| 1 |

PRADHAN B .A study on effectiveness of inorganic and organic corrosion inhibitors on rebar corrosion in concrete:a review[J].Materials Today:Proceedings,2022,65(2):1360-1366.

|

| 2 |

XU P, JIANG L, GUO M Z,et al .Influence of sulfate salt type on passive film of steel in simulated concrete pore solution[J].Construction and Building Materials,2019,223:352-359.

|

| 3 |

SABEL C F, VICTOR D G .Governing global problems under uncertainty:making bottom-up climate policy work[J].Climatic Change,2015,144(1):15-27.

|

| 4 |

KAMARUZZAMAN W M I W M, NASIR N A M, HAMIDI N A S M,et al .Frontiers in organic corrosion inhibitors for chloride and acidic media:a review[J].Journal of Bio- and Tribo-Corrosion,2022,8(2):1-18.

|

| 5 |

ANGST U M .Challenges and opportunities in corrosion of steel in concrete[J].Materials and Structures,2018,51(1):1-20.

|

| 6 |

BOLZONI F, BRENNA A, ORMELLESE M .Recent advances in the use of inhibitors to prevent chloride-induced corrosion in reinforced concrete[J].Cement and Concrete Research,2022,154:1-9.

|

| 7 |

RAJA P B, GHOREISHIAMIRI S, ISMAIL M .Natural corrosion inhibitors for steel reinforcement in concrete-a review[J].Surface Review and Letters,2015,22(3):1-8.

|

| 8 |

BOLZONI F, COPPOLA L, GOIDANICH S,et al .Corrosion inhibitors in reinforced concrete structures Part 1:preventative technique [J].Corrosion Engineering,Science and Technology,2013,39(3):219-228.

|

| 9 |

VERMA C, OLASUNKANMI L O, EBENSO E E,et al .Substituents effect on corrosion inhibition performance of organic compounds in aggressive ionic solutions:a review[J].Journal of Molecular Liquids,2018,251:100-118.

|

| 10 |

GENG J, LIU J, YAN J,et al .Chemical composition of corrosion products of rebar caused by carbonation and chloride[J].International Journal of Corrosion,2018,2018:1-7.

|

| 11 |

XU Y, GUO X, CHEN N,et al .Synthesis and corrosion inhibitory effect of a novel β-amino alcohol compound[J].Colloids and Surfaces A Physicochemical and Engineering Aspects,2021,610(3):1-9.

|

| 12 |

LOTHENBACH B, WINNEFELD F, ALDER C,et al .Effect of temperature on the pore solution,microstructure and hydration products of Portland cement pastes[J].Cement and Concrete Research,2007,37(4):483-491.

|

| 13 |

GHODS P, ISGOR O B, CARPENTER G J C,et al .Nano-scale study of passive films and chloride-induced depassivation of carbon steel rebar in simulated concrete pore solutions using FIB/TEM[J].Cement and Concrete Research,2013,47:55-68.

|

| 14 |

赵冰,杜荣归,林昌健 .三种有机缓蚀剂对钢筋阻锈作用的电化学研究[J].电化学,2005,11(4):382-386.

|

|

ZHAO Bing, DU Ronggui, LIN Changjian .A study of three corrosion inhibitors for reinforcing steel in SPS solution by electrochemical methods[J].Electrochemistry,2005,11(4):382-386.

|

| 15 |

NER B E .Corrosion inhibitors for reinforced concrete-an EFC state of the art report[J].Corrosion of Reinforcement in Concrete:Monitoring,Prevention and Rehabilitation Techniques,2014,38:170-184.

|

| 16 |

STEFANONI M, ANGST U, ELSENER B .Influence of calcium nitrate and sodium hydroxide on carbonation-induced steel corrosion in concrete[J].Corrosion,2019,75(7):737-744.

|

| 17 |

SINGH J K, YANG H M, LEE H S,et al .Role of L-arginine on the formation and breakdown of passive film onto the steel rebars surface in chloride contaminated concrete pore solution[J].Journal of Molecular Liquids,2021,337:1-15.

|

| 18 |

TOUJAS S, VAZQUEZ M, VALCARCE M B .Unexpected effect of citrate ions on the corrosion process of carbon steel in alkaline solutions[J].Corrosion Science,2017,128(11):94-99.

|

| 19 |

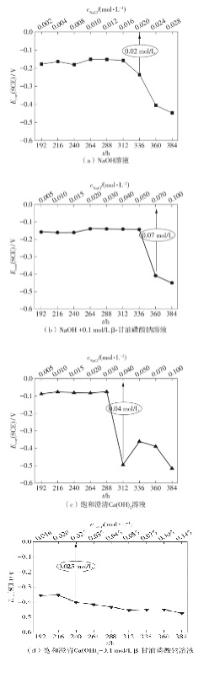

周霄骋,穆松,马麒,等 .混凝土模拟孔溶液中有机钢筋阻锈剂的加速评价及等效性分析[J].硅酸盐学报,2021,49(8):1713-1721.

|

|

ZHOU Xiaocheng, MU Song, MA Qi,et al .Accelerated evaluation of organic steel corrosion inhibitor in simulated pore solution of concrete and its equivalence analysis[J].Journal of the Chinese Ceramic Society,2021,49(8):1713-1721.

|

| 20 |

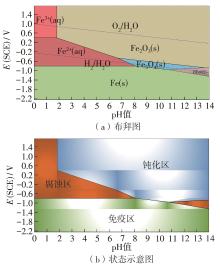

POURBAIX M .Applications of electrochemistry in corrosion science and in practice[J].Corrosion Science,1974,14(1):25-82.

|

| 21 |

PEDEFERRI P, PEDEFERRI P .Pourbaix diagrams[M].Corrosion Science and Engineering,2018:57-72.

|

| 22 |

THOMPSON W T, KAYE M H, BALE C W,et al .Pourbaix diagrams for multielement systems[J].Uhlig’s Corrosion Handbook,2011,3:103-109.

|

| 23 |

BEVERSKOG B, PUIGDOMENECH I .Revised pourbaix diagrams for iron at 25-300 C[J].Corrosion Science,1996,38(12):2121-2135.

|

| 24 |

MCCAFFERTY E .Introduction to corrosion science[M].New York,NY:Springer,2010.

|

| 25 |

DAS J K, PRADHAN B .Effect of cation type of chloride salts on corrosion behaviour of steel in concrete powder electrolyte solution in the presence of corrosion inhibitors[J].Construction and Building Materials,2019,208(30):175-191.

|

| 26 |

ZHENG H, DAI J G, POON C S,et al .Influence of calcium ion in concrete pore solution on the passivation of galvanized steel bars[J].Cement and Concrete Research,2018,108:46-58.

|

| 27 |

WANG D, MING J, SHI J .Enhanced corrosion resistance of rebar in carbonated concrete pore solutions by Na2HPO4 and benzotriazole[J].Corrosion Science,2020,174:1-12.

|

| 28 |

TEYMOURI F, SAMIEIi I, ALLAHKARAM S R,et al .Passive film alteration of reinforcing steel through [MoO42-]/[RCOO-]interfacial co-interaction for enhanced corrosion resistance in chloride contaminated concrete pore solution[J].Journal of Molecular Liquids,2022,356:1-18.

|

| 29 |

ZHAO Y, PAN T, YU X,et al .Corrosion inhibition efficiency of triethanolammonium dodecylbenzene sulfonate on Q235 carbon steel in simulated concrete pore solution[J].Corrosion Science,2019,158:1-12.

|

| 30 |

SHI J, SUN W, JIANG J,et al .Influence of chloride concentration and pre-passivation on the pitting corrosion resistance of low-alloy reinforcing steel in simulated concrete pore solution[J].Construction & Building Materials,2016,111(15):805-813.

|

| 31 |

QIANG Y, ZHANG S, XU S,et al .The effect of 5-nitroindazole as an inhibitor for the corrosion of copper in a 3.0% NaCl solution[J].RSC Adv,2015,5(78):63866-63873.

|

| 32 |

SáNCHEZ M, GREGORI J, ALONSO M C,et al .Anodic growth of passive layers on steel rebars in an alkaline medium simulating the concrete pores[J].Electrochimica Acta,2006,52(1):47-53.

|

| 33 |

XU W, DAUB K, ZHANG X,et al .Oxide formation and conversion on carbon steel in mildly basic solutions[J].Electrochimica Acta,2009,54(24):5727-5738.

|

| 34 |

FREIRE L, NóVOA X R, MONTEMOR M F,et al .Study of passive films formed on mild steel in alkaline media by the application of anodic potentials[J].Materials Chemistry and Physics,2009,114(2/3):962-972.

|

| 35 |

WANG F, ZHANG Z, WU S,et al .Effect of inhibitor on adsorption behavior and mechanism of micro-zone corrosion on carbon steel[J].Materials,2019,12(12):1901-1911.

|