华南理工大学学报(自然科学版) ›› 2024, Vol. 52 ›› Issue (1): 26-37.doi: 10.12141/j.issn.1000-565X.220840

连续钢梁SFRC组合桥面板的优化设计

徐晨1 许琴东1 孙旭霞2 吴用贤2 张玉彬3 徐艺1

- 1.同济大学 土木工程学院, 上海 200092

2.同济大学建筑设计研究院(集团)有限公司, 上海 200092

3.兴泰建设集团有限公司, 内蒙古 呼和浩特 010000

Optimal Design of Steel-SFRC Composite Deck of Continuous Steel Girder

XU Chen1 XU Qindong1 SUN Xuxia2 WU Yongxian2 ZHANG Yubin3 XU Yi1

- 1.College of Civil Engineering,Tongji University,Shanghai 200092,China

2.Tongji Architectural Design (Group) Co. ,Ltd. ,Shanghai 200092,China

3.Xingtai Construction Group Co. ,Ltd. ,Hohhot 010000,Inner Mongolia,China

摘要:

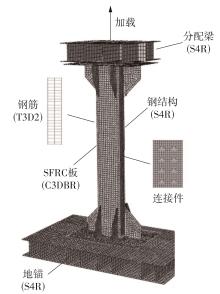

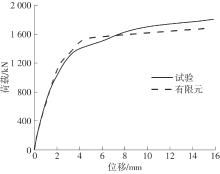

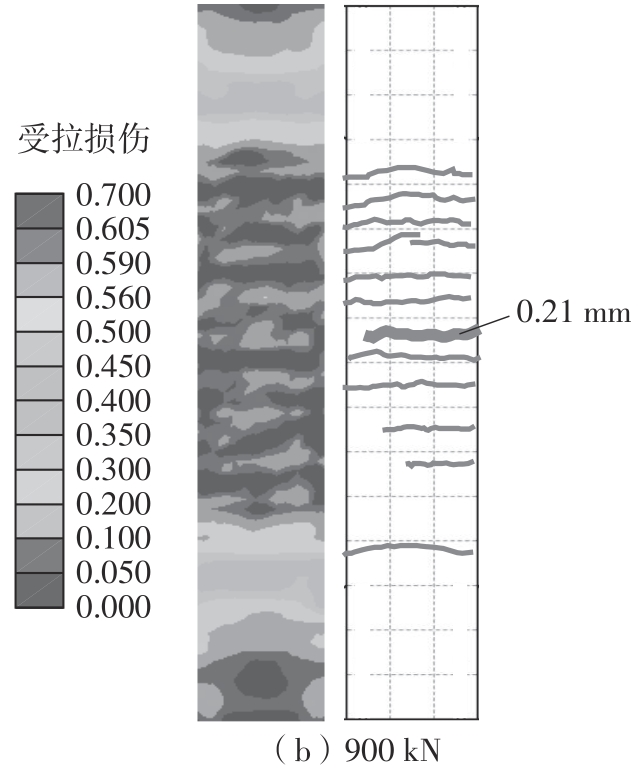

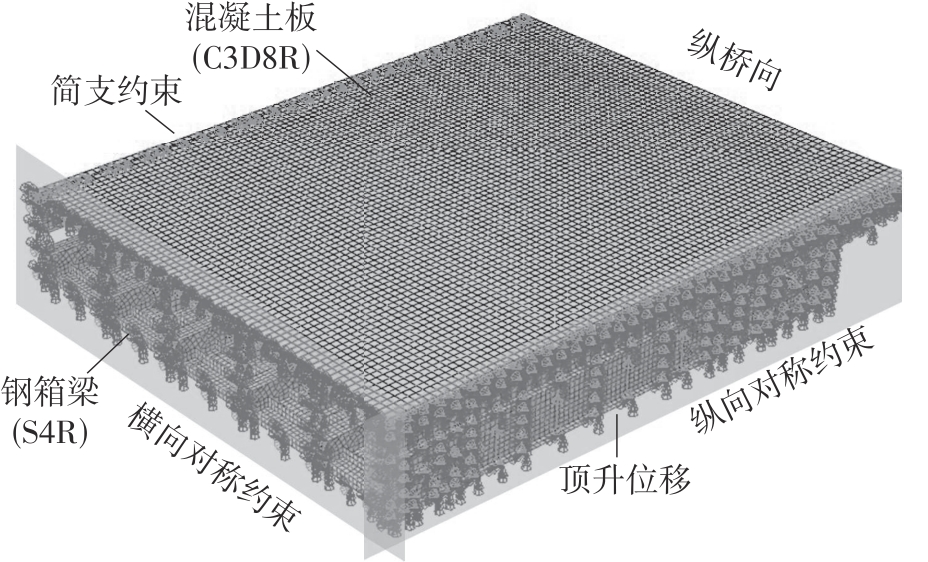

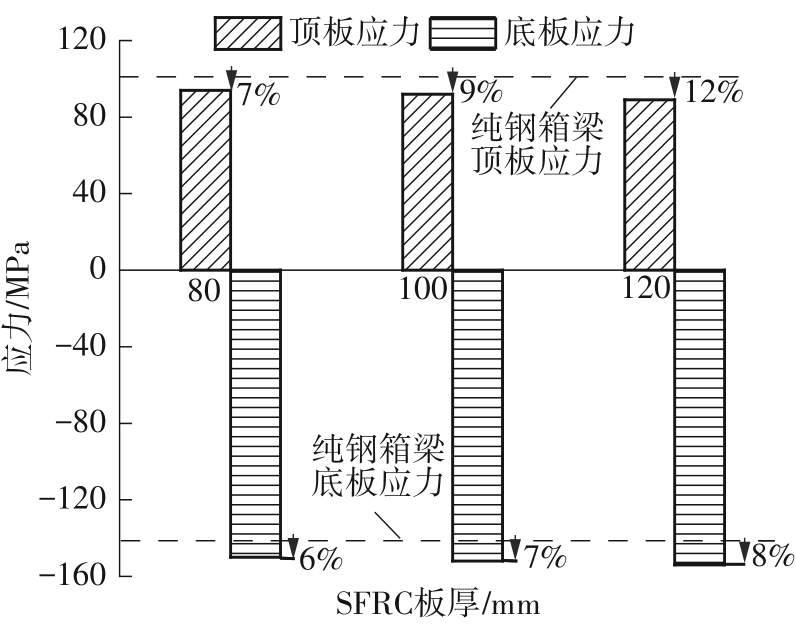

为探究中大跨径连续钢梁钢纤维混凝土(SFRC)组合桥面板优化设计方法,研究结合SFRC组合板偏拉试验与数值模拟所得SFRC受拉开裂特性,依据现有连续钢梁构造特点,采用SFRC代替原设计中C50混凝土铺装,通过Abaqus建立SFRC组合桥面板钢箱梁节段模型进行参数分析,考察了SFRC板厚、钢顶板厚、配筋率对主梁抗弯刚度、钢结构应力影响的特点。在此基础上以主梁弹性抗弯刚度和关键截面应力为约束条件,以上部结构自重与材料成本为优化目标,对中跨50 m和80 m连续钢梁进行优化。最后依据变量优化结果,采用Midas建立考虑负弯矩区SFRC开裂的杆系模型来验证优化结果的合理性。结果表明:文中引入材料塑性损伤的有限元分析方法具有可靠性,所建立的SFRC裂缝宽度与受拉损伤因子关系可以表征SFRC开裂状态。连续钢梁上80~120 mm厚SFRC层参与受力后使主梁弹性抗弯刚度提升17%~24%,当SFRC裂缝宽度达0.20 mm时,主梁抗弯刚度折减13%~20%;钢顶板应力降低7%~12%,主梁负弯承载力无明显变化。增大顶板厚度与配筋率均可有效改善钢顶板应力。对SFRC层厚、配筋率、钢顶板与顶板加劲肋尺寸进行优化分析,结果表明:相比原设计,优化后的50 m和80 m SFRC组合桥面板连续钢梁用钢量分别降低13%与6%,上部结构自重分别减小12%与6%,材料的成本分别降低14%与9%,该优化设计流程与优化结果可为SFRC组合桥面板在连续钢梁中推广应用提供参考。

中图分类号: