华南理工大学学报(自然科学版) ›› 2022, Vol. 50 ›› Issue (10): 87-93.doi: 10.12141/j.issn.1000-565X.210510

所属专题: 2022年电子、通信与自动控制

圆柱腔径向双层介质厚度的测量方法

张淑娥1,2,3 赖帅1 张京席1,2

- 1.华北电力大学 电子与通信工程系,河北 保定 071003

2.华北电力大学 河北省电力物联网技术重点实验室,河北 保定 071003

3.华北电力大学 保定市光纤传感与光通信技术重点实验室,河北 保定 071003

Measurement Method of Radial Double-Layer Dielectric Thickness of Cylindrical Cavity

ZHANG Shue1,2,3 LAI Shuai1 ZAHNG Jingxi1,2

- 1.Department of Electronic and Communication Engineering,North China Electric Power University,Baoding 071003,Hebei,China

2.Hebei Key Laboratory of Power Internet of Things Technology,North China Electric Power University,Baoding 071003,Hebei,China

3.Baoding Key Laboratory of Optical Fiber Sensing and Optical Communication Technology,North China Electric Power University,Baoding 071003,Hebei,China

摘要:

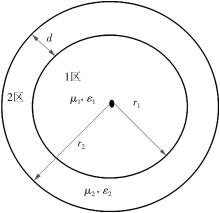

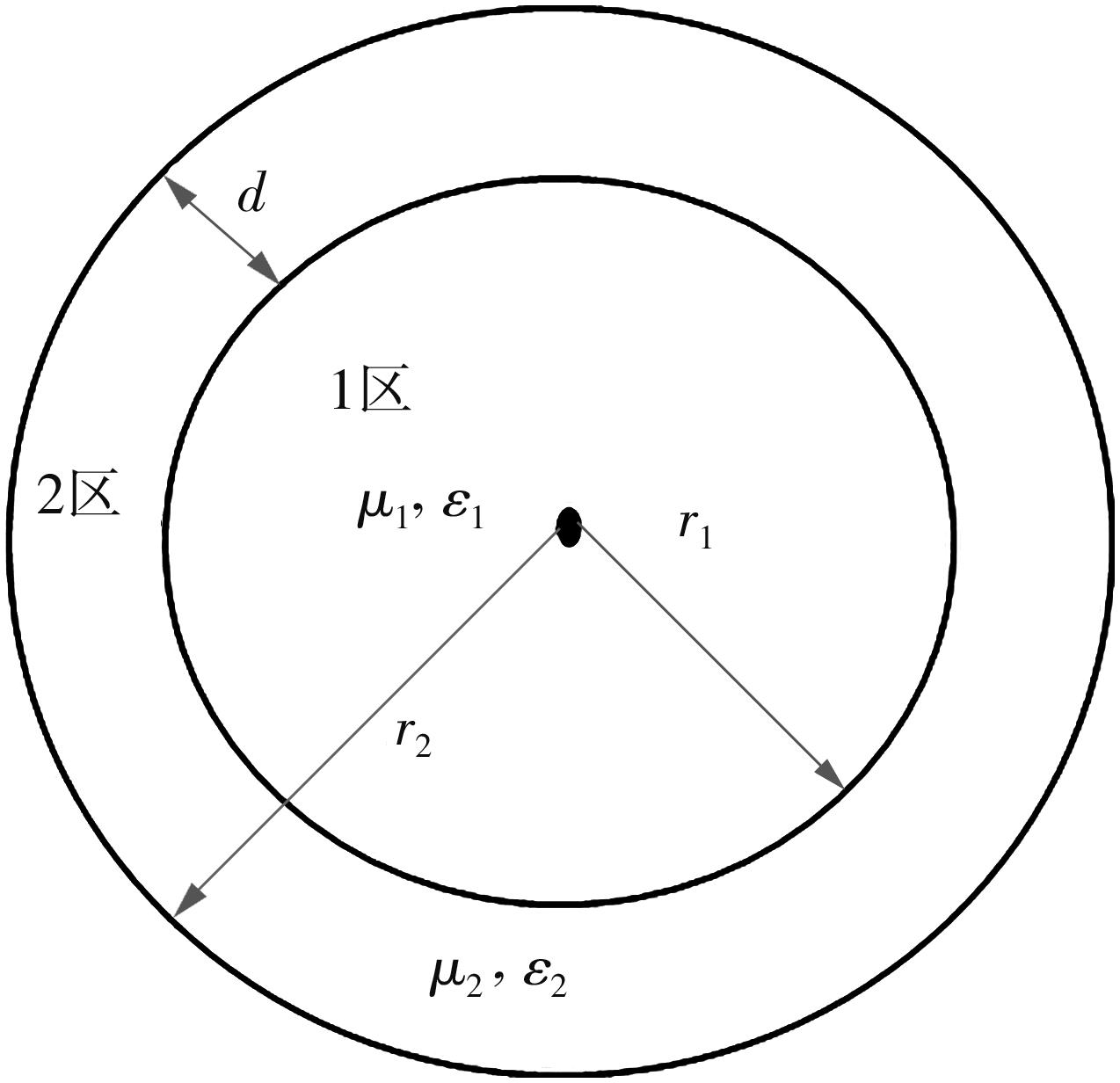

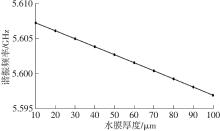

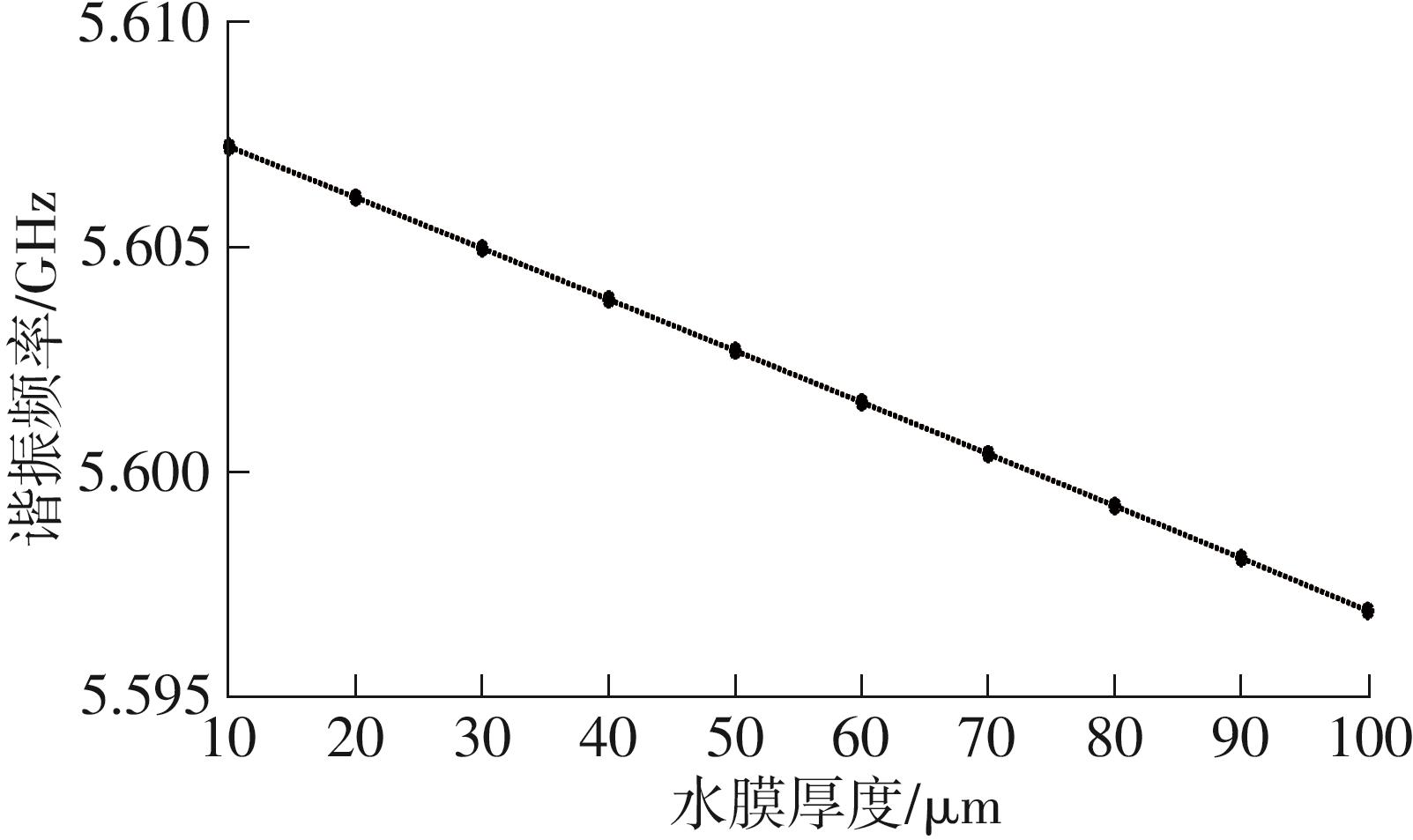

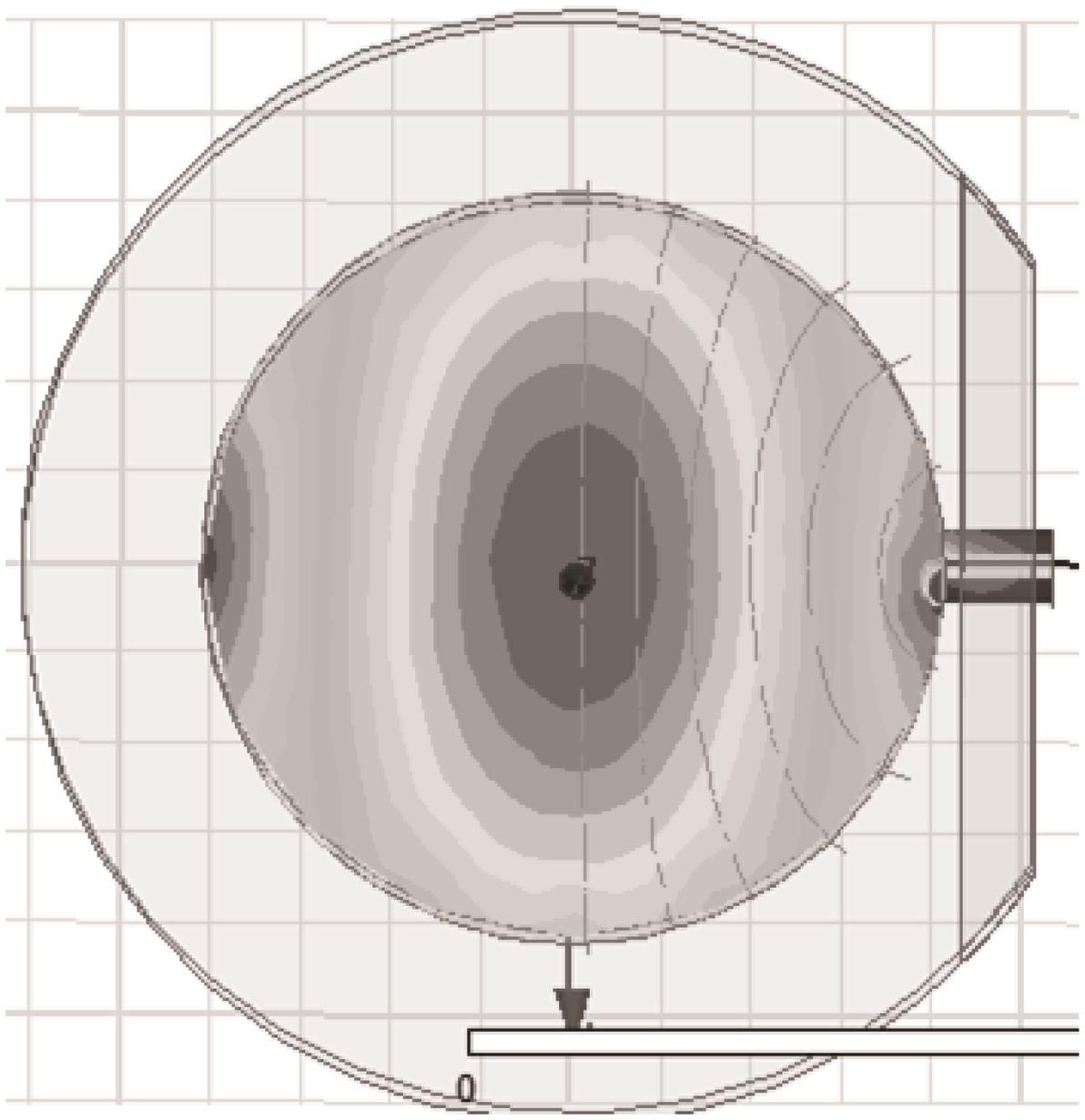

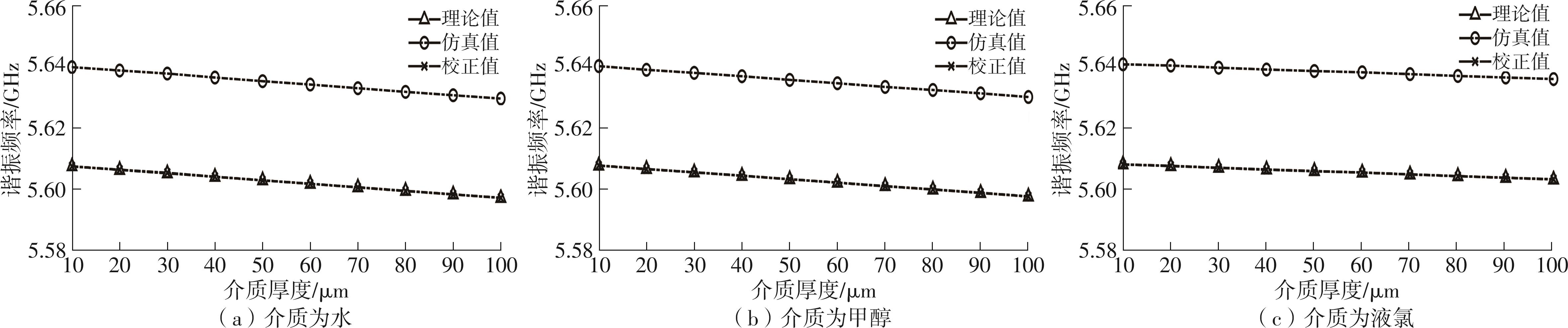

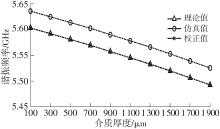

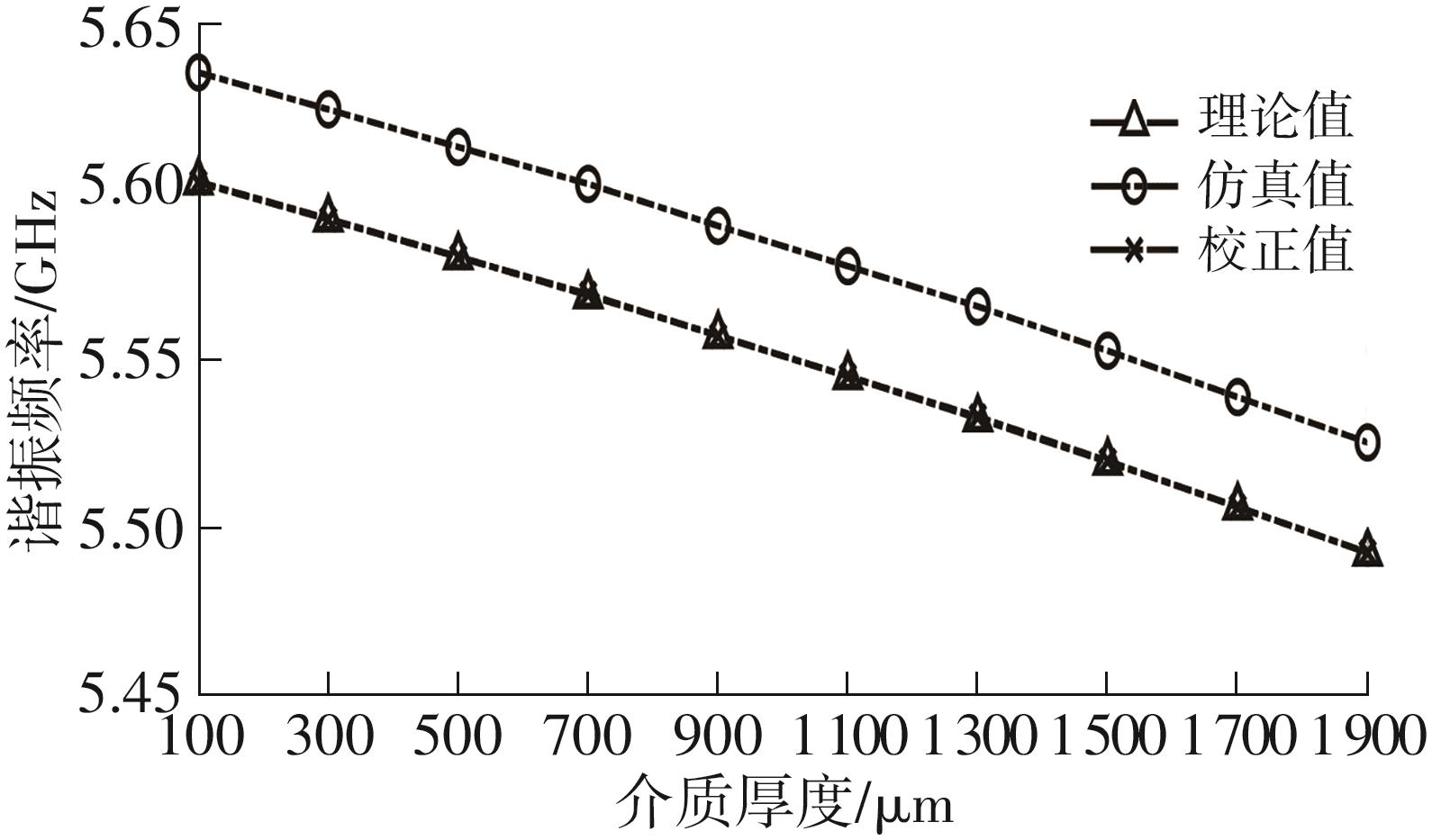

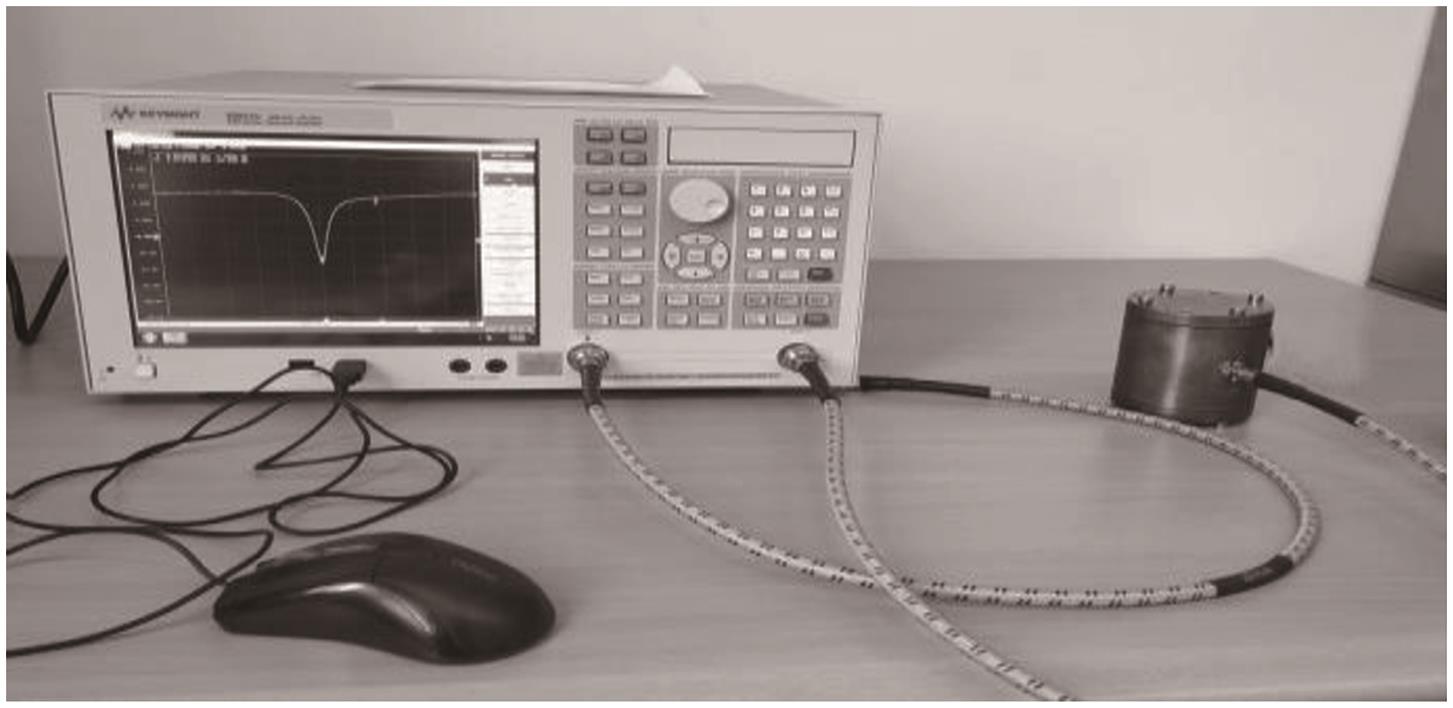

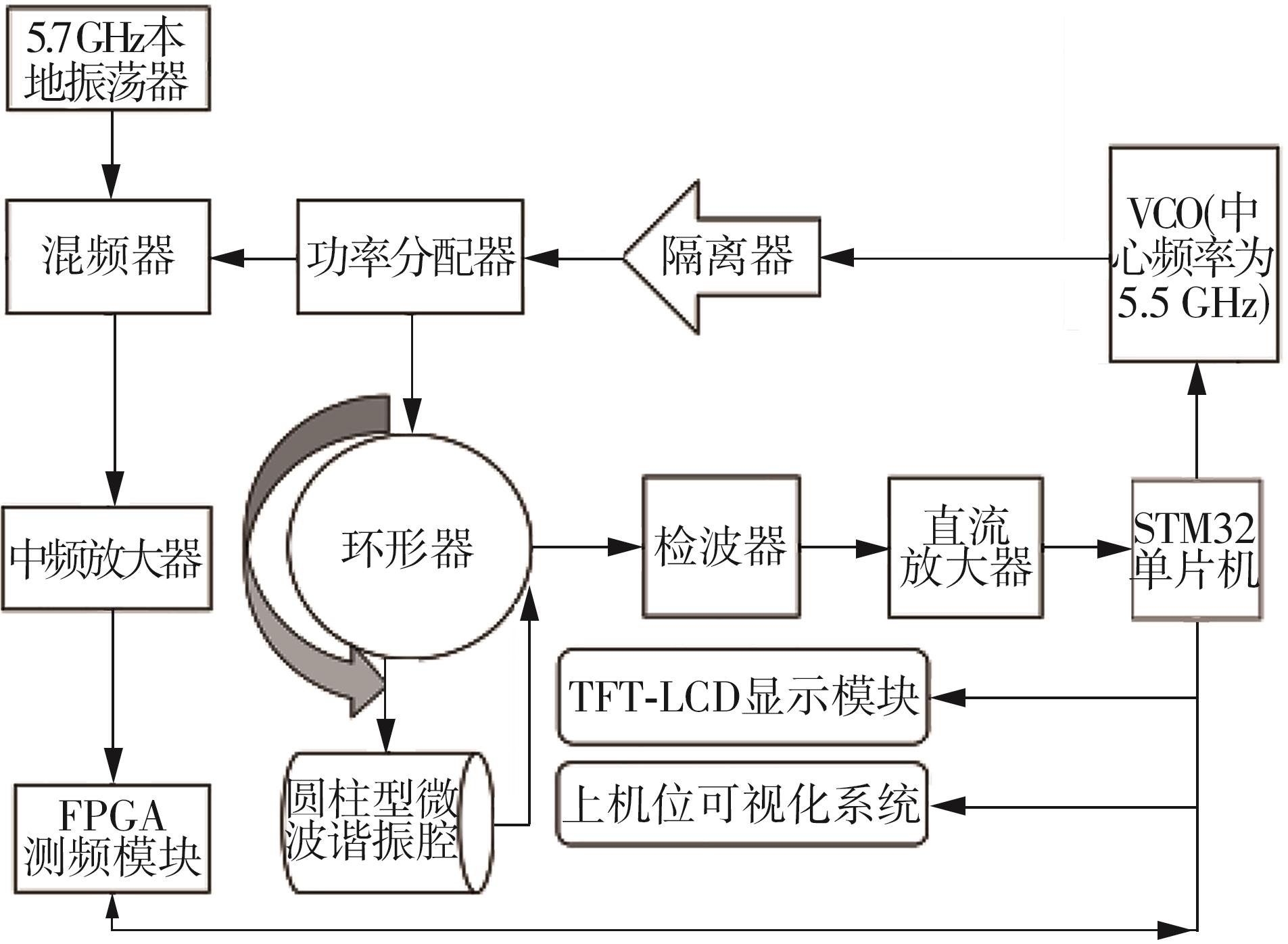

蒸汽湿度的精确测量对维护汽轮机的稳定性有重大意义,而蒸汽湿度的测量又受水膜厚度的影响。为了解决圆柱腔内壁水膜厚度的测量问题,基于介质加载圆柱谐振腔内谐振频率随介质厚度变化的原理,提出一种用于测量圆柱腔内壁介质厚度的新方法。根据介质加载圆柱波导所满足的麦克斯韦方程组和边界条件,推导了填充双层介质圆柱波导的特征方程。在给定介质厚度的情况下,根据特征方程给出了传播模式的相位常数和波导工作频率间的关系;基于推导的特征方程,建立了圆柱腔内壁介质厚度和谐振频率值之间的关系模型。应用MATLAB软件进行数值求解,得到不同介质、不同厚度下对应的谐振频率。在与数值求解设定的同等参数下,利用HFSS软件仿真分析了双层介质加载圆柱腔对应的谐振频率。将仿真数据和理论计算数据进行对比,结果表明随着介质厚度的增加,两者都呈平行下降趋势,且谐振频率频偏与介质厚度呈线性关系的规律,验证了该方法的可行性。该方法测量的介质厚度没有限制(在半径以内),具有普适性。文中还利用网络分析仪进行了相关实验,并搭建了实用性测量系统,当介质厚度在100 μm以内时,每间隔10 μm所能测得的介质厚度值的间隔约为6.8~7.1 μm,相对测量误差不超过24.6%。通过理论数据与实验数据对比,发现该方法测出的数据更为精确。

中图分类号: