华南理工大学学报(自然科学版) ›› 2025, Vol. 53 ›› Issue (5): 1-10.doi: 10.12141/j.issn.1000-565X.240467

型腔恒负载加工的组合轨迹设计与进给速度优化

王清辉1, 王金强1, 丁雪松1, 廖昭洋2

- 1.华南理工大学 机械与汽车工程学院,广东 广州 510640

2.广东省科学院智能制造研究所 广东省现代控制技术重点实验室,广东 广州 510070

Hybrid Toolpath Planning and Feed Rate Optimization for Cavity Machining Under Constant Loads

WANG Qinghui1, WANG Jinqiang1, DING Xuesong1, LIAO Zhaoyang2

- 1.School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510640,Guangdong,China

2.Guangdong Key Laboratory of Modern Control Technology,Institute of Intelligent Manufacturing of Guangdong Academy of Sciences,Guangzhou 510070,Guangdong,China

摘要:

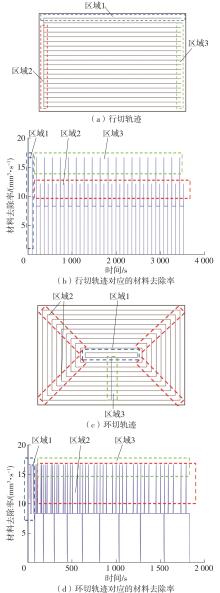

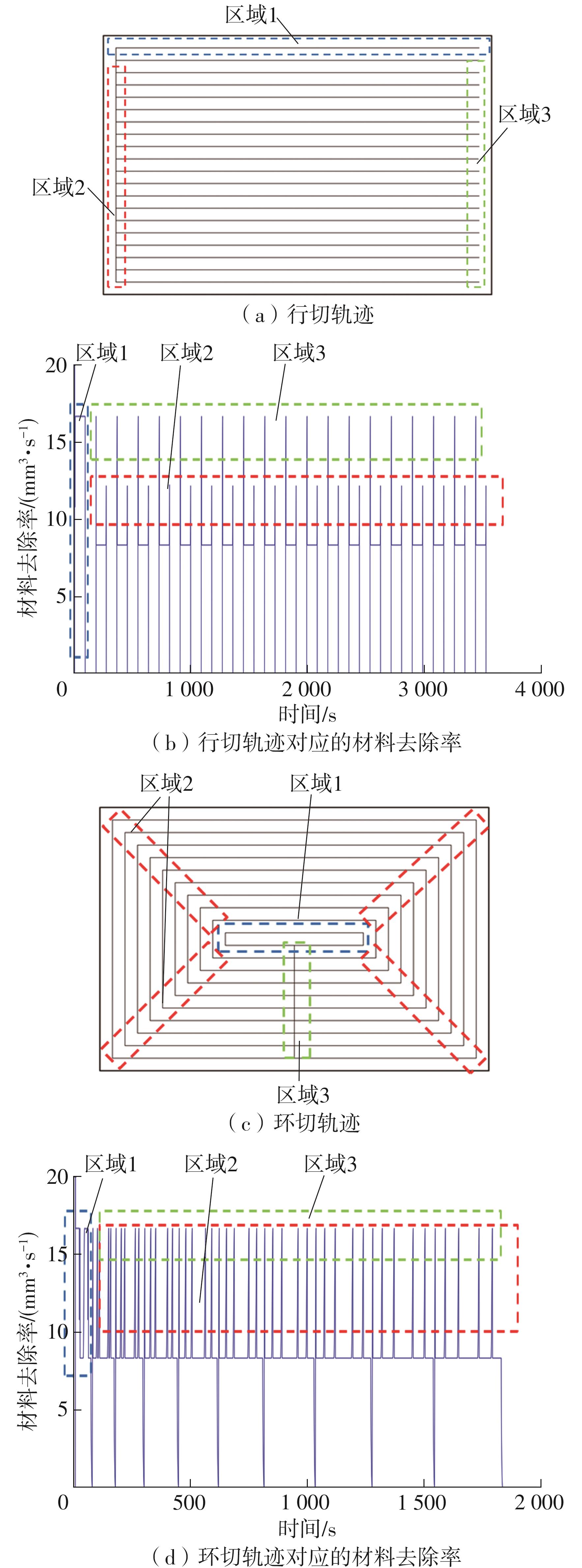

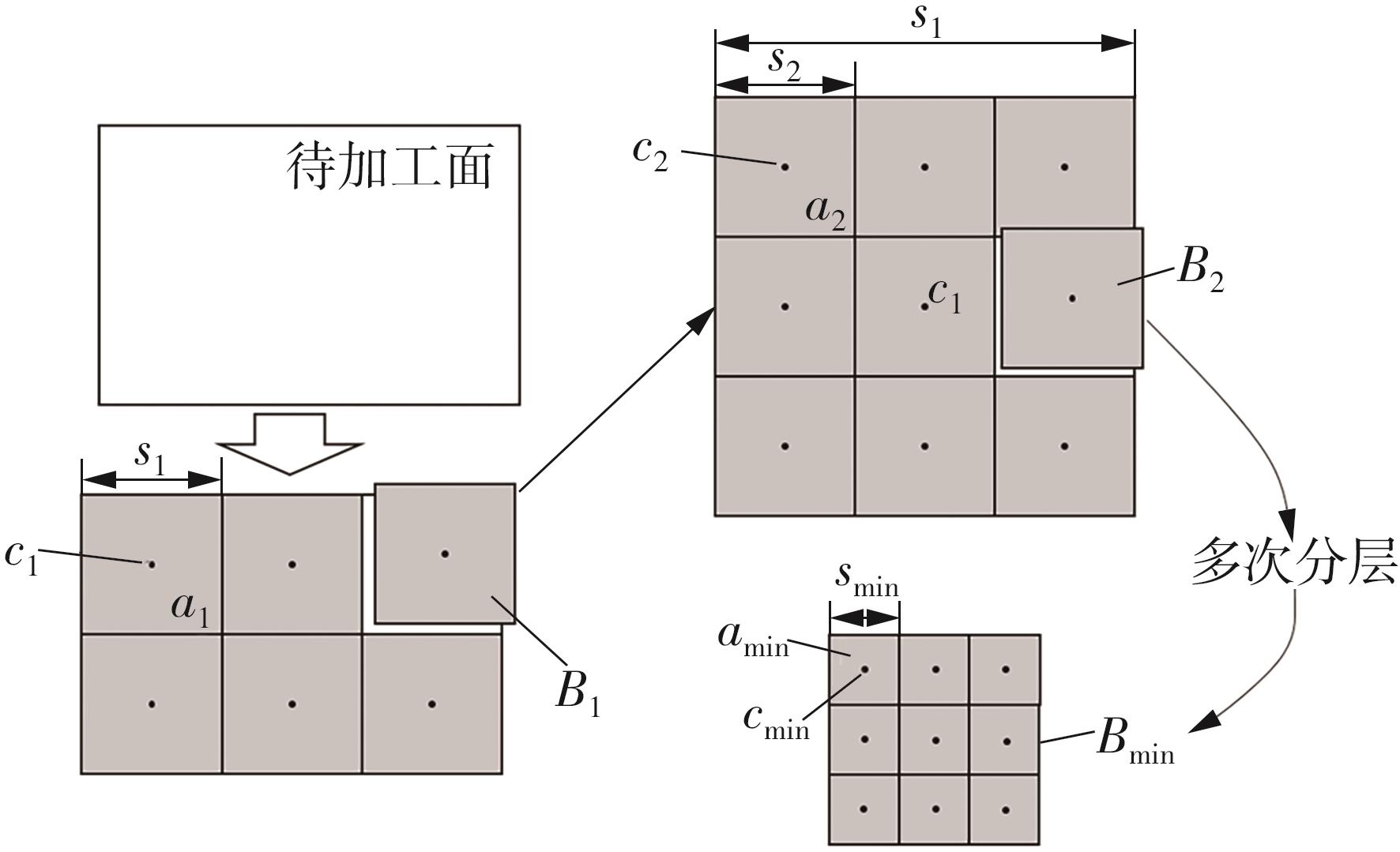

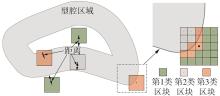

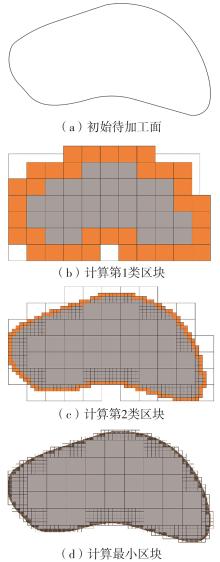

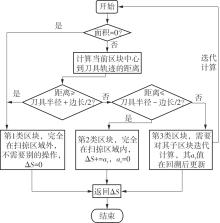

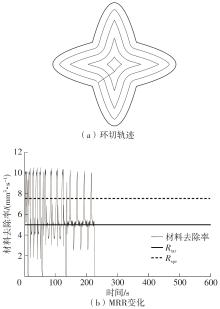

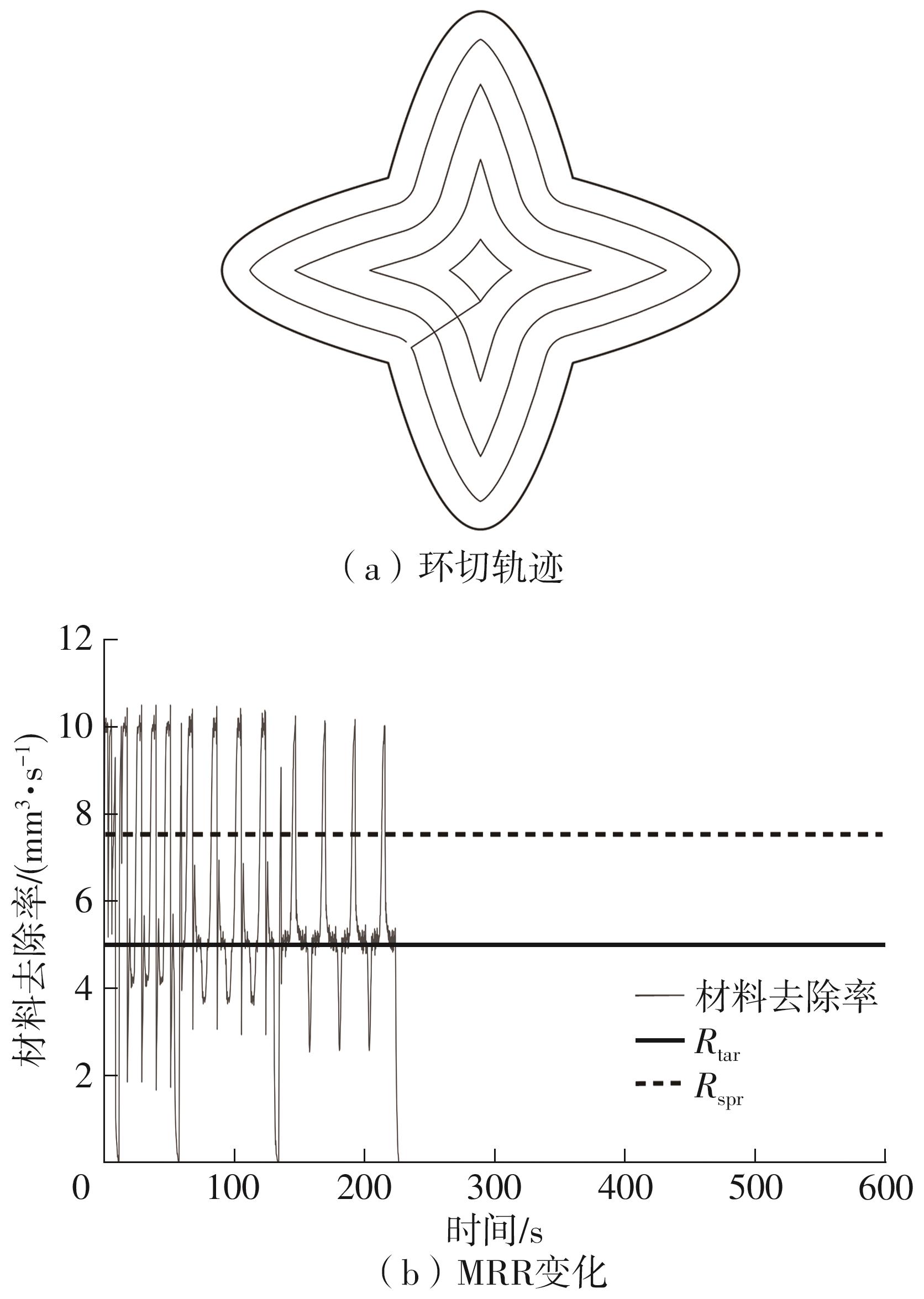

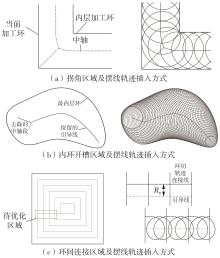

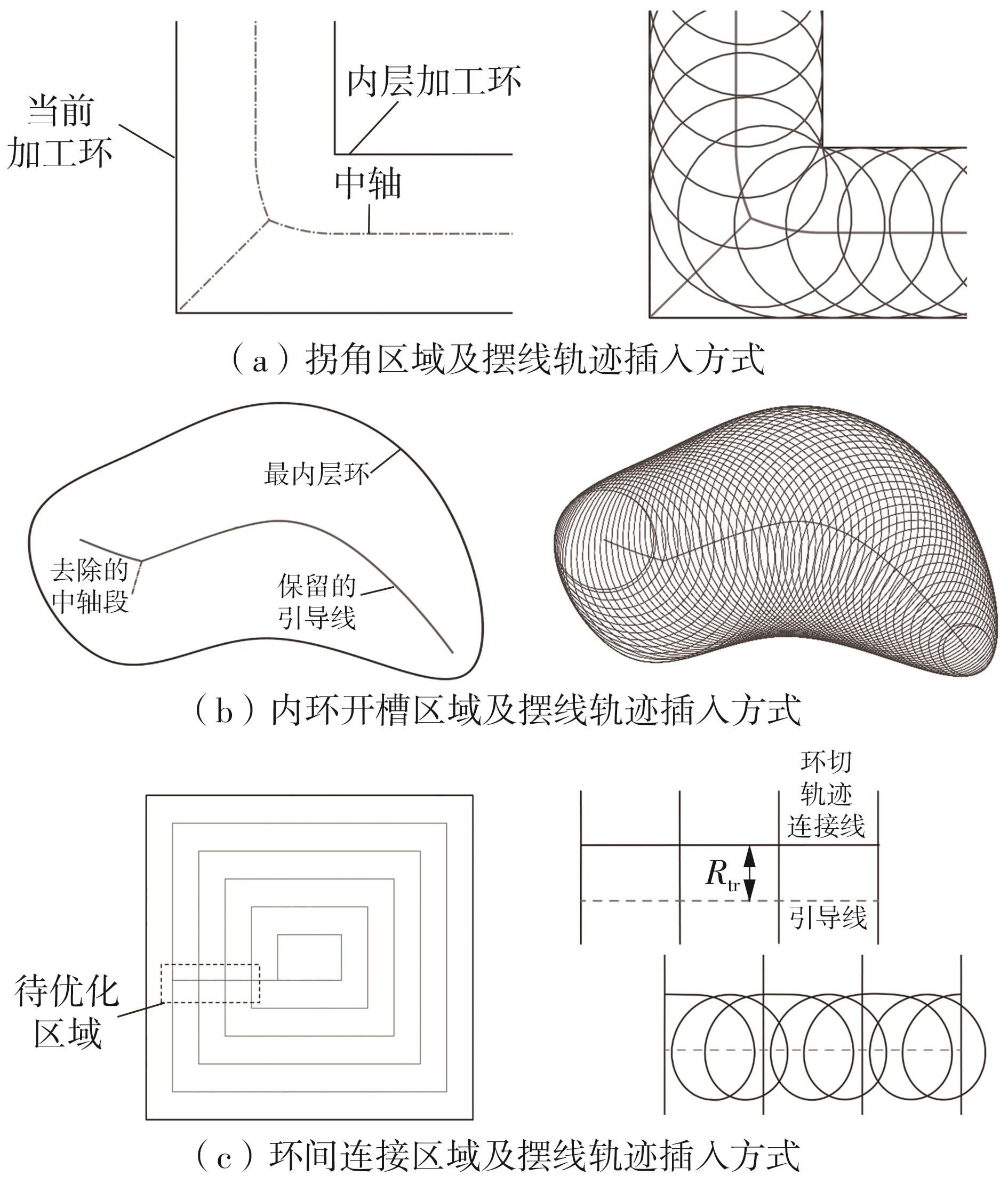

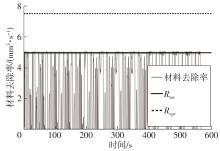

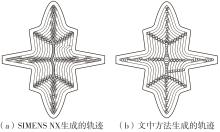

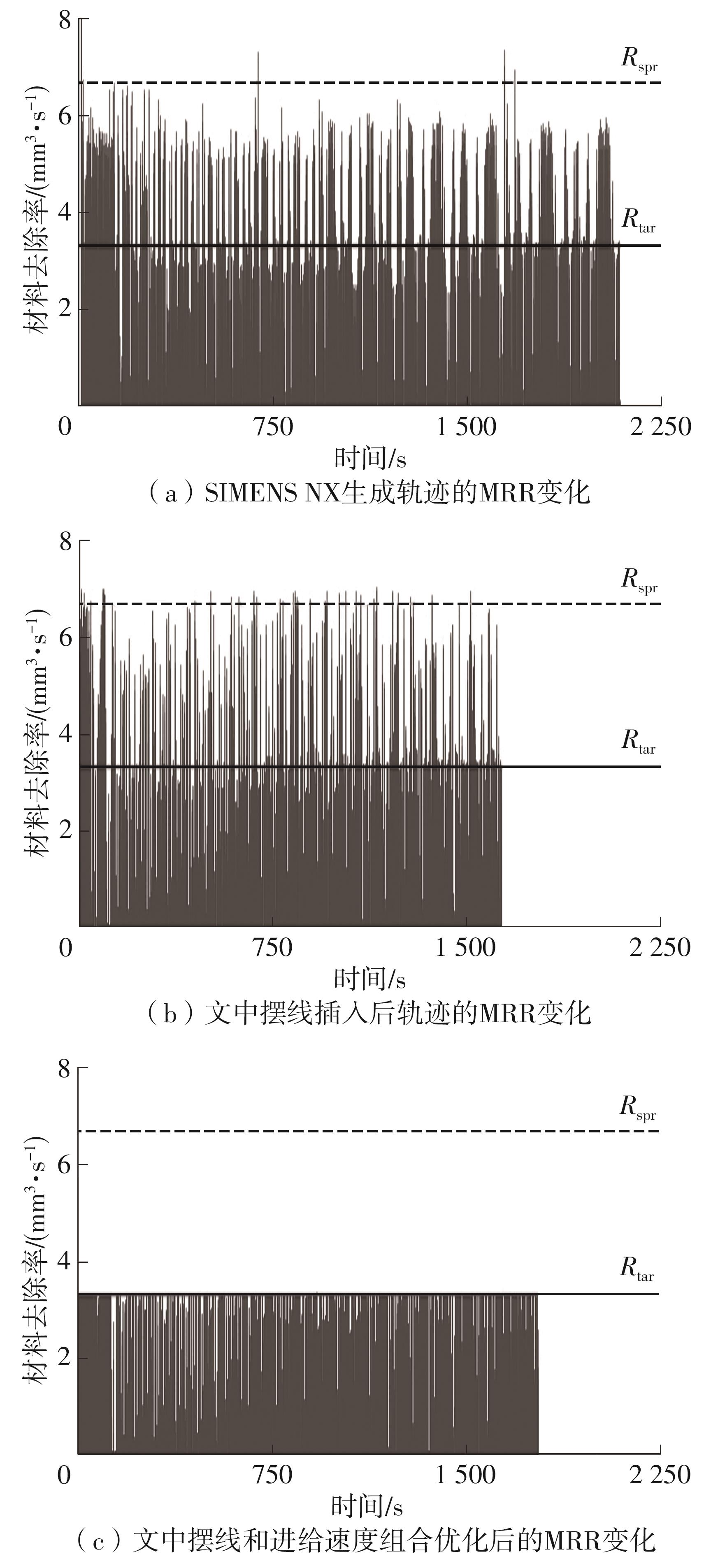

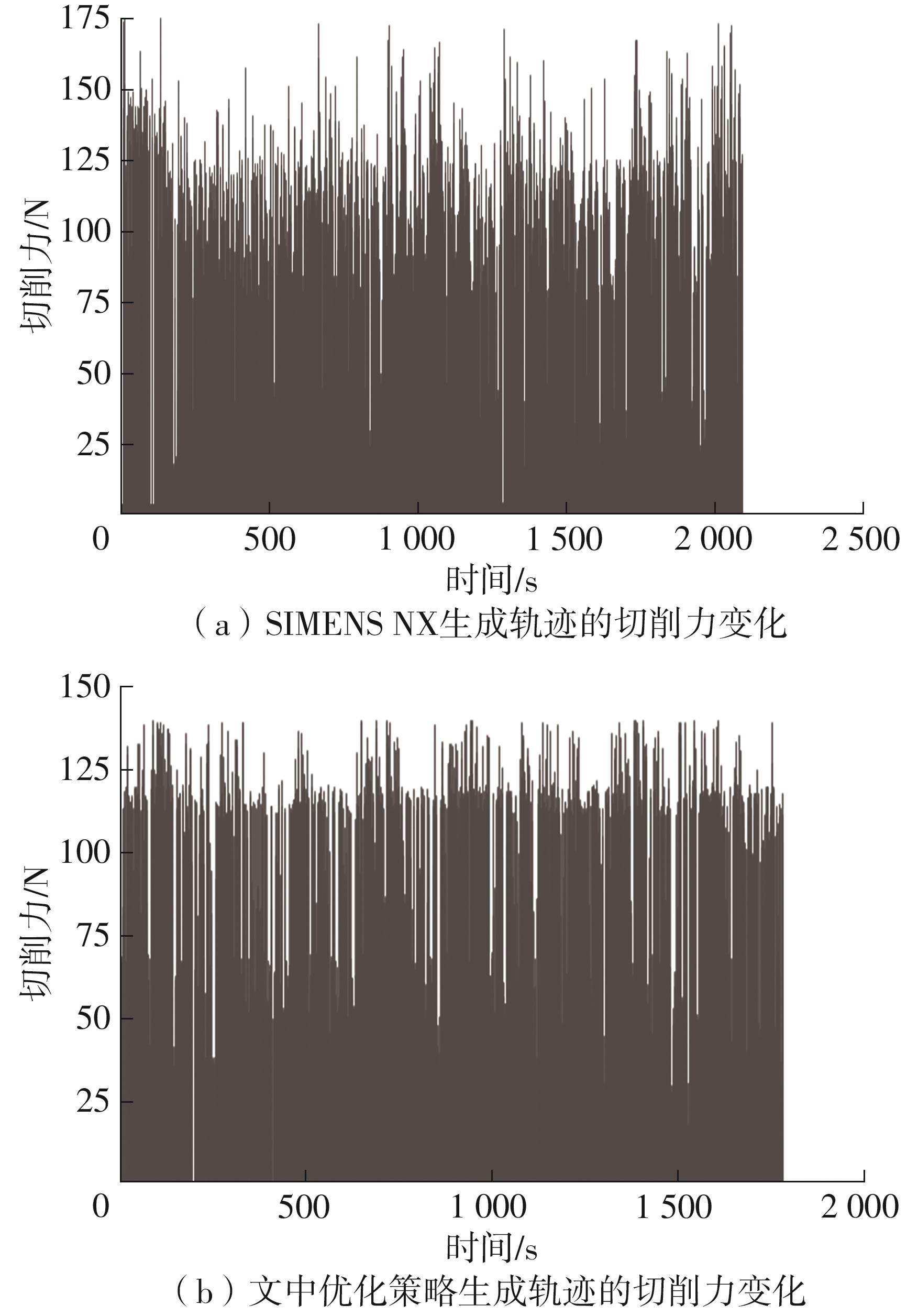

模具及各类三维零件的数控加工包含了大量型腔的加工,型腔加工轨迹的设计会直接影响加工质量与效率。随着高速铣削技术的进步,数控机床为提高型腔加工效率提供了硬件基础,但也对CAM轨迹设计提出了更高要求。传统的CAM轨迹在处理型腔拐角、开槽和加工内外环轨迹交汇等区域时,容易导致切削负载突变,这种负载不稳定性限制了进给速度和切削深度的提升,影响了加工效率和质量。鉴于此,该文提出了一种面向型腔恒负载加工的组合轨迹设计与进给速度优化方法。该方法基于多层次区块结构,首先计算材料去除率,并据此将加工区域划分为稳定、半稳定和负载突变区域。针对不同区域,采用环切轨迹、进给速度优化以及变半径摆线轨迹相结合的策略,实现加工过程中负载的平稳控制,特别是通过在负载突变区域应用摆线轨迹,降低了瞬时负载的波动,确保了加工过程的稳定性。实验结果表明,该文提出的轨迹设计与进给速度优化方法能够适应各类复杂型腔的CAM轨迹生成,并保障加工过程的负载稳定性,进而提高加工质量。

中图分类号: