华南理工大学学报(自然科学版) ›› 2022, Vol. 50 ›› Issue (10): 106-113.doi: 10.12141/j.issn.1000-565X.220287

所属专题: 2022年流体动力与机电控制工程

基于虚拟双目视觉的锥阀振动测试

李贝贝1 魏令行1 刘秀梅1 赵巧2 刘启航1 张雨佳1

- 1.中国矿业大学 机电工程学院,江苏 徐州 221116

2.中国矿业大学 大学生创新训练中心,江苏 徐州 221116

Vibration Testing of Poppet Valve Based on Virtual Binocular Vision

LI Beibei1 WEI Lingxing1 LIU Xiumei1 ZHAO Qiao2 LIU Qihang1 ZHANG Yujia1

- 1.School of Mechatronic Engineering, China University of Mining and Technology, Xuzhou 221116, Jiangsu, China

2.College Student Innovation Training Center, China University of Mining and Technology, Xuzhou 221116, Jiangsu, China

摘要:

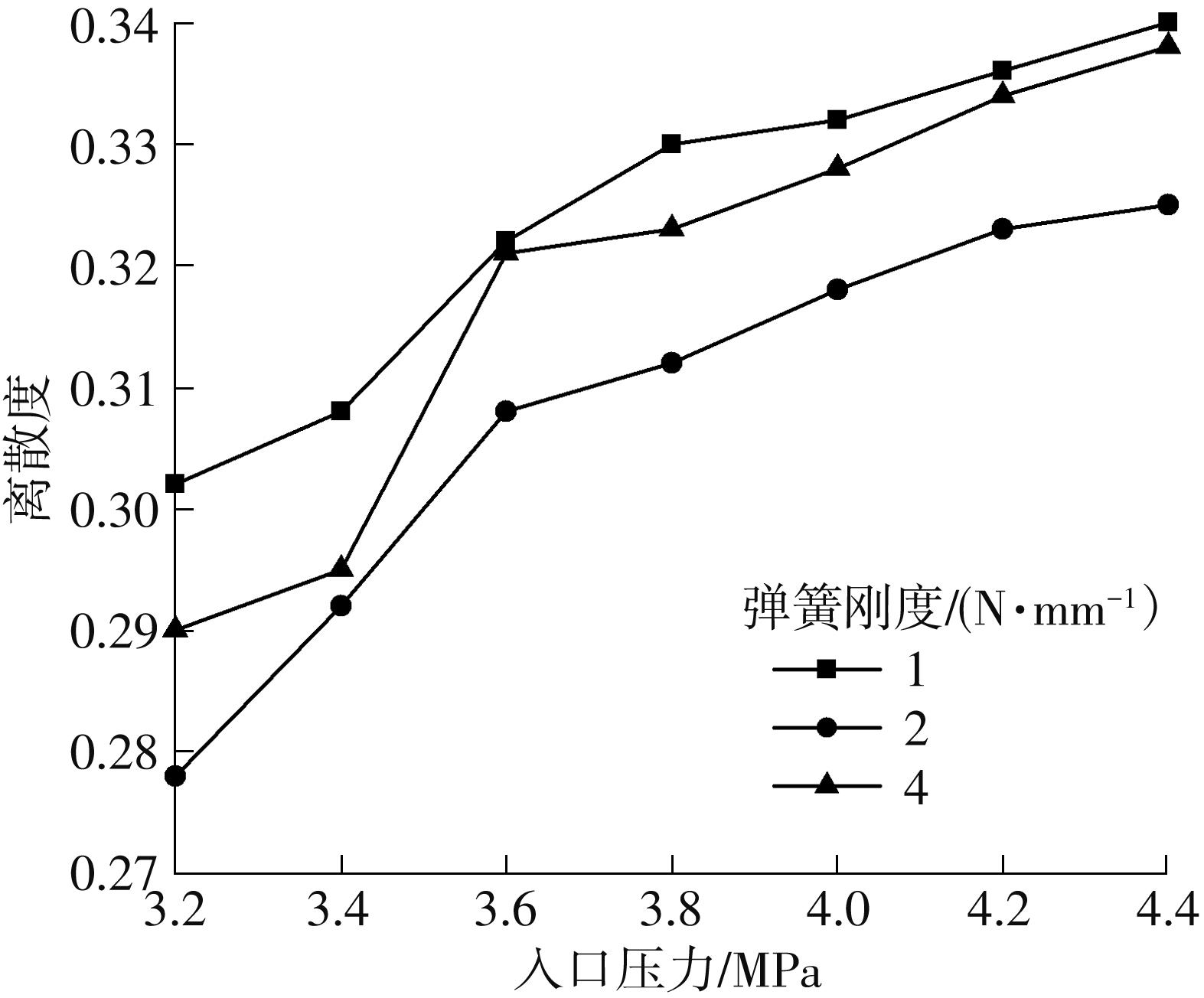

液压阀阀芯附近介质流量变化导致的阀芯振动对锥阀的稳定性和使用寿命有重要影响。为了探究锥阀的三维振动特性,文中提出了一种基于虚拟双目视觉的可视化实验方法,并获得了阀芯振动的图像序列。通过对阀芯轮廓拟合得出了阀芯几何顶点的空间坐标值,提高了阀芯位置的测量精度。通过分析不同出入口压力、弹簧刚度等条件下的阀芯振动特性,发现阀芯振动的空间范围和冲击程度与液压系统运行状况和阀芯结构密切相关。入口压力从3.2 MPa增大至4.4 MPa时,阀芯振动逐渐加剧,离散度增大;预压缩量从14 mm增大至17 mm时,阀芯振动趋于平稳,离散度减小;此外,随着弹簧刚度和阀芯半锥角的增大,阀芯振动的离散度也呈现出先减小后增大的趋势,且其最小值分别在弹簧刚度为2 N/mm和阀芯半锥角为30°时出现。在阀芯振动的沿轴向、正面和侧面3个方向的投影中,侧面径向振动的波形因子大于正面径向的波形因子,而轴向振动的波形因子最小。波形因子的变化趋势与离散度的变化趋势一致,阀芯振动的离散度和波形因子呈正相关关系,且在阀芯半锥角为30°、弹簧刚度为2 N/mm时的波形因子最小。文中研究结果可以为锥阀结构的液压阀的结构设计提供理论支撑,从而提高液压系统运行的稳定性,减小振动对于液压阀的损害。

中图分类号: