收稿日期: 2023-10-07

网络出版日期: 2023-11-13

基金资助

广东省科技专项资金资助项目(210907154533470)

Research on Material Flow Behavior of Gear Blank with Deep Spoke During Multi Station Close Die Forging

Received date: 2023-10-07

Online published: 2023-11-13

Supported by

the Science and Technology Special fund of Guangdong Province(210907154533470)

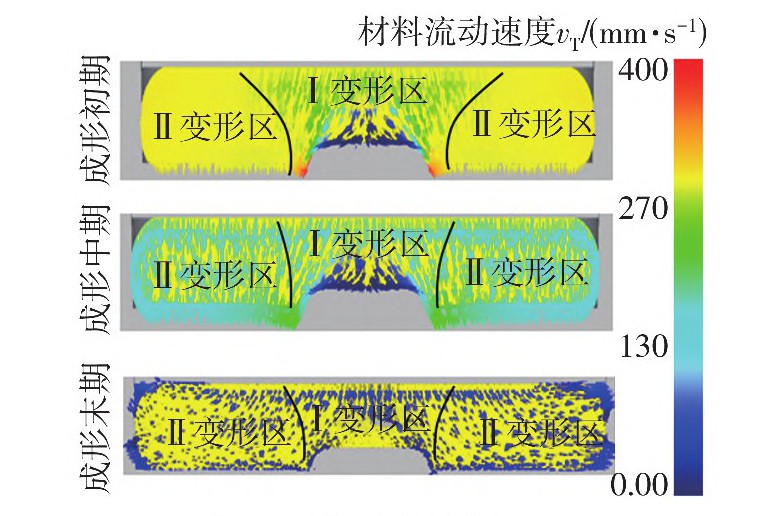

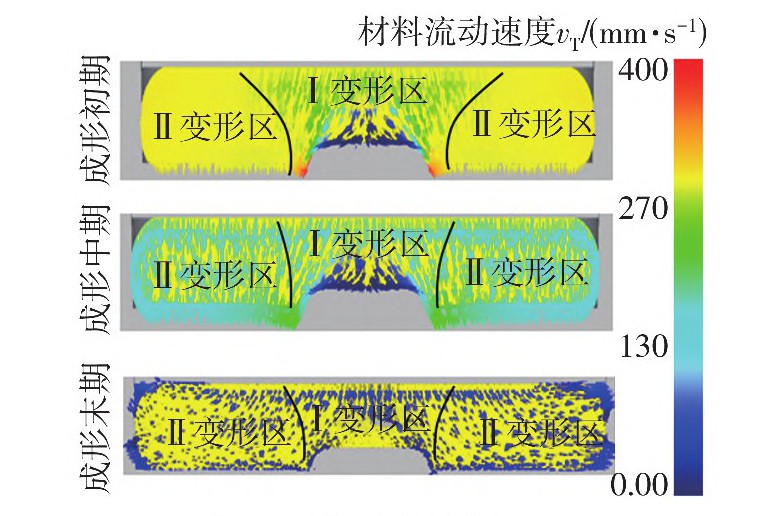

探索闭式热模锻成形时材料的流动规律是控制充填不满等成形缺陷、获得高精度模锻件的理论基础。针对深轮辐齿坯件热模锻成形时易出现填充不满的问题,以某SCr420H深轮辐齿坯为研究对象,基于齿坯件结构分析,设计了“下料—加热—镦粗—预锻Ⅰ—预锻Ⅱ—终锻”的多工位闭式热模锻工艺方案;基于Deform软件,构建了深轮辐齿坯件多工位闭式热模锻全流程有限元模拟模型;采用试验验证了有限元模型的可靠性,并对多工位闭式热模锻成形过程中材料的流动规律进行了研究。结果表明:镦粗比为3.7时,可获得外形良好的圆饼形预制坯,镦粗时受上下表面摩擦效应的影响,材料径向流动不均匀,在坯件腰部出现鼓形;预锻Ⅰ工位成形出用于定位的底面内凹结构,同时减小了后续工位材料填充难度;预锻Ⅱ和终锻成形时的材料流动规律相似,成形前期材料集中流向轮缘部分、成形中期主要流向轮毂部分、末期流向圆角处;终锻成形时未出现材料填充不满的缺陷,在成形后期,少量金属材料从终锻上下模的导向间隙中流出,形成纵向飞边。通过生产试验,成形出填充良好的深轮辐齿坯件,模拟数值获得温度与实际生产数值最大误差不超过3.15%,纵向飞边高度小于0.5 mm,零件各尺寸偏差均小于0.2 mm,验证了所设计多工位闭式模锻工艺的合理性。

夏琴香 , 彭冲 , 刘梅华 , 肖刚锋 , 徐尔灵 . 深轮辐齿坯多工位闭式模锻材料流动规律研究[J]. 华南理工大学学报(自然科学版), 2024 , 52(9) : 35 -41 . DOI: 10.12141/j.issn.1000-565X.230619

Exploring the material flow behavior during the closed die forging is the theoretical basis for controlling forming defects such as insufficient filling and obtaining high-precision die forgings. In response to the problem of insufficient filling during hot die forging of gear blanks with deep spoke, this study selected the SCr420H gear blank with deep spoke as the research object and designed a multi-station closed hot die forging process of “cutting—heating—upsetting—preforging Ⅰ—preforging Ⅱ—final forging” based on structure analysis of the gear blank. Based on Deform, it established a finite element simulation model for the entire process of multi-station closed hot die forging. The reliability of the finite element model was verified by the experimental results, and the material flow law during the multi-station closed hot die forging process was studied. The results show that a circular cake shaped blank can be obtained when the upsetting ratio is 3.7. The material flow along radial direction is uneven due to the friction effect between the upper and lower surfaces, resulting in a bulge shape at the waist of the billet during upsetting. A concave structure was formed on the bottom surface for positioning during pre-forging station Ⅰ, and it reduced the difficulty of material filling in subsequent stations. The material flow law during pre-forging Ⅱ and final forging are similar. The material mainly flows to the wheel flange part in the early stage of forming. It mainly flows to the wheel hub part in the middle stage, and flows to the rounded corner in the late stage. There is no defect of insufficient material filling during final forging. In the late forming stage, a small amount of metal material flows out of the guide gap of the upper and lower die of the final forging, forming a longitudinal flying edge. Through the production test, the well-filled gear blank with deep spoke was formed. The maximum error between the simulated value and the actual production value is not more than 3.15%, the longitudinal flying edge height is less than 0.5 mm, and the size deviation of each part is less than 0.2 mm, which verifies the rationality of the designed multi-stage closed die forging process.

| 1 | 王玉,李丽君,孙弘毅,等 .变速箱齿轮多工况疲劳寿命分析[J].煤矿机械,2021,42(12):75-78. |

| WANG Yu, LI Lijun, SUN Hongyi,et al .Fatigue life analysis of transmission gears under multiple working conditions[J].Coal Mining Machinery,2021,42(12):75-78. | |

| 2 | 卢杰,龚宪生 .基于有限元的齿轮坯锻造模拟及工序改进[J].热加工工艺,2013,42(21):97-99,102. |

| LU Jie, GONG Xiansheng .Simulation and process improvement of gear blank forging based on finite element method[J].Hot Working Process,2013,42(21):97-99,102. | |

| 3 | 佟莹 .端盖闭式模锻数值模拟分析[J].热加工工艺,2013,42(3):134-136. |

| TONG Ying .Numerical simulation analysis of closed die forging for end caps[J].Hot Working Process,2013,42(3):134-136. | |

| 4 | 祝万钱,刘晓霏,陈国学 .齿轮坯多工步闭式模锻工艺的优化研究[J].锻压技术,2005,30(z1):116-118. |

| ZHU Wanqian, LIU Xiaofei, CHEN Guoxue .Optimization research on multi step closed die forging process for gear billets[J].Forging Technology,2005,30(z1):116-118. | |

| 5 | 曾德涛,周杰,张辉,等 .某齿轮坯精锻金属流动规律分析及工艺优化[J].热加工工艺,2012,41(5):84-86. |

| ZENG Detao, ZHOU Jie, ZHANG Hui,et al .Analysis of metal flow law and process optimization for precision forging of a gear blank[J].Hot Working Process,2012,41(5):84-86. | |

| 6 | 中国机械工程学会塑性工程学会 .锻压手册[M].北京:机械工业出版社,2020. |

| 7 | 李天兴,张迅雷,傅建中,等 .轿车用齿坯精锻工艺参数与模具结构对金属流线的影响[J].机械传动,2015,39(10):154-157,175. |

| LI Tianxing, ZHANG Xunlei, FU Jianzhong,et al .The influence of precision forging process parameters and mold structure on metal flow lines for car gear blanks [J].Mechanical Transmission,2015,39(10):154-157,175. | |

| 8 | 苏梁,弓硕,王福明 .预热处理工艺对SCr420H齿轮钢高温渗碳奥氏体晶粒长大行为的影响[J].特殊钢,2023,44(3):1-10. |

| SU Liang, GONG Shuo, WANG Fuming .The effect of preheating treatment process on the grain growth behavior of high-temperature carburized austenite in SCr420H gear steel[J].Special Steel,2023,44(3):1-10. | |

| 9 | 李英 .变速箱输入轴用SCR420H钢的研制[J].山西冶金,2017,40(6):13-14,17. |

| LI Ying .Development of SCR420H steel for gearbox input shaft[J].Shanxi Metallurgy,2017,40(6):13-14,17. | |

| 10 | 刘赣华,王霞,林和荣,等 .从动螺旋锥齿轮齿坯热模锻工艺参数优化设计[J].机械设计与制造,2017,55(3):250-253. |

| LIU Ganhua, WANG Xia, LIN He Rong,et al .Optimization design of hot die forging process parameters for driven spiral bevel gear blank[J].Mechanical Design and Manufacturing,2017,55(3):250-253. | |

| 11 | 林雅杰,仲太生,丁武学 .车用齿轮毛坯多工位精密热模锻工艺分析及模具设计[J].锻压装备与制造技术,2019,54(3):82-87. |

| LIN Yajie, ZHONG Taisheng, DING Wuxue .Analysis of multi station precision hot die forging process and die design for automotive gear blank[J].Forging Equipment and Manufacturing Technology,2019,54(3):82-87. | |

| 12 | 王琪,赵耀,陶丽佳,等 .基于Deform的剥皮齿热锻过程仿真及工艺参数优化[J].锻压技术,2021,46(7):14-21. |

| WANG Qi, ZHAO Yao, TAO Lijia,et al .Simulation and process parameter optimization of hot forging process for peeling teeth based on Deform[J].Forging Technology,2021,46(7):14-21. | |

| 13 | JI H C, LI Y M, LI W D,et al .Study on forging process of valve based on response surface method[J].Metalurgija,2020,59(3):321-324. |

| 14 | ZHANG Hui, PAN Aiqiong, ZHANG Yanqin,et al .Research on the shunting precision forging of ribbed plate gear blank based on DEFORM-3D finite element analysis under the framework of new engineering[J].Journal of Physics:Conference Series,2019,1302(4):42029. |

| 15 | 程里 .模锻实用技术[M].北京:机械工业出版社,2013. |

| 16 | 张海渠 .模锻工艺与模具设计[M].北京:化学工业出版社,2009. |

/

| 〈 |

|

〉 |