| 1 |

夏绪辉,荆为民,张泽琳,等 .振动筛仿真研究、应用现状及发展趋势[J].中南大学学报(自然科学版),2020,51(10):2689-2706.

|

|

XIA Xuhui, JING Weimin, ZHANG Zelin,et al .Simulation research,application status and development trend of vibrating screen[J].Journal of Central South University (Science and Technology),2020,51(10):2689-2706.

|

| 2 |

赵环帅 .我国振动筛的市场现状及发展对策[J].矿山机械,2018,46(4):1-6.

|

|

ZHAO Huanshuai .Status of domestic vibrating screen market as well as development countermeasures[J].Mining & Processing Equipment,2018,46(4):1-6.

|

| 3 |

MAKINDE O A, RAMATSETSE B I, MPOFU K .Review of vibrating screen development trends:linking the past and the future in mining machinery industries[J].International Journal of Mineral Processing,2015,145:17-22.

|

| 4 |

YIN Z, ZHANG H, HAN T .Simulation of particle flow on an elliptical vibrating screen using the discrete element method[J].Powder Technology,2016,302:443-454.

|

| 5 |

CHEN B, YAN J, MO W,et al .DEM simulation and experimental study on the screening process of elliptical vibration mechanical systems[J].Journal of Vibroengineering,2019,21(8):2025-2038.

|

| 6 |

刘义伦,苏家辉,赵先琼 .基于离散元法的振动筛的筛分效率研究[J].东北师大学报(自然科学报),2018,50(4):78-83.

|

|

LIU Yi-lun, SU Jia-hui, ZHAO Xian-qiong .The study of vibrating screen efficiency based on discrete element method[J].Journal of Northeast Normal University (Natural Science Edition),2018,50(4):78-83.

|

| 7 |

MONCADA M M, RODRÍGUEZ C G, RUTA G .Dynamic modeling of a vibrating screen considering the ore inertia and force of the ore over the screen calculated with discrete element method[J].Shock and Vibration,2018(12):1714738/1-13.

|

| 8 |

YANG X, WU J, JIANG H,et al .Dynamic modeling and parameters optimization of large vibrating screen with full degree of freedom[J].Shock and Vibration,2019(1):1915708/1-12.

|

| 9 |

彭利平,刘初升,赵跃民,等 .混联弹簧减振系统下自同步直线振动筛的动力学特性[J].煤炭学报,2014,39(10):2114-2120.

|

|

PENG Li-ping, LIU Chu-sheng, ZHAO Yue-min,et al .Dynamic characteristics of a self-synchronous linear vibrating screen with hybrid-spring isolators[J].Journal of China Coal Society,2014,39(10):2114-2120.

|

| 10 |

程加远,任廷志,张子龙,等 .基于多体动力学与离散元耦合的惯性圆锥破碎机动态性能研究[J].振动与冲击,2021,40(8):98-109,130.

|

|

CHENG Jiayuan, REN Tingzhi, ZHANG Zilong,et al .A study on dynamic performance of an inertia cone crusher based on multi-body dynamics and discrete element coupling method[J].Journal of Vibration and Shock,2021,40(8):98-109,130.

|

| 11 |

WU Y-R, Y-C CHUNG, WANG I-C .Two-way coupled MBD-DEM modeling and experimental validation for the dynamic response of mechanisms containing damping particles[J].Mechanism and Machine Theory,2021,159:104257/1-38.

|

| 12 |

SHI S, GAO L, CAI X,et al .Effect of tamping operation on mechanical qualities of ballast bed based on DEM-MBD coupling method[J].Computers and Geotechnics,2020,124:103574/1-10.

|

| 13 |

LIU C, ZHANG S, ZHOU H,et al .Dynamic analysis and simulation of four-axis forced synchronizing banana vibrating screen of variable linear trajectory[J].Journal of Central South University,2012,19(6):1530-1536.

|

| 14 |

JIANG H, ZHAO Y, DUAN C,et al .Dynamic characteristics of an equal-thickness screen with a variable amplitude and screening analysis[J].Powder Technology,2017,311:239-246.

|

| 15 |

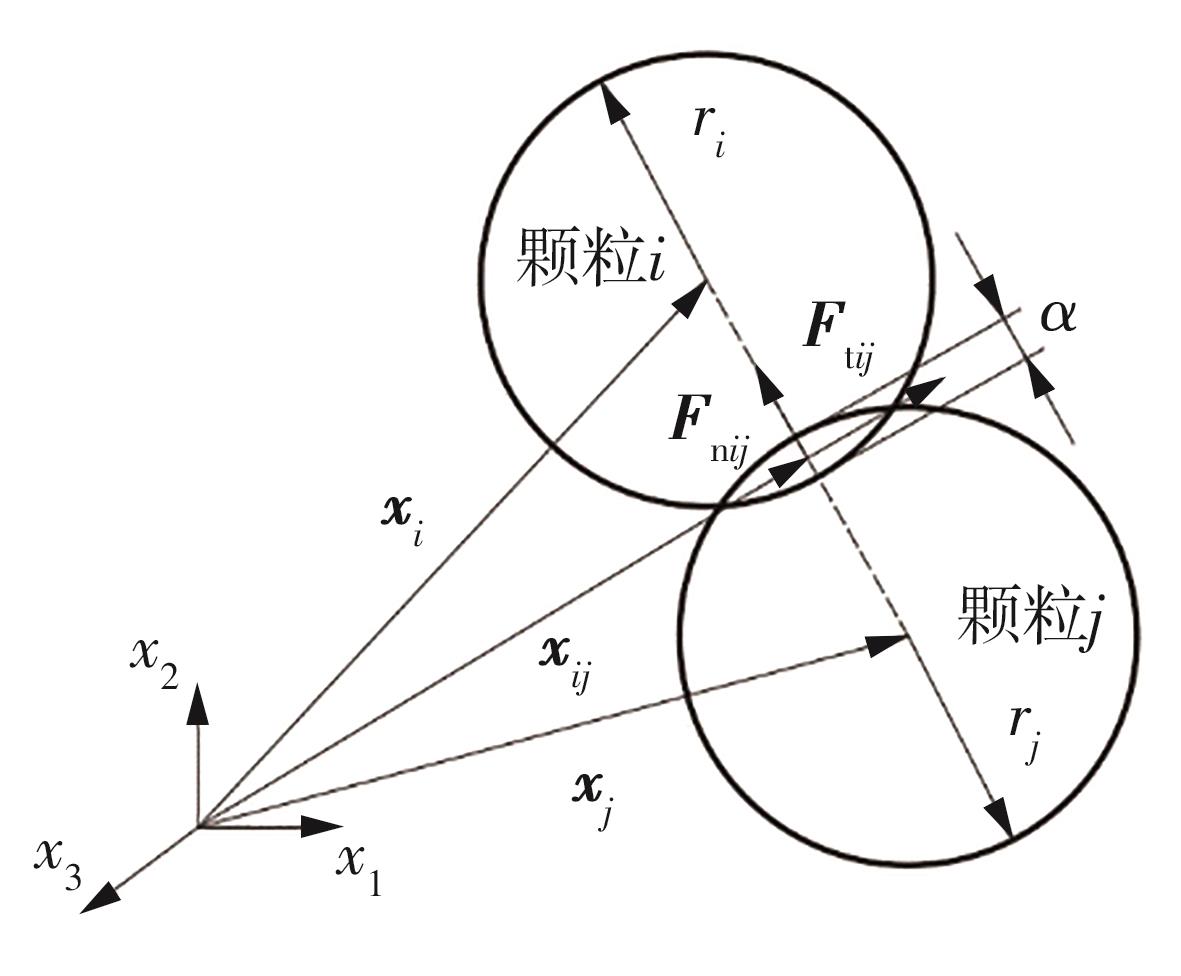

季顺迎 .计算颗粒力学及工程应用[M].北京:科学出版社,2018:43-55.

|

| 16 |

ELSKAMP F, KRUGGEL-EMDEN H .Review and benchmarking of process models for batch screening based on discrete element simulations[J].Advanced Powder Technology,2015,26(3):679-697.

|

| 17 |

孙其诚,王光谦 .颗粒物质力学导论[M].北京:科学出版社,2009:31-35.

|

| 18 |

刘春 .地质与岩土工程矩阵离散元分析[M].北京:科学出版社,2019:4-6.

|

| 19 |

BARRIOS G K P, CARVALHO DE R M, KWADE A,et al .Contact parameter estimation for DEM simulation of iron ore pellet handling[J].Powder Technology,2013,248(11):84-93.

|

| 20 |

陆永海 .选煤实际产率计算方法初探[J].煤质技术,1997(5):30-32,35.

|

|

Lu Yonghai .Preliminary study on calculation method of actual yield of products from coal preparation[J].Coal Quality Technology,1997(5):30-32,35.

|

| 21 |

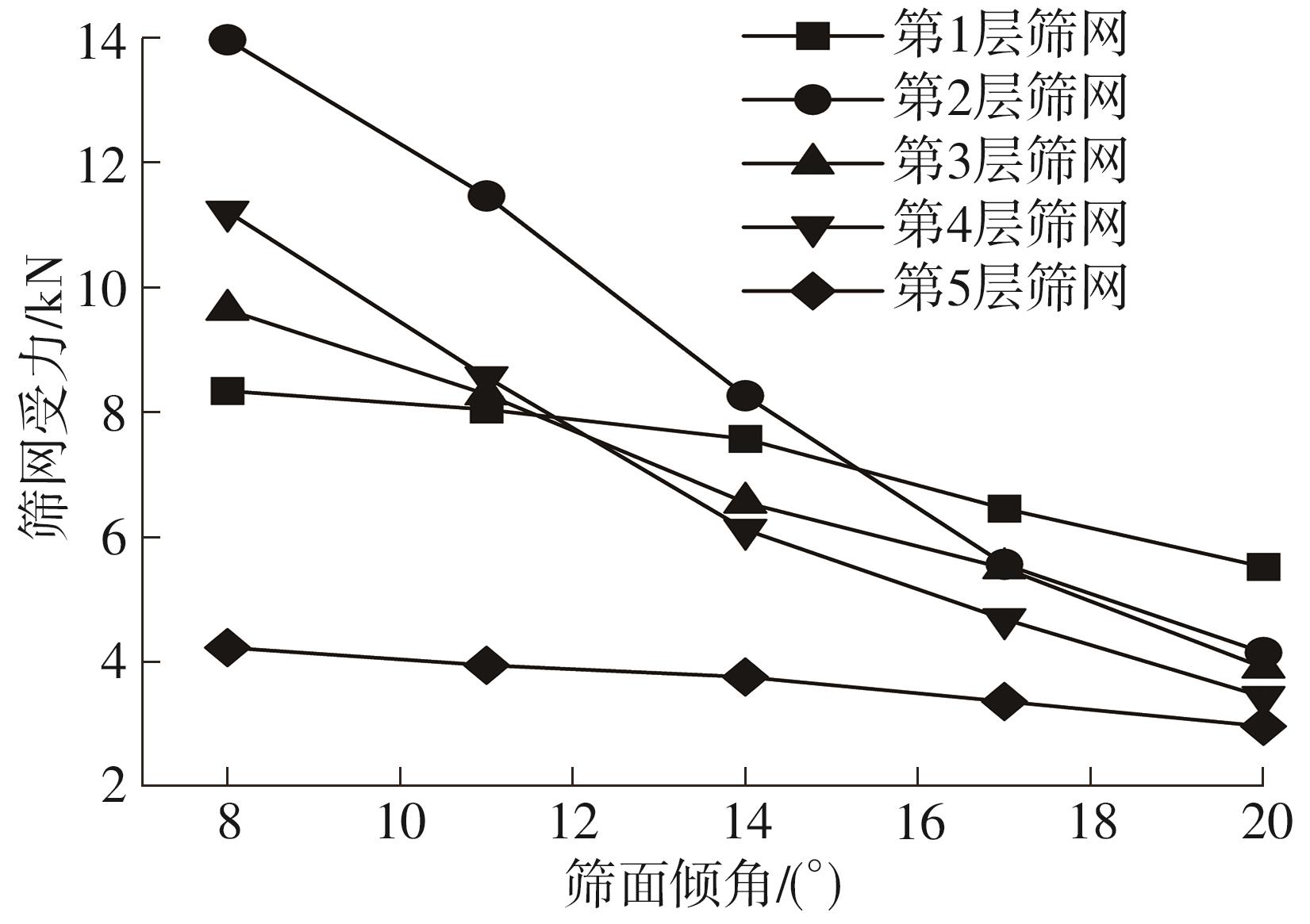

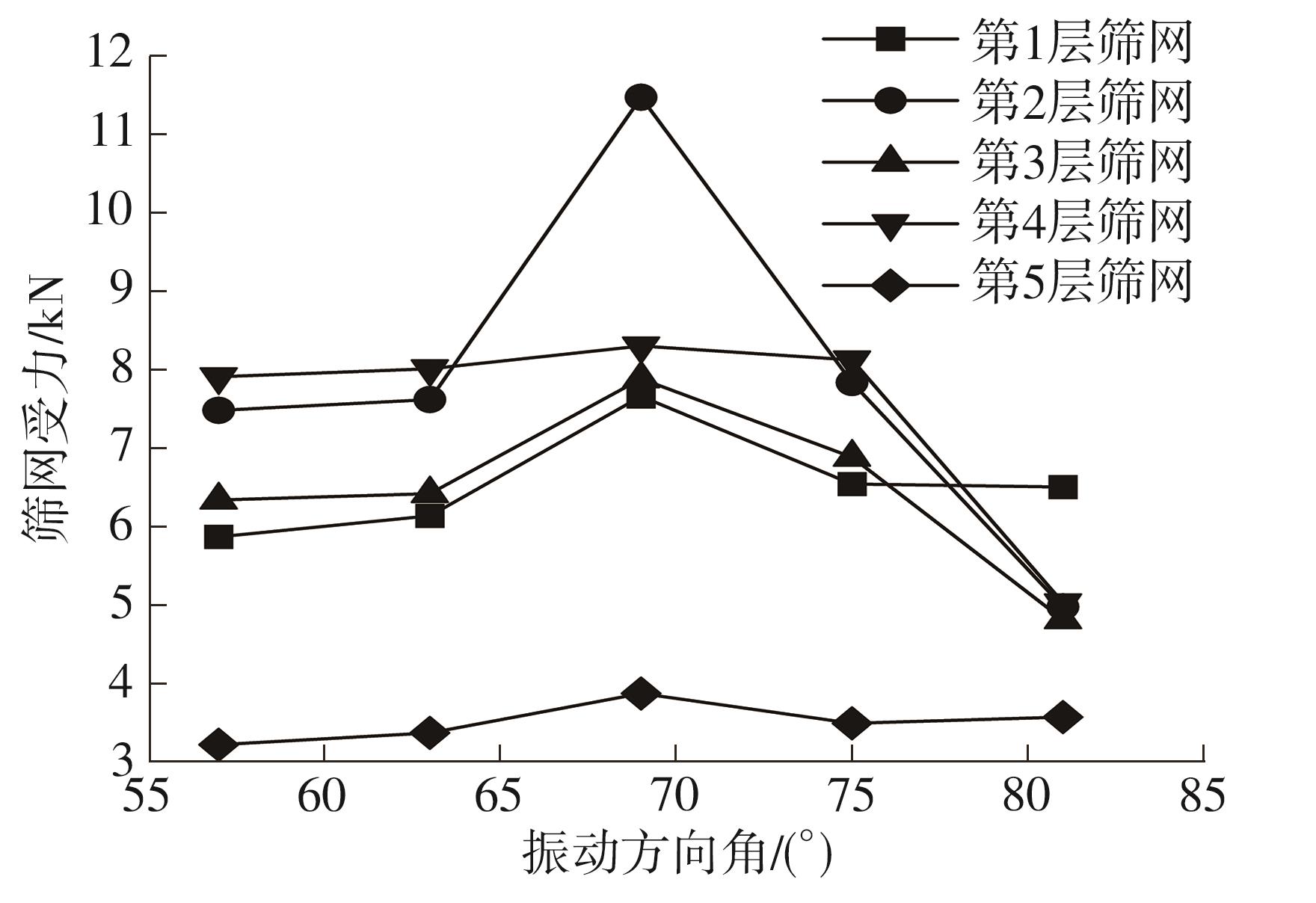

贺朝霞,胡明建,杨龙飞 .沥青搅拌设备多层振动筛分效率计算及影响规律研究[J].噪声与振动控制,2018,38(3):203-209.

|

|

HE Zhaoxia, HU Mingjian, YANG Longfei .Analysis of screening efficiency of multi-layer vibrating screens of asphalt mixing equipment[J].Noise and Vibration Control,2018,38(3):203-209.

|

| 22 |

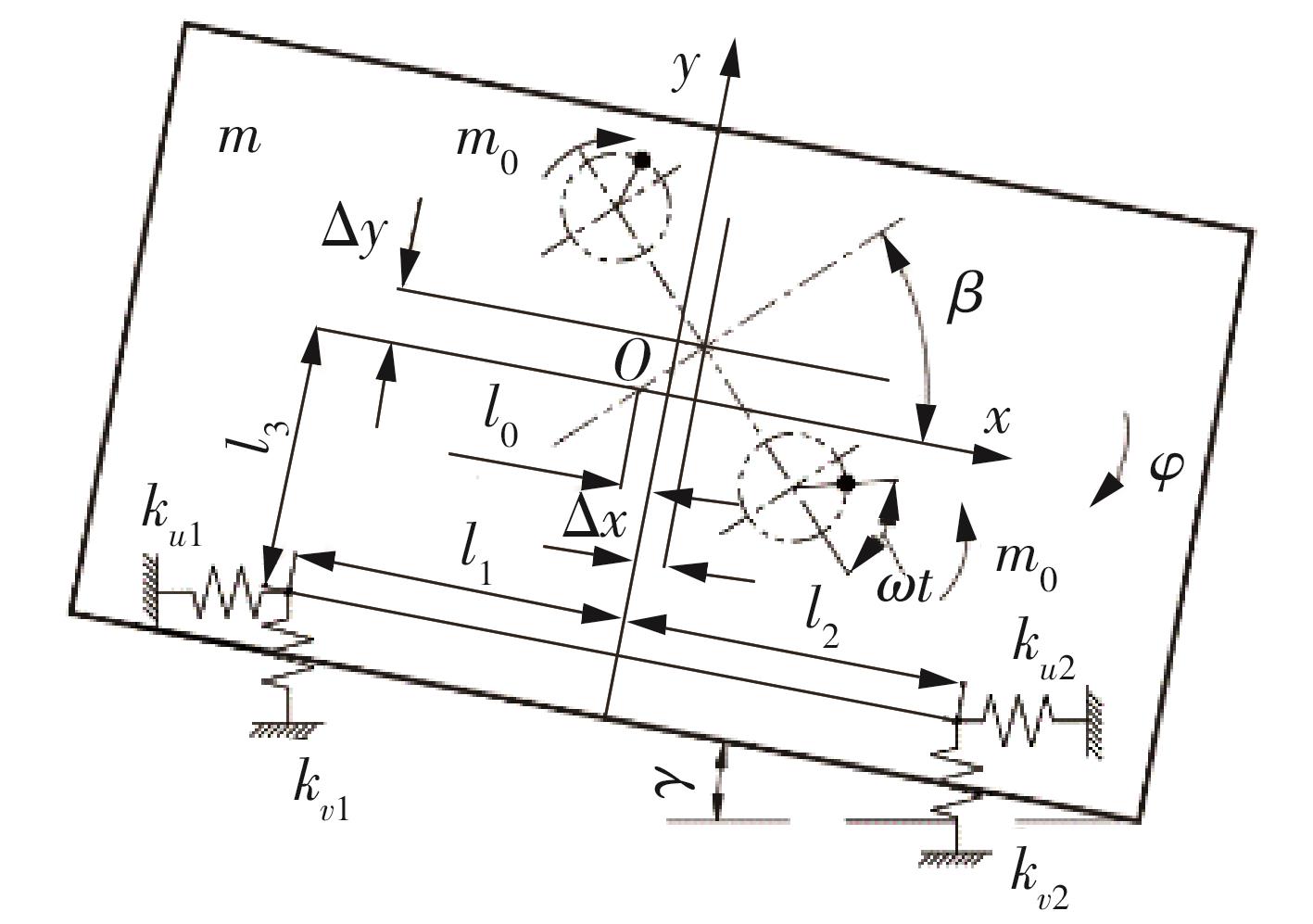

李杨杨,贺朝霞,宋绪丁,等 .沥青搅拌设备振动筛系统动力学分析及其参数影响研究[J].计算力学学报,2015,32(4):565-570.

|

|

LI Yang-yang, HE Zhao-xia, SONG Xu-ding,et al .Dynamic analysis and influence study of structure parameters on the asphalt mixing plant vibration screen system[J].Chinese Journal of Computational Mechanics,2015,32(4):565-570.

|