| 1 |

虞将苗,杨倪坤,于华洋 .道路高性能沥青超薄磨耗层技术研究与应用现状[J].中南大学学报(自然科学版),2021,52(7):2287-2298.

|

|

YU Jiangmiao, YANG Nikun, YU Huayang .Research and application status of high-performance asphalt ultra-thin wearing layer technology[J].Journal of Central South University (Natural Science Edition),2021,52(7):2287-2298.

|

| 2 |

《中国公路学报》编辑部 .中国路面工程学术研究综述2020[J].中国公路学报,2020,33(10):1-66.

|

|

China Journal of Highway and Transport. Review on china’s pavement engineering research 2020[J].China Journal of Highway and Transport,2020,33(10):1-66.

|

| 3 |

BELLANGER J, BROSSEAUD Y, GOURDON J .Thinner and thinner asphalt layers for the maintenance of French roads[J].Transportation Research Record:Journal of the Transportation Research Board,1992,1334:9-11.

|

| 4 |

KANDHAL P S, LOCKETT L .Construction and performance of ultra-thin asphalt friction course[R].Auburn:National Center for Asphalt Technology,1997:1-12.

|

| 5 |

JAHREN C T, BEHLING K R .Thin maintenance surface treatments:comparative study[J].Transportation Research Record:Journal of the Transportation Research Board,2004,1866(1):20-27.

|

| 6 |

COOLEY L A J, JAMES R S, BUCHANAN S .Development of mix design criteria for 4.75 mm superpave mixes[J].Transportation Research Record:Journal of the Transportation Research Board,2003,1819(1):125-133.

|

| 7 |

XIE H B, COOLEY L A J, HUNER M H .4.75 mm NMAS stone matrix asphalt (SMA) mixtures[R].Auburn:National Center for Asphalt Technology,2003:1-17.

|

| 8 |

彭华荣 .超薄磨耗层NovaChip在广深高速公路的应用研究[D].广州:华南理工大学,2011.

|

| 9 |

王勋,梁勇,陈搏,等 .骨架约束作用对沥青磨耗层抗滑性能影响研究[J].路基工程,2022,40(2):56-62.

|

|

WANG Xun, LIANG Yong, CHEN Bo,et al .Research on the influence of skeleton constraint on the skid-resistance performance of asphalt wearing layer[J].Subgrade Engineering,2022,40(2):56-62.

|

| 10 |

关博文,薛兴杰,孟建党,等 .SMA-5煅烧铝矾土超薄磨耗层路用性能与抗滑性能评价[J].长安大学学报(自然科学版),2022,42(4):10-19.

|

|

GUAN Bo-wen, XUE Xing-jie, MENG Jian-dang,et al .Evaluation of road performance and skid resistance of ultra-thin wear layer using calcined bauxite aggregate[J].Journal of Chang’an University (Natural Science Edition),2022,42(4):10-19.

|

| 11 |

ZONG Y J, LI S, ZHANG J B,et al .Effect of aggregate type and polishing level on the long-term skid resistance of thin friction course[J].Construction and Building Materials,2021,128:122730/1-10.

|

| 12 |

虞将苗,陈富达,彭馨彦,等 .高韧超薄沥青磨耗层在港珠澳大桥珠海人工岛通道上的应用[J].清华大学学报(自然科学版),2020,60(1):48-56.

|

|

YU Jiangmiao, CHEN Fuda, PENG Xinyan,et al .Hight-toughness,ultra-thin friction course for the channel on the channel on the Zhuhai artificial island of the Hongkong-Zhuhai-Macao Bridge[J].Journal of Tsinghua University (Natural Science Edition),2020,60(1):48-56.

|

| 13 |

陈富达 .高韧超薄沥青磨耗层的力学性能和功能属性研究[D].广州:华南理工大学,2020 .

|

| 14 |

黄卫东,张家伟,吕泉,等 .基于间接拉伸开裂方法评价超薄磨耗层混合料抗裂性能[J].同济大学学报(自然科学版),2020,48(11):1588-1594.

|

|

HUANG Weidong, ZHANG Jiawei, Quan LYU,et al .Evaluation of cracking performance of ultra-thin friction course mixture based on indirect tensile asphalt cracking test[J].Journal of Tongji University (Natural Science Edition),2020,48(11):1588-1594.

|

| 15 |

公路沥青路面施工技术规范: [S].

|

| 16 |

雷超旭 .路面表面功能加速加载系统研究[D].广州:华南理工大学,2010.

|

| 17 |

丁蓬勃 .基于加速加载试验的高性能表面处治的研究[D].广州:华南理工大学,2015.

|

| 18 |

陈玉宏,王金兵,杨航,等 .正交异性钢桥面超薄铺装层加速加载试验研究[J].公路,2021,66(6):97-100.

|

|

CHEN Yuhong, WANG Jinbing, YANG Hang,et al .Experimental study on accelerated loading of ultra-thin paving layer of orthotropic steel bridge deck[J].Highway,2021,66(6):97-100.

|

| 19 |

AHAMME M A, TIGHE S L .Pavement surface mixture,texture,and skid resistance:a factorial analysis[C]∥Proceedings of Airfield & Highway Pavements.[S.l.]:ASCE,2009:370-384.

|

| 20 |

梁遐意 .低噪声功能路面表面纹理优化研究[D].广州:华南理工大学,2020.

|

| 21 |

徐驰 .湿热地区沥青路面抗滑性能衰减机理与改善措施研究[D].广州:华南理工大学,2022.

|

| 22 |

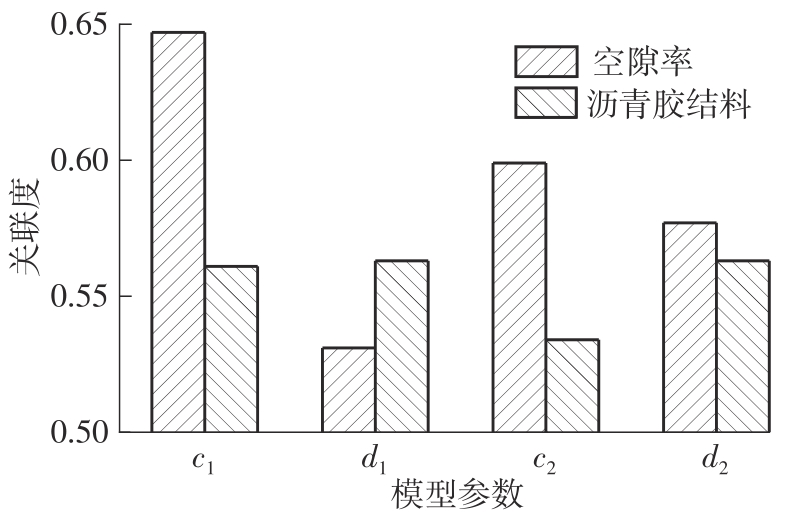

谭学瑞,邓聚龙 .灰色关联分析:多因素统计分析新方法[J].统计研究,1995,12(3):46-48.

|

|

TAN Xuerui, DENG Julong .Grey correlation analysis:a new method for multivariate statistical analysis [J].Statistical Research,1995,12(3):46-48.

|

), LI Yanbiao1, PAN Yanzhu2

), LI Yanbiao1, PAN Yanzhu2