| 1 |

张纪刚,舒凡,赵铁军,等 .不锈钢管中管混凝土海洋平台导管腿轴压性能试验研究[J].建筑结构学报,2018,39(S1):279-285.

|

|

ZHANG Jigang, SHU Fan, ZHAO Tiejun,et al .Experimental study on axial compressive behavior of concrete-filled double skin stainless steel tube jacket leg of offshore platform[J].Journal of Building Structures,2018,39(S1):279-285.

|

| 2 |

乔崎云,张雯雯,曹万林,等 .薄壁不锈钢管-钢骨混凝土短柱轴压力学性能试验研究[J].工业建筑,2020,50(2):143-149.

|

|

QIAO Qiyun, ZHANG Wenwen, CAO Wanlin,et al .Experimental research on the mechanical properties of thin-walled stainless steel tube composite short columns filled with steel-reinforced concrete under axial compression[J].Industrial Construction,2020,50(2):143-149.

|

| 3 |

代鹏,杨璐,卫璇,等 .不锈钢管混凝土短柱轴压承载力试验研究[J].工程力学,2019,36(S1):298-305.

|

|

DAI Peng, YANG Lu, WEI Xuan,et al .Experimental studies on the behavior and capacity of concrete filled stainless steel tube short columns[J].Engineering Mechanics,2019,36(S1):298-305.

|

| 4 |

LAM D, GARDNER L .Structural design of stainless steel concrete filled columns[J].Journal of Constructional Steel Research,2008,64(11):1275-1282.

|

| 5 |

UY B, TAO Z, HAN L H .Behaviour of short and slender concrete-filled stainless steel tubular columns[J].Journal of Constructional Steel Research,2011,67(3):360-378.

|

| 6 |

陈俊龙 .CFRP约束圆不锈钢管混凝土短柱轴压性能研究[D].成都:西华大学,2021.

|

| 7 |

BAMBACH M R, ELCHALAKANI M .Plastic mechanism analysis of steel SHS strengthened with CFRP under large axial deformation[J].Thin-Walled Structures,2007,45(2):159-170.

|

| 8 |

BAMBACH M R .Axial capacity and crushing behavior of metal-fiber square tubes-steel,stainless steel and aluminum with CFRP[J].Composites Part B:Engineering,2010,41(7):550-559.

|

| 9 |

唐红元,周祥,黄靖翔,等 .CFRP与不锈钢界面黏结性能试验研究[J].建筑结构学报,2018,39(12):185-193.

|

|

TANG Hongyuan, ZHOU Xiang, HUANG Jingxiang,et al .Experimental study on bond behavior of CFRP-to-stainless steel interface[J].Journal of Building Structures,2018,39(12):185-193.

|

| 10 |

唐红元,马梦淋,陈俊龙,等 .碳纤维复材布加固不锈钢圆管短柱轴心受压试验研究[J].工业建筑,2019,49(10):185-191,207.

|

|

TANG Hongyuan, MA Menglin, CHEN Junlong,et al .Experimental investigation on stainless steel tube short column starengthened with CFRP under axial compression[J].Industrial Construction,2019,49(10):185-191,207.

|

| 11 |

NAZARI A R, KABIR M Z, HOSSEINI-TOUDESHKY H .Development of work-hardening performance in stainless-steel cylindrical columns by application of CFRP jackets[J].Composite Structures,2018,203:38-49.

|

| 12 |

SHARIF A M, AL-MEKHLAFI G M, AL-OSTA M A .Structural performance of CFRP-strengthened concrete-filled stainless steel tubular short columns[J].Engineering Structures,2019,183:94-109.

|

| 13 |

TANG H, CHEN J, FAN L,et al .Experimental investigation of FRP-confined concrete-filled stainless steel tube stub columns under axial compression[J].Thin-Walled Structures,2020,146:106483.

|

| 14 |

XU Y, TANG H, CHEN J,et al .Numerical analysis of CFRP-confined concrete-filled stainless steel tubular stub columns under axial compression[J].Journal of Building Engineering,2021,37(2):102130.

|

| 15 |

王金刚 .奥氏体不锈钢再钝化膜的耐腐蚀性能研究[J].西安石油大学学报(自然科学版),2006,21(5):79-81,95.

|

|

WANG Jingang .Study on the corrosion resistance of the repassivation film of austenitic stainless steel[J].Journal of Xi’an Shiyou University (Natural Science Edition),2006,21(5):79-81,95.

|

| 16 |

王竹,冯喆,张雷,等 .电化学方法在不锈钢腐蚀研究中的应用现状及发展趋势[J].工程科学学报,2020,42(5):549-556.

|

|

WANG Zhu, FENG Zhe, ZHANG Lei,et al .Current application and development trend in electrochemical measurement methods for the corrosion study of stainless steels[J].Chinese Journal of Engineering,2020,42(5):549-556.

|

| 17 |

GUO M, HU B, XING F,et al .Characterization of the mechanical properties of eco-friendly concrete made with untreated sea sand and seawater based on statistical analysis[J].Construction and Building Materials,2020,234:117339.

|

| 18 |

LI Y L, ZHAO X L, SINGH R K R,et al .Experimental study on seawater and sea sand concrete filled GFRP and stainless steel tubular stub columns[J].Thin-Walled Structures,2016,106:390-406.

|

| 19 |

LI Y L, ZHAO X L, SINGH R K R,et al .Tests on seawater and sea sand concrete-filled CFRP,BFRP and stainless steel tubular stub columns[J].Thin-Walled Structures,2016,108:163-184.

|

| 20 |

严康 .FRP-不锈钢管-海水海砂混凝土柱轴压力学性能试验研究[D].广州:广东工业大学,2020.

|

| 21 |

柏佳文,魏洋,张依睿,等 .新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J].复合材料学报,2021,38(9):3076-3085.

|

|

BAI Jiawen, WEI Yang, ZHANG Yirui,et al .Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J].Acta Materiae Compositae Sinica,2021,38(9):3076-3085.

|

| 22 |

WEI Y, BAI J, ZHANG Y,et al .Compressive performance of high-strength seawater and sea sand concrete-filled circular FRP-steel composite tube columns[J].Engineering Structures,2021,240:112357.

|

| 23 |

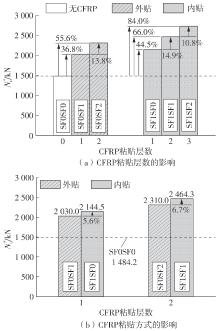

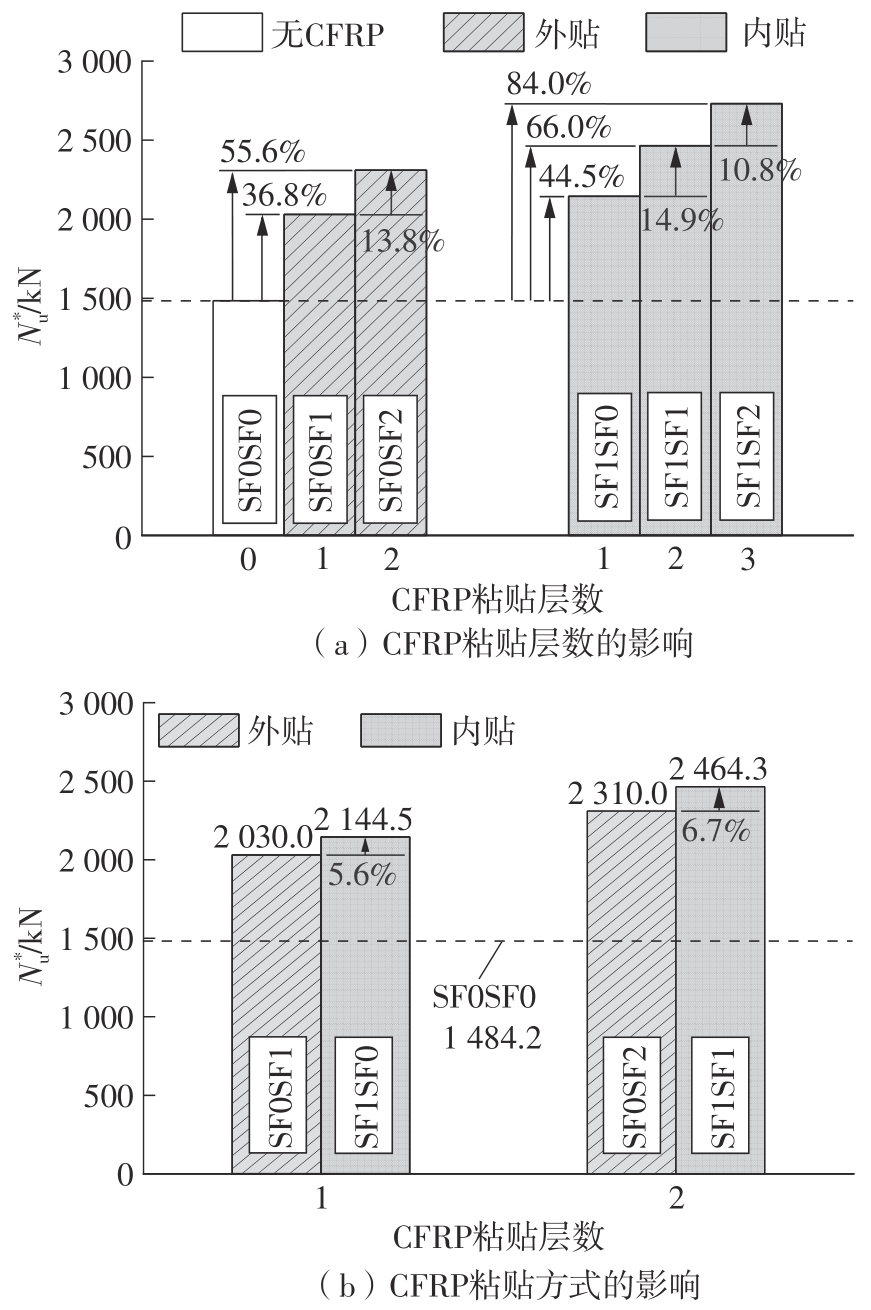

陈宗平,庞云升,许瑞天,等 .CFRP-钢复合约束海洋混凝土柱轴压性能试验研究及承载力计算[J].建筑结构学报,2023,44(7):116-128.

|

|

CHEN Zongping, PANG Yunsheng, XU Ruitian,et al .Experimental study on axial compression performance and bearing capacity calculation of CFRP-steel confined Ocean concrete columns[J].Journal of Building Structures,2023,44(7):116-128.

|

| 24 |

CHEN Z, PANG Y, XU R,et al .Mechanical performance of ocean concrete-filled circular CFRP-steel tube columns under axial compression[J].Journal of Constructional Steel Research,2022,198:107514.

|

| 25 |

陈宗平,徐炜圣,周济 .CFRP铝合金复合管海洋混凝土柱轴压性能试验及承载力计算[J].土木工程学报,2023,56(6):25-37.

|

|

CHEN Zongping, XU Weisheng, ZHOU Ji .Axial compression experiment and bearing capacity calculation of marine concrete filled CFRP aluminum alloy tube columns[J].China Civil Engineering Journal,2023,56(6):25-37.

|

| 26 |

CHEN Z, XU W, ZHOU J .Mechanical performance of marine concrete filled CFRP-aluminum alloy tube columns under axial compression:experiment and finite element analysis[J].Engineering Structures,2022,272:114993.

|

| 27 |

BUCHANAN C, GARDNER L, LIEW A .The continuous strength method for the design of circular hollow sections[J].Journal of Constructional Steel Research,2016,118:207-216.

|

| 28 |

过镇海,王传志 .多轴应力下混凝土的强度和破坏准则研究[J].土木工程学报,1991,24(3):1-14.

|

|

GUO Zhenhai, WANG Chuanzhi .Investigation of strength and failure criterion of concrete under multi-axial stresses[J].China Civil Engineering Journal,1991,24(3):1-14.

|

| 29 |

CECS 28.Technical specification for concrete-filled steel tubular[M].Beijing:China Planning Press,2012.

|

| 30 |

杨国静 .钢管活性粉末混凝土柱轴压受力性能和极限承载力试验研究[D].北京:北京交通大学,2013.

|

| 31 |

LIANG M, WU Z M, UEDA T,et al .Experiment and modeling on axial behavior of carbon fiber reinforced polymer confined concrete cylinders with different sizes[J].Journal of Reinforced Plastics and Composites,2012,31(6):389-403.

|

| 32 |

LAM L, TENG J G .Design-oriented stress-strain model for FRP-confined concrete[J].Construction and Building Materials,2003,17(6/7):471-489.

|