华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (1): 1-7.doi: 10.12141/j.issn.1000-565X.220075

所属专题: 2023年机械工程

30CrMnSiA薄壁杯形件的强韧化工艺方法

夏琴香 谢章雄 陈灿 肖刚锋

- 华南理工大学 机械与汽车工程学院,广东 广州 510640

Strengthening and Toughening Process Method of 30CrMnSiA Thin-Wall Cup-Shaped Parts

XIA Qinxiang XIE Zhangxiong CHEN Can XIAO Gangfeng

- School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510640,Guangdong,China

摘要:

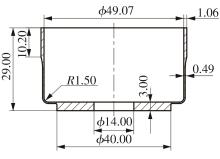

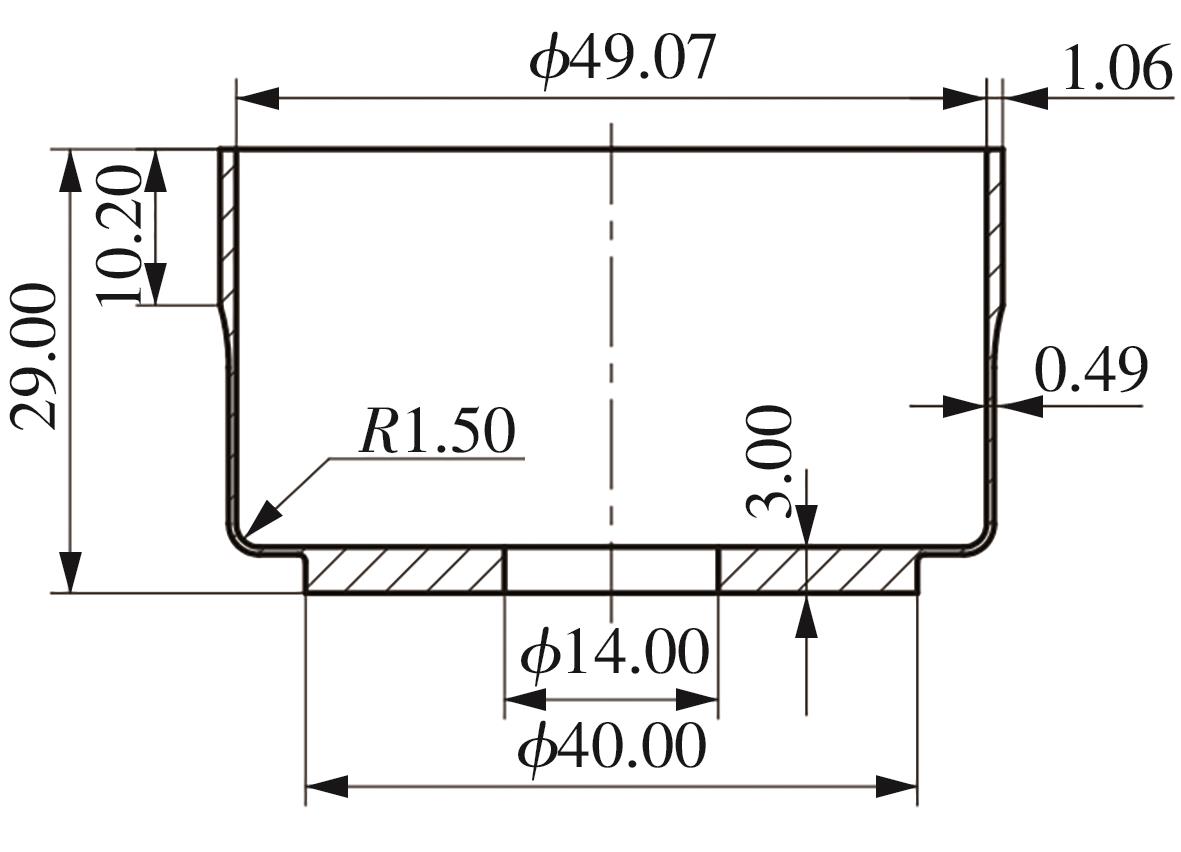

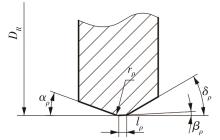

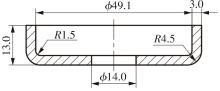

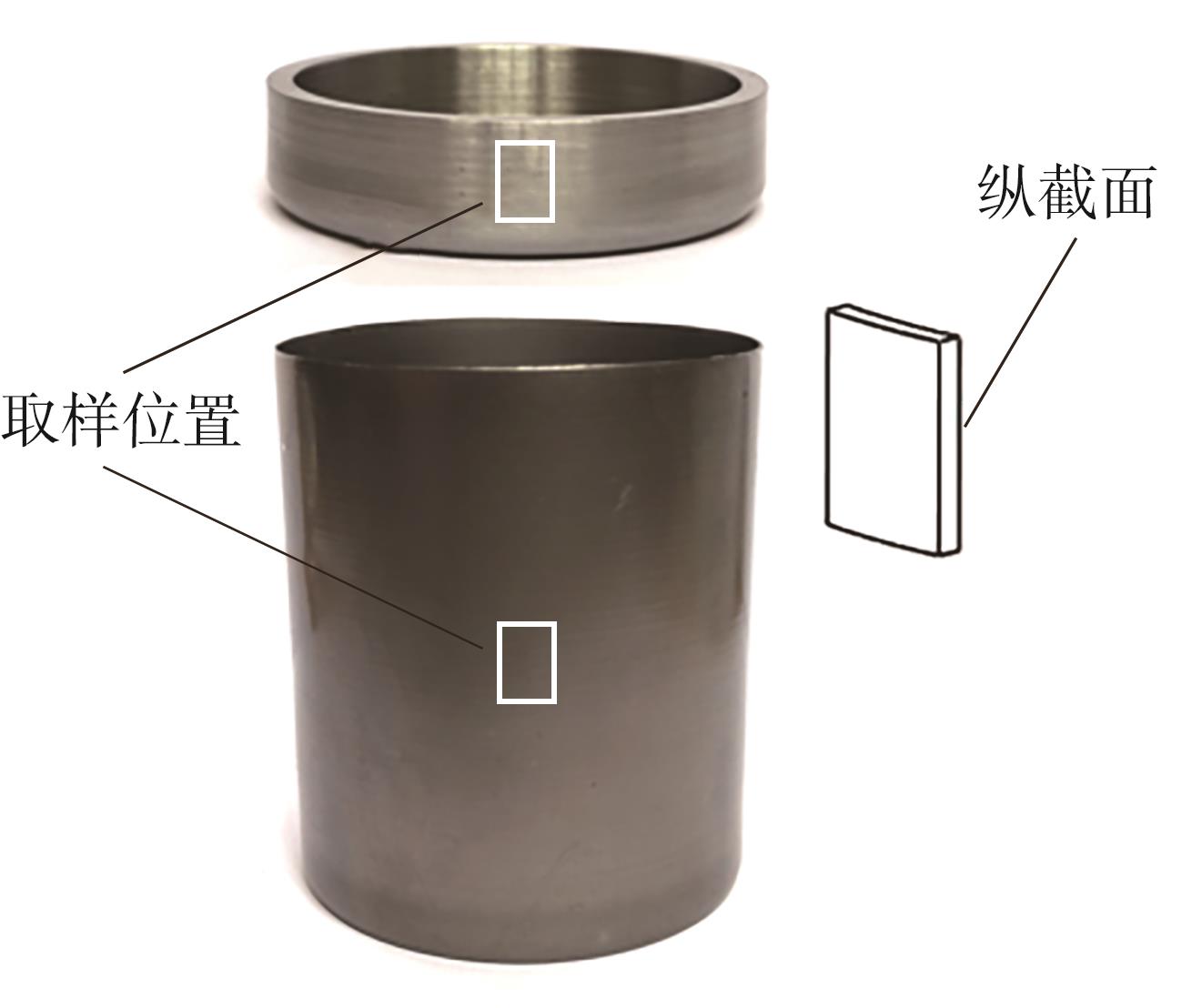

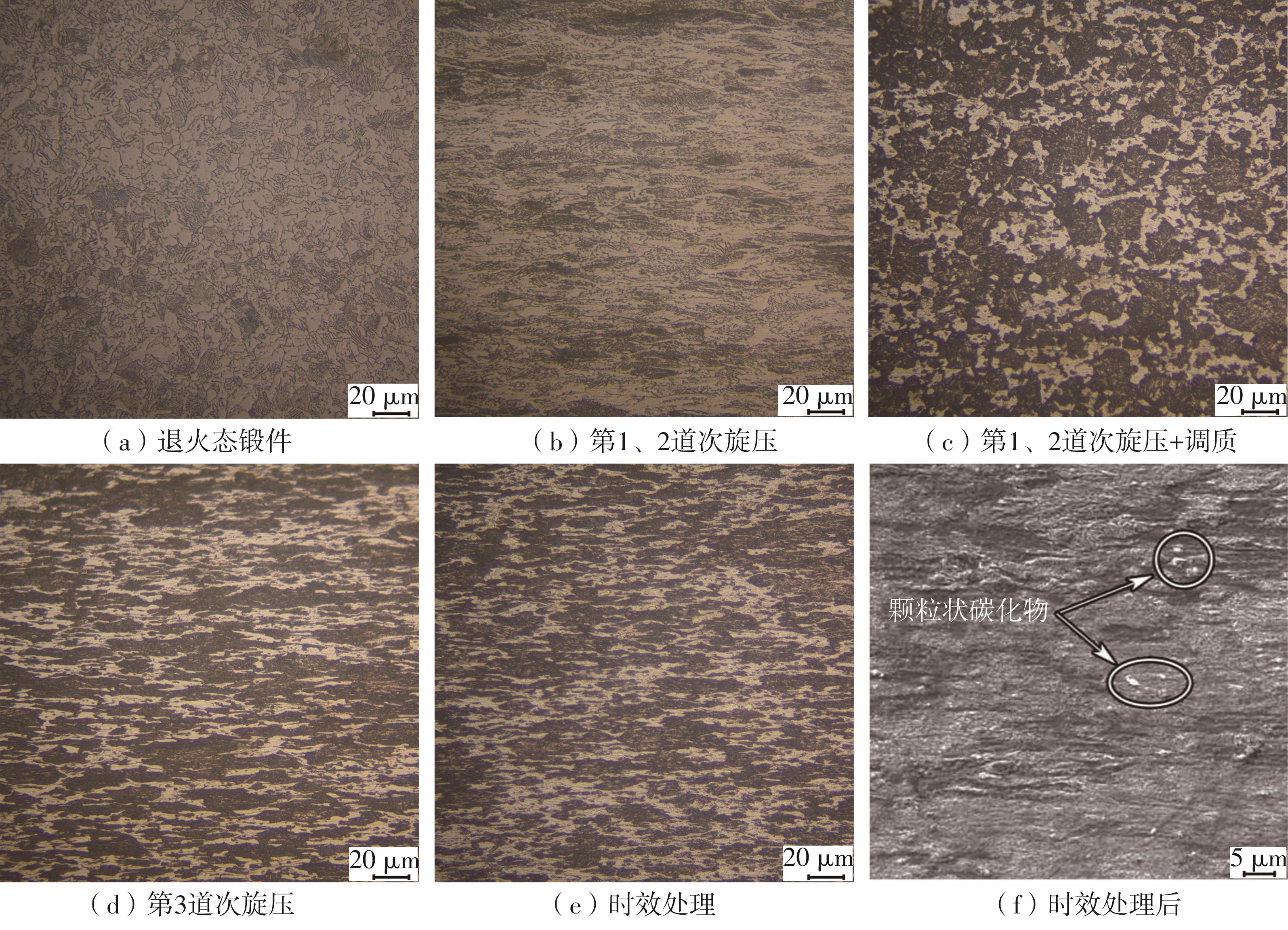

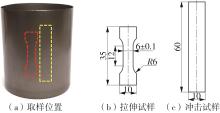

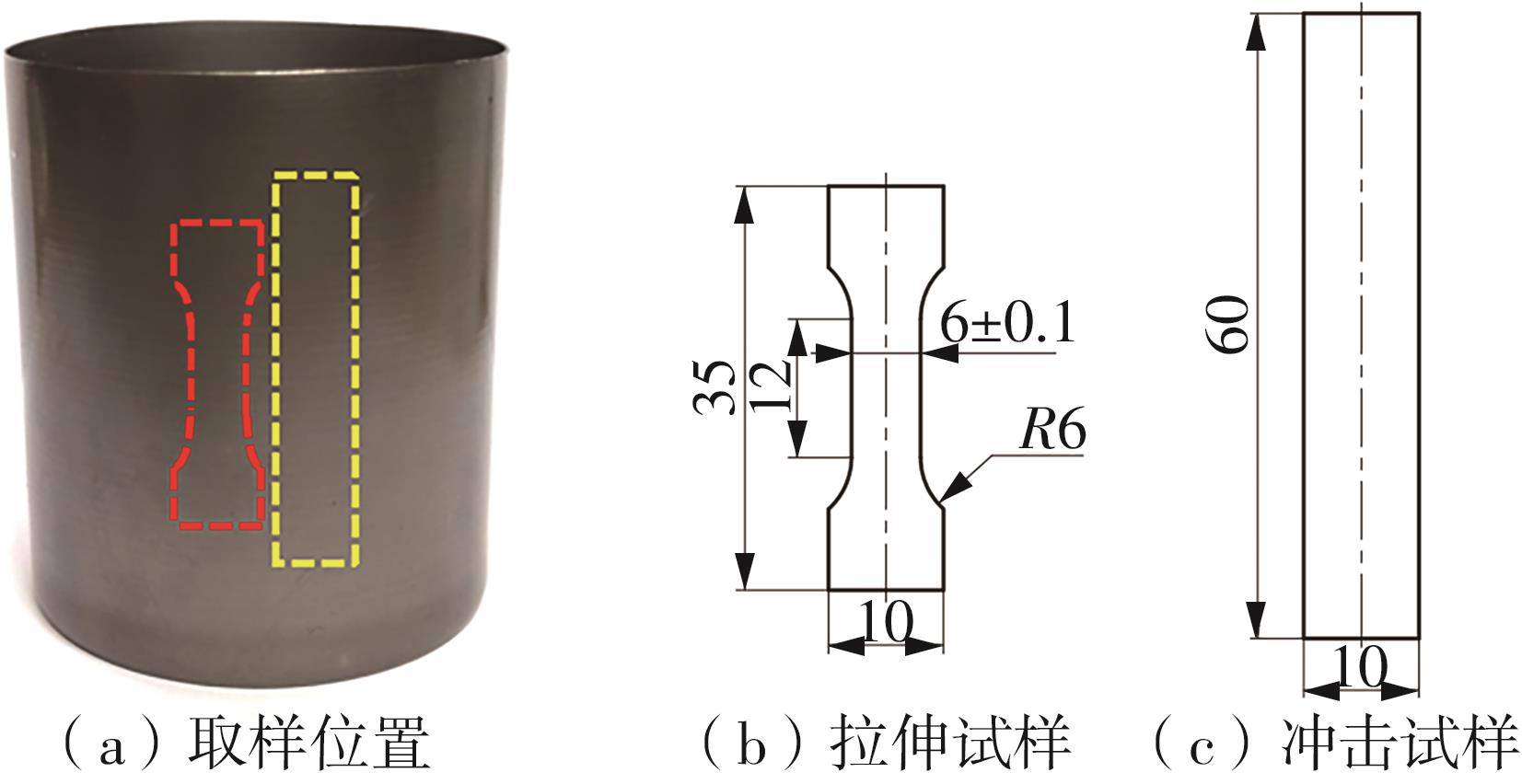

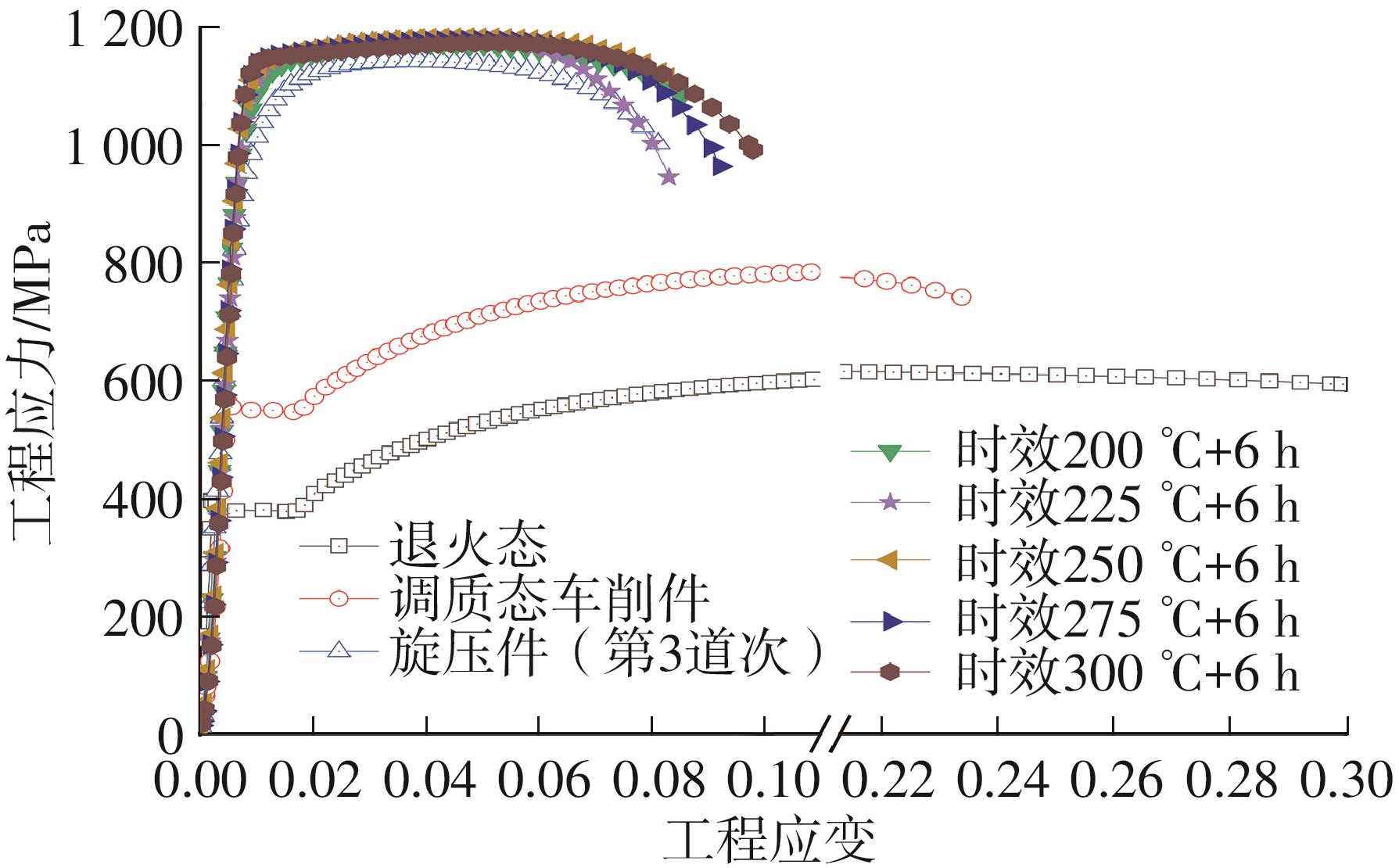

30CrMnSiA薄壁杯形件是广泛应用于谐波减速器柔轮壳体的一类关键基础零部件。文中针对传统采用车削制备的30CrMnSiA薄壁杯形件强韧性不足而导致谐波减速器承载能力较低及寿命较短的问题,提出采用旋压-调质-旋压-时效的形变-热处理工艺来实现30CrMnSiA薄壁杯形件的少、无切削高性能制备;并通过拉伸及冲击实验,对比各工序件的力学性能变化规律,对各工序件的微观组织进行了分析。结果表明:旋压-调质工艺可获得具有较高强度的回火索氏体组织,但是材料的塑性降低;时效处理使旋压成形获得的纤维状微观组织进一步细化,并在铁素体基体上析出均匀弥散分布的细小碳化物;在300 ℃+6 h时效处理时可同时获得较高的强度和良好的塑性。相比调质后车削成形,采用形变-热处理相结合制备的30CrMnSiA薄壁杯形件的屈服强度和抗拉强度分别提高了93.65%和47.88%,硬度提高了26.87%,冲击强度提高了12.01%,同时还具有较好的塑性,断后伸长率和断面收缩率分别达11.60%和24.64%。采用旋压-调质-旋压-时效的形变-热处理工艺可实现薄壁杯形件的强韧化制造,为高强韧性薄壁杯形件的生产提供一种新的工艺方法。

中图分类号: