华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (5): 130-140.doi: 10.12141/j.issn.1000-565X.220404

所属专题: 2023年机械工程

磁弹磨粒双磁盘磁力钝化仿真与实验研究

赵雪峰 游科 袁银 殷小龙

- 贵州大学 机械工程学院,贵州 贵阳 550025

Simulation and Experimental Research on Dual-Disk Magnetic Preparation Based on Magneto-Elastic Abrasive

ZHAO Xuefeng YOU Ke YUAN Yin YIN Xiaolong

- School of Mechanical Engineering,Guizhou University,Guiyang 550025,Guizhou,China

摘要:

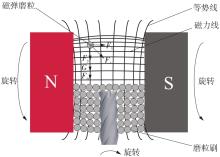

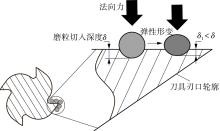

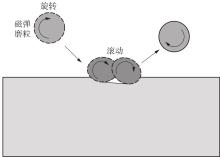

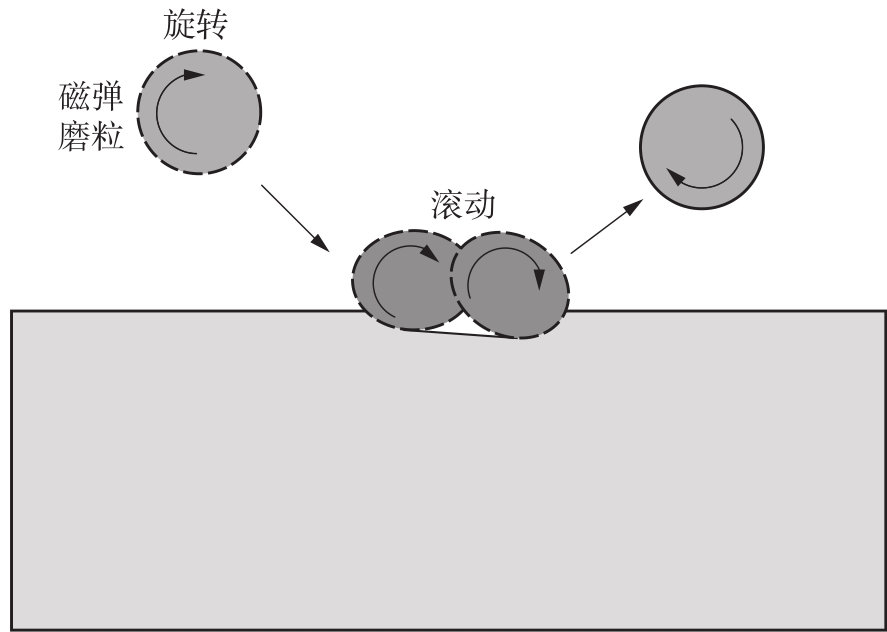

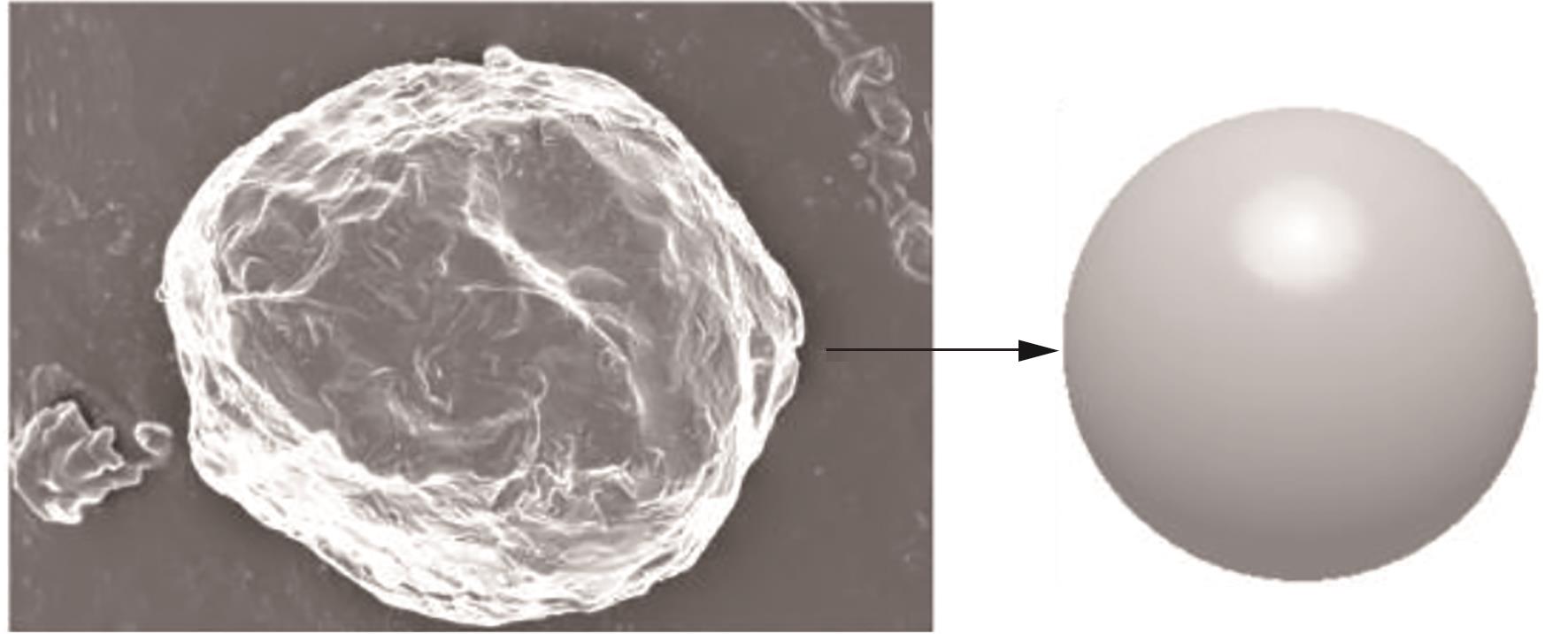

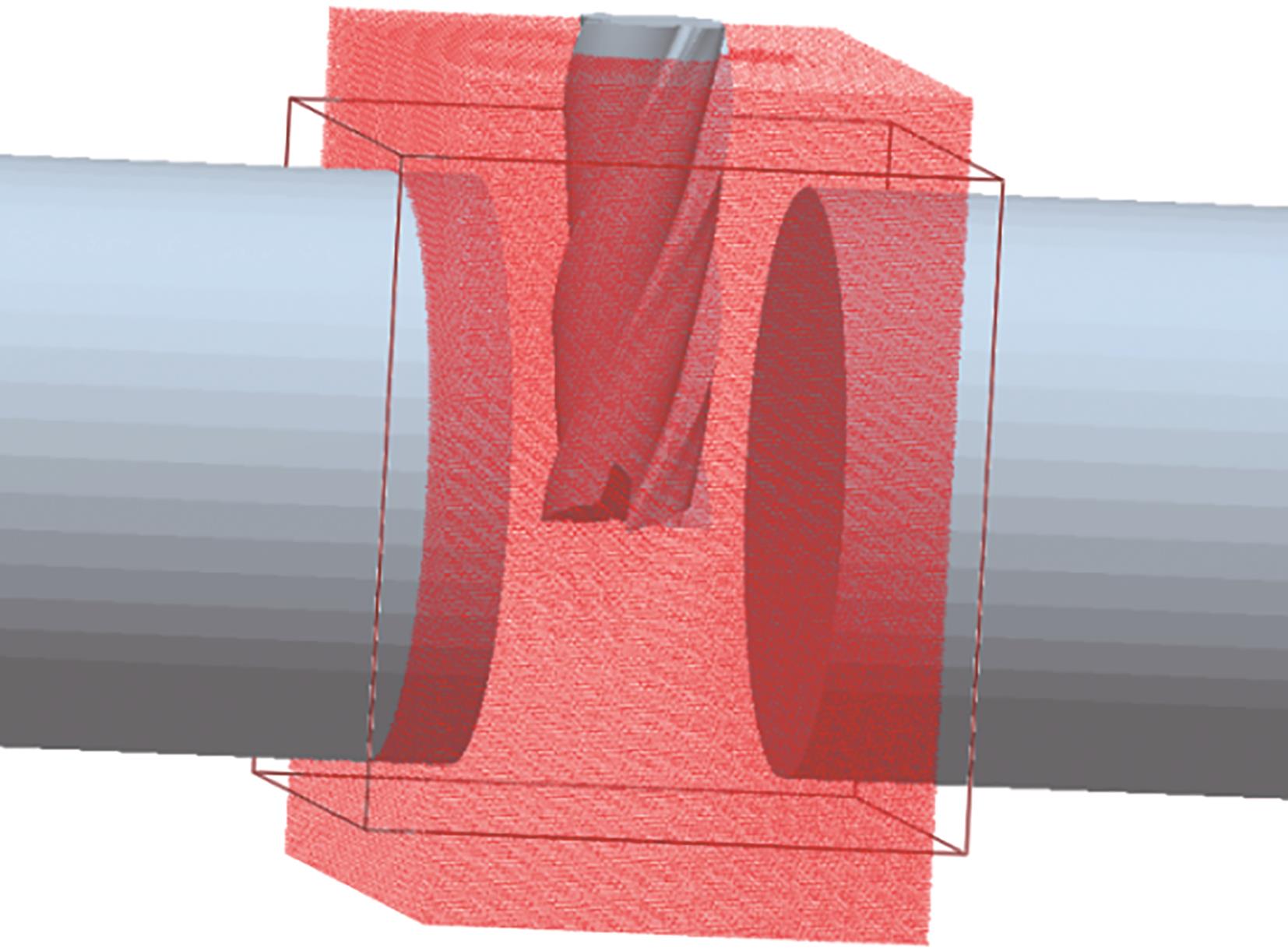

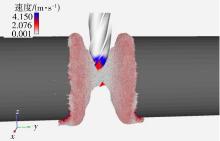

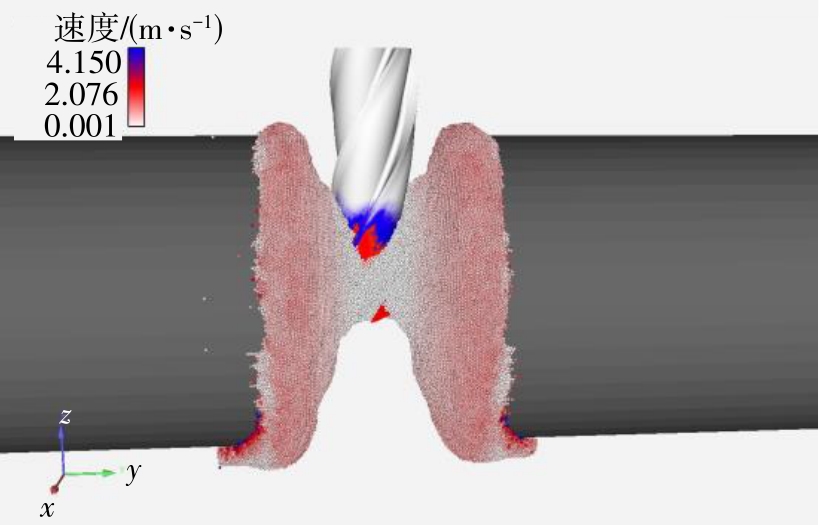

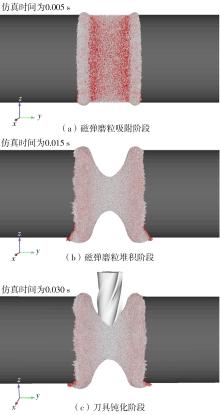

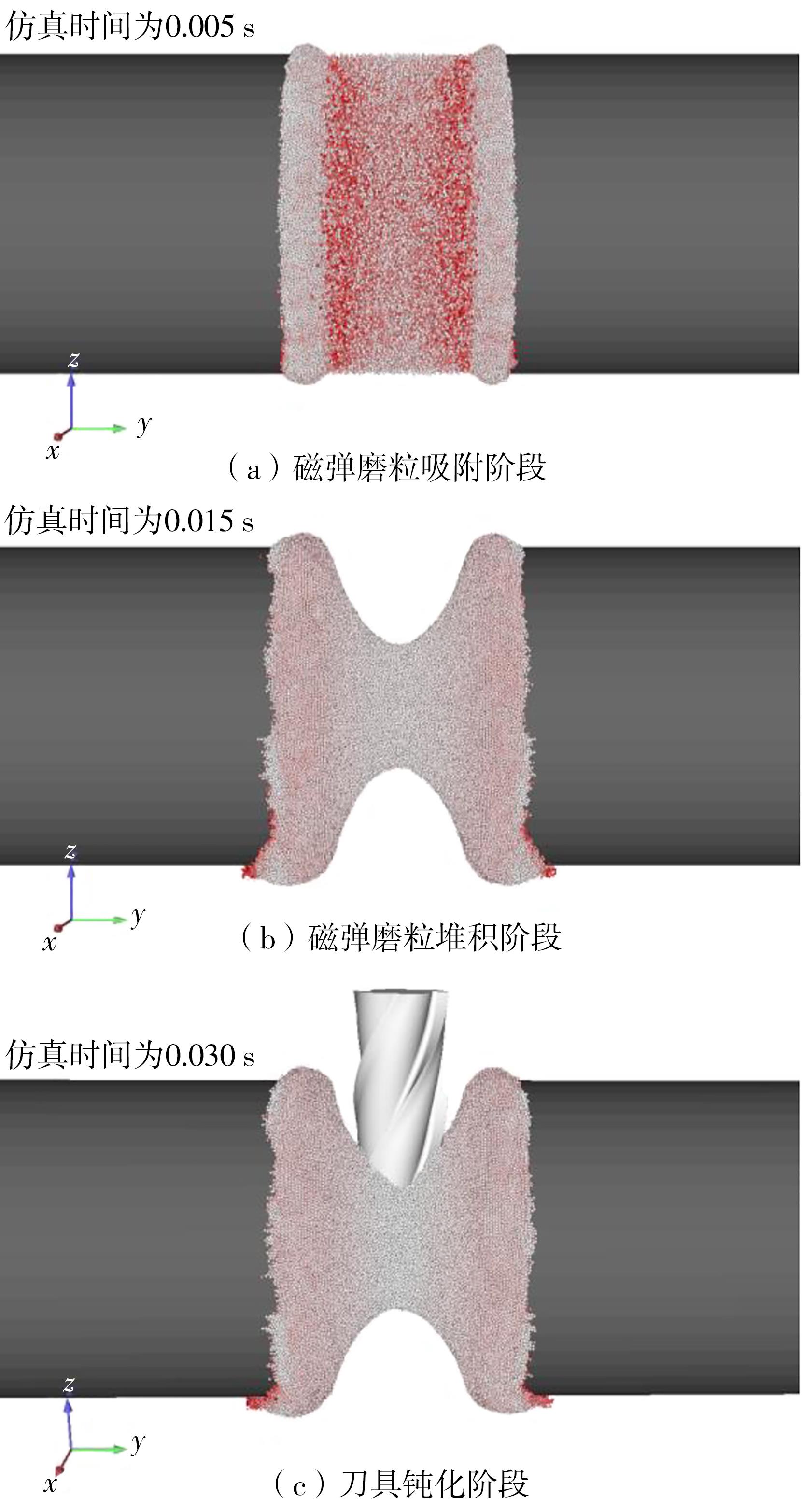

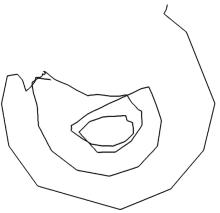

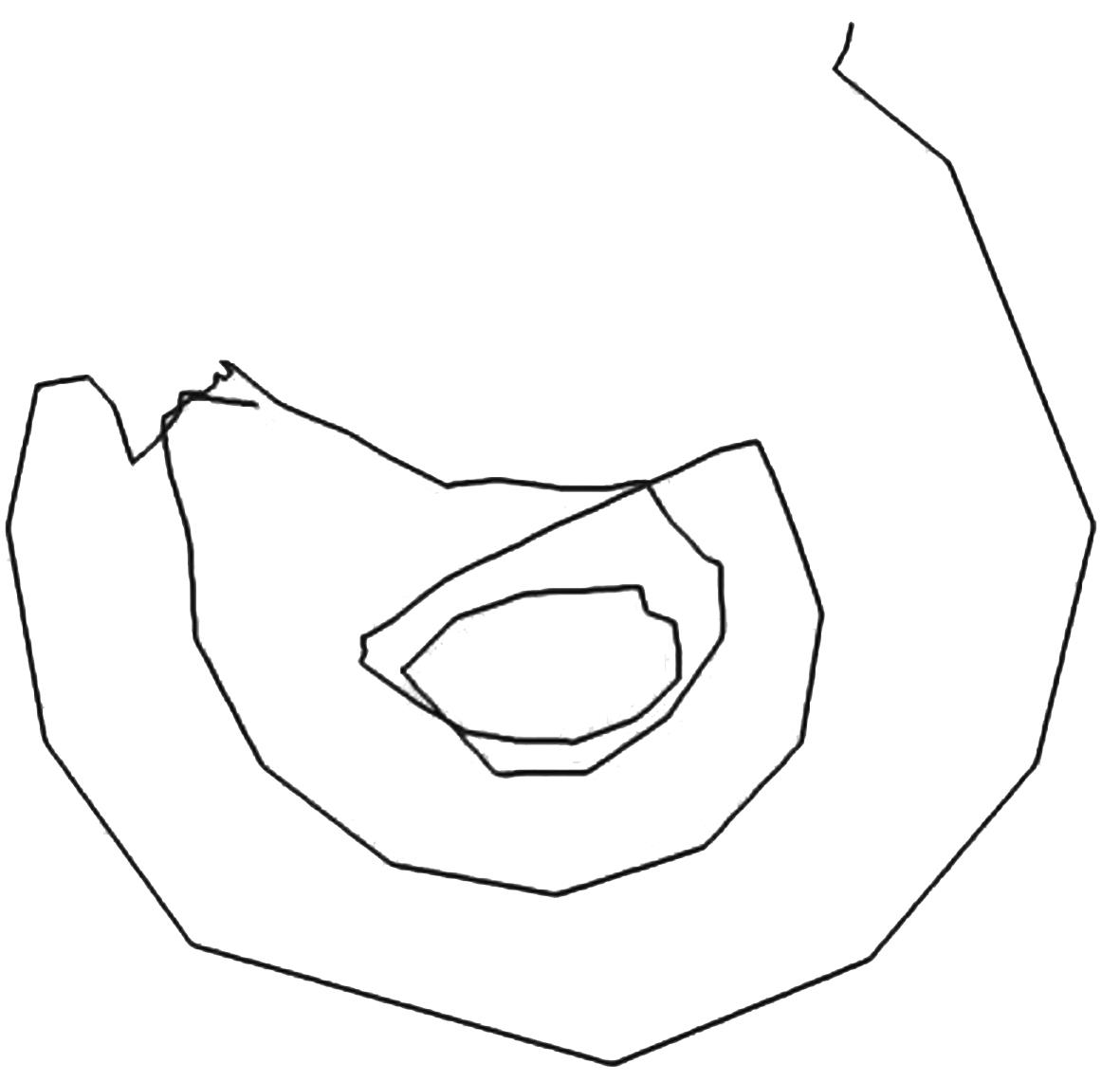

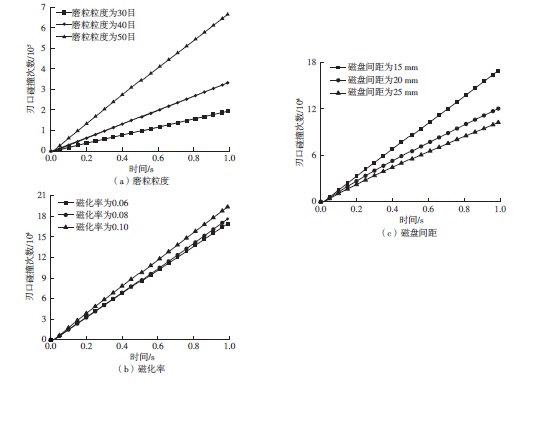

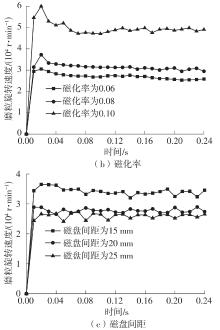

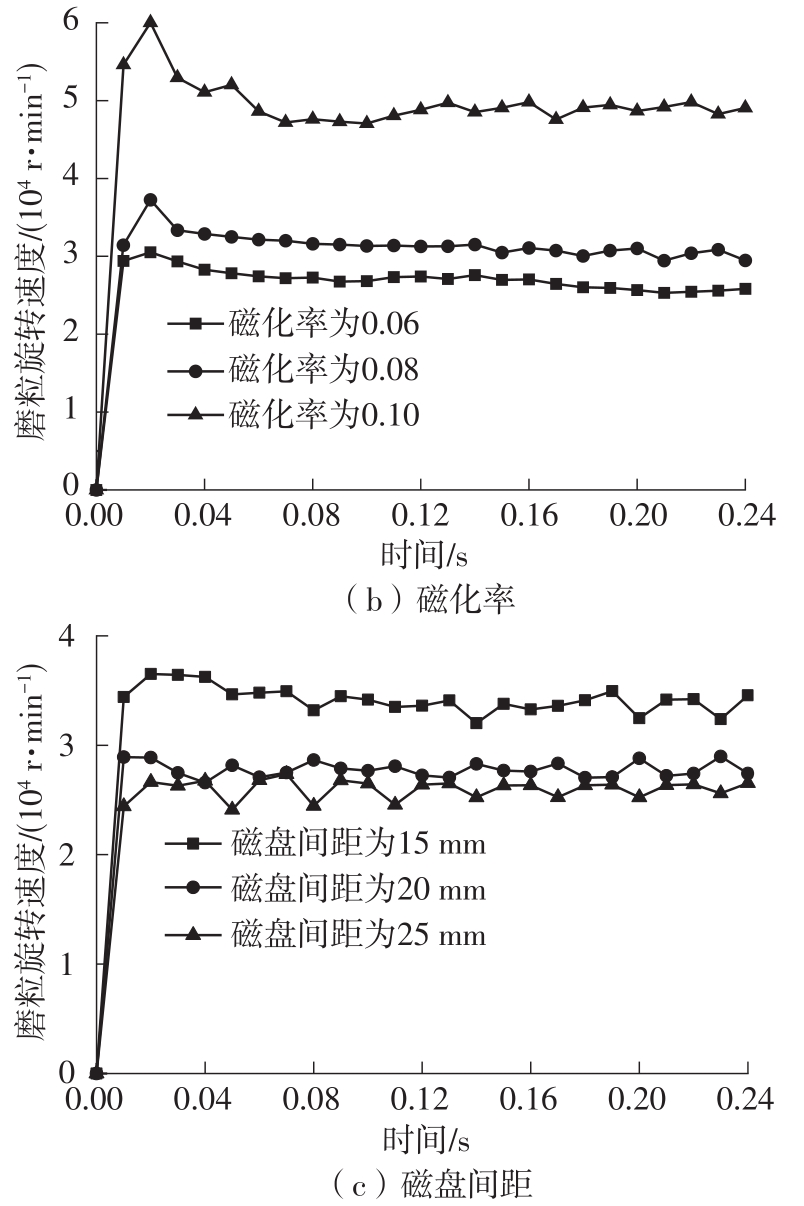

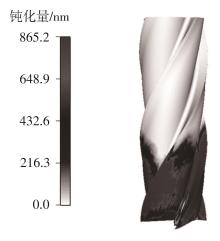

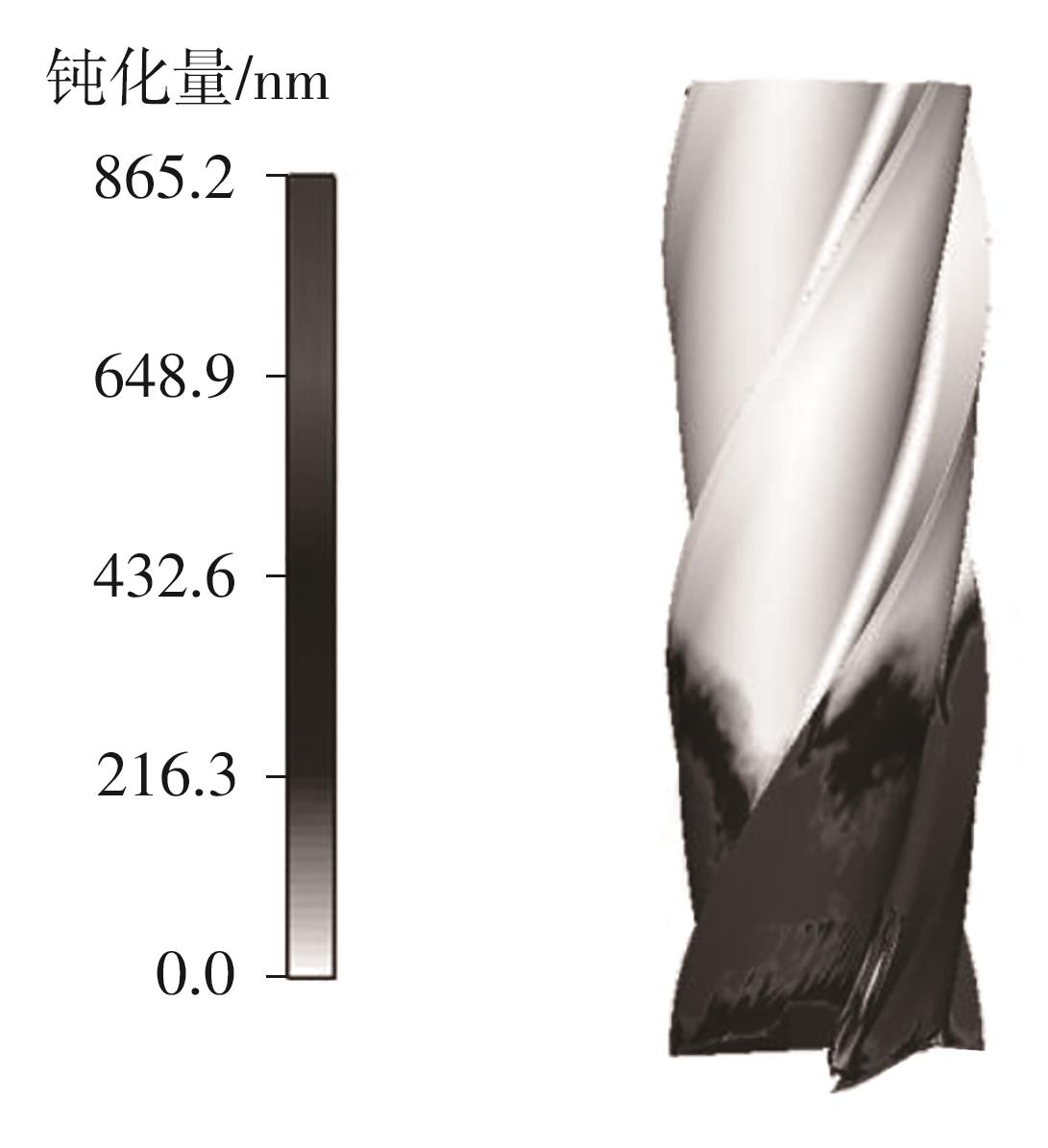

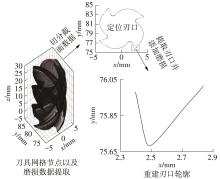

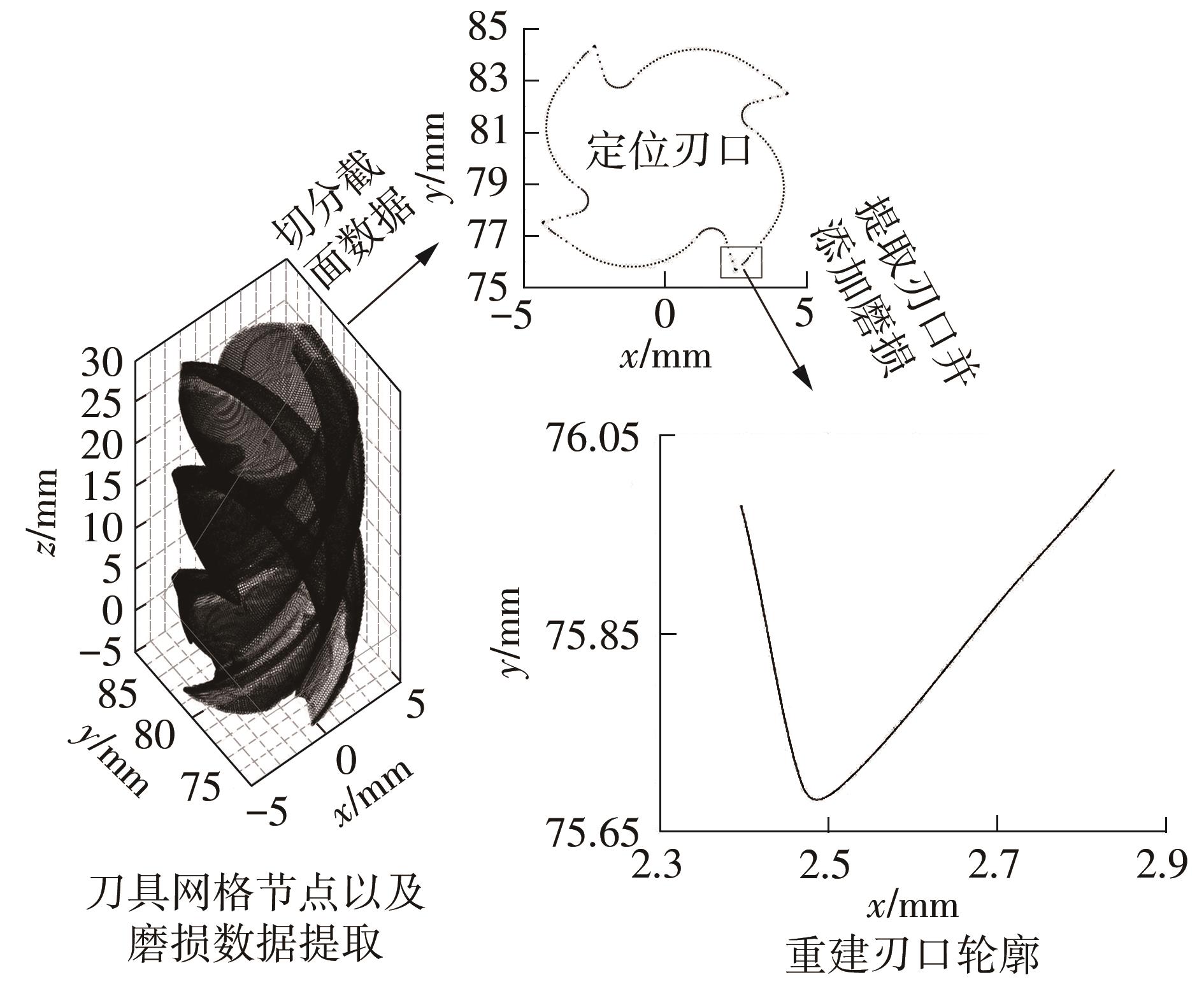

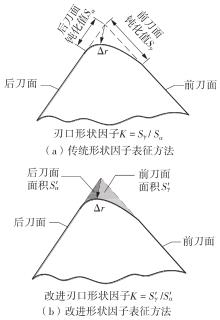

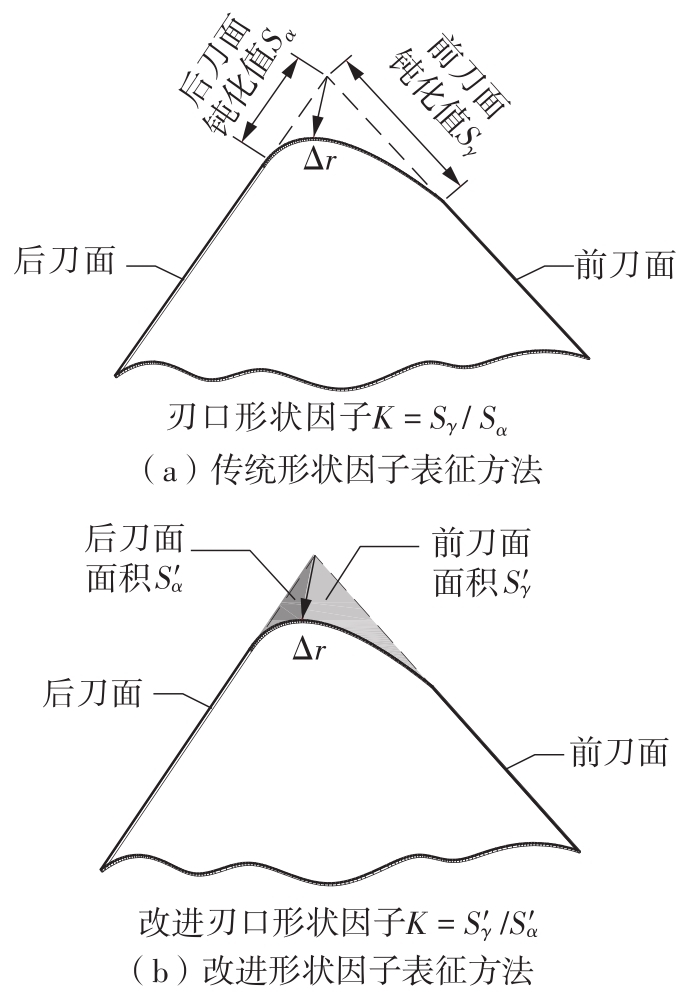

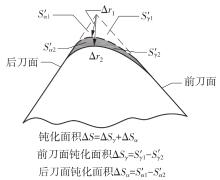

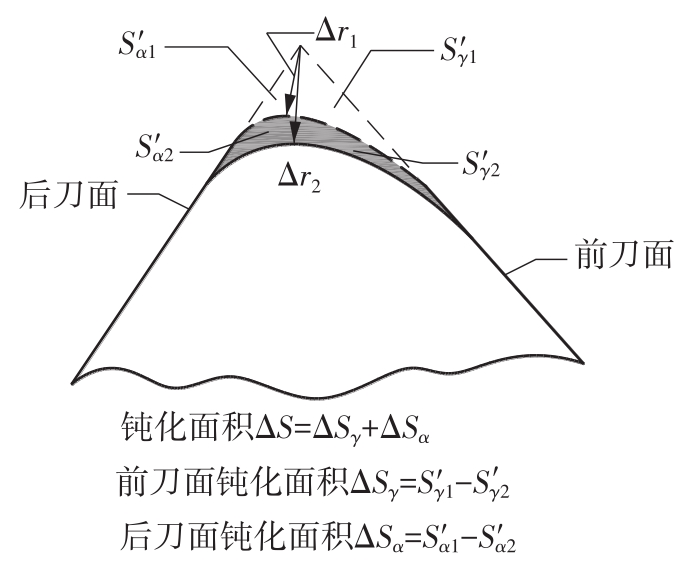

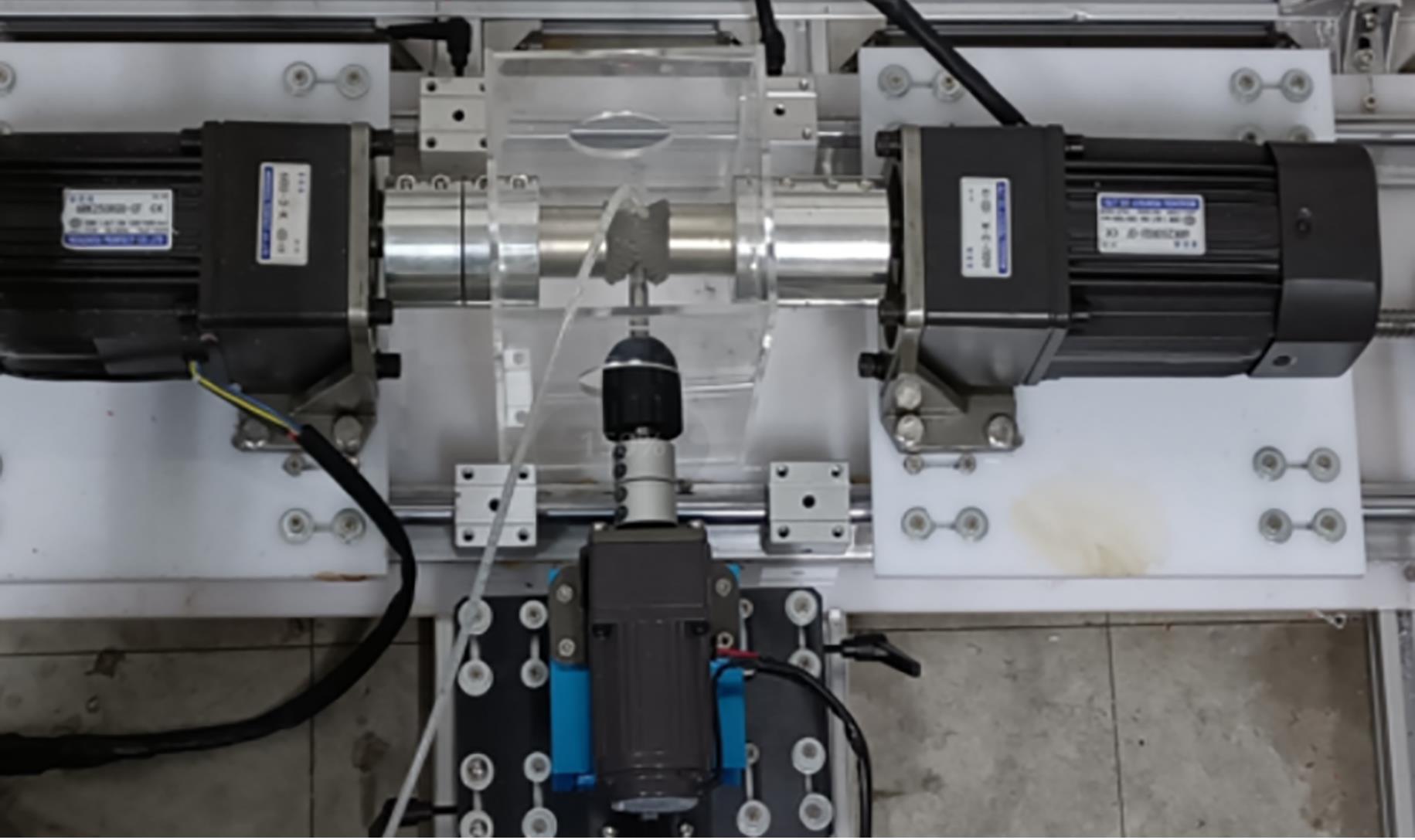

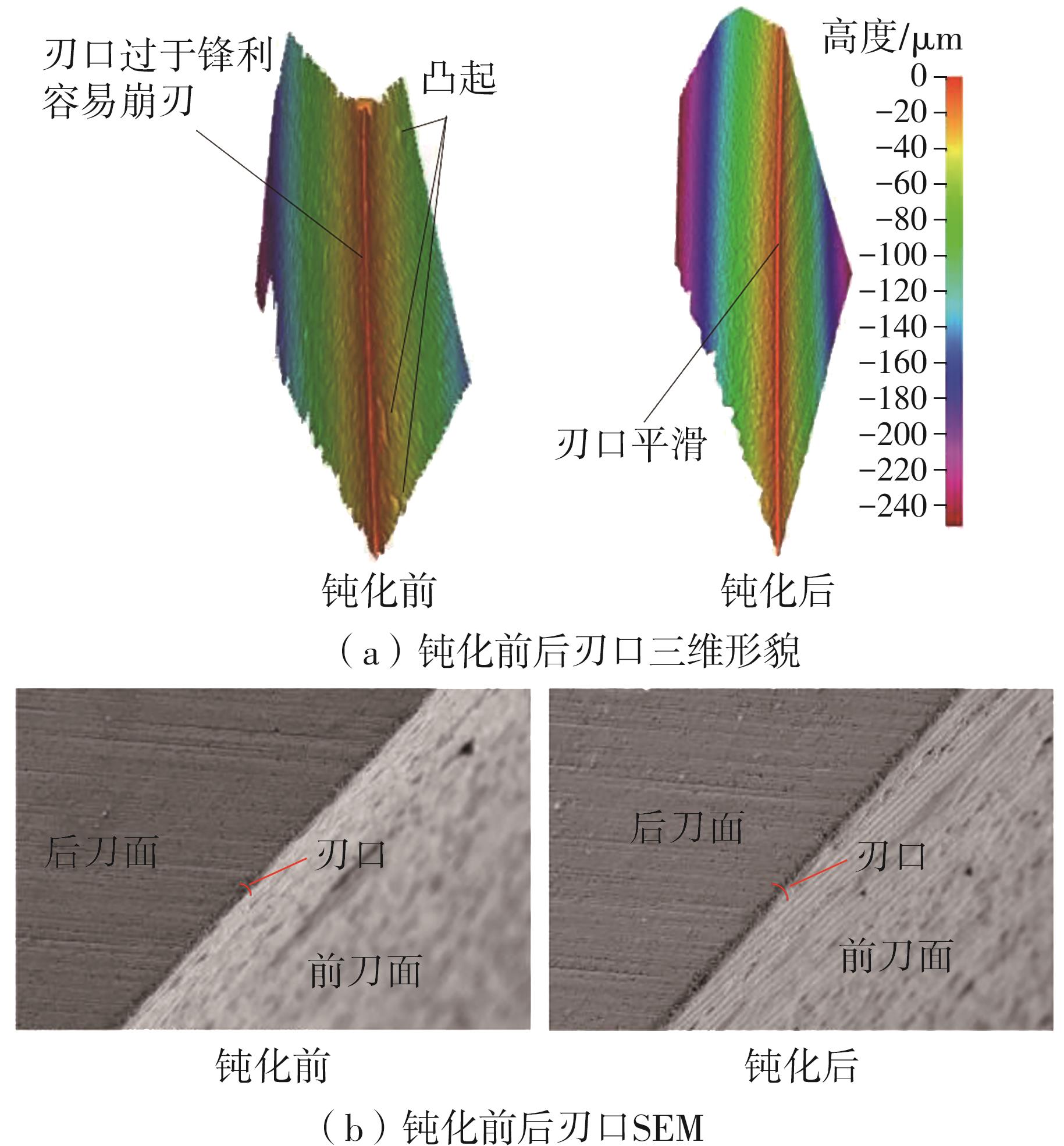

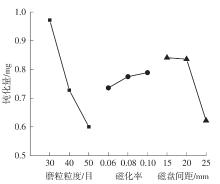

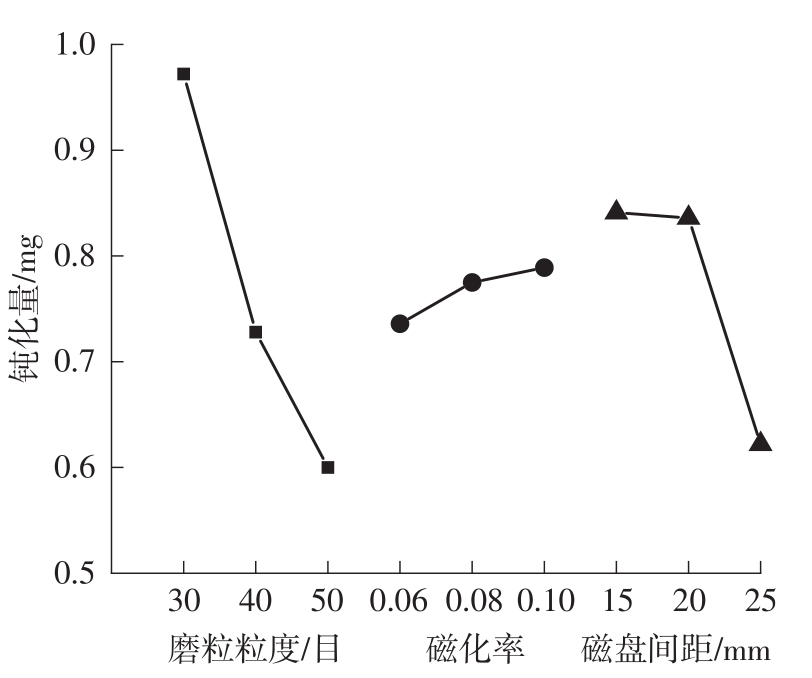

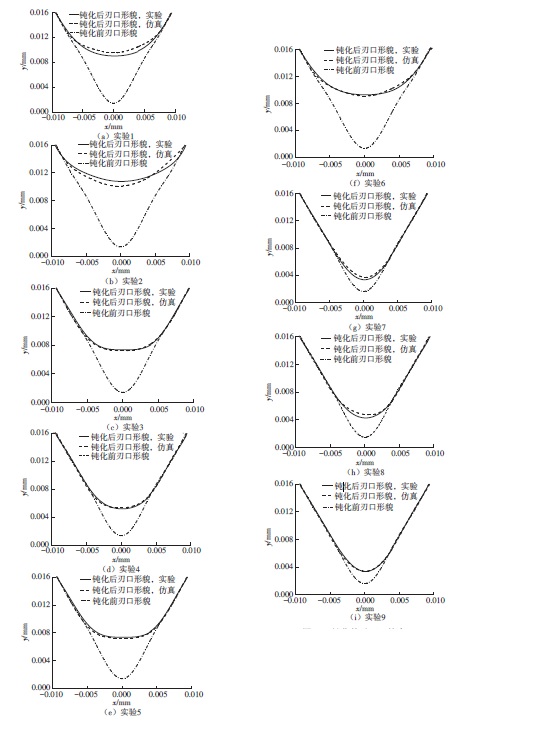

磁弹磨粒具有磁性、低弹性模量以及优良的研磨性能,能够提高加工效率和加工质量。首先,基于磁场基本理论和磁弹磨粒特性,分析了磁弹磨粒双磁盘磁力刀具钝化机制;然后,基于磁场中磁弹磨粒的磁场力对离散元软件EDEM进行二次开发,建立了磁弹磨粒双磁盘磁力刀具钝化过程仿真模型,研究了磨粒粒度、磁化率和磁盘间距对刃口碰撞次数和磨粒旋转速度的影响规律;最后,采用Matlab软件对刀具刃口轮廓进行重建,提出了基于钝化面积的改进形状因子表征方法,通过正交实验研究了磨粒粒度、磁化率和磁盘间距对刃口钝化量的影响规律,并验证了所提改进形状因子表征方法的可行性。结果表明:随着磁弹磨粒粒度的增大、磁化率的增加和磁盘间距的减小,刃口碰撞次数和磨粒旋转速度增大;钝化参数对刃口钝化量的影响程度大小依次为磨粒粒度、磁盘间距、磁化率,最优钝化参数组合为磨粒粒度40目、磁化率0.1、磁盘间距15 mm;仿真与实验钝化面积的最大相对误差为16.33%,最小相对误差为0.42%,仿真能够较好地预测刃口钝化形貌,且改进的刃口形状因子能够较好地表征刀具刃口钝化形貌。

中图分类号: