Journal of South China University of Technology(Natural Science) >

Shelf Layout and Equipment Configuration Strategy of Four-Way Shuttle Stereoscopic Warehouse

Received date: 2024-06-24

Online published: 2024-09-23

Supported by

the Ministry of Education Supply and Demand Matching Employment Education Project(20230106827);the Natural Science Foundation of Gansu Province(20JR5RA396);the Blue Dot Distributed Intelligent Computing Project of China University Innovation Fund(2021LDA07002);the Gansu Provincial Education Department 2023 Innovation and Entrepreneurship Education Model Course for Colleges and Universities (202306)

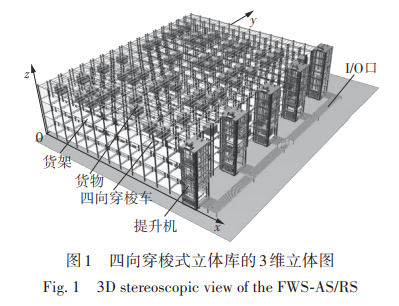

Four-way Shuttle Automated Storage and Retrieval System (FWS-AS/RS) is a storage form widely used in industries such as e-commerce, pharmaceuticals, and food in recent years. It has the characteristics of flexible system configuration, high storage density, high efficiency, and high automation. To efficiently design the shelves layout and equipment configuration of FWS-AS/RS, this paper firstly considered the possibility of arranging shelf rows, columns, and layers under different storage scales and discussed the impact of changes in horizontal aisle layout position and quantity as well as different shelf depths on operational efficiency. Then, taking the different configurations of shuttle cars and lifts as well as the different placement positions of lifts and input/output (I/O) ports as variables, it established the motion models of shuttle cars and lifts considering acceleration, deceleration, no-load, load energy consumption, and energy recovery during braking; it used the total cost, transport distance, energy consumption, and space utilization rate as evaluation indicators. Through simulation experiments, regular design strategies were obtained for constructing four-way shuttle style stereoscopic warehouse shelves, including row, column, layer, depth, tunnel position, number and position of I/O ports, the ratio of four-way shuttle cars (FWS) to lifts, and the relationship between lifts and longitudinal tunnels. Finally, taking a storage capacity of 5 000 as an example, the study applied these strategies to design simulation. The simulation results show that the three optimization schemes reduced the transport distance, energy consumption, total cost, and floor area by an average of 43.30%, 57.69%, 11.17%, and 8.60%, while increasing the space utilization rate by an average of 5.66%, thus verifying the correctness of the design strategy. The design strategy can provide reference for the construction and operation of such stereoscopic warehouses.

LI Jianguo , GONG Xincheng . Shelf Layout and Equipment Configuration Strategy of Four-Way Shuttle Stereoscopic Warehouse[J]. Journal of South China University of Technology(Natural Science), 2025 , 53(3) : 68 -79 . DOI: 10.12141/j.issn.1000-565X.240327

| 1 | VAUGHAN T S, PETERAEN C G . The effect of warehouse cross aisles on order picking efficiency[J]. International Journal of Production Research, 1999, 37( 4): 881- 897. |

| 2 | EKREN B Y, KAYA B, Kü?üKYA?AR M . Shuttle-based storage and retrieval systems designs from multi-objective perspectives:total investment cost,throughput rate and sustainability[J]. Sustainability, 2023, 15: 762/1- 16. |

| 3 | BATTARRA I, ACCORSI R, MANZINI R, et al . Hybrid model for the design of a deep-lane multisatellite AVS/RS[J]. The International Journal of Advanced Manufacturing Technology, 2022, 121: 1191- 1217. |

| 4 | MAROLT J, KOSANI? N, LERHER T . Relocation and storage assignment strategy evaluation in a multiple-deep tier captive automated vehicle storage and retrieval system with undetermined retrieval sequence[J]. The International Journal of Advanced Manufacturing Technology, 2022, 118: 3403- 3420. |

| 5 | ROODBERGEN K J, VIS I F A, TAYLOR G D . Simultaneous determination of warehouse layout and control policies[J]. International Journal of Production Research, 2015, 53( 11): 3306- 3326. |

| 6 | MARCHET G, MELACINI M, PEROTTI S, et al . Development of a framework for the design of autonomous vehicle storage and retrieval systems[J]. International Journal of Production Research, 2013, 51( 14): 4365- 4387. |

| 7 | BORTOLINI M, FACCIO M, FERRARI E, et al . Design of diagonal cross-aisle warehouses with class-based storage assignment strategy[J]. International Journal of Advanced Manufacturing Technology, 2019, 100: 2521- 2536. |

| 8 | 张志勇, 王琴, 梁艳 . 仓库内部布局的双叶Leaf方法及其通道角度优化[J]. 系统工程, 2019, 37( 2): 70- 80. |

| ZHANG Zhi-yong, WANG Qin, LIANG Yan . Twin leaf method for warehouse internal layout and its aisles angle optimization[J]. Systems Engineering, 2019, 37( 2): 70- 80. | |

| 9 | 祝凌瑶, 周丽 . 现代仓储中心存储布局的优化研究[J]. 工程数学学报, 2022, 39( 6): 862- 874. |

| ZHU Lingyao, ZHOU Li . Study on storage layout optimization of modern warehouse center[J]. Chinese Journal of Engineering Mathematics, 2022, 39( 6): 862- 874. | |

| 10 | YAN Q, LU J S, SHAO Y P, et al . A scheduling optimization method for stacker path in double-ended compact storage system[J]. Advances in Mechanical Engineering, 2023, 15( 2): 1- 14. |

| 11 | ALNAHHAL M, SALAH B, AHMAD R . Increasing throughput in warehouses:the effect of storage reallocation and the location of input/output station[J]. Sustainability, 2022, 14: 4611/1- 16. |

| 12 | SONG Y B, MU H B . Integrated optimization of input/output point assignment and twin stackers scheduling in multi-input/output points automated storage and retrieval system by ant colony algorithm[J]. Mathematical Pro-blems in Engineering, 2022, 2022: 5997095/1- 18. |

| 13 | HAO J J, YU Y G, ZHANG L L . Optimal design of a 3D compact storage system with the I/O port at the lower mid-point of the storage rack[J]. International Journal of Production Research, 2015, 53( 17): 5153- 5173. |

| 14 | HU M H, CHEN M C, KU M Y . Storage location assignment and I/O location design on storage planning[J]. International Journal of Information Systems and Supply Chain Management, 2016, 9( 4): 43- 57. |

| 15 | YAN Q, LU J S, TANG H T, et al . Travel time analysis and dimension optimisation design of double-ended compact storage system[J]. International Journal of Production Research, 2023, 61( 20): 6718- 6745. |

| 16 | 王晓军, 王博, 晋民杰, 等 . AutoStore仓储系统资源配置仿真与优化[J]. 计算机仿真, 2022, 39( 5): 480- 487,503. |

| WANG Xiao-jun, WANG Bo, JIN Min-jie, et al . Simulation and Optimization of Resource Allocation in Auto Store Storage System[J]. Computer Simulation, 2022, 39( 5): 480- 487,503. | |

| 17 | 姚道金, 殷雄, 罗真, 等 . 复杂环境下AGVS路径规划算法[J]. 华南理工大学学报(自然科学版), 2023, 51( 11): 56- 62. |

| YAO Daojin, YIN Xiong, LUO Zhen, et al . AGVS path planning agorithm in complex environments[J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51( 11): 56- 62. | |

| 18 | RAGHURAM P, ARJUNAN M K . Design framework for a lean warehouse:a case study-based approach[J]. International Journal of Productivity and Performance Management, 2022, 71( 6): 2410- 2431. |

| 19 | WU Y, ZHOU C, MA W, et al . Modelling and design for a shuttle-based storage and retrieval system[J]. International Journal of Production Research, 2020, 58( 16): 4808- 4828. |

| 20 | ZHAO N, LOU L, ZHANG S P, et al . An efficient simulation model for rack design in multi-elevator shuttle-based storage and retrieval system[J]. Simulation Mo-delling Practice and Theory, 2016, 67: 100- 116. |

| 21 | MA Y F, HU Y N, YANG X J, et al . Optimal lift scheduling in modular warehouse systems[J]. System Engineering Theory and Practice, 2023, 43( 11): 3307- 3319. |

| 22 | ZHAO Q X, ZHANG X D, WANG P . Multi-type equipment selection and quantity decision optimization in intelligent warehouse[J]. IEEE Access, 2024, 12: 63515- 63527. |

/

| 〈 |

|

〉 |