收稿日期: 2023-10-20

网络出版日期: 2024-01-26

基金资助

陕西省自然科学基金资助项目(2024JC-YBMS-336)

Loaded Tooth Contact Analysis for Double-Helical Planetary Gear Sets with Floating Components

Received date: 2023-10-20

Online published: 2024-01-26

Supported by

the Natural Science Foundation of Shaanxi Province(2024JC-YBMS-336)

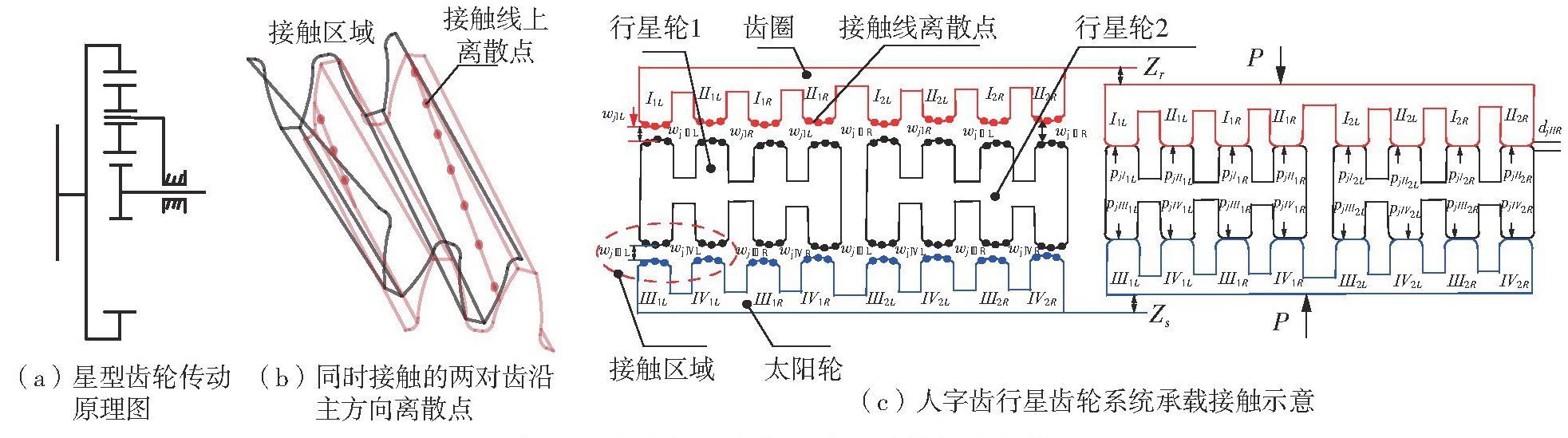

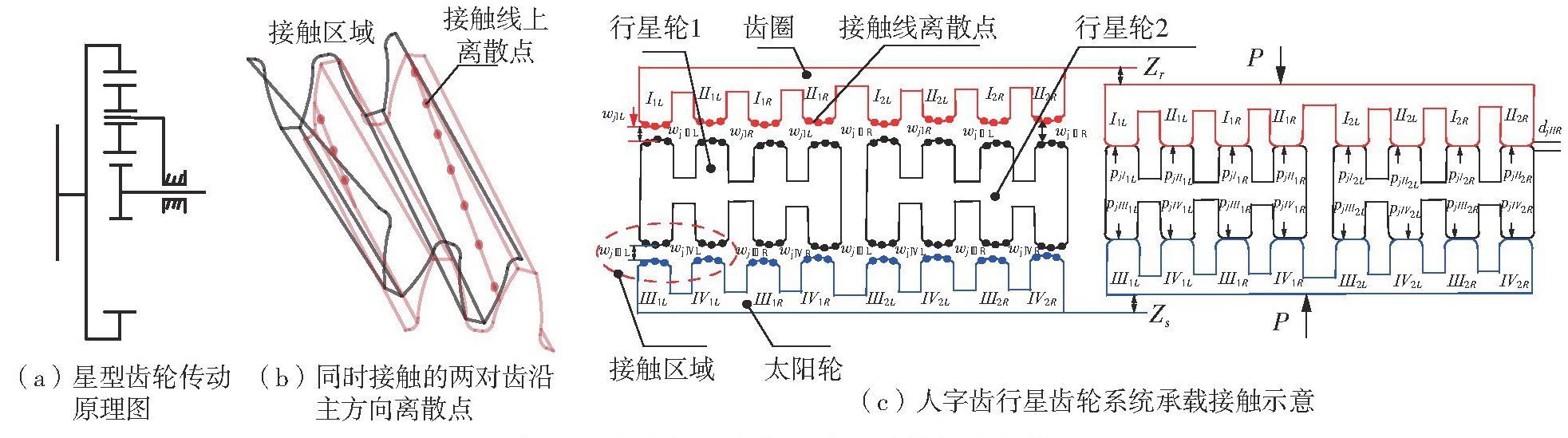

针对单排人字行星齿轮的轴向自由窜动受太阳轮与齿圈限制及其齿面接触间隙、力的耦合特点,提出考虑构件浮动的齿面承载接触分析数值方法,为重要应用场合人字齿功率分支系统的齿面设计、分析提供理论参考。该方法以啮合理论、有限元及优化方法为基础,建立内、外齿轮副瞬时啮合齿对的变形协调、啮合总力平衡、构件径向和轴向浮动下行星轮的力学平衡等方程;将各齿轮副左、右齿面的精确几何与力学特性紧密融合,更能够反映齿面分布力系的相互耦合作用,仅需一次有限元数值计算可快速获得齿面载荷、承载变形、浮动位移和均载系数等。结果表明:中心轮的径向浮动保证行星轮之间载荷均匀,而行星轮左、右齿面的均载性与其轴向自由窜动位移相关,当行星轮轴向浮动前的内与外啮合副轴向力方向相反即行星轮整体轴向力被抵消大部分时,则浮动后的行星轮的轴向窜动位移较小,其左、右齿面均载性能无大的改善;反之,当行星轮轴向浮动前的两齿侧轴向力方向相同时,则其浮动后的轴向窜动位移相对较大,左与右齿面均载性有较大改善。浮动后的承载传动误差幅值及均值减小,且各内、外齿轮副的几何传误差或均载系数或轴向力数值规律基本相同。从结构上保证行星轮的轴向自由窜动是改善人字齿行星传动系左、右齿面偏载的关键。

蒋进科 , 李猛 . 考虑构件浮动人字行星齿轮传动系承载接触分析[J]. 华南理工大学学报(自然科学版), 2024 , 52(9) : 51 -61 . DOI: 10.12141/j.issn.1000-565X.230649

Considering coupling characteristics of forces and contact gaps of tooth between planet gear pairs for double-helical planetary gears sets (DHPG) with one set planet gears whose free axial movement is restricted by sun gear and ring gear, this paper proposed a numerical method of loaded tooth contact analysis (LTCA) for DHPG, which provides theoretical references of tooth design and performance analysis for the important application of power split and convergence double helical gears. Firstly, based on the meshing theory, finite element method and optimization method, it established the equations of the deformation coordination, the balance of the meshing total force, and the forces balance of the radial and axial floating components. Secondly, precise geometric and mechanical characteristics of left and right tooth of each inner and outer gear pair were integrated closely,which can better reflect the mutual coupling effect of the distribution force system of gear pairs. Finally, load distribution, bearing deformations, load sharing coefficients and floating displacements of each gear pair were obtained quickly based the LTCA with finite element numerical calculation once.The result show that Radial floating of the sun and ring gear is contributed to load sharing of the planet gears, while axial free floating of planet gear is contributed to load sharing of left and right tooth of planet gears. In case of opposite axial forces on both tooth flank of planet gear without floating, namely overall axial force of the planet gear being greatly offset, the axial floating displacements are a little for planet gear with floating, so the load sharing of left and right tooth is improved a little.Conversely, in case of axial forces from the same direction on both tooth flank of planet gear without floating, the axial floating displacements are much for planet gear with floating, and the load sharing of left and right tooth is improved significantly. Besides, both the amplitude and mean value of loaded transmission are reduced, which are contribute to improving dynamic performances of DHPG with floating components. Furthermore, the geometric transmission error, load sharing coefficient and axial force of the inner gear pair are basically the same as the outer gear pair. It is the key to ensure the free axial movement of the planet gear based on structure to improve the uneven loads sharing between left and right teeth for DHPG.

| 1 | LITVIN F L, GONZALEZ P I, FUENTES A,et al .Generalized concept of meshing and contact of involute crossed helical gears and its application[J].Computer Methods in Applied Mechanics & Engineering,2005,194(34/35):3710-3745. |

| 2 | 唐进元,刘艳平 .直齿面齿轮加载啮合有限元仿真[J].机械工程学报,2012,48(5):124-131. |

| TANG Jinyuan, LIU Yanping .Loaded meshing simulation of face-gear drive with spur involute pinion based on Finite Element analysis[J].Journal of Mechanical Engineering,2012,48(5):124-131. | |

| 3 | 吴勇军,王建军,韩勤锴,等 .基于接触有限元分析的斜齿轮齿廓修形与实验[J].航空动力学报,2011,26(2):410-415. |

| WU Yongjun, WANG Jianjun, HAN Qinkan,et al .Tooth profile modification of helical gear and experimental staudy based on finite element contact analysis[J].Journal of Aerospace Power.2011,26(2):410-415. | |

| 4 | 周长江,唐进元,钟志华,等 .齿轮有限元精确建模中边界界定的研究[J].中国机械工程,2005,16(22):2044-2049 |

| ZHOU Changjiang, TANG Jinyuan, ZHONG Zhihua,et al .Research on boundary of exact modeling of gear of FEM[J].China Mechanical Engineer,2005,16(22):2044-2049 | |

| 5 | 杨生华 .齿轮接触有限元分析[J].计算力学学报, 2003,20(2):189-194. |

| YANG Shenghua. Finite element analysis of gear contact[J].Chinese Journal of Computational Mechanics,2003,20(2):189-194. | |

| 6 | UMEYAMA M, KATO M, INOUE K .Effects of gear dimensions and tooth surface modifications on the loaded transmission error of a helical gear pair[J].Journal of Mechanical Design,1998,120(1):119-125. |

| 7 | SIMON V V .Loaded tooth contact analysis and stresses in spiral bevel gears[C]∥ Processing of ASME 2009 International Design Engineering Technical Conferences and Computers and Information in Engineering Confe-rence.California:American Society of Mechanical Engineers,2009:271-279. |

| 8 | GOSSELIN C, CLOUTIER L, NGUYEN Q D .A general formulation for the calculation of the load Sharing and transmission error under Load of spiral bevel and hypoid gears[J].Mechanism and Machine Theory,1995,30(3):433-450. |

| 9 | 黄昌华,温诗铸,李润方,等 .弧齿锥齿轮和准双曲面齿轮润滑加载接触分析[J].清华大学学报(自然科学版),1996,36(4):48-53. |

| HUANG Changhua, WEN Shizhu, LI Runfang,et al .Preliminary design tool-LLTCA for spiral bevel and hypoid gear[J].Journal of Tsinghua University (Science and Technology),1996,36(4):48-53. | |

| 10 | 王延忠,周云飞,周济,等 .考虑轮齿制造误差的螺旋锥齿轮加载接触分析[J].机械科学与技术,2002,21(2):224-227. |

| WANG Yanzhong, ZHOU Yunfei, ZHOU Ji,et al .Load tooth contact analysis of bevel gear based on manufacture error[J].Mechanical Science and Technology,2002,21(2):224-227. | |

| 11 | 李政民卿,朱如鹏 .面齿轮传动的承载接触分析[J].南京航空航天大学学报,2010,42(2):219-223. |

| LI Zhengminqing, ZHU Rupeng .Load tooth contact analysis on face gear driver[J].Journal of Nanjing University of Aeronautics &Astronautics,2010,42(2):219-223. | |

| 12 | 方宗德 .修形斜齿轮的承载接触分析[J].航空动力学报,1997,12(3):251-254. |

| FANG Zongde .Loaded tooth contact analysis of modification of helical gears[J].Journal of Aerospace Power,1997,12(3):247-254. | |

| 13 | 王成,方宗德,谷建功,等 .人字齿轮承载接触分析与试验[J].航空动力学报,2010,25(3):718-722. |

| WANG Cheng, FANG Zongde, GU Jiangong,et al .Loaded tooth contact analysis of double helical gears and experimental investigation[J].Journal of Aerospace Power,2010,25(3):718-722. | |

| 14 | LI S .Effects of machining errors,assembly errors and tooth modifications on loading capacity,load-sharing ratio and transmission error of a pair of spur gears[J].Mechanism and Machine Theory,2007,42(6):698-726. |

| 15 | QU W, DING H, TANG J .An innovative semi-analytical determination approach to numerical loaded tooth contact analysis (NLTCA) for spiral bevel and hypoid gears[J].Advances in Engineering Software,2020,149:102892/1-18. |

| 16 | 魏冰阳,李家琦,王文胜 .基于差齿面拓扑的轮齿承载拟赫兹接触分析[J].中国机械工程,2021,32(18):2174-2180. |

| WEI Bingyang, LI Jiaqi, WANG Wensheng .Quasi-hertz loaded tooth contact analysis of gears based on easeoff surface topology[J].China Mechanical Engineering,2021,32(18):2174-2180. | |

| 17 | VIVET M, TAMAROZZI T, DESMET W,et al .On the modelling of gear alignment errors in the tooth contact analysis of spiral bevel gears[J].Mechanism and Machine Theory,2021,155:104065/1-22. |

| 18 | BRUZZONE F, MAGGI T, MARCELLINI C,et al .Proposal of a novel approach for 3D tooth contact analysis and calculation of the static transmission error in loaded gears[J].Procedia Structural Integrity,2019,24:178-189. |

| 19 | YE S Y, TSAI S J .A computerized method for loaded tooth contact analysis of high-contact-ratio spur gears with or without flank modification considering tip corner contact and shaft misalignment[J].Mechanism and Machine Theory,2016,97:190-214. |

| 20 | SHYI J, TSAI S J, SIANG Y,et al .A computerized approach for loaded tooth contact analysis of planetary gear drives considering relevant deformations[J].Mechanism & Machine Theory Dynamics of Machine Systems Gears & Power Trandmissions Robots & Manipulator Systems Computer Aided Design Methods,2018,122:252-278. |

| 21 | 常乐浩,袁冰,宋文,等 .齿轮副非线性接触特性与动力学耦合分析方法[J].西安交通大学学报,2022,56(10):1-10. |

| CHANG Lehao, YUAN Bing, SONG Wen,et al .A model for coupling analysis of the nonlinear contact characteristics and dynamics of gear pair[J].Journal of Xi’an Jiaotong University,2022,56(10):1-10. | |

| 22 | 蒋进科,方宗德,刘红梅 .行星传动多体齿轮承载接触特性分析[J].机械工程学报,2019,55(15):174-182. |

| JIANG Jinke, FANG Zongde, LIU Hongmei .Loaded tooth contact characteristic analysis of multi-gear for planetary transmission[J].Journal of Mechanical Engineering,2019,55(15):174-182. | |

| 23 | 蒋进科,刘红梅,刘钊 .一种行星传动人字齿轮有限元网格自动建模与装配方法:CN110008594B[P].2022-09-16 |

| 24 | 蒋进科,方宗德,卞翔 .人字齿轮齿向修形优化设计[J].哈尔滨工业大学学报,2013,45(11):86-92. |

| JIANG Jinke, FANG Zongde, BIAN Xiang .Optimal design of longitudinal correction of double helical gear[J].Journal of Harbin of Institute of technokogy,2013,45(11):86-92. | |

| 25 | 蒋进科,刘钊,刘红梅 .基于承载啮合特性的斜齿轮行星系统均载分析[J].华中科技大学学报(自然科学版),2023,51(6):75-82. |

| JIANG Jinke, LIU Zhao, LIU Hongmei .Analysis of load sharing based on loaded meshing characteristics for planetaryhelical gear sets[J].Journal of Huazhong University of Science and Technology (Natural Science Edition),2023,51(6):75-82. |

/

| 〈 |

|

〉 |