收稿日期: 2024-03-13

网络出版日期: 2024-04-25

基金资助

国家自然科学基金资助项目(12272137)

Calculation of Fatigue Life of Rubber Vibration Isolators Under Random Vibration Loads

Received date: 2024-03-13

Online published: 2024-04-25

Supported by

the National Natural Science Foundation of China(12272137)

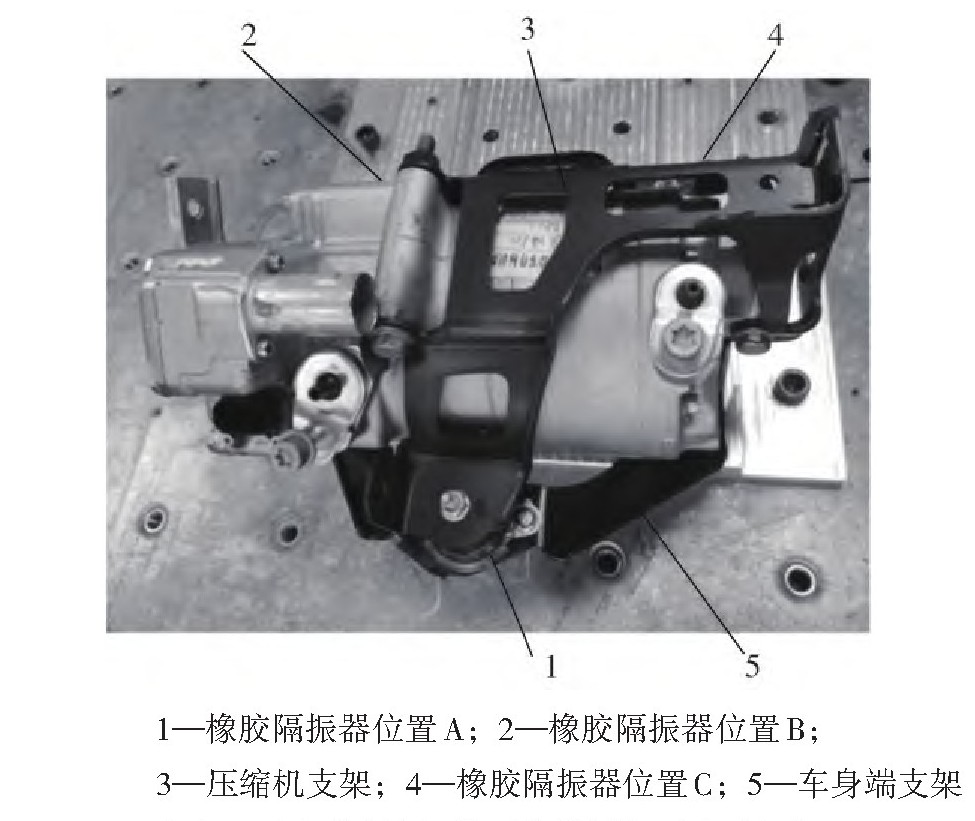

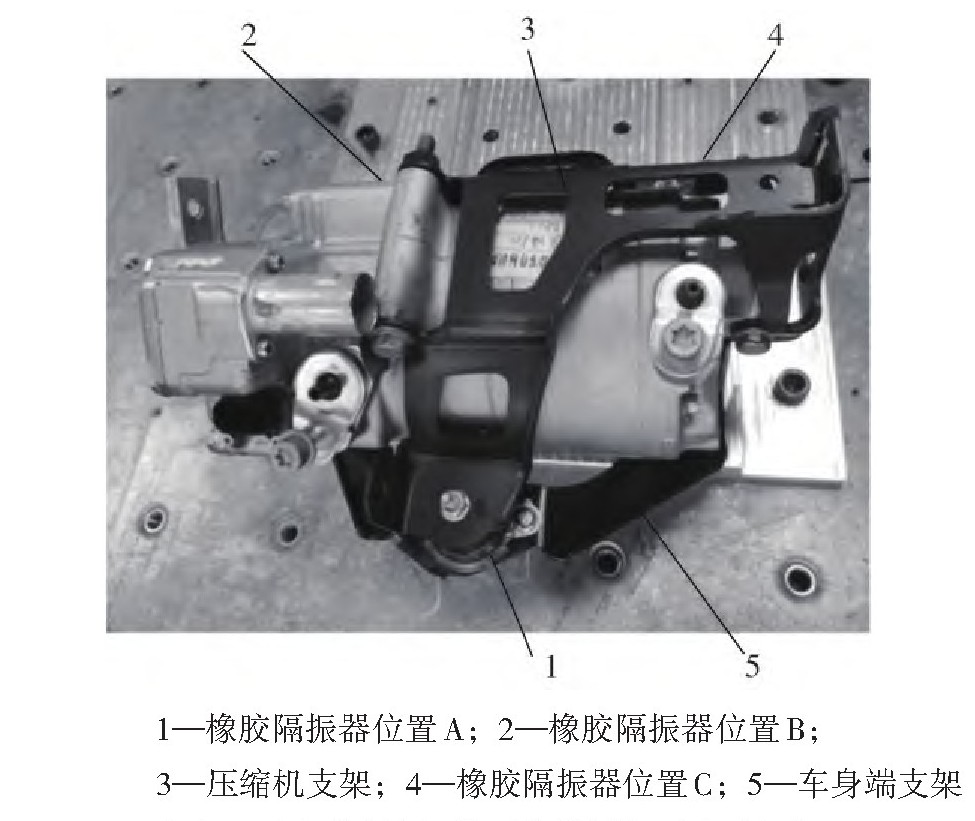

为探寻有效的随机振动下橡胶隔振器疲劳寿命计算方法,以某电动汽车空调压缩机橡胶隔振器为研究对象,开展隔振器路谱采集试验,获得隔振器主动端的加速度时间历程信号。利用傅里叶变换方法将加速度信号转变为加速度功率谱密度,以加速度功率谱密度作为载荷输入,在变温恒湿环境下开展了压缩机橡胶隔振器的随机振动试验,观察到橡胶隔振器主簧部位出现开裂现象。建立了橡胶隔振器的有限元模型,开展了静态特性试验,静态刚度仿真值与试验值相对误差在

李旻 , 姚棋水 . 随机振动载荷下橡胶隔振器的疲劳寿命计算[J]. 华南理工大学学报(自然科学版), 2024 , 52(12) : 14 -21 . DOI: 10.12141/j.issn.1000-565X.240118

In order to effectively calculate the fatigue life of rubber vibration isolator under random vibration loads, a rubber vibration isolator for air conditioning compressor of an electric vehicle was taken as the research object, and the road spectrum acquisition of rubber vibration isolator was carried out, by which the acceleration signals versus time of rubber vibration isolator were obtained. Then, Fourier transform was used to transform the acceleration signals into the acceleration power spectral density as load input, and a random vibration test of rubber vibration isolator for compressor was carried out under variable temperature and constant humidity conditions, with the cracking of main spring of rubber vibration isolator being observed. Moreover, a finite element model of rubber vibration isolator was established, with its validity being verified by static characteristic tests as the relative error between simulation value and test value is within ±5%. In addition, frequency response of rubber vibration isolator under unit load was analyzed by ABAQUS, that is, extracting and importing stress response PSD of rubber element into Fe-safe, and using acceleration PSD as load input to calculate the fatigue life. The calculated results were compared with the random vibration test results, finding that the predicted life is consistent with test data, with a relative error of only 2.5%, and that fatigue danger position of rubber vibration isolator unit can be effectively predicted. Finally, the structure of rubber vibration isolator was improved, through which the fatigue life of rubber vibration isolator is 2.8 times that before the improvement, meaning that the fatigue life design requirements are successfully met. This study helps to shorten the design cycle of rubber vibration isolator and reduce the cost of sample test.

| 1 | 陈克,骆嘉晖 .纯电动汽车动力总成悬置系统隔振性能研究[J].中国工程机械学报,2021,19(6):492-499. |

| CHEN Ke, LUO Jiahui .Research on vibration isolation performance of powertrain mount system of battery electric vehicle[J].Chinese Journal of Construction Machinery,2021,19(6):492-499. | |

| 2 | LIU X, ZHAO X, SHANGGUAN W .Fatigue life prediction of natural rubber components using an artificial neural network[J].Fatigue & Fracture of Engineering Materials & Structures,2022,45(6):1678-1689. |

| 3 | YOUNG D G .Application of fatigue methods based on fracture mechanics for tire compound development[J].Rubber Chemistry and Technology,1990,63(4):567-581. |

| 4 | XIAN J, SU C, WANG Z .Non-stationary non-Gaussian random vibration analysis of Duffing systems based on explicit time-domain method[J].Structural Safety,2023,105:102368/1-16. |

| 5 | LEI W, JIANG Y, ZENG X,et al .A novel excitation signal generation technology for accelerated random vibration fatigue testing based on the law of kurtosis transmission[J].International Journal of Fatigue,2022,159:106835/1-11. |

| 6 | LUO Z, CHEN H, HE X,et al .Two time domain models for fatigue life prediction under multiaxial random vibrations[J].Proceedings of the Institution of Mechanical Engineers,Part C:Journal of Mechanical Engineering Science,2019,233(13):4707-4718. |

| 7 | ZUO P, SHI X, HUANG Z,et al .Random vibration analysis of composite laminated conical-cylindrical cabin structures of air vehicles considering thermal load[J].Structures,2023,55:626-637. |

| 8 | WU S, SHANG D, LIU P,et al .Fatigue life prediction based on modified narrowband method under broadband random vibration loading[J].International Journal of Fatigue,2022,159:106832/1-10. |

| 9 | GAO D, YAO W, WEN W,et al .A multiaxial fatigue life prediction method for metallic material under combined random vibration loading and mean stress loading in the frequency domain[J].International Journal of Fatigue,2021,148:106235/1-15. |

| 10 | GE J, SUN Y, ZHOU S,et al .A hybrid frequency-time domain method for predicting multiaxial fatigue life of 7075-T6 aluminium alloy under random loading[J].Fatigue & Fracture of Engineering Materials & Structures,2015,38(3):247-256. |

| 11 | SANTHARAGURU N, ABDULLAH S, CHIN C H,et al .Failure behaviour of strain and acceleration signals using various fatigue life models in time and frequency domains[J].Engineering Failure Analysis,2022,139:106454/1-26. |

| 12 | AMINI Y, FATEHI P, HESHMATI M,et al .Time domain and frequency domain analysis of functionally graded piezoelectric harvesters subjected to random vibration:finite element modeling[J].Composite Structures,2016,136:384-393. |

| 13 | MANOUCHEHRYNIA R, ABDULLAH S, SINGH S S K .Fatigue-based reliability in assessing the failure of an automobile coil spring under random vibration loadings[J].Engineering Failure Analysis,2022,131:105808/1-18. |

| 14 | MA Y, TANG X, WANG Y,et al .Design of nonlinear metal rubber isolator subjected to random vibration[J].Mechanical Systems and Signal Processing,2023,197:110375/1-18. |

| 15 | 上官文斌,谢新星,丁维,等 .汽车动力总成悬置耐久性模拟试验研究[J].振动与冲击,2011,30(10):39-44. |

| SHANGGUAN Wen-bin, XIE Xin-xing, DING Wei,et al .Road simulation test for automobile powertrain durability[J].Journal of Vibration and Shock,2011,30(10):39-44. | |

| 16 | SU H .Automotive structural durability design using dynamic simulation and fatigue damage sensitivity techniques[J].SAE International Journal of Materials and Manufacturing,2010,3(1):1-12. |

| 17 | SCHIEPPATI J, SCHRITTESSER B, WONDRACEK A,et al .Temperature impact on the mechanical and fatigue behavior of a non-crystallizing rubber[J].International Journal of Fatigue,2021,144:106050/1-8. |

| 18 | 王小莉,上官文斌,刘泰凯,等 .填充橡胶材料单轴拉伸疲劳试验及疲劳寿命模型研究[J].机械工程学报,2013,49(14):65-73. |

| WANG Xiaoli, SHANGGUAN Wenbin, LIU Taikai,et al .Experiment of uniaxial tension fatigue and modeling of fatigue life for filled natural rubbers.[J].Journal of Mechanical Engineering,2013,49(14):65-73. | |

| 19 | SHI L, GU L .Practical approach of material modeling for body seal analysis Ⅱ-elastomer foam[C]∥Proceedings of the SAE 2002 World Congress.Detroit:SAE,2002. |

| 20 | DIRLIK T .Application of computers in fatigue analysis[D].Coventry:University of Warwick,1985. |

/

| 〈 |

|

〉 |