Journal of South China University of Technology(Natural Science Edition) ›› 2025, Vol. 53 ›› Issue (5): 45-55.doi: 10.12141/j.issn.1000-565X.240397

• Mechanical Engineering • Previous Articles Next Articles

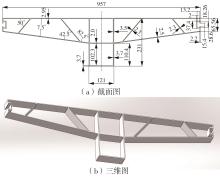

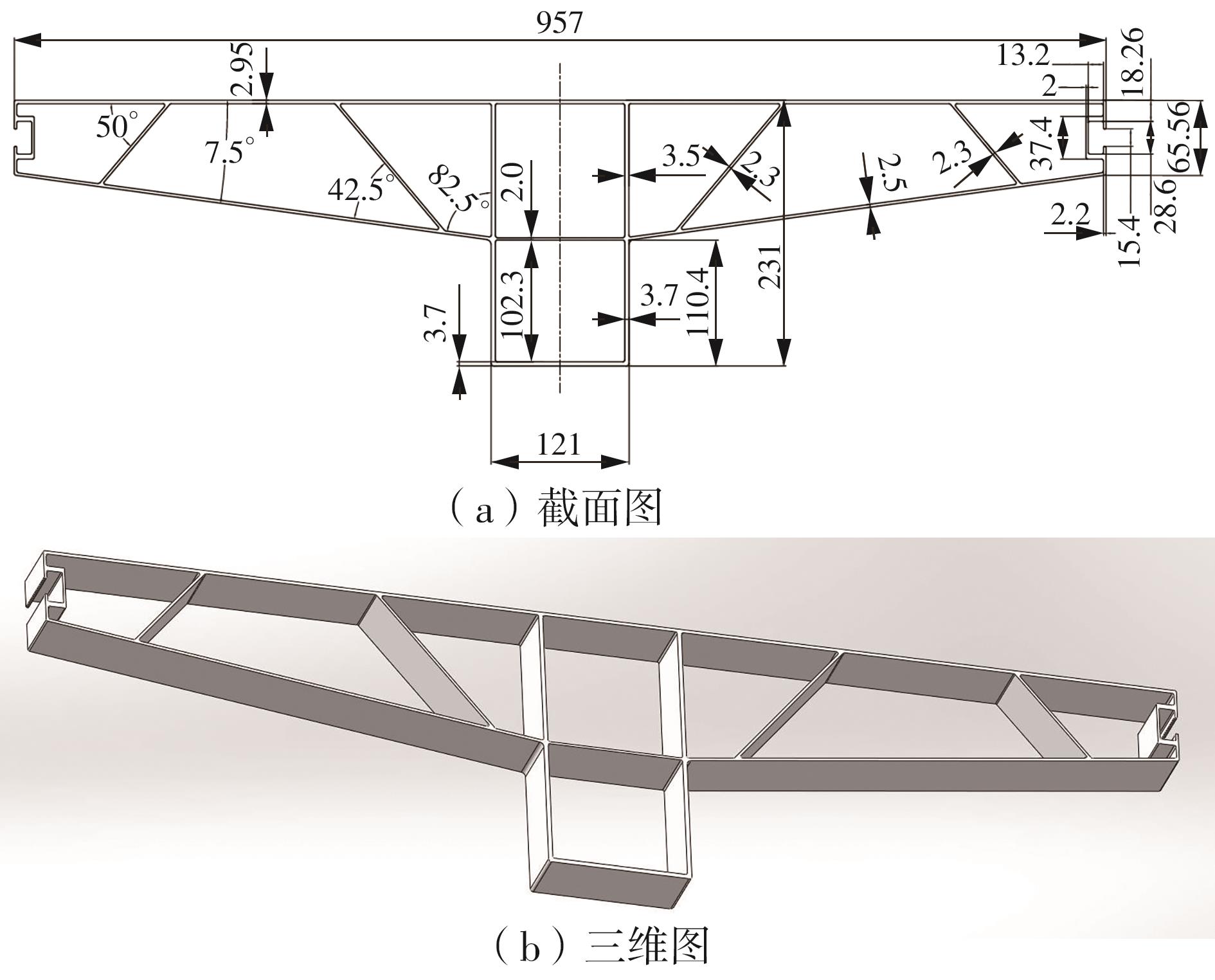

Analysis of Extrusion Law of Large-Scale and Small-Scale Aluminum Profiles with Hollow Thin Wall for Rails

LIU Guoyong, GAO Shize, ZHU Dongmei

- School of Mechanical Engineering,University of Science and Technology Beijing,Beijing 100083,China

-

Received:2024-08-04Online:2025-05-25Published:2024-10-25 -

About author:刘国勇(1969—),男,博士,副教授,主要从事多物理场耦合建模与优化、机械装备力学行为研究。E-mail: gy_liu666@ustb.edu.cn -

Supported by:the Key Field Research and Development Plan of Guangdong Province(2020B010186002)

CLC Number:

Cite this article

LIU Guoyong, GAO Shize, ZHU Dongmei. Analysis of Extrusion Law of Large-Scale and Small-Scale Aluminum Profiles with Hollow Thin Wall for Rails[J]. Journal of South China University of Technology(Natural Science Edition), 2025, 53(5): 45-55.

share this article

Table1

Verification results of grid independence for large-scale aluminum profile"

| 方案 | 网格数 | 网格最小尺寸与特征尺寸之比 | 最大变形/mm | 最大变形误差/% | 最高流速/(mm·s-1) | 最大流速误差/% |

|---|---|---|---|---|---|---|

| a | 2 751 578 | 0.300 | 42.16 | 0.28 | 59.55 | 9.21 |

| b | 3 050 509 | 0.275 | 42.11 | 0.17 | 57.27 | 5.02 |

| c | 3 483 596 | 0.250 | 42.02 | 0.05 | 54.52 | 0.02 |

| d | 4 169 856 | 0.225 | 42.04 | 0.00 | 54.54 | 0.02 |

| e | 4 789 498 | 0.200 | 42.04 | 0.00 | 54.53 | 0.00 |

| f | 5 837 692 | 0.175 | 42.04 | 0.00 | 54.53 | 0.00 |

| 1 | 冯林威,王春海,齐金星 .轨道交通用大型特种铝型材生产工艺研究[J].世界有色金属,2016(4):23-5. |

| FENG Linwei, WANG Chunhai, QI Jinxing .Study on the production process of large special aluminum profiles for rail transit[J].World Nonferrous Metals,2016(4):23-25. | |

| 2 | 吴博 .轨道交通用宽幅薄壁加筋板挤压型材的生产制备技术[J].铝加工,2024(4):54-58. |

| WU Bo .Production and preparation technology of extruded profiles with wide thin wall ribbed panel for rail transit[J].Aluminium Fabrication,2024(4):54-58. | |

| 3 | 王刚,王明坤 .轨道交通用铝合金挤压型材的发展现状[J].世界有色金属,2016(10):23-25. |

| WANG Gang, WANG Mingkun .Development status of aluminum alloy extruded profiles for rail transit[J].World Nonferrous Metals,2016(10):23-25. | |

| 4 | 吴海旭,杨丽,王周兵,等 .我国轨道交通车辆用铝型材发展现状[J].轻合金加工技术,2014,42(1):18-20,33. |

| WU Hai-xu, YANG Li, WANG Zhou-bing,et al .Development status of aluminum profiles applied on China’s rail vehicle[J].Light Alloy Fabrication Technology,2014,42(1):18-20,33. | |

| 5 | ZHAO H, WANG H, WANG M,et al .Simulation of extrusion process of complicated aluminium profile and die trial[J].Transactions of Nonferrous Metals Society of China,2012,22(7):1732-1737. |

| 6 | FANG G, ZHOU J, DUSZCZYK J .FEM simulation of aluminium extrusion through two-hole multi-step pocket dies[J].Journal of Materials Processing Technology,2009,209(4):1891-1900. |

| 7 | CHEN Y P, DENG Y W, ZHANG G H .A extrusion die structure with four cavities in a die of Al-alloy screen frame[J].Journal of Physics:Conference Series,2021,1939(1):012009/1-6. |

| 8 | PENG Z, SHEPPARD T .Simulation of multi-hole die extrusion[J].Materials Science & Engineering A,2003,367(1):329-342. |

| 9 | SAHA P K .Thermodynamics and tribology in aluminum extrusion[J].Wear,1998,218(2):179-190. |

| 10 | 钟建华,袁志燕,刘艳霞 .基于Altair HyperXtrude的空心铝型材挤压成型仿真模拟[J].上海有色金属,2015,36(4):167-172. |

| ZHONG Jianhua, YUAN Zhiyan, LIU Yanxia .The numerical simulation of solid aluminum profile extrusion based on Altair HyperXtrude[J].Shanghai Nonferrous Metals,2015,36(4):167-172. | |

| 11 | 孙有政,曹善鹏,李宾良,等 .反向挤压模具工作带对铝合金异型材变形的影响及其优化[J].材料导报,2023,37(S2):456-459. |

| SUN Youzheng, CAO Shanpeng, LI Binliang,et al .Analysis of reverse extrusion deformation and working belt optimization of aluminum alloy profile[J].Materials Reports,2023,37(S2):456-459. | |

| 12 | 王东 .6N01大型空心扁宽铝型材挤压流动分析及新型工模具优化设计[D].济南:山东大学,2017. |

| 13 | 张海超 .大型复杂铝合金型材挤压过程数值模拟与模具优化及热处理工艺研究[D].济南:山东大学,2021. |

| 14 | DONATI L, KHALIFA B N, TOMESANI L,et al .Effect of porthole design and welding chamber dimensions on material flow and weld deformability of extruded aluminium profiles[J].Key Engineering Materials,2012,1665(504/505/506):523-528. |

| 15 | JO H H, LEE S K, JUNG C S,et al .A non-steady state FE analysis of Al tubes hot extrusion by a porthole die[J].Journal of Materials Processing Technology,2005,173(2):223-231. |

| 16 | LIU G, ZHOU J, DUSZCZYK J .FE analysis of metal flow and weld seam formation in a porthole die during the extrusion of a magnesium alloy into a square tube and the effect of ram speed on weld strength[J].Journal of Materials Processing Technology,2007,200(1):185-198. |

| 17 | 傅建,彭必友,李军 .铝型材挤出速度对模具工作带的影响[J].塑性工程学报,2005,12(3):27-30. |

| FU Jian, PENG Biyou, LI Jun .Influence of exit velocity at the aluminum profile extrusion on the die land[J].Journal of Plasticity Engineering,2005,22(3):27-30. | |

| 18 | 唐妍 .不同挤压速度对铝型材挤压过程的影响[J].机械设计与制造工程,2013,42(9):58-61. |

| TANG Yan .The effects of different extrusion speed on the aluminum profile extrusion process[J].Machine Design and Manufacturing Engineering,2013,42(9):58-61. |

| [1] | MA Guonan, ZHANG Le, OU Yang, et al. Microstructure and Mechanical Properties of SiC Particle Reinforced AlMgScZr Composites by Selective Laser Melting [J]. Journal of South China University of Technology(Natural Science Edition), 2025, 53(1): 118-128. |

| [2] | DING Xiaobin, XIE Yuxuan, SHI Yu. Crack Extension Analysis of Rock-Like Material Based on the Improved Contact Model [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(8): 146-158. |

| [3] | LIU Xiumei, MA Xuemin, LI Beibei, et al. Simulated and Experimental Investigation into Coupled Wear of Cavitation and Erosion in Regulating Valves [J]. Journal of South China University of Technology(Natural Science Edition), 2024, 52(12): 109-118. |

| [4] | YU Mingquan, ZHAO Jiyun, MAN Jiaxiang, et al.. Study of Distribution Structure for High Water-Based Hydraulic Motor [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(9): 19-29. |

| [5] | LU Zhimin, LI Bohang, TANG Wen, et al. Optimization Simulation of Ammonia Injection in SCR DeNO x System of Coal-Fired Power Plant [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(8): 62-70. |

| [6] | LIU Dingping, ZHANG Xiangyang, CHEN Aihua, et al. Numerical Analysis of Performance of Cyclone-Tube Demister Based on Orthogonal Design [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(6): 89-96. |

| [7] | MA Xiangjun, WANG Zhen, YAO Zhiqiang, et al. Numerical Simulation on Melt Flow Characteristics of UHMWPE in Eccentric Rotor Extruder [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(5): 114-121. |

| [8] | DAI Gonglian, CHEN Kun, GE Hao, et al. Research on Numerical Simulation of Rail Non-contact Nondestructive Testing Technology [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(4): 44-52. |

| [9] | LI Shuxun, HU Yinggang, LI Cheng, et al. Optimization of Body Profile Line of Axial Flow Control Valve Based on Surrogate Model [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(3): 41-52. |

| [10] | LENG Sheng, FU Youwei, MA Wantai, et al. Study on the Morphology Control Technology of Spray Forming Ingot Billets Based on GA-BP Neural Network [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(2): 27-34. |

| [11] | TIAN Lifeng, GUO Meiqi, DING Hao, et al. On Aero-optical Effect and Control of Supersonic Boundary Layer [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(2): 137-146. |

| [12] | YU Mingquan, ZHAO Jiyun, MAN Jiaxiang, et al.. Study on Flow Distribution Mechanism of Low Speed High Torque Hydraulic Motor [J]. Journal of South China University of Technology(Natural Science Edition), 2023, 51(11): 101-109. |

| [13] | DU Jianming, FANG Qian , WANG Gan, et al. Characteristics of Transient Pressure and Pressure Gradient of a High-Speed Train Travelling Through a Double-Track Tunnel [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(9): 58-68. |

| [14] | GONG Nan, LI Peizhen, HE Xuming. Design of an Innovative Eddy Current Replaceable Coupling Beam and Its Numerical Analysis [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(7): 25-34. |

| [15] | DU Jianming, FANG Qian, LI Jianye. Influences of Train to Tunnel Area Ratio on Aerodynamic Pressure Characteristics of High-Speed Railway Tunnel Wall [J]. Journal of South China University of Technology(Natural Science Edition), 2022, 50(5): 56-64. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||