华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (7): 21-33.doi: 10.12141/j.issn.1000-565X.220626

所属专题: 2023年机械工程

基于多头卷积和差分自注意力的小样本故障诊断方法

陈新度1 扶治森1,2,3 吴智恒2,3 陈启愉2,3 郭伟科2,3

- 1.广东工业大学 机电工程学院, 广东 广州 510006

2.广东省科学院 智能制造研究所, 广东 广州 510030

3.广东省现代控制技术重点实验室, 广东 广州 510030

Small-Sample Fault Diagnosis Method Based on Multi-Head Convolution and Differential Self-Attention

CHEN Xindu1 FU Zhisen1,2,3 WU Zhiheng2,3 CHEN Qiyu2,3 GUO Weike2,3

- 1.School of Mechanical and Electrical Engineering,Guangdong University of Technology,Guangzhou 510006,Guangdong,China

2.Intelligent Manufacturing Research Institute,Guangdong Academy of Sciences,Guangzhou 510030,Guangdong,China

3.Guangdong Provincial Key Laboratory of Modern Control Technology,Guangzhou 510030,Guangdong,China

摘要:

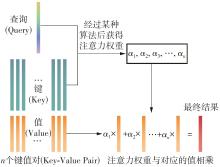

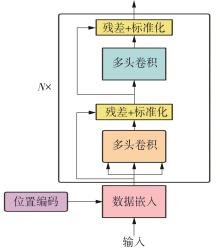

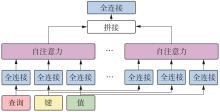

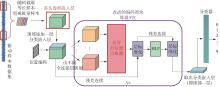

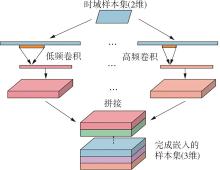

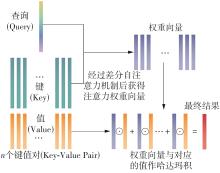

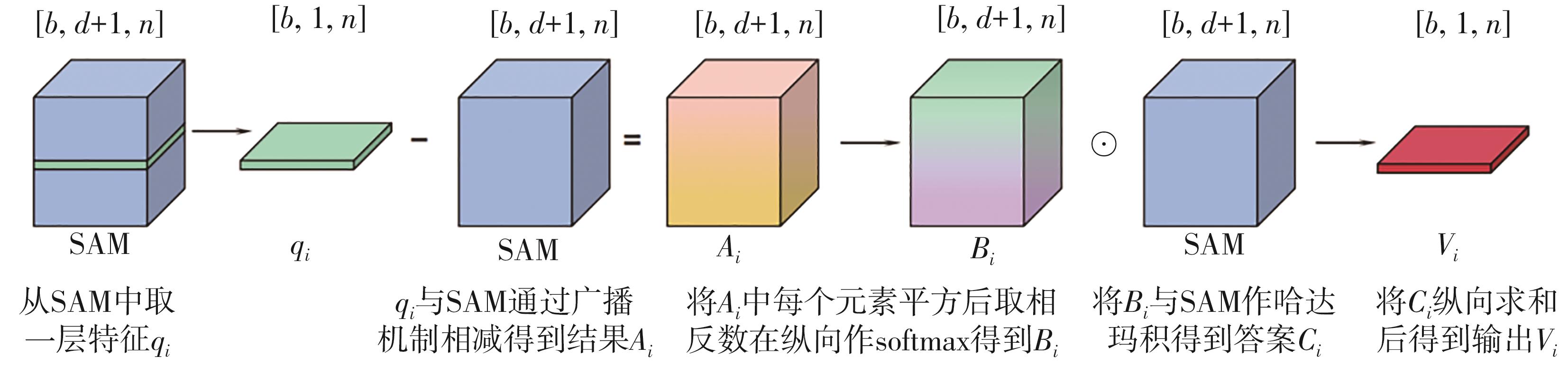

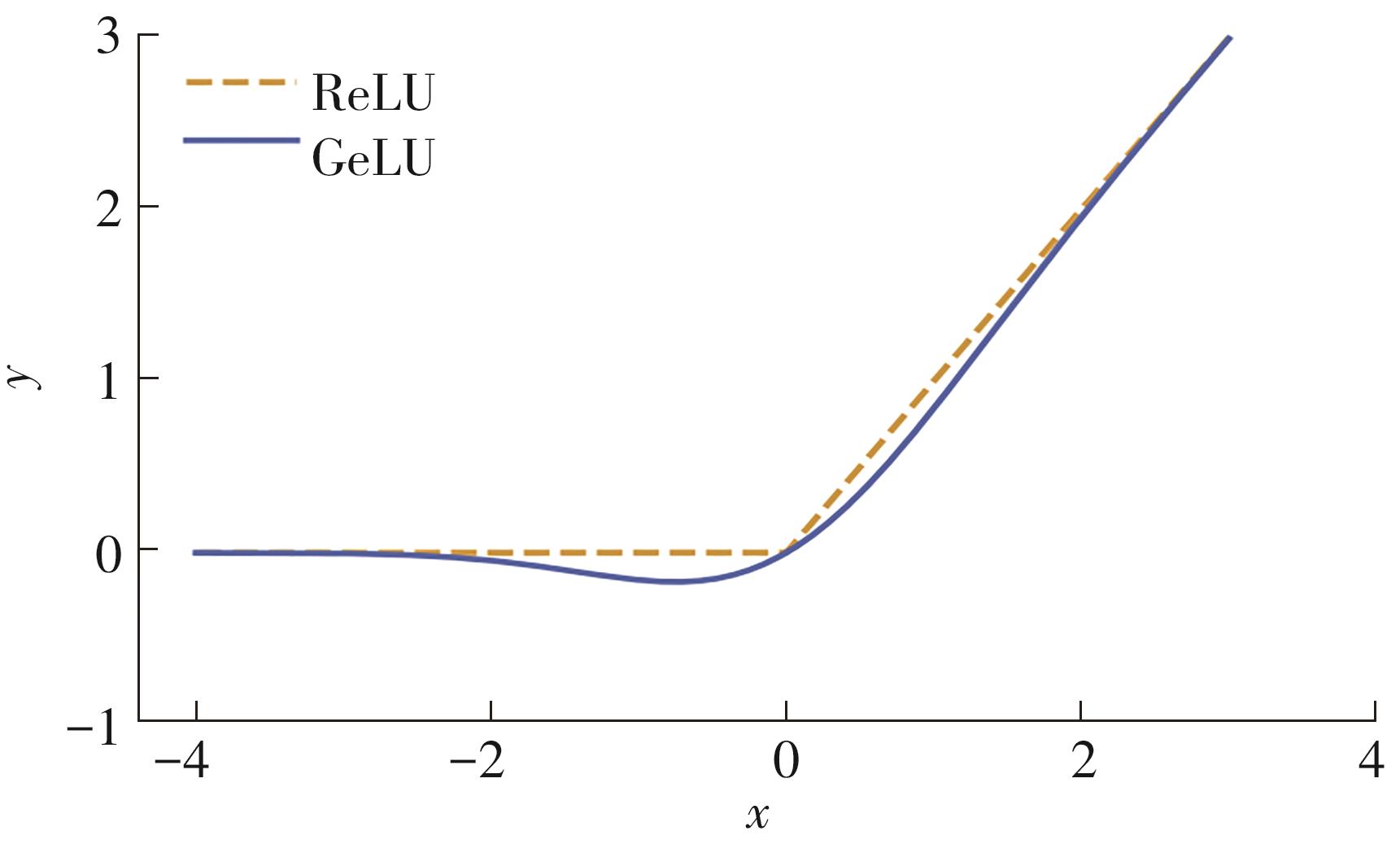

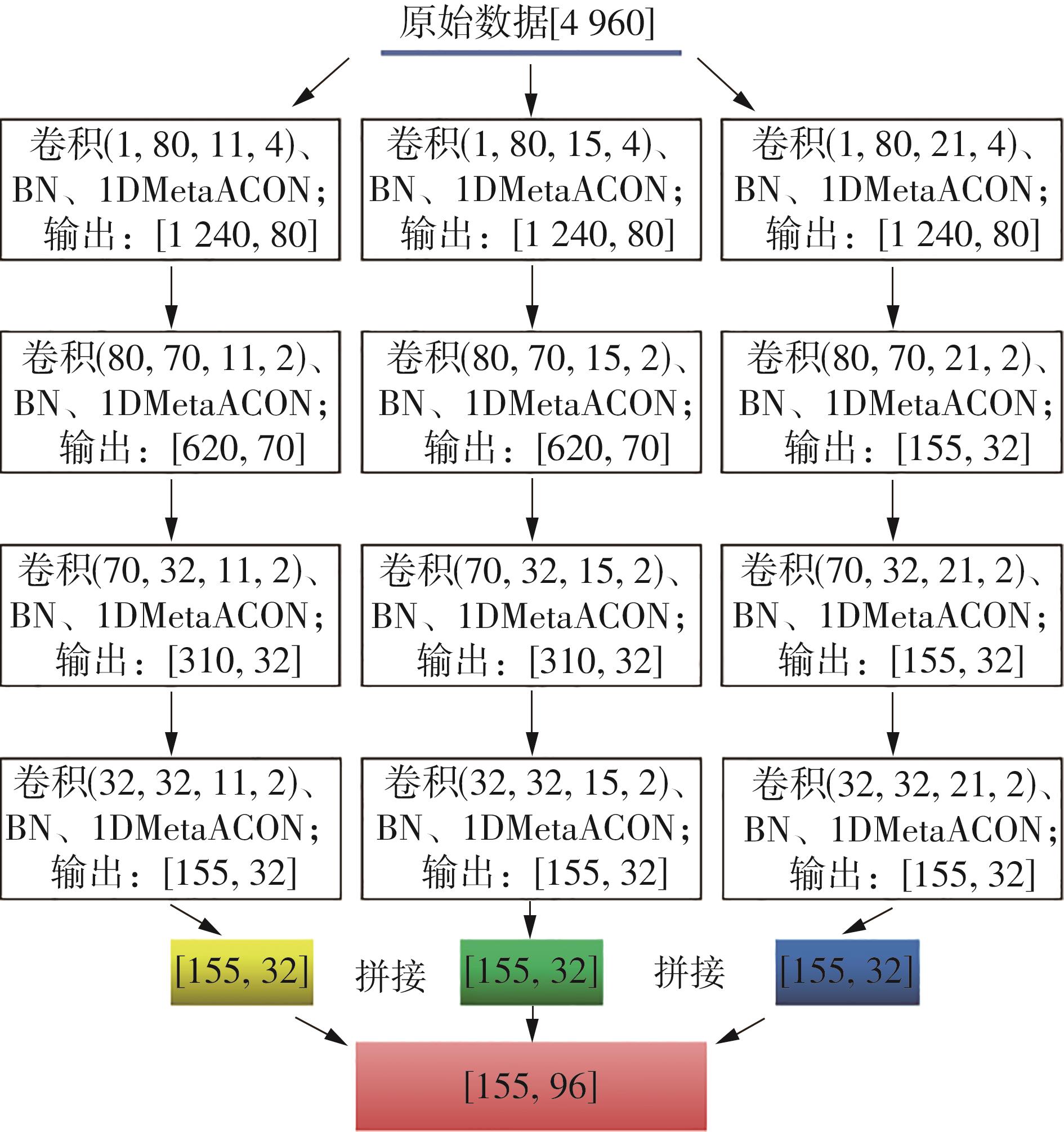

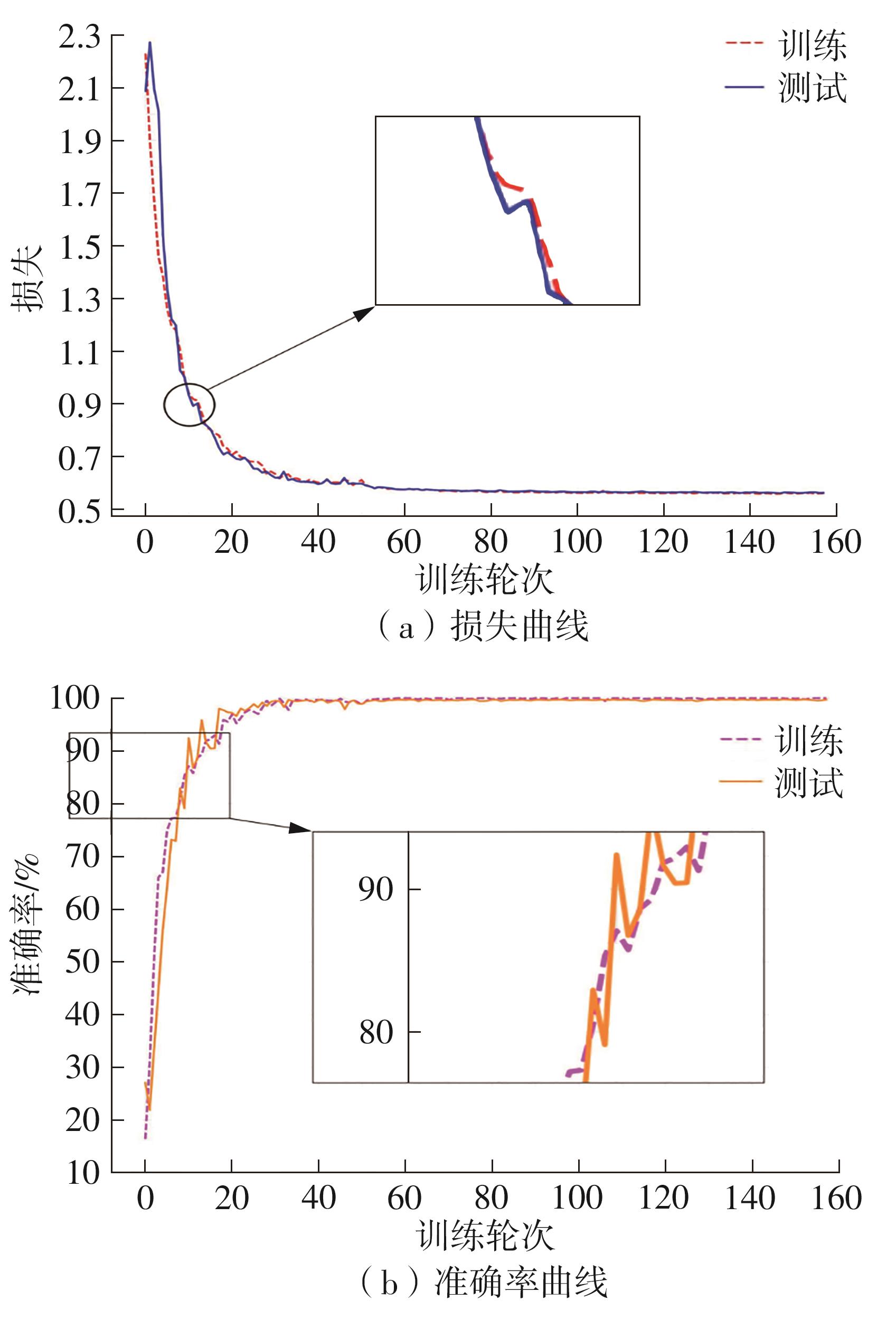

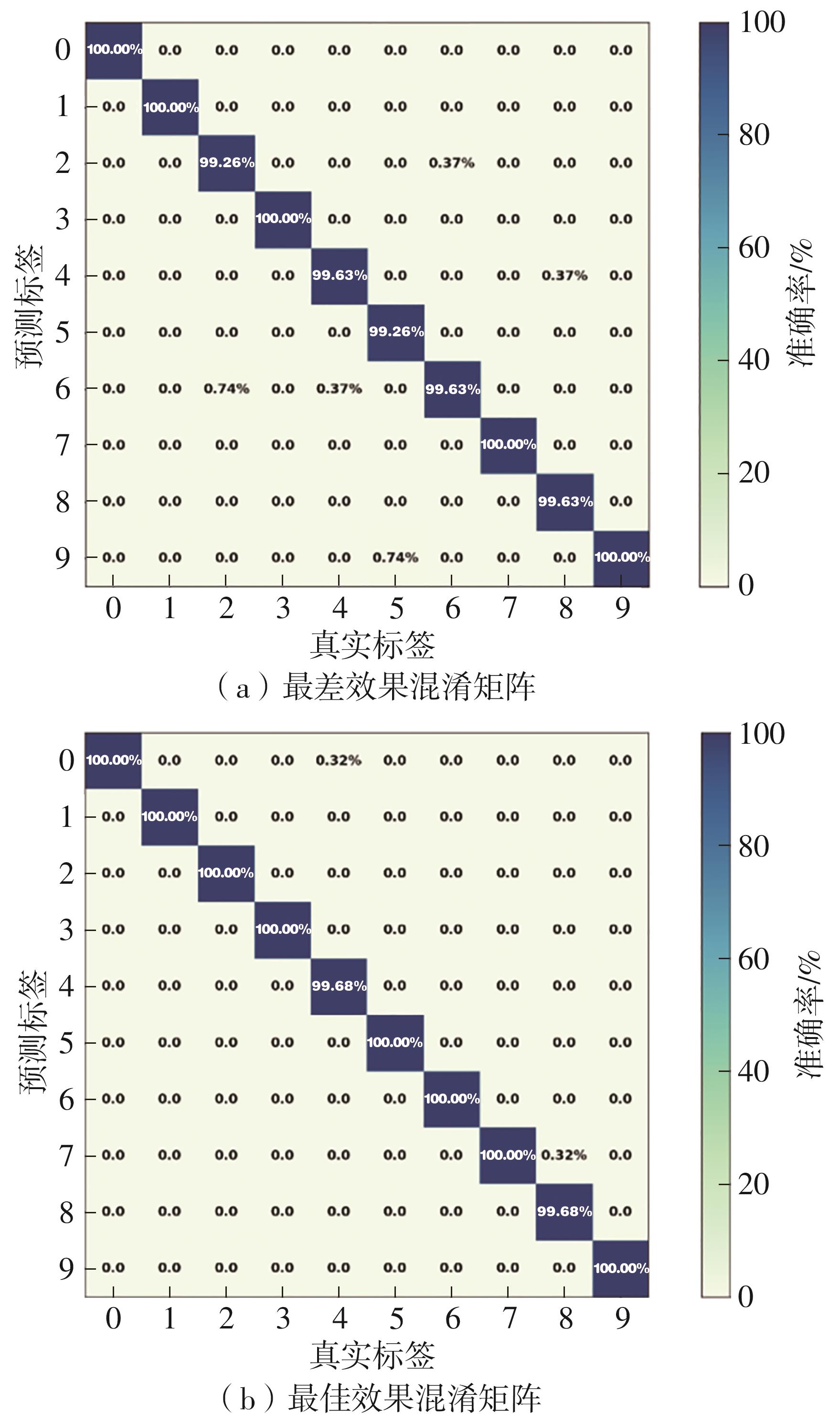

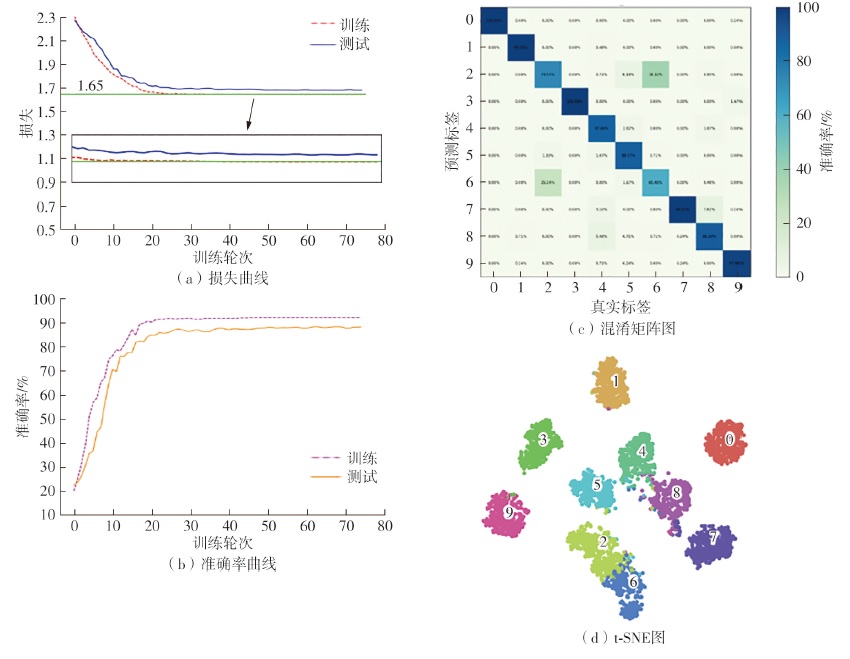

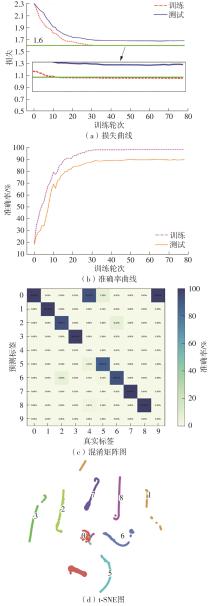

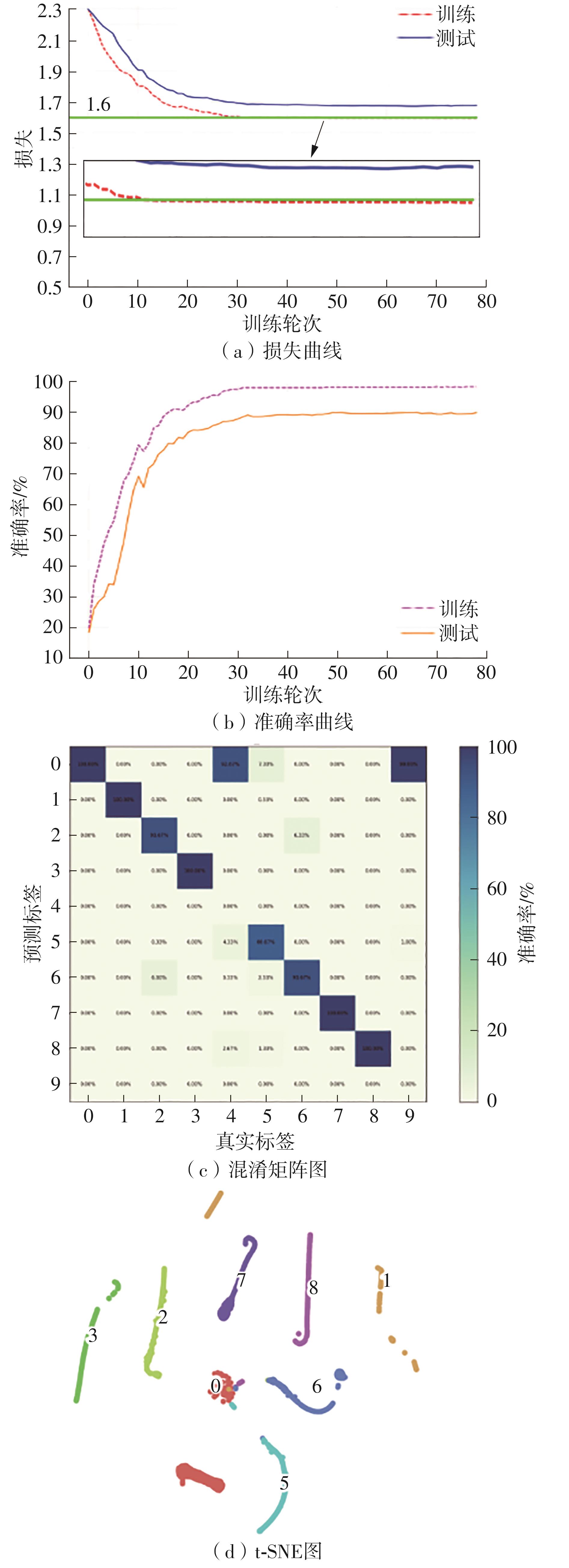

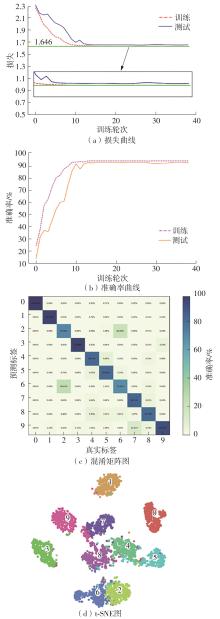

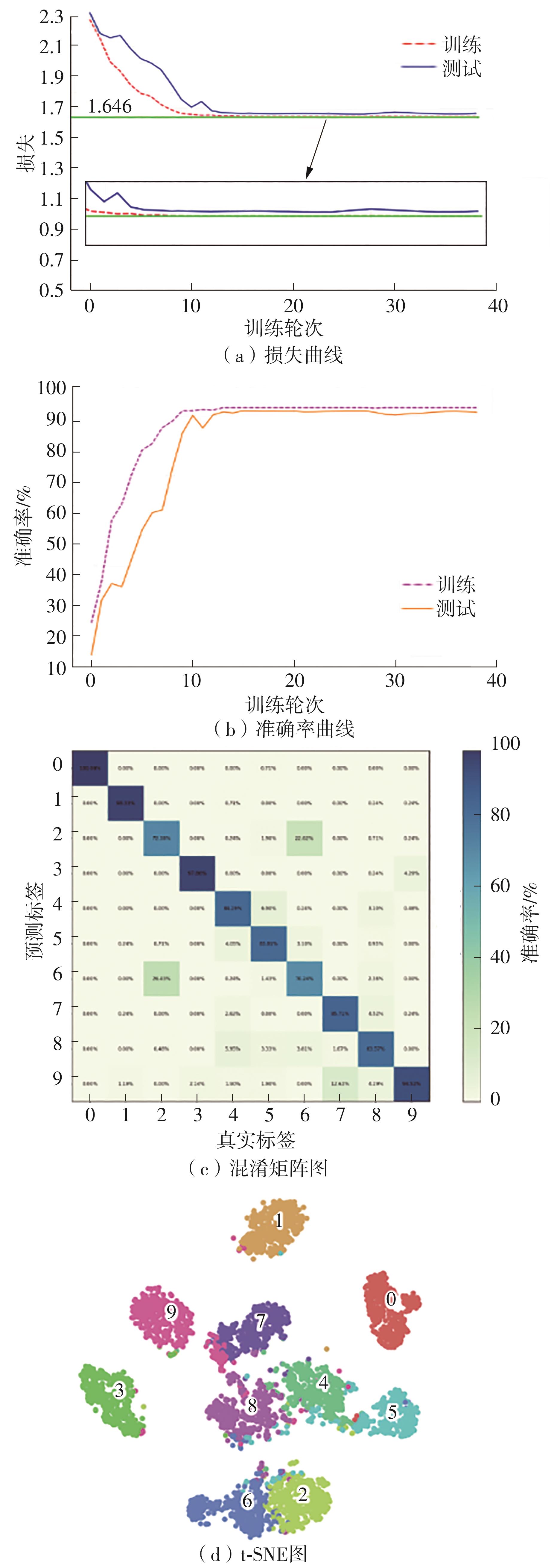

轴承是工业设备中使用最广泛的旋转部件之一,如果轴承在故障状况下运行较长时间,将会造成巨大的经济损失并威胁人身安全,因此,对轴承故障诊断进行研究具有十分重要的意义。基于深度学习的故障诊断技术目前日趋成熟,但在小样本情况下存在过拟合、效果不稳定、准确率不高等问题。为了解决这类问题,文中提出了一种融合多头卷积(Multi-Head Convolution,MC)的数据嵌入新算法和差分自注意力(Differential Self-Attention,DSA)机制的Transformer变种模型MDT(Multi-Head Convolution and Differential Self-Attention Transformer),以实现端到端的小样本故障诊断。MC算法对样本进行多路径一维卷积,由多通道输出将样本从一维扩展到二维,通过多个卷积核尺寸提取出原样本中各个频域的丰富故障信息。相较于Transformer中原有的点积自注意力机制,DSA机制通过差分为每个特征求得对应的注意力权重向量,从而可从样本中提取出更为深层次的故障特征。MDT继承了Transformer对于处理序列数据的强大能力,可从时域信号中提取更为丰富的故障信息,同时避免了小样本模型中常见的过拟合问题。实验结果表明,该方法在每个故障种类仅有100个训练样本的轴承故障诊断任务中能稳定获得99%以上的测试准确率,具有强抗过拟合性和强鲁棒性。

中图分类号: