华南理工大学学报(自然科学版) ›› 2024, Vol. 52 ›› Issue (5): 101-113.doi: 10.12141/j.issn.1000-565X.230116

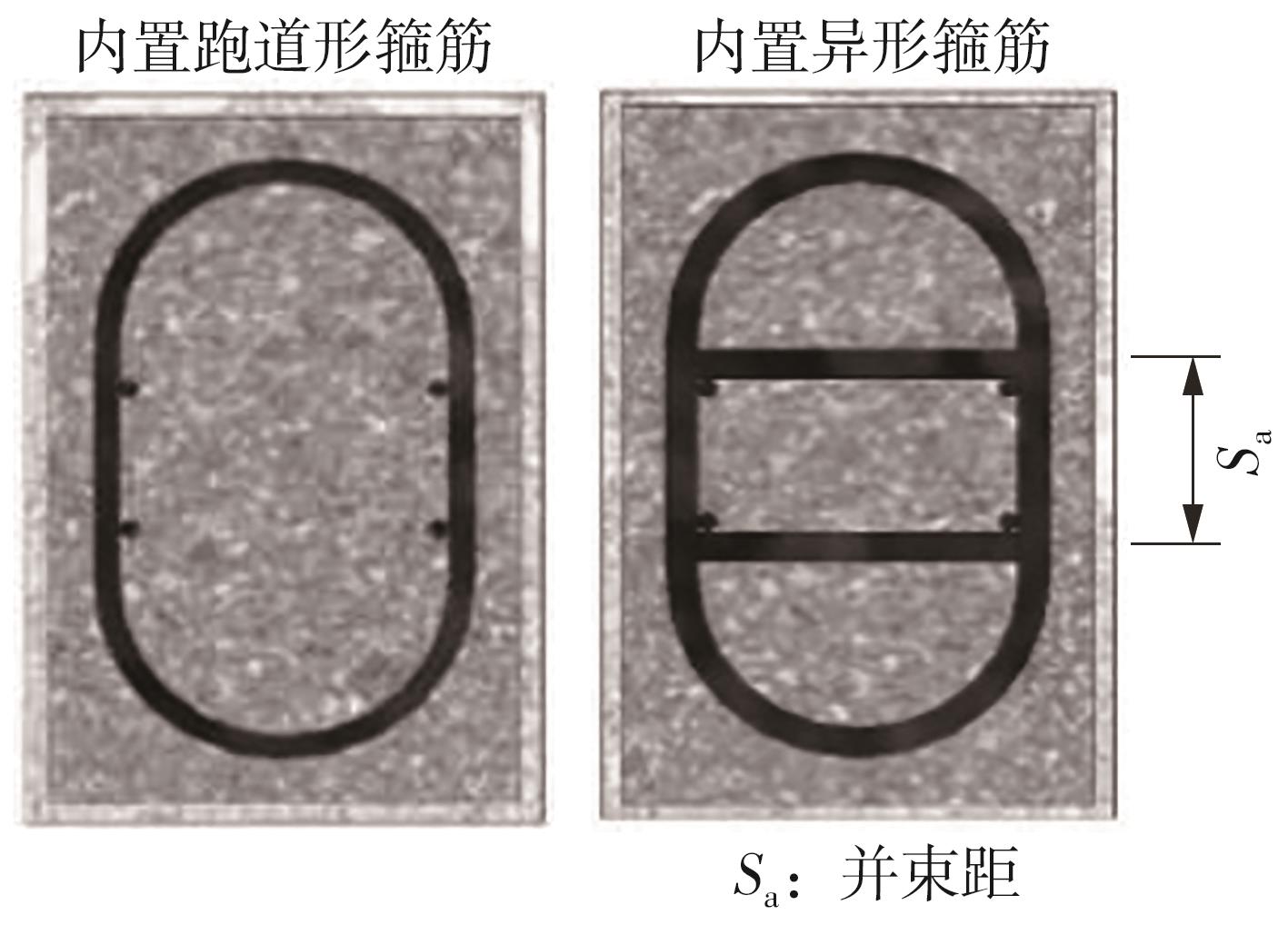

内置异形箍筋矩形钢管混凝土柱的轴压力学性能

- 华南理工大学 土木与交通学院/亚热带建筑与城市科学全国重点实验室,广东 广州 510640

Axial Compression Behavior of Rectangular Concrete-Filled Steel Tube Columns Reinforced by Built-In Profiled Stirrup

KANG Lan( ), CHEN Xuan, HONG Shutao

), CHEN Xuan, HONG Shutao

- School of Civil Engineering and Transportation/State Key Laboratory of Subtropical Building and Urban Science,South China University of Technology,Guangzhou 510640,Guangdong,China

摘要:

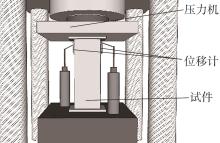

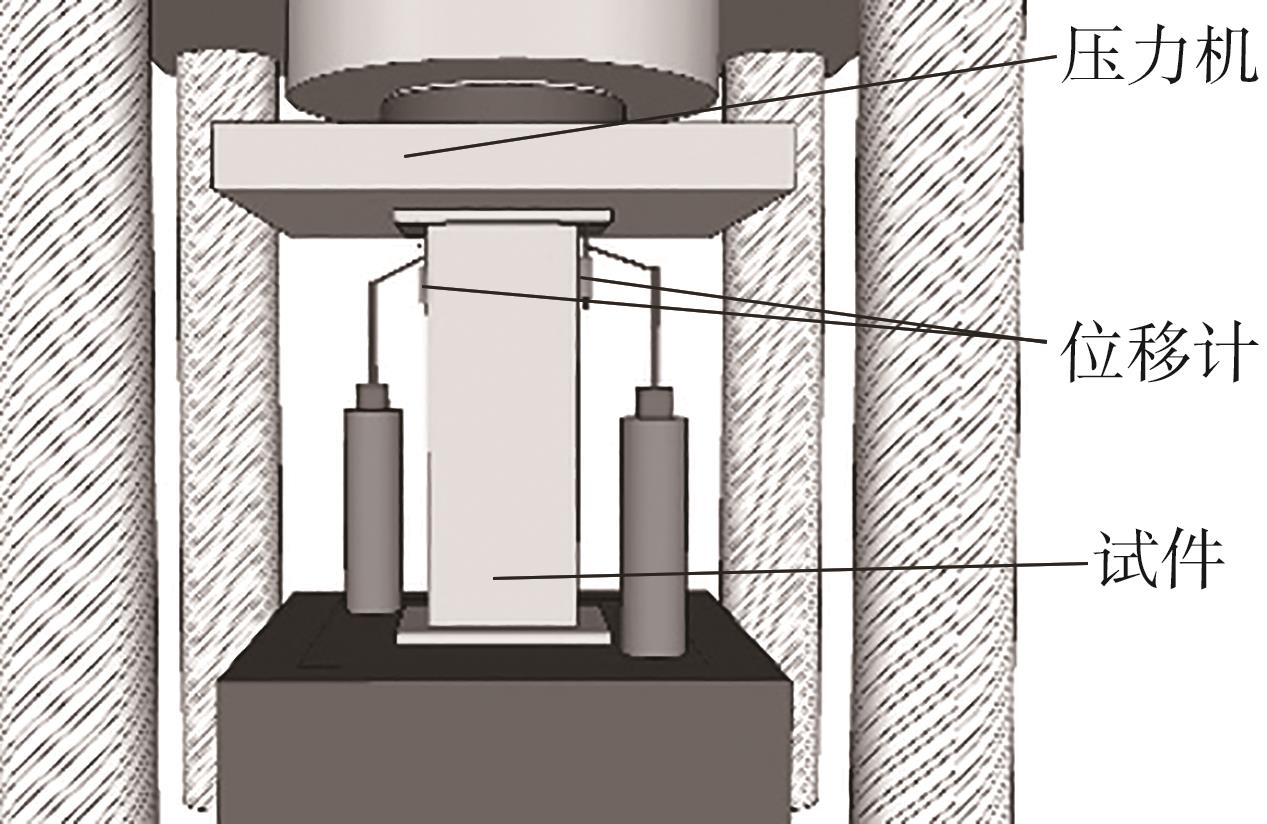

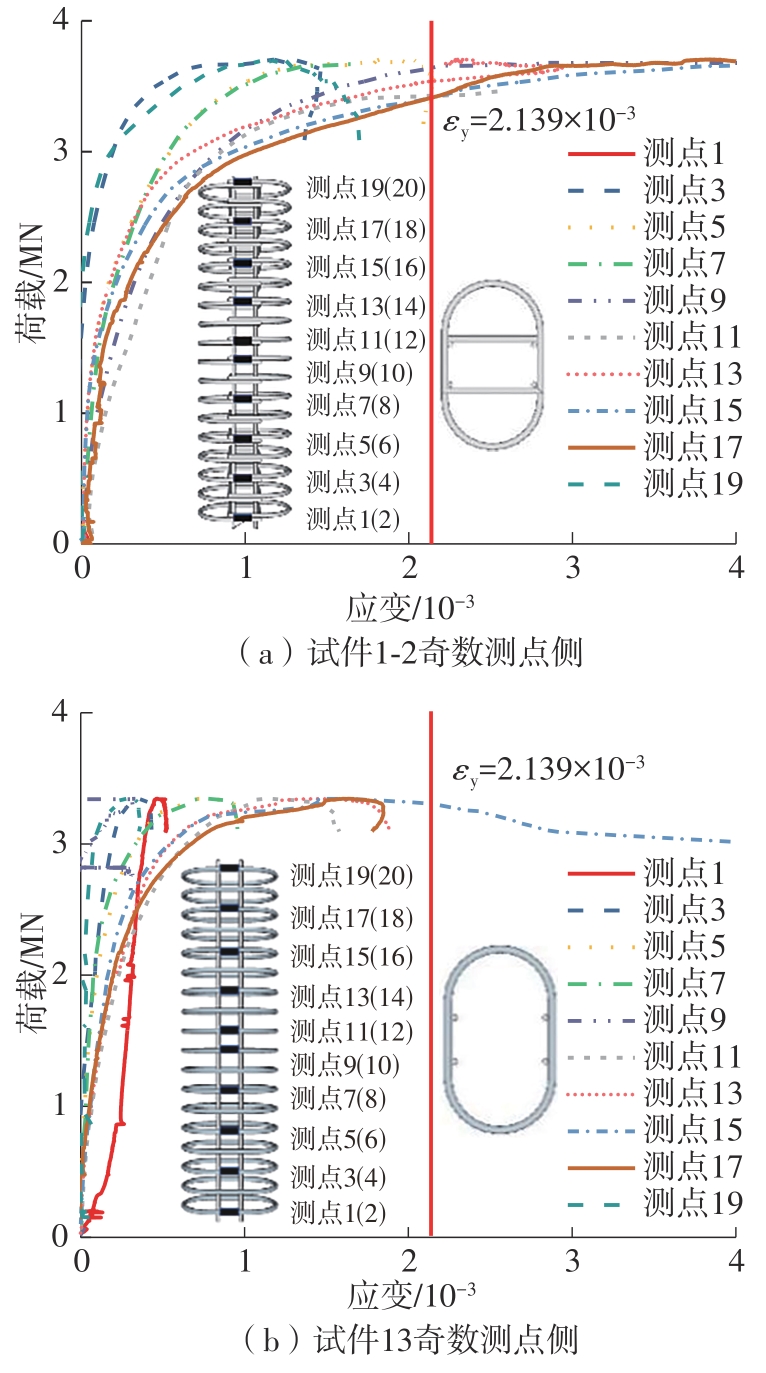

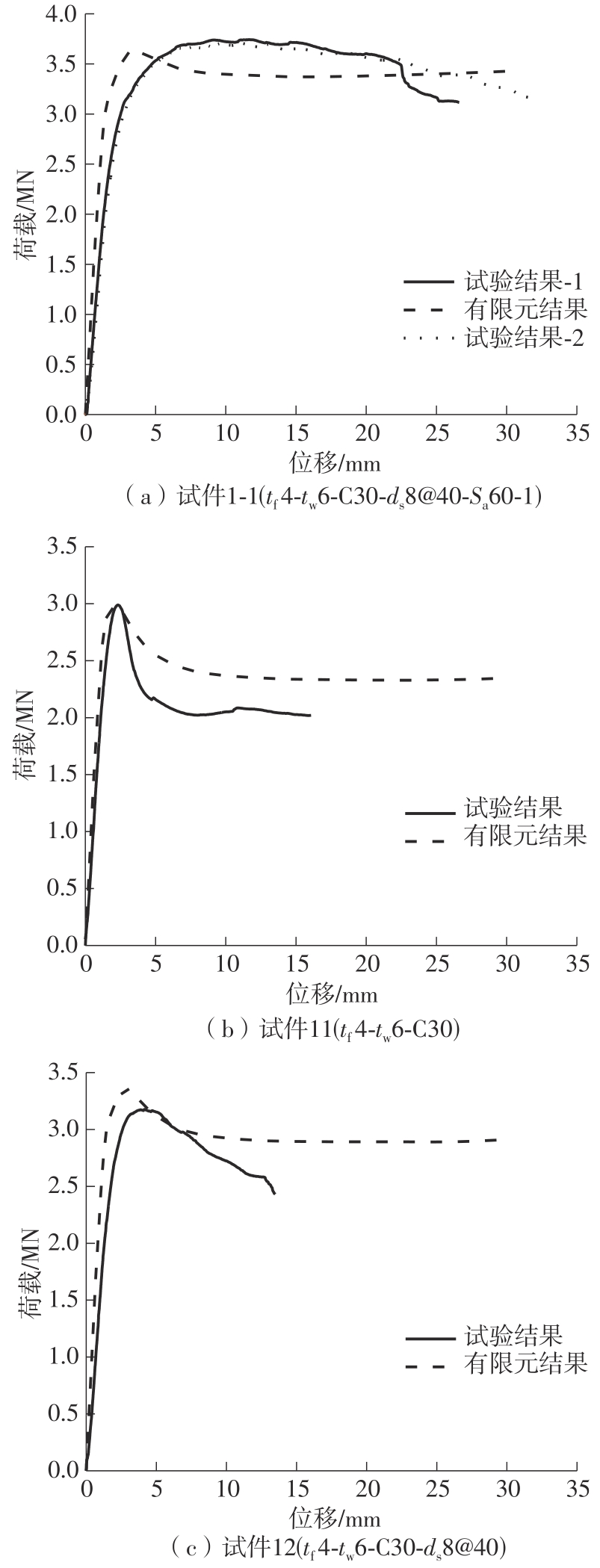

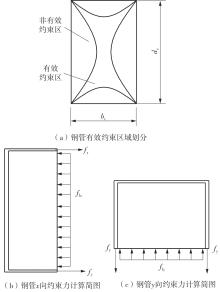

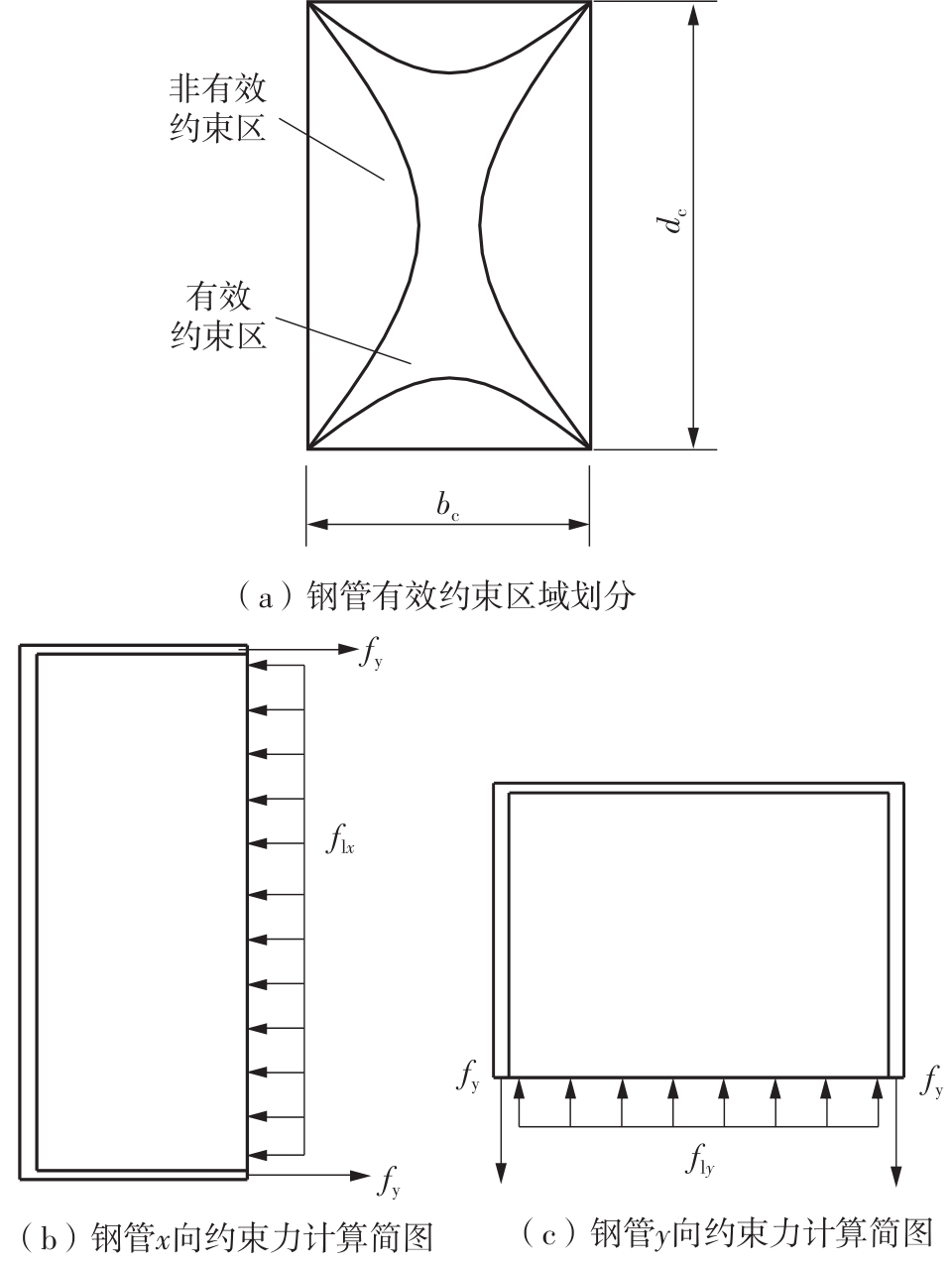

钢管混凝土作为一种发展前景广阔的结构形式,具有较好的承载力和塑性变形能力。矩形钢管混凝土柱作为其中常见的一种形式,在实际工程中的应用较为广泛。该研究基于矩形钢管混凝土在实际应用中存在的长短边约束不一致和对核心混凝土约束不足两个问题,探究一种新型的矩形钢管混凝土构件,即内置异形箍筋矩形钢管混凝土柱。为此,对11根内置异形箍筋矩形钢管混凝土柱、2根内置跑道形箍筋的矩形钢管混凝土柱、2根普通矩形钢管混凝土柱开展了轴压力学性能试验,重点分析了并束距、钢管壁厚、混凝土强度等级、箍筋间距、箍筋直径、内置用钢量等重要参数对内置异形箍筋矩形钢管混凝土柱的轴压承载力和延性的影响规律。结果表明:在总用钢量不变的情况下,将矩形钢管的壁厚减薄,并加工成异形箍筋内置于核心混凝土中,能够有效地提高试件的轴压承载力和延性;内置异形箍筋矩形钢管混凝土柱的轴压过程可以分为4个阶段——弹性阶段、弹塑性阶段、塑性强化段、下降段;相比于普通矩形钢管混凝土柱,内置异形箍筋矩形钢管混凝土柱有更为饱满的塑性强化段。在试验和参数分析结果的基础上,采用已有的约束混凝土本构模型,推导得到内置异形箍筋矩形钢管混凝土柱的轴压承载力计算公式。该研究可为实际工程应用提供科学依据和数据参考。

中图分类号: