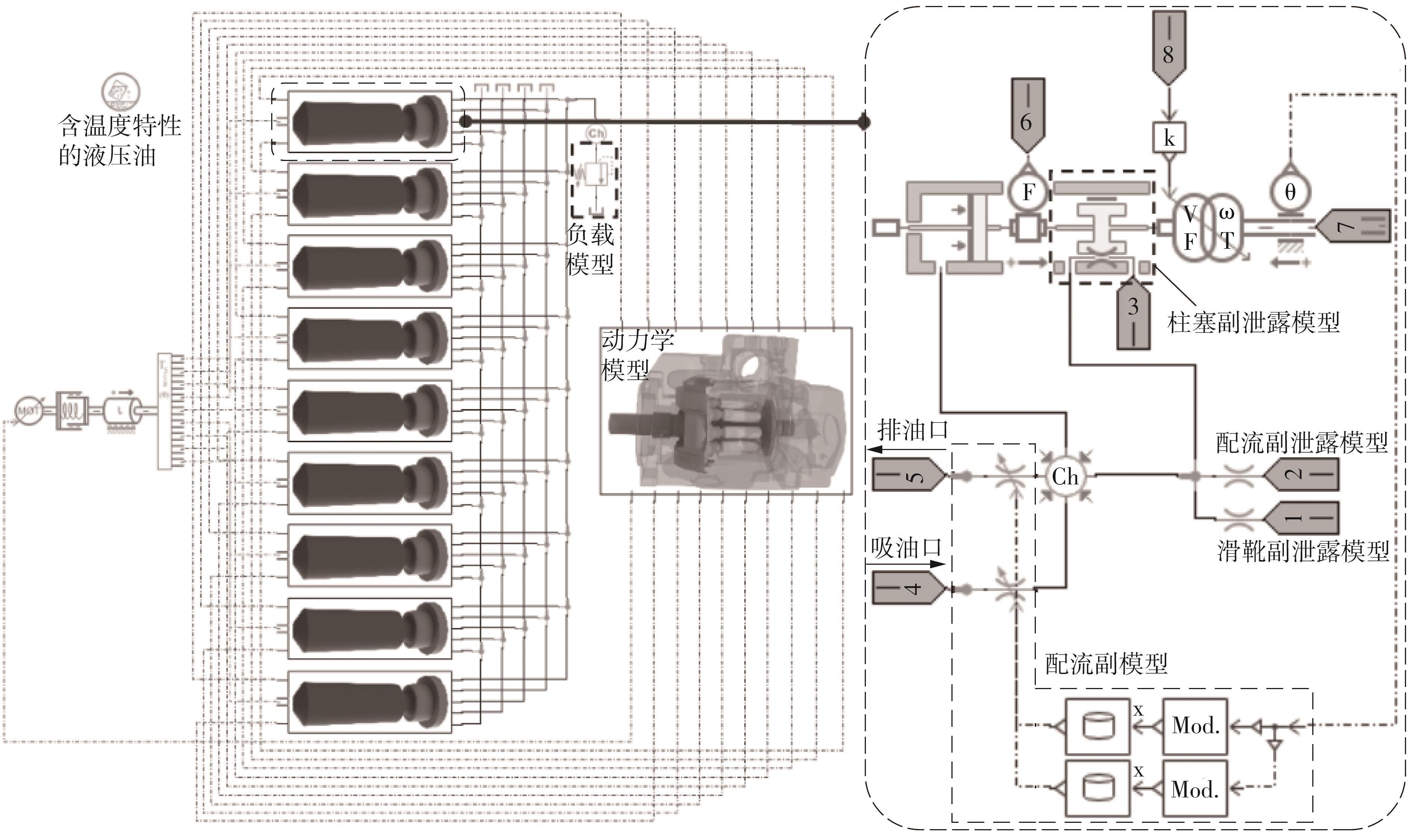

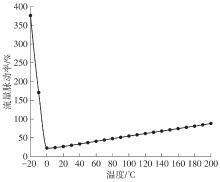

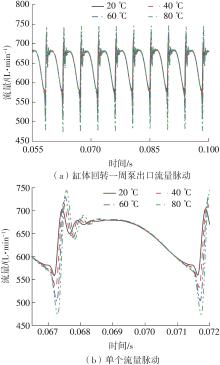

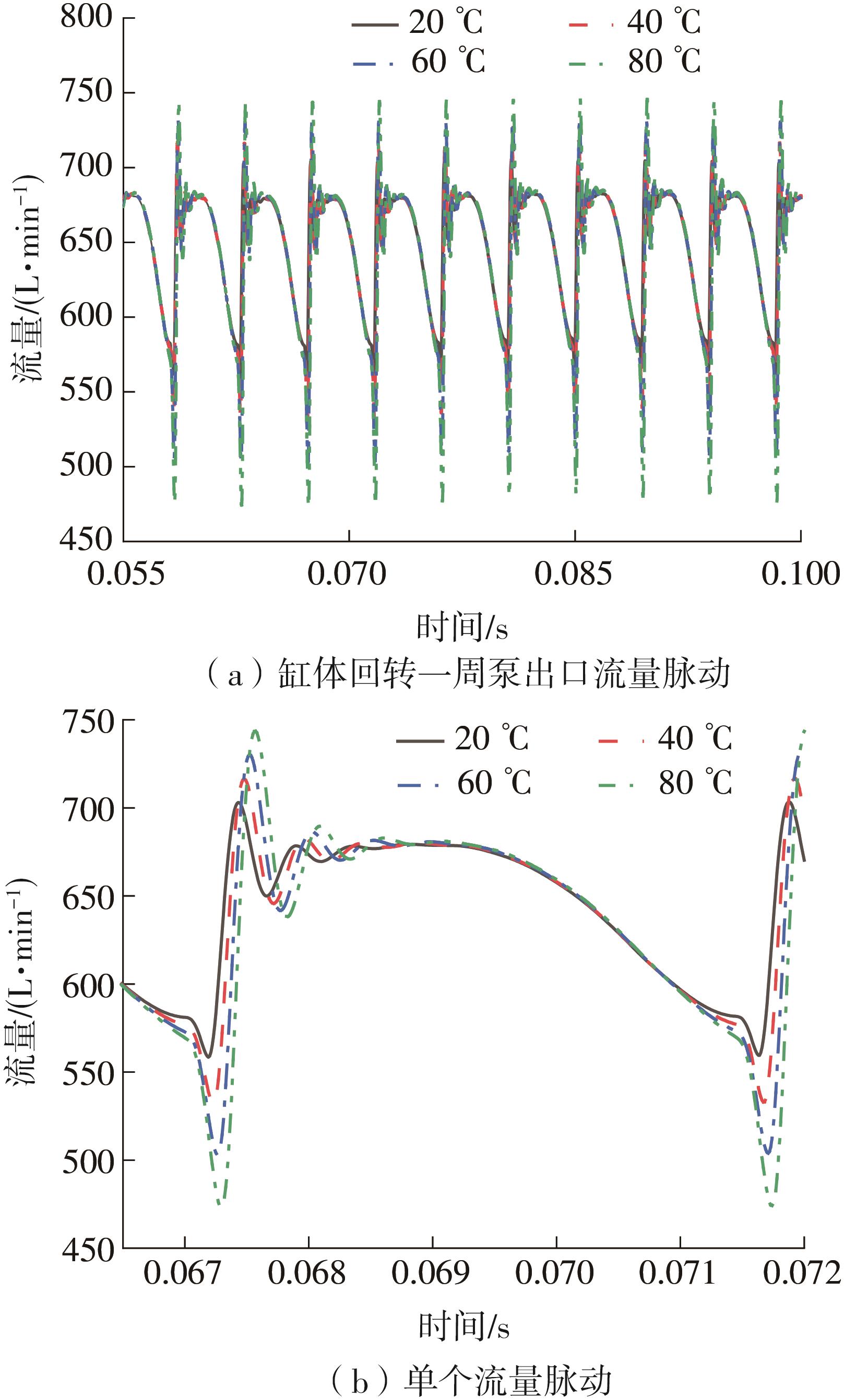

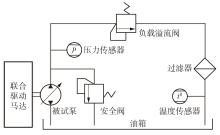

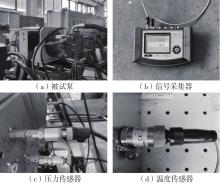

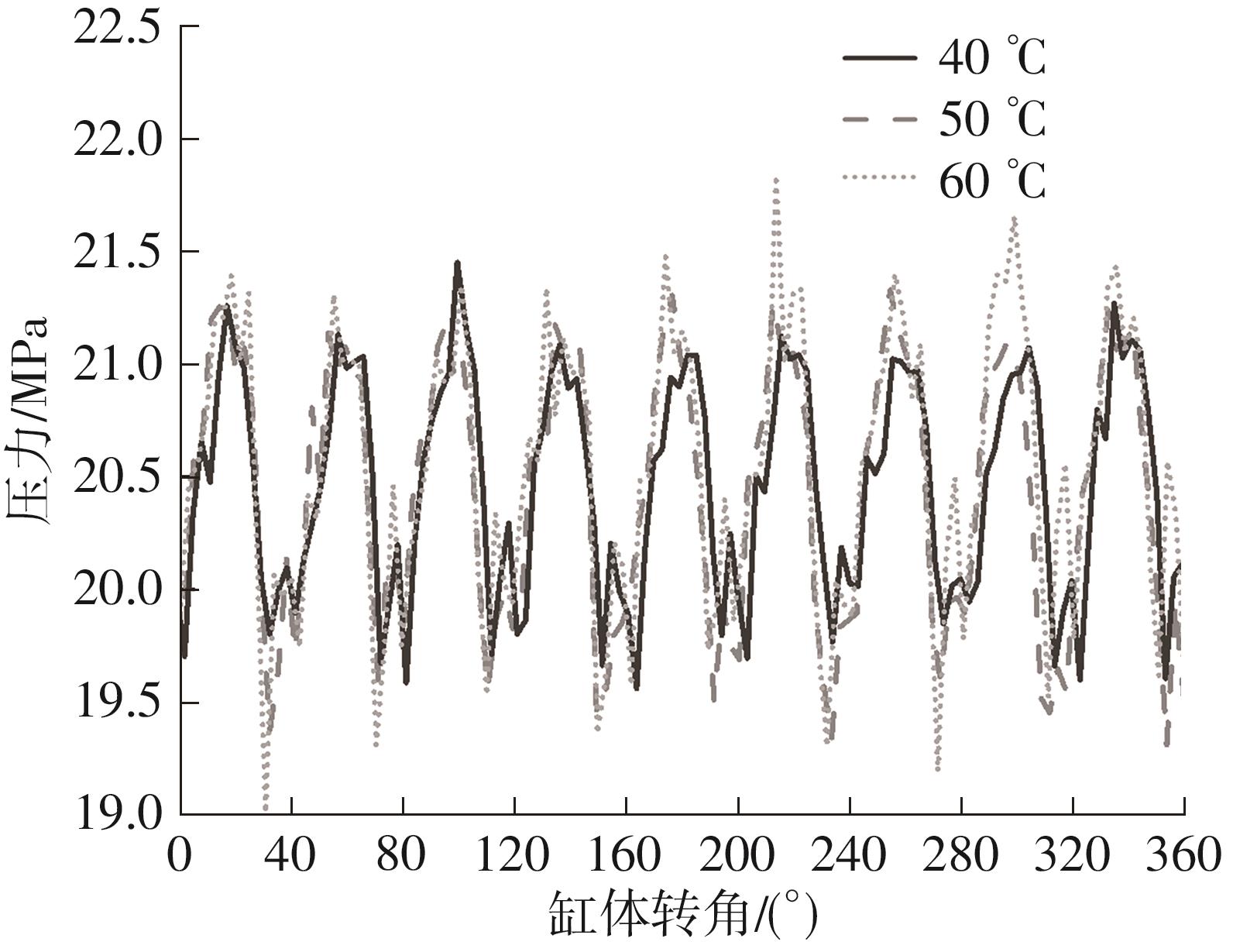

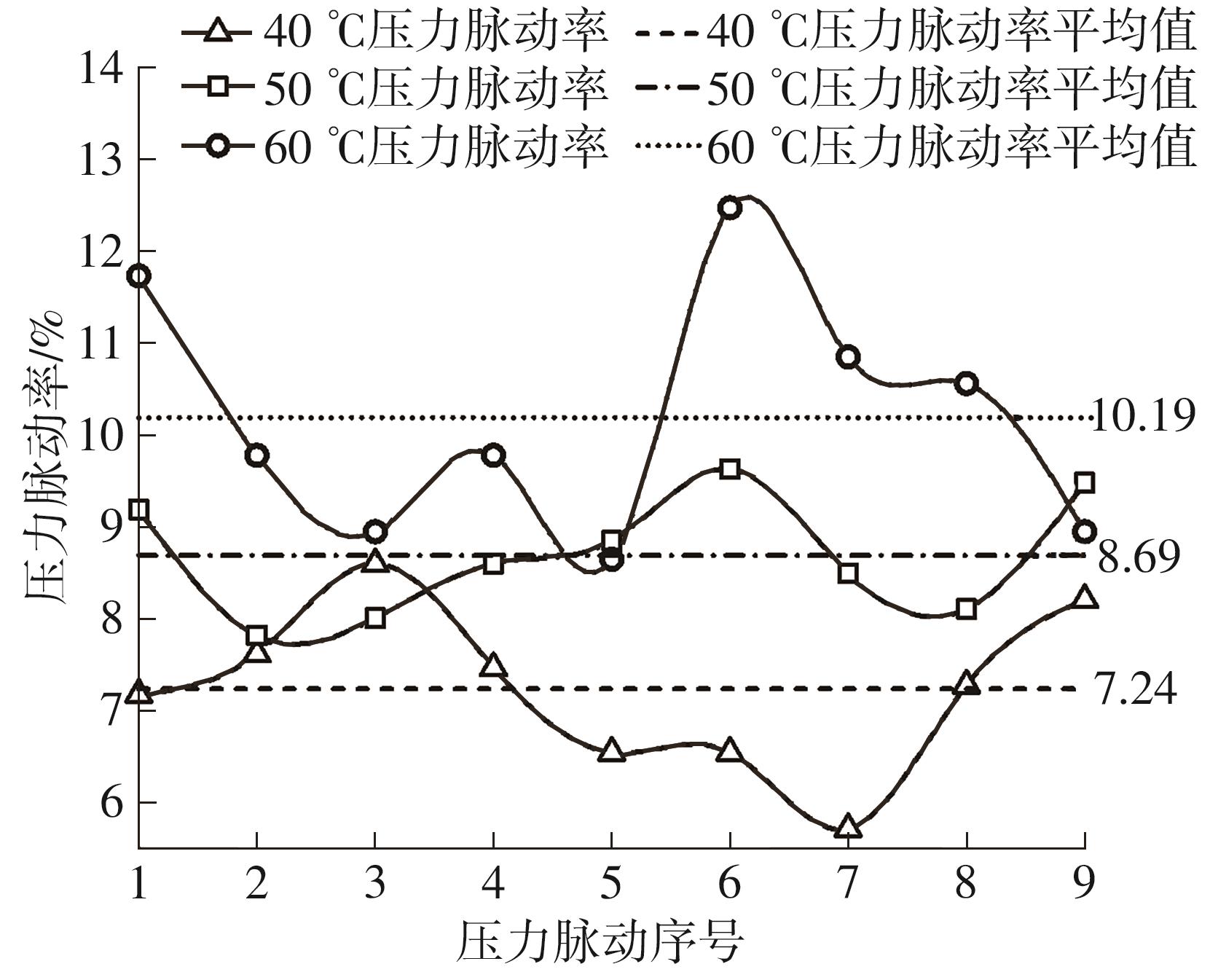

挖掘机、盾构机等大型工程机械工作过程中,由于工况复杂、环境多变,其液压系统动力元件大排量柱塞泵相较于常规柱塞泵存在更大的液压冲击,进而引起较大的流量脉动与压力脉动。为降低大排量柱塞泵在挖掘、盾构等工况下的流量、压力脉动,减小油液介质对下游元件的冲击损坏,以及为选择油液介质方法提供理论指导,文中搭建了基于温度场影响的油液动力黏度、密度与体积弹性模量数学模型,在此基础上建立固-液-温耦合作用的柱塞泵数学模型;并使用ADAMS、AMESim软件完成固-液-温耦合作用下750 mL/r柱塞泵联合仿真,得到不同温度影响下柱塞泵流量脉动与压力脉动变化规律;通过整泵试验探究油液温度对柱塞泵压力脉动的影响规律,验证了750 mL/r柱塞泵固-液-温耦合联合仿真模型的正确性。针对油液的3种特性,分别使用正交试验法与单因素分析法考量其对柱塞泵流量脉动率的影响程度和规律。结果表明:柱塞泵出口流量脉动、压力脉动随温度的升高而增大;在设定工况下,油液体积弹性模量对流量脉动率影响占比为97.19%,密度占比为2.03%,动力黏度占比为0.78%;为降低油液特性对柱塞泵出口脉动率的影响,应选择体积弹性模量较大且密度较小的液压油。

中图分类号: