收稿日期: 2024-06-12

网络出版日期: 2025-01-13

基金资助

黑龙江省自然科学基金项目(ZD2021E005);先进制造智能化技术教育部重点实验室开放课题(KFKT202301)

Analysis of Bidirectional Fluid-Structure Interaction Characteristics of Gas Bearing-Rotor Systems and the Establishment and Verification of Equivalent Gas Film Thickness

Received date: 2024-06-12

Online published: 2025-01-13

Supported by

the Natural Science Foundation of Heilongjiang Province(ZD2021E005)

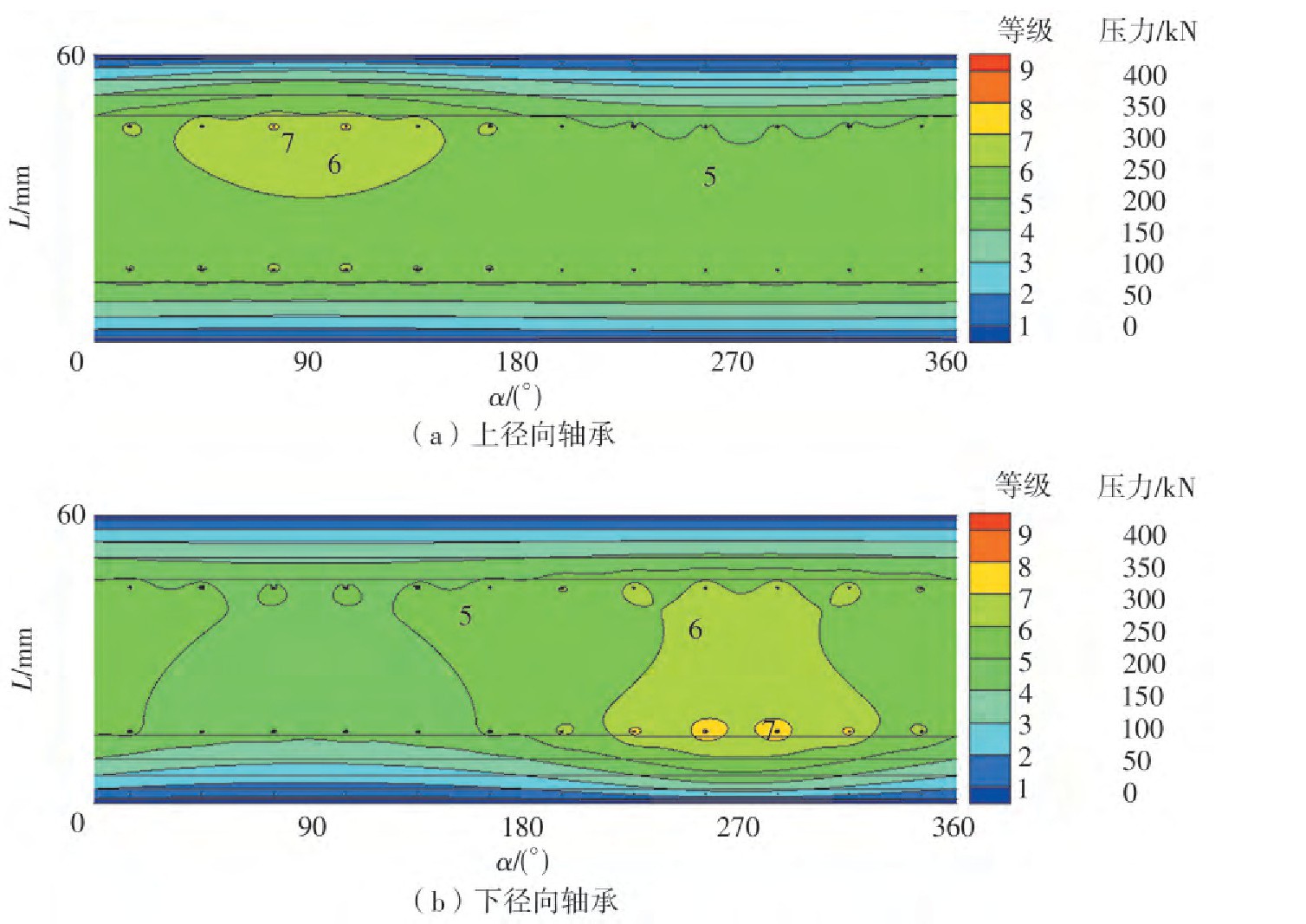

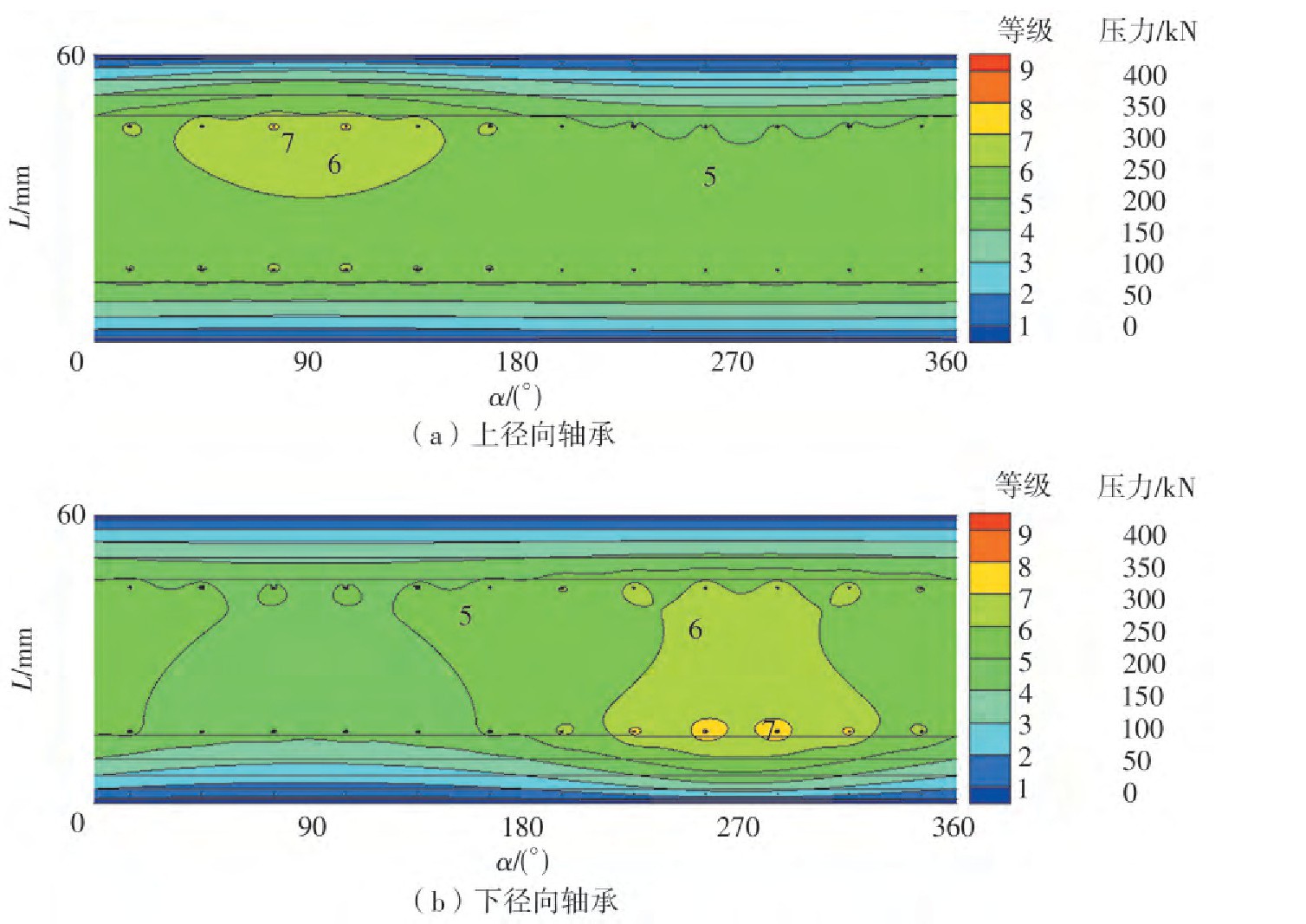

采用计算流体动力学(CFD)方法对气体轴承-转子系统进行流场特性仿真时,气膜厚度是至关重要的结构参数之一,但零件加工过程中产生的形状、尺寸误差以及系统装配造成的偏差等,会导致实际气膜与理想设计气膜在空间形貌及尺度上存在一定的偏差,进而影响数值计算结果的可靠性及准确性。为此,该文首先提出了流场有效气膜厚度的概念,通过双向流固耦合数值仿真与实验结果的对比分析及修正,最终确定合理的等效气膜厚度。研究结果表明:采用双向流固耦合数值仿真方法可揭示气膜流场瞬态特性及转子姿态的变化规律,并对气体轴承-转子系统是否能够安全运行进行预判和评估,节省了实验测试成本;采用转子倾斜角作为对比分析特征,为数值仿真结果和实验测试结果之间的系统性能偏差分析提供了直观的参考依据;等效气膜厚度的建立可最大程度上简化数值仿真模型,提高数值仿真效率,同时其结果又具有一定的可靠性;以供气压力0.6 MPa、单边稳态力80 N为例,通过误差分析和逼近,循环建立和修正流固耦合仿真模型中预估的等效气膜厚度,最终将系统倾斜角的相对误差控制在5%以内,极大地提高了数值仿真结果与实际工程系统性能的一致性,进而为气体轴承-转子仿真系统在结构设计、性能预测及评估中的应用提供了可靠方法及依据。

马文琦 , 马海龙 , 秦雨彬 , 黄大利 . 气体轴承-转子系统双向流固耦合特性分析及等效气膜厚度的建立与验证[J]. 华南理工大学学报(自然科学版), 2025 , 53(9) : 98 -105 . DOI: 10.12141/j.issn.1000-565X.240305

When simulating the flow field characteristics of the gas bearing-rotor system using the computational fluid dynamics (CFD) method, the gas film thickness is one of the crucial structural parameters. However, shape and dimensional errors arising during component machining, as well as the deviations caused by the system assembly, can lead to certain discrepancies between the actual gas film and the ideal designed gas film in terms of the spatial morphology and scale. This further affects the reliability and accuracy of the numerical calculation results. Therefore, this paper first proposed the concept of effective gas film thickness for the flow field. Through the comparative analysis and correction of the bidirectional fluid-structure interaction numerical simulation and experimental results, the reasonable equivalent gas film thickness was finally determined. The research results show that the adoption of the bidirectional fluid-structure interaction numerical simulation method can reveal the transient characteristics of the gas film flow field and the variation law of the rotor attitude, and predict and evaluate whether the gas bearing-rotor system can operate safely, saving the cost of experimental testing. The rotor inclination angle was adopted as the comparative analysis feature, providing an intuitive reference basis for the system performance deviation analysis between numerical simulations and experimental tests. The established equivalent gas film thickness maximally simplifies the numerical simulation model while enhancing computational efficiency, and simultaneously maintains reasonable result reliability. Taking a supply pressure of 0.6 MPa and a unilateral steady-state force of 80 N as an example, through error analysis and approximation, the estimated equivalent gas film thickness in the fluid-structure interaction simulation model was cyclically established and corrected. Eventually, the relative error of the system inclination angle was controlled within 5%, which greatly improved the consistency between the numerical simulation results and the performance of the actual engineering system. Furthermore, this approach provides a reliable method and basis for the application of the gas bearing-rotor simulation system in structural design, performance prediction and evaluation.

| [1] | 兰明锦 .微孔节流气体静压轴承的静动态特性研究[D].哈尔滨:哈尔滨工业大学,2020. |

| [2] | 任天明,冯明,忽敏学,等 .加工误差对陀螺电机用动压气体轴承刚度的影响[J].中国惯性技术学报,2019,27(3):378-383. |

| REN Tianming, FENG Ming, HU Minxue,et al .Influence of machining errors on stiffness of hydrodynamic gas bearing in gyroscope motor[J].Journal of Chinese Inertial Technology,2019,27(3):378-383. | |

| [3] | WANG X, XU Q, WANG B,et al .Effect of surface waviness on the static performance of aerostatic journal bearings[J].Tribology International,2016,103:394-405. |

| [4] | CHEN P, DING J, ZHUANG H,et al .Influence of manufacturing errors and misalignment on the performances of air journal bearings considering inertia effects based on SUPG finite element method[J].Measurement,2022,189:110443/1-12. |

| [5] | CUI H, WANG Y, YUE X,et al .Effects of manufacturing errors on the static characteristics of aerostatic journal bearings with porous restrictor[J].Tribology International,2017,115:246- 260. |

| [6] | 倪壮 .气体静压径向轴承的流场特性及波纹误差影响研究[D].柳州:广西科技大学,2018. |

| [7] | 姚英学,杜建军,刘暾,等 .制造误差对气体静压轴颈-止推轴承静特性影响[J].哈尔滨工业大学学报,2003,35(3):315-318. |

| YAO Ying-xue, DU Jian-jun, LIU Dun,et al .Effect of manufacturing errors on static characteristics of externally pressurized gas journal-thrust bearings[J].Journal of Harbin Institute of Technology,2003,35(3):315-318. | |

| [8] | ZHANG P, CHEN Y, LIU X .Relationship between roundness errors of shaft and radial error motions of hydrostatic journal bearings under quasi-static condition[J].Precision Engineering,2018,51:564-576. |

| [9] | LIN Q, BAO Q, LI K,et al .An investigation into the transient behavior of journal bearing with surface texture based on fluid-structure interaction approach[J].Tribology International,2018,118:246-255. |

| [10] | LI Q, TANG X H, ZHANG S,et al .Dynamic response analysis of tilting pad journal bearing considering fluid-structure interaction[J].Journal of Applied Fluid Mechanics,2021,14(6):1827-1837. |

| [11] | WU Y, CHEN W, ZHANG Q,et al .The direct-coupling method for analyzing the performance of aerostatic bearings considering the fluid-structure interaction effect[J].Lubricants, 2023,11:148/1-17. |

| [12] | 岳金珂 .空气静压轴承-转子系统动态耦合特性分析[D].郑州:中原工学院,2021. |

| [13] | QI L, LIU L, GAO Q,et al .Investigation on the influence of structural rigidity on the stiffness of aerostatic guideway considering fluid-structure interaction[J].Tribology International,2022,173:107658/1-9. |

| [14] | ZHANG W, ALAHYARI A A, CHIAPPETTA L .A fully coupled fluid-structure interaction model for foil gas bearings[J].Journal of Engineering for Gas Turbines and Power,2017,139(2):022501/1-5. |

| [15] | WANG B, DING Q, YANG T .Soft rotor and gas bearing system:two-way coupled fluid-structure interaction[J].Journal of Sound and Vibration,2019,445:29-43. |

| [16] | CAI H, JIANG J, MENG X,et al .Fluid-structure coupling model and output characteristics of a diaphragm-type restrictor[J].Advances in Mechanical Engineering,2022,14(9):1-12. |

| [17] | XU H, YANG J, GAO L,et al .The influences of bump foil structure parameters on the static and dynamic characteristics of bump-type gas foil bearings[J].Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology,2020,234(10):1642-1657. |

| [18] | WANG B, SUN Y, DING Q .Free fluid-structure interaction method for accurate nonlinear dynamic characteristics of the plain gas journal bearings[J].Journal of Vibration Engineering & Technologies,2020,8:149-161. |

| [19] | 朱希玲,李学慧 .考虑轴倾斜的滑动轴承流固耦合瞬态分析[J].上海工程技术大学学报,2022,36(3):267-271. |

| ZHU Xiling, LI Xuehui .Transient Analysis of misaligned journal bearings based on fluid-structure interaction approach[J].Journal of Shanghai University of Engineering Science,2022,36(3):267-271. |

/

| 〈 |

|

〉 |