华南理工大学学报(自然科学版) ›› 2024, Vol. 52 ›› Issue (1): 38-51.doi: 10.12141/j.issn.1000-565X.220770

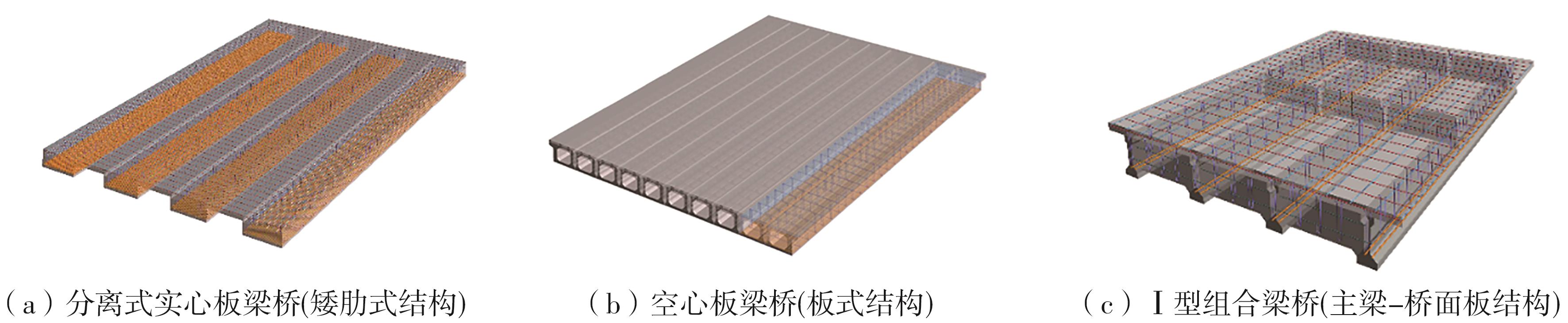

新型分离式实心板梁桥全过程受力性能分析

蒋冬启 吴浩 范进

- 南京理工大学 理学院,江苏 南京 210094

Study on Whole-Process Mechanical Behavior of Novel Spread Slab Beam Bridges

JIANG Dongqi WU Hao FAN Jin

- School of Science,Nanjing University of Science and Technology,Nanjing 210094,Jiangsu,China

摘要:

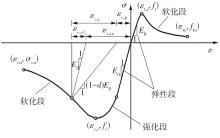

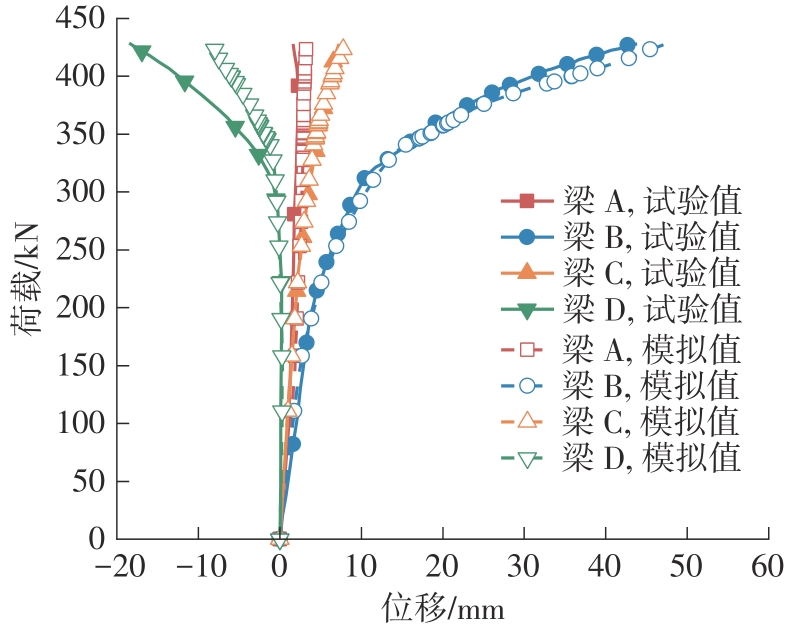

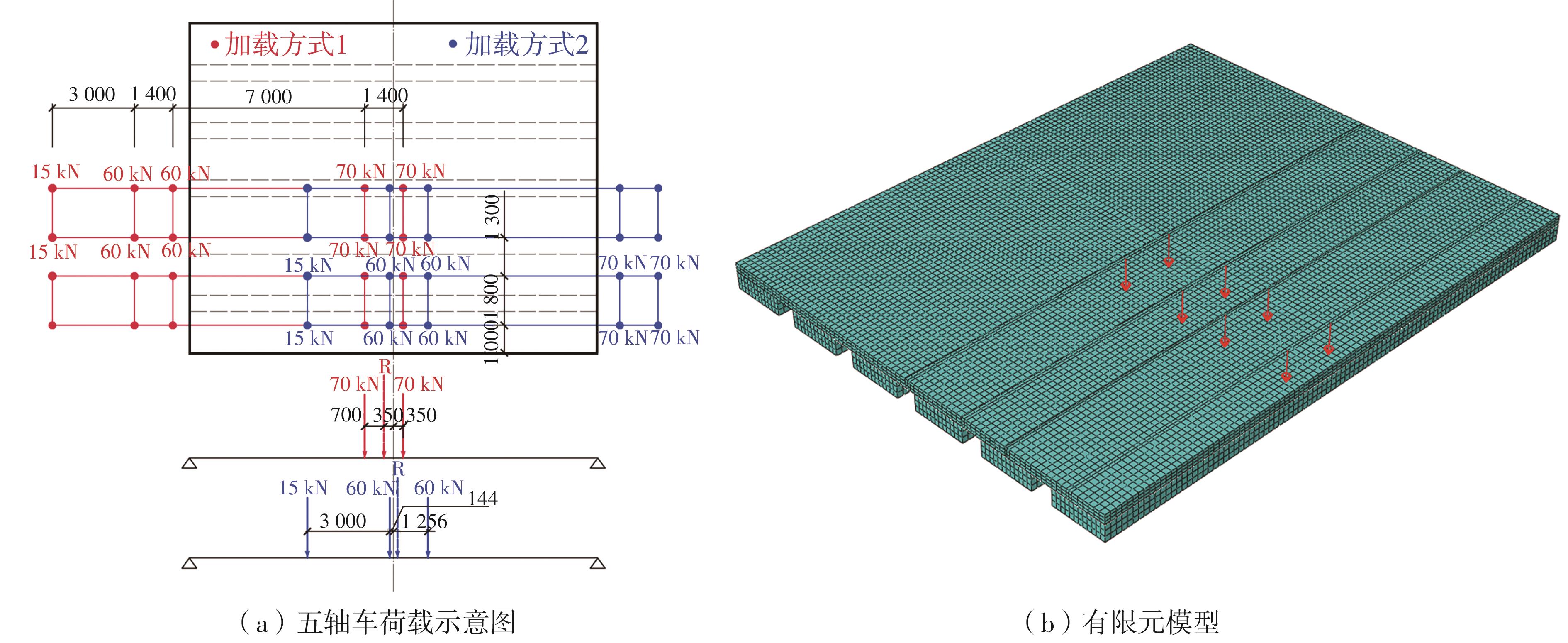

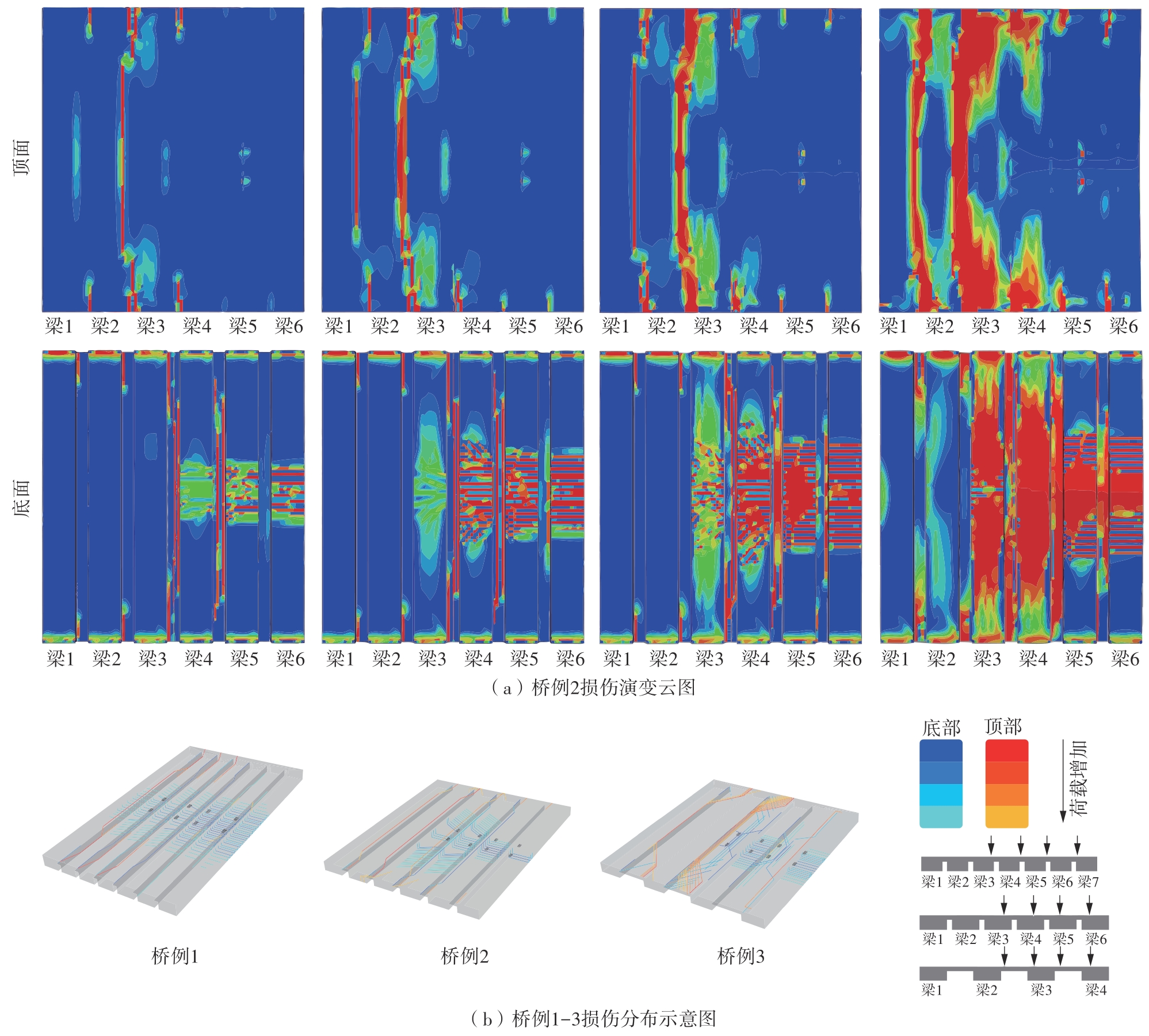

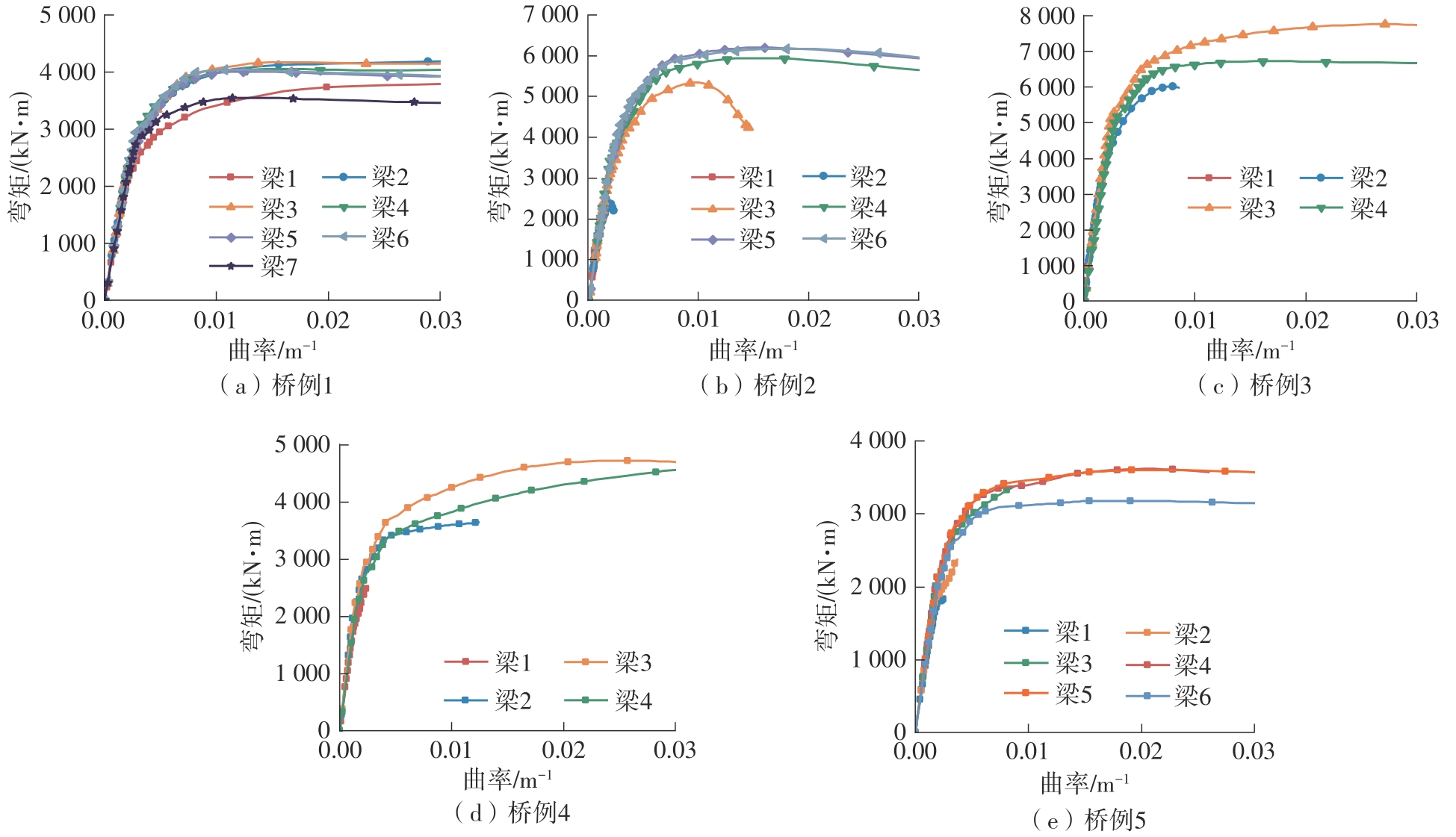

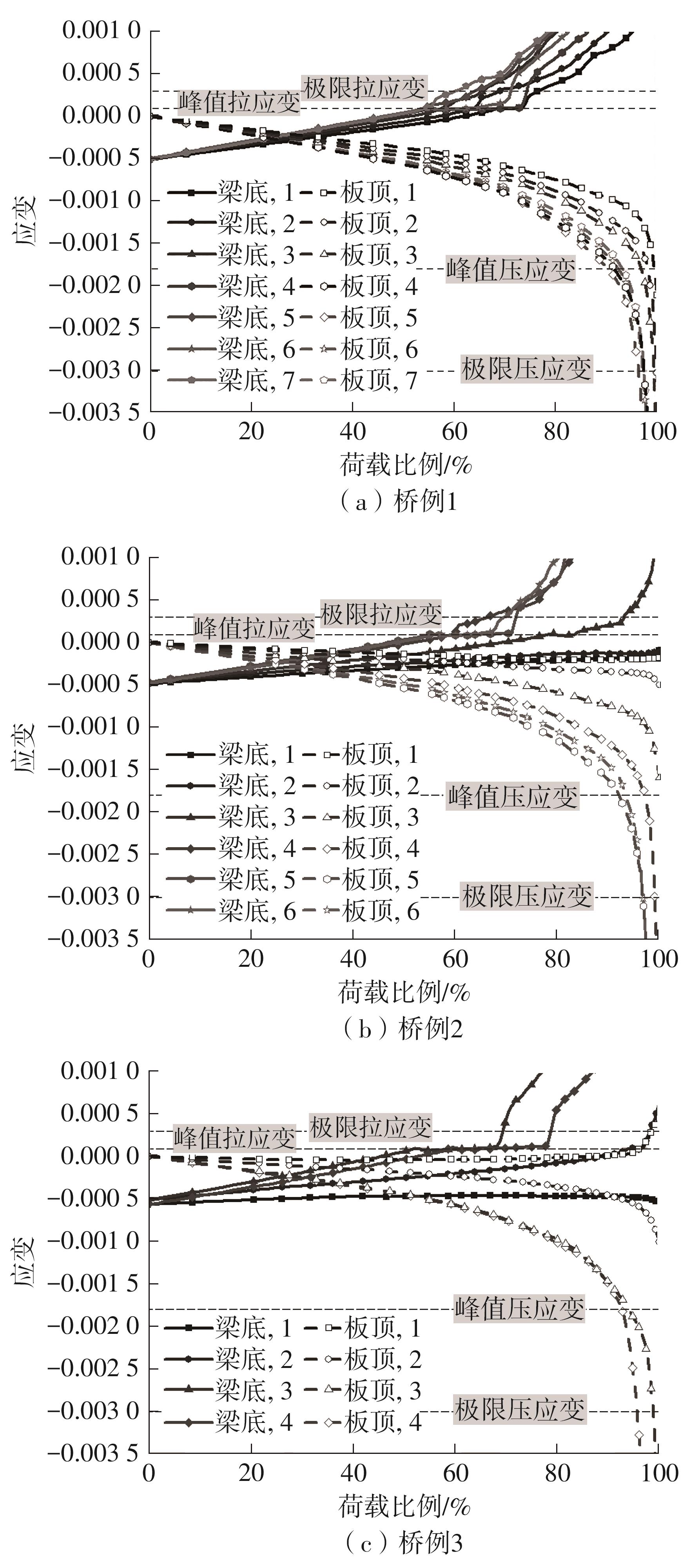

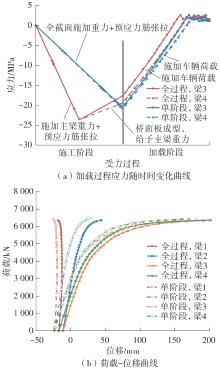

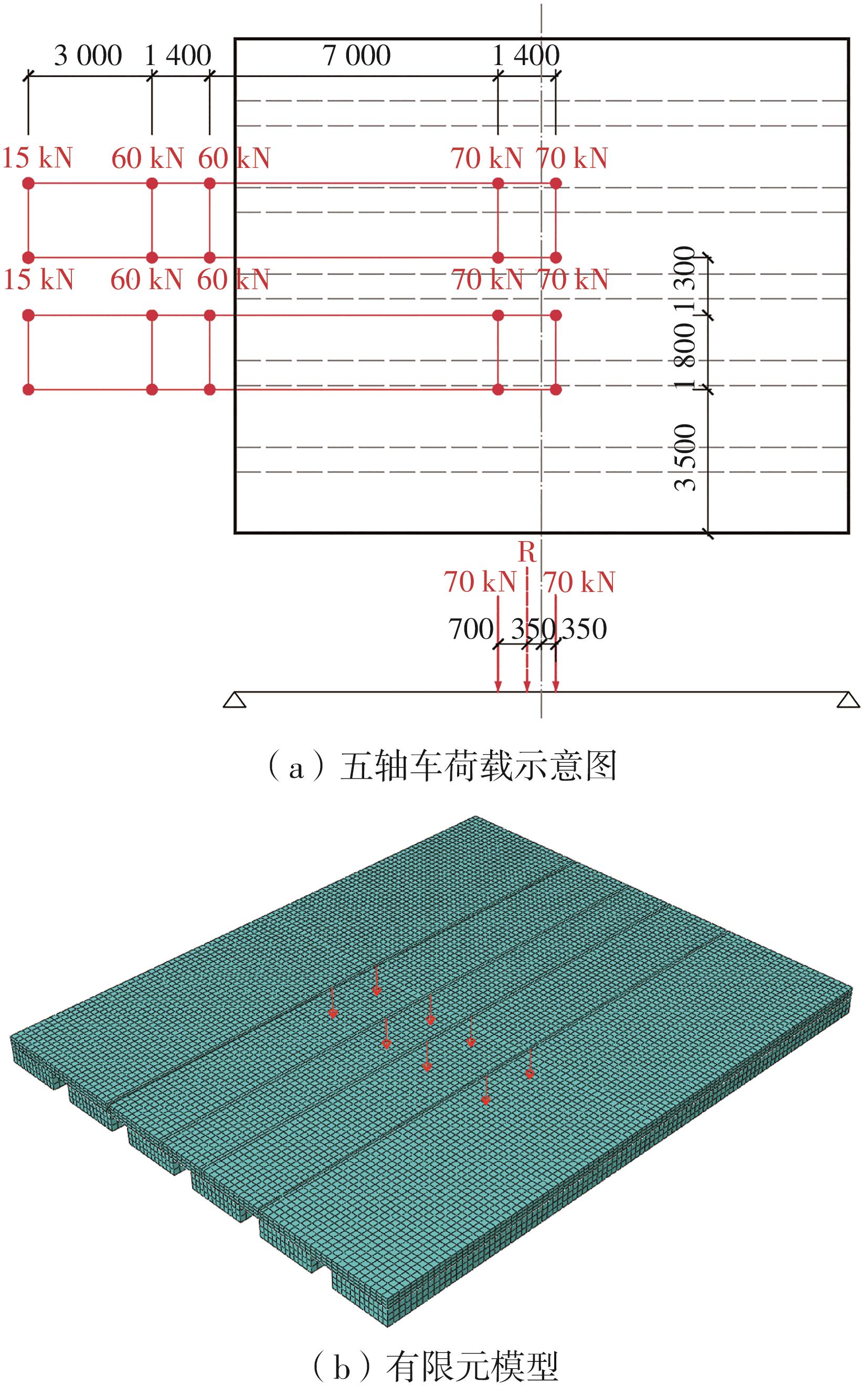

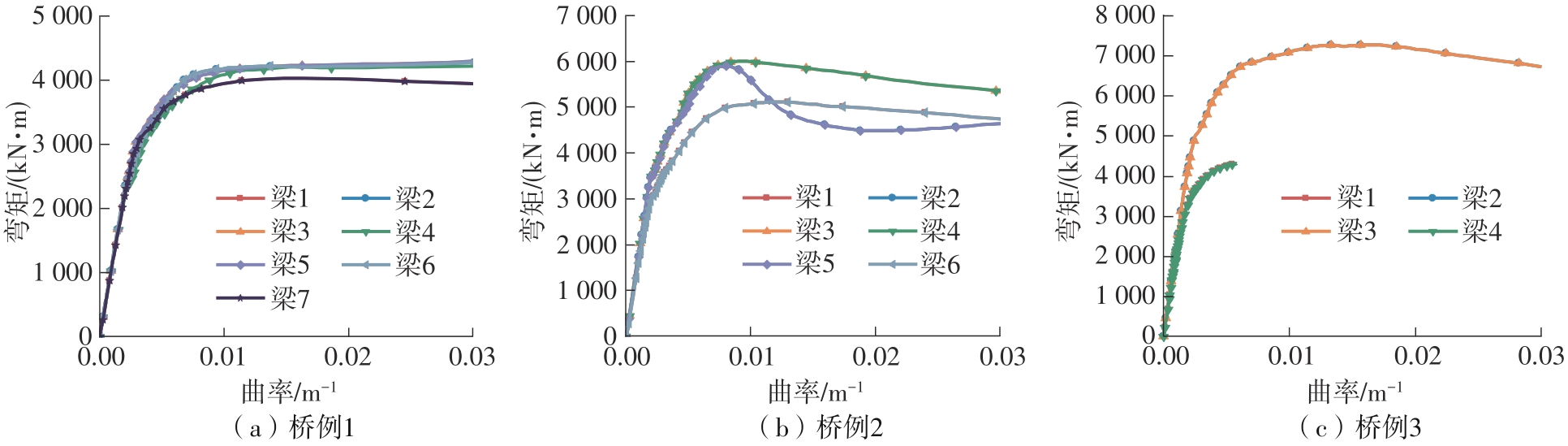

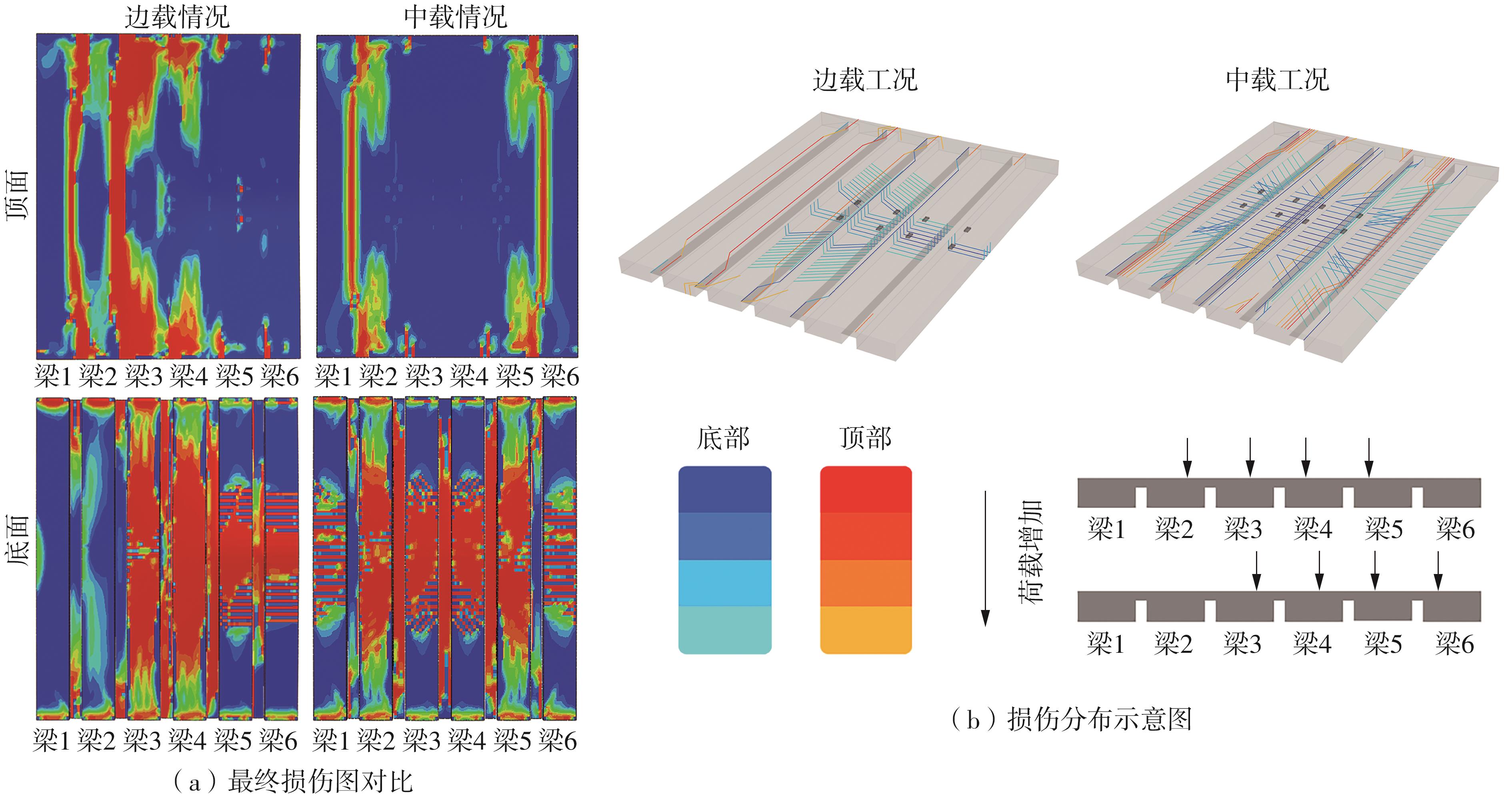

为研究新型分离式实心板梁桥的全过程受力性能,以主梁净距、主梁数目和预应力筋配置情况等为关键参数,基于ABAQUS有限元软件平台对该桥梁体系开展非线性数值分析,探究分离式实心板梁桥从施工、运营到加载破坏的损伤演变及失效模式。结果表明:主梁破坏与主梁-桥面板组合破坏为分离式实心板梁桥结构的两类主要破坏模式。当主梁净距较小时,全桥各梁变形基本一致,承载能力较高,易发生主梁破坏;反之,主梁净距较大时,桥梁横向传力性能较弱,不同主梁之间存在变形滞后现象,易发生主梁-桥面板组合破坏。对于相近桥宽和跨径的分离式实心板梁桥,主梁间距过大不利于横向协同受力,全桥承载能力会降低约40%~50%;主梁数目较少的桥例可通过增加预应力筋配置数量来改善承载性能,单梁承载力提高幅度可达10%~30%,但预制阶段的上拱问题在设计中应予以重视。与一次浇筑整体式梁桥相比,该组合梁桥体系全过程受力分析所得的位移和应力响应历程有所区别,但极限承载能力差异较小。总体而言,新型分离式实心板梁桥具有良好的承载和变形能力,且自重小、建筑高度低、施工便捷,在国内具有良好的应用前景。

中图分类号: