收稿日期: 2025-02-24

网络出版日期: 2025-03-17

基金资助

国家自然科学基金项目(U24A2048);宁夏回族自治区中央引导地方科技发展专项(2023FRD05006);中国博士后基金项目(2024M750943)

Mix Design and Performance Optimization of Stone Powder-Rich Manufactured Sand Concrete

Received date: 2025-02-24

Online published: 2025-03-17

Supported by

the National Natural Science Foundation of China(U24A2048);the Local Science and Technology Development Projects in Ningxia Hui Autonomous Region Supported by Central Government Guidance(2023FRD05006);the China Postdoctoral Science Foundation(2024M750943)

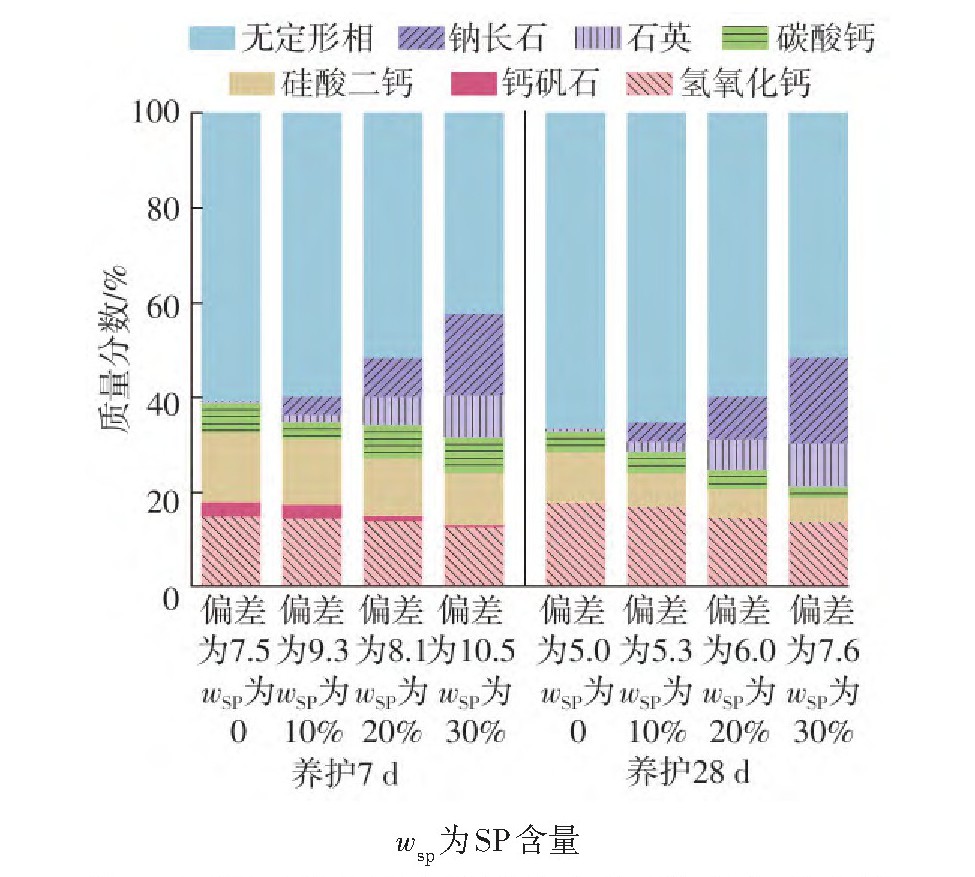

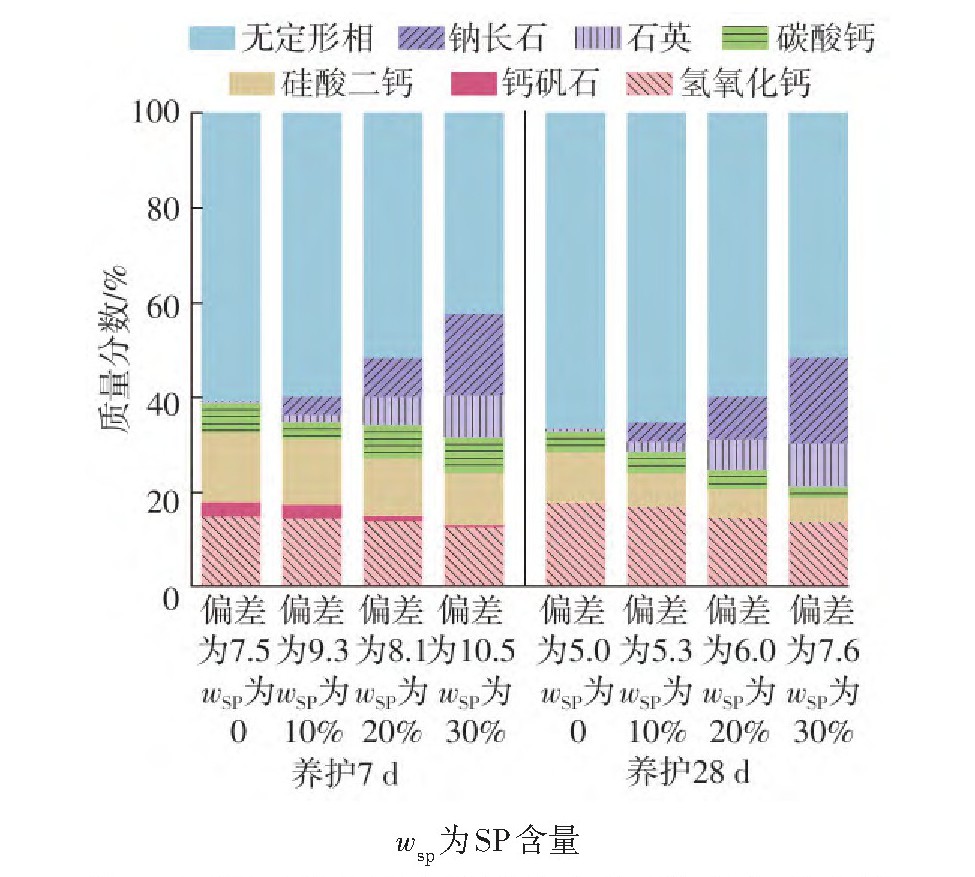

在机制砂制备过程中,大量石粉被筛分掩埋,导致资源浪费和环境污染。为提高机制砂石粉利用率,将废弃石粉高值化应用在混凝土中,并将机制砂中的石粉视作胶凝组分替代水泥,使用XRD、TG、SEM等测试手段研究花岗岩石粉对硬化水泥浆体微结构演变的影响,确定了石粉替代水泥最佳范围。通过调控机制砂石粉含量、粗骨料级配、砂率与水胶比等,优化混凝土工作性能和力学性能,揭示浆体体积分数对混凝土工作性能和力学性能的影响机制,利用高石粉含量机制砂制备了低成本、工作性能与力学性能满足要求的混凝土。结果表明:石粉替代10%(质量分数)的P.II 52.5硅酸盐水泥时,7 d和28 d浆体水化产物数量没有明显减少,微结构仍然较为致密;当石粉替代水泥比例超过20%(质量分数)时,浆体中水化产物数量减少超过20%(质量分数)、孔隙增多,导致强度大幅度降低;随机制砂石粉含量的增加,相同坍落度下混凝土减水剂掺量有所增加,浆体体积分数在31%~32%时,混凝土可获得良好工作性能和力学性能。在此基础上,采用石粉含量(质量分数)为15.1%、16.5%和18.7%的机制砂分别制备了满足工程性能要求的C30、C40和C50混凝土,水泥用量分别减少54、63和92 kg/m3,显著降低了混凝土成本和碳排放。

张同生 , 李凯 , 谭康豪 , 常泽洲 , 谭艳臣 , 唐亮 , 杨东来 , 曾思清 . 高石粉机制砂混凝土组成设计与性能优化[J]. 华南理工大学学报(自然科学版), 2025 , 53(8) : 123 -136 . DOI: 10.12141/j.issn.1000-565X.250042

During the production of manufactured sand, a large amount of stone powder was sieved and buried, leading to resource waste and environmental pollution. To improve the utilization rate of manufactured sand stone powder, this study explores the high-value application of waste stone powder in concrete. By treating the stone powder in manufactured sand as a cementitious component to partially replace cement, the effects of granite stone powder on the microstructural evolution of hardened cement paste were investigated using XRD, TG, SEM, and other characterization methods, leading to the identification of the optimal cement replacement range. Furthermore, by adjusting the stone powder content in manufactured sand, coarse aggregate gradation, sand ratio, and water-to-binder ratio, the workability and mechanical properties of concrete were optimized. The study reveals the mechanism by which paste volume fraction influences concrete’s workability and mechanical performance, and successfully produced low-cost concrete with acceptable workability and mechanical strength using manufactured sand with a high stone powder content. The results show that cement paste with 10% stone powder retained a denser microstructure, as the amount of hydration products showed negligible reduction compared to that of pure cement paste after 7-day and 28-day curing. However, when the substitution of cement with stone powder exceeded 20%, the amount of hydration products decreased significantly by more than 20%, leading to a porous microstructure and lower compressive strength compared to that of pure cement paste. When manufactured sand (MS) with high stone powder content is used in concrete production, the dosage of superplasticizer needs to be increased slightly under the same slump requirement. Additionally, the optimal workability and mechanical properties of MS concrete were achieved when the volume fraction of paste lay in the range of 31~32%. Consequently, C30, C40, and C50 concretes meeting target property requirements were prepared using MS with 15.1%, 16.5%, and 18.7% stone powder content, respectively, resulting in cement consumption reductions of 54, 63, and 92 kg/m³, and thereby significant reductions in cost and carbon emissions.

| [1] | DOBISZEWSKA M, BAGCAL O, BEYCIO?LU A,et al .Utilization of rock dust as cement replacement in cement composites:an alternative approach to sustainable mortar and concrete productions[J].Journal of Building Engineering,2023,69:106180/1-12. |

| [2] | ALI M B, SAIDUR R, HOSSAIN M S .A review on emission analysis in cement industries[J].Renewable and Sustainable Energy Reviews,2011,15(5):2252-2261. |

| [3] | DAMTOFT J S, LUKASIK J, HERFORT D,et al .Sustainable development and climate change initiatives[J].Cement and Concrete Research,2008,38(2):115-127. |

| [4] | 刘战鳌,周明凯,姚楚康 .机制砂中细粉的危害性及评价研究[J].建筑材料学报,2015,18(1):150-155. |

| LIU Zhan-ao, ZHOU Ming-kai, YAO Chu-kang .Research on harmfulness and evaluation of various microfines in manufactured sand[J].Journal of Building Materials,2015,18(1):150-155. | |

| [5] | ALIABDO A A, ELMOATY M ABD, AUDA E M .Re-use of waste marble dust in the production of cement and concrete[J].Construction and Building Materials,2014,50(4):28-41. |

| [6] | 建设用砂: [S]. |

| [7] | JEKNAVORIAN A A, KOEHLER E .Use of chemical admixtures to modify the rheological behavior of cementitious systems containing manufactured aggregates[J].Journal of Civil Engineering and Architecture,2012,6(10):1263-1272. |

| [8] | LI J .Study on different factors for working performance and strength of concrete with machined-sand[J].New Building Materials,2020,47(5):13-21. |

| [9] | 王将华,薛翠真,张宇,等 .花岗岩石粉对砂浆干燥收缩性能的影响[J].材料导报,2023,37(22):111-116. |

| WANG Jianghua, XUE Cuizhen, ZHANG Yu,et al .Effect of granite powder on drying shrinkage[J].Materials Reports,2023,37(22):111-116. | |

| [10] | JADHAV P A, KULKARNI D K .An experimental investigation on the properties of concrete containing manufactured sand[J].International Journal of Advanced Engineering Technology,2012,3(2):101-104. |

| [11] | 李化建,赵国堂,谢永江,等 .石灰石粉作为混凝土矿物掺合料的研究[J].铁道建筑,2012,458(4):135-138. |

| LI Hua-jian, ZHAO Guo-tang, XIE Yong-jiang,et al .Study on limestone powder as mineral admixture in concrete[J].Railway Engineering,2012,458(4):135-138. | |

| [12] | 刘战鳌,周明凯,李北星 .石粉对机制砂混凝土性能影响的研究进展[J].材料导报,2014,28(19):100-103. |

| LIU Zhan-ao, ZHOU Ming-kai, LI Bei-xing .Research progress on influence of microfines on manufactured sand concrete’s performance[J].Materials Reports,2014,28(19):100-103. | |

| [13] | TAO F, LIANG J L, LAN Y F,et al .Effect of stone powder content on mechanical properties of manufactured sand concrete[J].Iranian Journal of Science and Technology,Transactions of Civil Engineering,2022,46(6):4255-4264. |

| [14] | CHE D L, WANG J J, DING Z W,et al .Research on the performance of manufactured sand concrete with different stone powder content[C]∥ Proceedings of the 3rd International Conference on Civil,Architecture and Urban Engineering.Guangzhou:Academic Exchange Information Centre,2021,283:01044/1-13. |

| [15] | 王振,李化建,黄法礼,等 .石灰岩机制砂混凝土抗冻性能研究[J].建筑材料学报,2023,26(5):516-523,537. |

| WANG Zhen, LI Huajian, HUANG Fali,et al .Frost resistance of limestone manufactured sand concrete[J].Journal of Building Materials,2023,26(5):516-523,537. | |

| [16] | 周翱翔,张云升,钱如胜,等 .花岗岩石粉对机制砂混凝土基本性能及气体渗透特性的影响[J].复合材料学报,2024,41(7):3704-3715. |

| ZHOU Aoxiang, ZHANG Yunsheng, QIAN Rusheng,et al .Influence of granite stone powder on the basic properties and gas permeability characteristics of mechanism sand concrete[J].Acta Materiae Compositae Sinica,2024,41(7):3704-3715. | |

| [17] | KUMAR K P, RAMESH P S, ARAVINDA P T .Effect of fines on strength and durability of concrete with manufactured sand[J].Materials Today:Proceedings,2022,66(13):2381-2386. |

| [18] | ABD E M .Mechanical properties and corrosion resistance of concrete modified with granite dust[J].Construction and Building Materials,2013,47(24):743-752. |

| [19] | BINICI H, YARDIM Y, AKSOGAN O,et al .Durability properties of concretes made with sand and cement size basalt[J].Sustainable Materials and Technologies,2020,23:e00145/1-9. |

| [20] | DOBISZEWSKA M, SCHINDLER A K, PICHóR W .Mechanical properties and interfacial transition zone microstructure of concrete with waste basalt powder addition[J].Construction and Building Materials,2018,177:222-229. |

| [21] | SINGH M, SRIVASTAVA A, BHUNIA D .Long term strength and durability parameters of hardened concrete on partially replacing cement by dried waste marble powder slurry[J].Construction and Building Materials,2019,198:553-569. |

| [22] | ?ZKILI? Y O, ZEYBEK ?, BAHRAMI A,et al .Optimum usage of waste marble powder to reduce use of cement toward eco-friendly concrete[J].Journal of Materials Research And Technology,2023,25:4799-4819. |

| [23] | CHEN P X, WANG X H, ZHANG T S,et al .Effect of ultrafine recycled brick powder on the properties of blended cement:hydration kinetics,microstructure evolution and properties development[J].Construction and Building Materials,2023,394:132239. |

| [24] | 普通混凝土拌合物性能试验方法标准: [S]. |

| [25] | 普通混凝土力学性能试验方法标准: [S]. |

| [26] | DOBISZEWSKA M, BAGCAL O, BEYCIO?LU A,et al .Utilization of rock dust as cement replacement in cement composites:an alternative approach to sustainable mortar and concrete productions[J].Journal of Building Engineering,2023,69:106180. |

| [27] | JAGADESH P, OYEBISI S, MUTHU A H,et al .Microscopic analyses and performance characteristics of granite powder blended cement[J].Construction and Building Materials,2024,426:136006/1-18. |

| [28] | BARRA B, MOMM L, GUERRERO Y,et al .Characterization of granite and limestone powders for use as fillers in bituminous mastics dosage[J].Anais da Academia Brasileira de Ciências,2014,86(2):995-1002. |

| [29] | SAPIAI N, JUMAHAT A, JAWAID M,et al .Mechanical performance of granite fine fly dust-filled basalt/glass polyurethane polymer hybrid composites[J].Polymers,2021,13(18):3032/1-8. |

| [30] | WANG J, XUE C, ZHANG Y,et al .Study of early-age hydration,mechanical properties development,and microstructure evolution of manufactured sand concrete mixed with granite stone powder[J].Materials,2023,16(13):48-57. |

| [31] | WANG D, SHI C, FARZADNIA N,et al .A review on use of limestone powder in cement-based materials:mechanism,hydration and microstructures[J].Construction and Building Materials.2018,181:659-672. |

| [32] | JAIN K L, SANCHETI G, GUPTA L K .Durability performance of waste granite and glass powder added concrete[J].Construction and Building Materials,2020,252:119075/1-11. |

| [33] | NANTHAGOPALAN P, SANTHANAM M .Fresh and hardened properties of self-compacting concrete produced with manufactured sand[J].Cement and Concrete Composites,2011,33(3):353-358. |

| [34] | SHEN W, LIU Y, WANG Z,et al .Influence of manufactured sand’s characteristics on its concrete performance[J].Construction and Building Materials,2018,172:574-583. |

| [35] | VARGAS P, RESTREPO-BAENA O, TOBóN J I .Microstructural analysis of interfacial transition zone (ITZ) and its impact on the compressive strength of lightweight concretes[J].Construction and Building Materials,2017,137:381-389. |

| [36] | 徐小宁 .中国水泥工业的生命周期评价[D].大连:大连理工大学,2013. |

| [37] | 汪伟 .低品质再生砂粉与盾构泥浆制备可控低强充填材料及性能研究[D].广州:华南理工大学,2022. |

| [38] | BASSANI M, KHOSRAVIFAR S, GOULIAS D,et al .Long-term resilient and permanent deformation behavior of controlled low-strength materials for pavement applications[J].Journal of Transportation Geotechnics,2015,2:108-118. |

/

| 〈 |

|

〉 |