| 1 |

靳聪,史亦韦,卢超,等 .铝合金预拉伸板残余应力的超声测量[J].无损检测,2015,37(11):68-72.

|

|

JIN Cong, SHI Yi-wei, LU Chao,et al .Ultrasonic measurement of residual stress in aluminum alloy pre-stretched aluminum alloy plate by using ultrasonic and its verification[J].Nondestructive Testing,2015,37(11):68-72.

|

| 2 |

路浩,邢立伟,邢敬伟 .超声波法焊接残余应力测量技术[J].焊管,2019,42(8):50-55.

|

|

LU Hao, XING Li-wei, XING Jing-wei .Ultrasonic method measurement of welding residual stress[J].Welded Pipe and Tube,2019,42(8):50-55.

|

| 3 |

郑雪鹏,吴伟 .GH4169合金环锻件残余应力超声检测[J].科学技术与工程,2020,20(4):1349-1354.

|

|

ZHENG Xue-peng, WU Wei .Ultrasonic testing of residual stress in GH4169 alloy ring forgings[J].Science Technology and Engineering,2020,20(4):1349-1354.

|

| 4 |

徐浪,潘勤学,宿亮,等 .焊接残余应力超声无损检测技术[J].计测技术,2012,32(6):29-32,53.

|

|

XU Lang, PAN Qinxue, SU Liang,et al .Compensation technology for nondestructive testing of welded residual stress by ultrasonic[J].Metrology & Measurement Technology,2012,32(6):29-32,53.

|

| 5 |

刘海波,张祥,刘彦坤,等 .电磁超声单向应力横纵波联合测量方法研究[J].机械设计与制造,2021(9):241-246.

|

|

LIU Hai-bo, ZHANG Xiang, LIU Yan-kun,et al .Study on combined measurement method of electromagnetic ultrasonic unidirectional stress transverse and longitudinal waves[J].Mechanical Design and Manufacturing,2021(9):241-246.

|

| 6 |

郑凯,武兴,李俊燕,等 .高温下金属材料厚度的激光超声检测研究[J].机械工程学报,2021,57(10):21-27.

|

|

ZHENG Kai, WU Xing, LI Junyan,et al .Laser ultrasonic evaluation of metallic material thickness at high temperature[J].Journal of Mechanical Engineering,2021,57(10):21-27.

|

| 7 |

刘永强,杨世锡,甘春标 .一种基于激光超声的薄层金属材料厚度检测方法研究[J].振动与冲击,2018,37(12):147-152.

|

|

LIU Yongqiang, YANG Shixi, GAN Chunbiao .Thickness measurement for thin metal material with the use of laser generated ultrasound[J].Journal of Vibration and Shock,2018,37(12):147-152.

|

| 8 |

REINA G, FOGLIA M .On the mobility of all-terrain rovers[J].Industrial Robot:An International Journal,2013,40(2):123-131.

|

| 9 |

郑康琳,张劲泉,王陶,等 .双横波声速法检测单向受压混凝土构件永存应力[J].应用声学,2021,40(3):367-375.

|

|

ZHENG Kanglin, ZHANG Jinquan, WANG Tao,et al .Study on the method of double shear wave velocity to detect the permanent stress of concrete members under uniaxial compression[J].Journal of Applied Acoustics,2021,40(3):367-375.

|

| 10 |

宋文涛,徐春广 .超声法的残余应力场无损检测与表征[J].机械设计与制造,2015(10):9-12,17.

|

|

SONG Wen-tao, XU Chun-guang .Residual stress field nondestructive testing and characterization using method of ultrasonic[J].Mechanical Design and Manufacturing,2015(10):9-12,17.

|

| 11 |

XU Y, YANG Z, ZHOU H,et al .Application of acoustoelasticity in studying compressive stress state in Polymer bonded explosive[C]∥ Proceedings of 2015 IEEE Far East NDT New Technology & Application Forum (FENDT).Zhuhai:IEEE,2015:109-113.

|

| 12 |

何伟明,郝艳捧,邹舟诣奥,等 .GIS盆式绝缘子应力超声检测技术应用与展望[J].广东电力,2021,34(1):13-20.

|

|

HE Weiming, HAO Yanpeng, ZOU Zhouyi’ao,et al .Application and prospect of ultrasonic testing technology for stress in GIS basin insulators[J] Guangdong Electric Power,2021,34(1):13-20.

|

| 13 |

刘彦坤,刘海波,李亚鹏,等 .基于电磁超声瑞利波的平面应力测量方法[J].无损检测,2020,42(9):33-38.

|

|

LIU Yankun, LIU Haibo, LI Yapeng,et al .Plane stress measurement method based on the electromagnetic ultrasonic Rayleigh wave[J].Nondestructive Testing,2020,42(9):33-38.

|

| 14 |

胡恒山 .拉梅常数的力学意义与剪切模量出现于纵波速度公式的原因[J].地球物理学进展,2018,33(1):219-222.

|

|

HU Heng-shan .Note on the Lamé constant and the reason for the presence of the shear modulus in the compressional wave speed formula[J].Progress in Geophysics,2018,33(1):219-222.

|

| 15 |

徐春广,李焕新,王俊峰,等 .残余应力的超声横纵波检测方法[J].声学学报,2017,42(2):195-204.

|

|

XU Chunguang, LI Huanxin, WANG Junfeng,et al .Ultrasonic shear and longitudinal wave testing method for residual stress[J].Acta Acustica,2017,42(2):195-204.

|

| 16 |

杨兴,冯强,孙赞朋,等 .6061铝合金在多向锻造过程中显微组织与拉伸性能的演变[J].机械工程材料,2018,42(7):73-77.

|

|

YANG Xing, FENG Qiang, SUN Zanpeng,et al .Evolution of microstructure and tensile properties of 6061 aluminum alloy during multi-directional forging[J].Materials for Mechanical Engineering,2018,42(7):73-77.

|

| 17 |

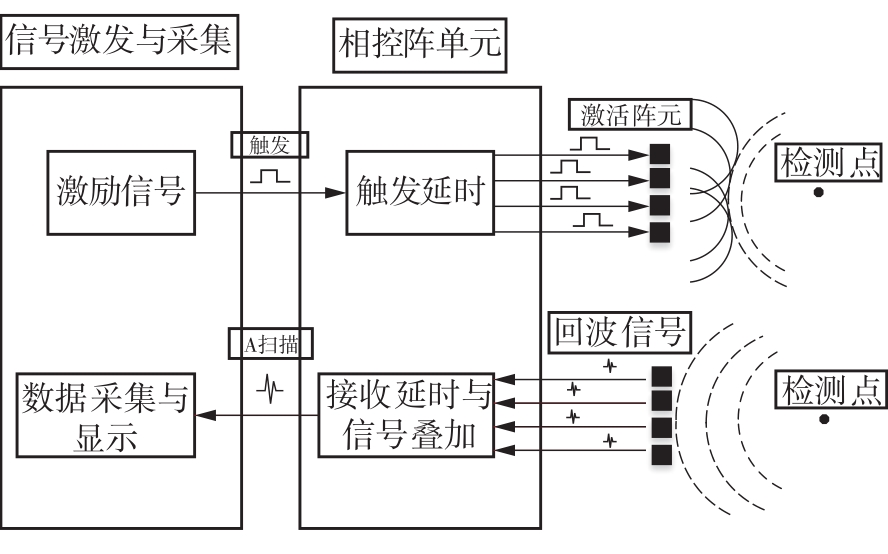

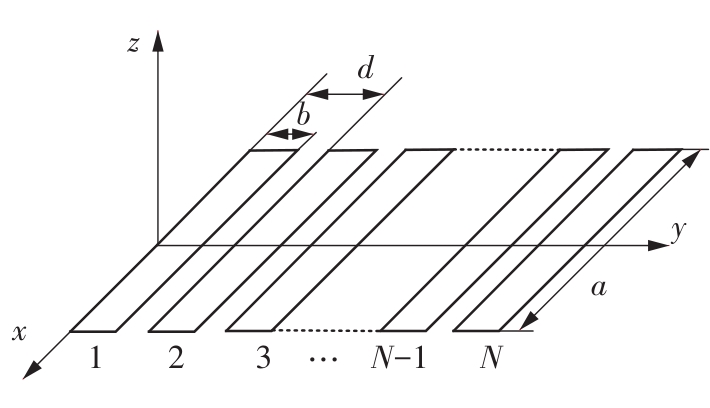

靳世久,杨晓霞,陈世利,等 .超声相控阵检测技术的发展及应用[J].电子测量与仪器学报,2014,28(9):925-934.

|

|

JIN Shijiu, YANG Xiaoxia, CHEN Shili,et al .Development and application of ultrasonic phased array testing technology[J].Journal of Electronic Measurement and Instrumentation,2014,28(9):925-934.

|