收稿日期: 2023-03-27

网络出版日期: 2023-06-21

基金资助

国家自然科学基金资助项目(52265009);内蒙古自然科学基金资助项目(2020BS05003);内蒙古直属高校基本科研业务费专项资金资助项目(JY20220284);内蒙古工业大学科学研究项目(ZZ0201903)

Fatigue Analysis and Life Prediction of Recirculating Planetary Roller Screw Mechanism

Received date: 2023-03-27

Online published: 2023-06-21

Supported by

the National Natural Science Foundation of China(52265009);the Natural Science Foundation of Inner Mongolia(2020BS05003)

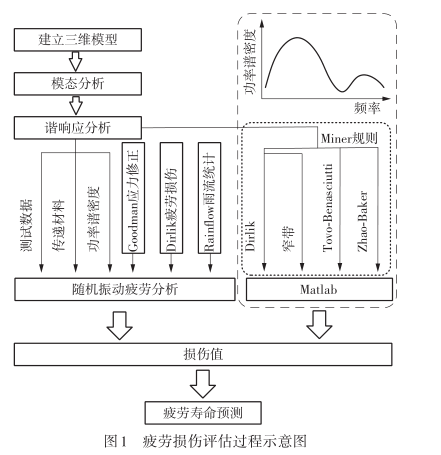

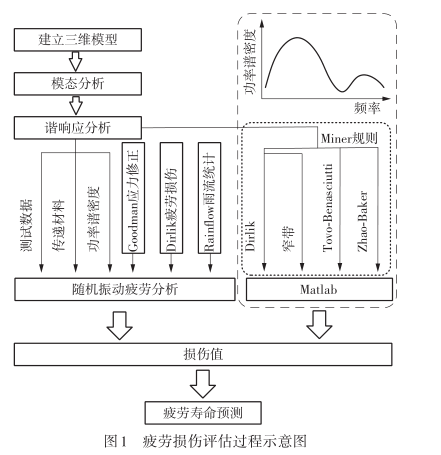

循环式行星滚柱丝杠副作为行星滚柱丝杠副的衍生机构,是一种通过多个沟槽状滚柱与丝杠、螺母螺纹啮合的传动机构。为了研究循环式行星滚柱丝杠副的随机振动疲劳特性,文中基于疲劳失效理论,建立了该传动机构的有限元模型,并进行了动力学分析和疲劳寿命预测。首先,根据材料应力-循环寿命(S-N)曲线和Miner线性疲劳累积损伤理论,利用疲劳分析软件对循环式行星滚柱丝杠副进行疲劳分析,得到了接触区域的疲劳结果云图和各节点的损伤值;然后,基于建立的4种疲劳寿命预测模型,将得到的解析解与仿真损伤值进行对比。结果表明:循环式行星滚柱丝杠副在3 960 Hz下引发的共振对其结构造成的损伤最大;循环式行星滚柱丝杠副在相同激励频率条件下的最大接触应力和最小疲劳寿命的区域相同;循环式行星滚柱丝杠副谐响应分析应力峰值和疲劳分析功率谱密度峰值的对应频率相同。该研究可为循环式行星滚柱丝杠副设计与抗疲劳优化提供理论指导。

关键词: 循环式行星滚柱丝杠副; 模态分析; 谐响应分析; 疲劳分析; 寿命预测

乔冠, 廖荣, 张校民, 等 . 循环式行星滚柱丝杠副的疲劳分析与寿命预测[J]. 华南理工大学学报(自然科学版), 2023 , 51(11) : 131 -139 . DOI: 10.12141/j.issn.1000-565X.230146

The recirculating planetary roller screw mechanism, as a derivative of planetary roller screw mechanism, is a transmission mechanism that is engaged by the screw or nut thread and multiple circular groove rollers. To study the random vibration fatigue characteristics of the recirculating planetary roller screw mechanism, this paper established a finite element model of the mechanism based on fatigue failure theory, and conducted the dynamic analysis and fatigue life prediction. Firstly, according to the material stress-number of cycles (S-N) curve and Miner’s linear damage accumulation theory, fatigue analysis was carried out on the recirculating planetary roller screw mechanism using the related software, and fatigue results in the contact area and damage values at each node were obtained. Then, based on the developed four fatigue life prediction models, the obtained analytical solutions were compared with the simulated damage values. The results show that the resonance induced by the recirculating planetary roller screw mechanism at 3 960 Hz causes the most damage to the mechanism. When the excitation frequency is the same, the area of maximum contact stress and minimum fatigue life is the same. Besides, the corresponding frequencies of the peak stress in the harmonic response analysis and that of the peak power spectral density in the fatigue analysis of the recirculating planetary roller screw mechanism are the same. This study can provide a theoretical guidance for the design and fatigue optimization of the recirculating planetary roller screw mechanism.

| 1 | 乔冠,廖荣,姜广君,等 .循环式行星滚柱丝杠副的运动特性及动力学分析[J].华南理工大学学报(自然科学版),2022,50(10):124-131. |

| QIAO Guan, LIAO Rong, JIANG Guangjun,et al .Kinematic characteristics and dynamic analysis of recirculating planetary roller screw mechanism [J].Journal of South China University of Technology (Natural Science Edition),2022,50(10):124-131. | |

| 2 | ZU L, ZHANG Z, GAO L .Design and bearing characteristics of planetary roller screws based on aerospace high-load conditions [J].Advances in Mechanical Engineering,2018,10:1-11. |

| 3 | 董永,刘更,马尚君,等 .行星滚柱丝杠副滚柱的设计方法与虚拟装配[J].机械设计,2013,30(8):53-58. |

| DONG Yong, LIU Geng, MA Shangjun,et al .Design method and virtual assembly of the planetary roller screw mechanism roller[J].Journal of Machine Design,2013,30(8):53-58. | |

| 4 | QIAO G, LIAO R, GUO S,et al .Design and dynamic analysis of the recirculating planetary roller screw mechanism[J].Chinese Journal of Mechanical Engineering,2022,35(1):1-16. |

| 5 | JONES M H, VELINSKY S A, LASKY T A .Dynamics of the planetary roller screw mechanism[J].Journal of Mechanisms and Robotics,2015,8(1):1-6. |

| 6 | MA S, LIU G, QIAO G,et al .Thermo-mechanical model and thermal analysis of hollow cylinder planetary roller screw mechanism[J].Mechanics Based Design of Structures and Machines,2015,43(3):359-381. |

| 7 | QIAO G, LIU G, MA S,et al .Thermal characteristics analysis and experimental study of the planetary roller screw mechanism[J].Applied Thermal Engineering,2019,149:1345-1358. |

| 8 | ZHANG W, LIU G, MA S,et al .Load distribution over threads of planetary roller screw mechanism with pitch deviation[J].Proceedings of the Institution of Mechanical Engineers Part C:Journal of Mechanical Engineering Science,2019,233(13):4653-4666. |

| 9 | 张文杰,刘更,佟瑞庭,等 .行星滚柱丝杠副螺纹牙均载设计方法研究[J].西北工业大学学报,2016,34(3):499-507. |

| ZHANG Wenjie, LIU Geng, TONG Ruiting,et al .Thread load balance design method of planetary roller screw mechanism [J].Journal of Northwestern Polytechnical University,2016,34(3):499-507. | |

| 10 | WU S D, SHANG D G, LIU P C,et al .Fatigue life prediction based on modified narrowband method under broadband random vibration loading[J].International Journal of Fatigue,2022,159:1-10. |

| 11 | MARQUES D E T, VANDEPITTE D, TITA V .Damage detection and fatigue life estimation under random loads:a new structural health monitoring methodology in the frequency domain[J].Fatigue & Fracture of Engineering Materials & Structures,2021,44(6):1622-1636. |

| 12 | 白金,李静,仇原鹰,等 .考虑多轴应力与共振影响的随机振动疲劳寿命预测[J].国防科技大学学报,2021,43(2):102-108. |

| BAI Jin, LI Jing, QIU Yuanying,et al .Random vibration fatigue life prediction considering the effects of multi-axial stress and resonance[J].Journal of National University of Defense Technology,2021,43(2):102-108. | |

| 13 | 陈志英,张兴森,周平 .基于多点随机激励的发动机管路振动疲劳寿命分析[J].推进技术,2019,40(7):1620-1627. |

| CHEN Zhiying, ZHANG Xingsen, ZHOU Ping .Vibration fatigue life analysis of engine piping system based on multi-point random excitation[J].Journal of Propulsion Technology,2019,40(7):1620-1627. | |

| 14 | 撒子成,王尚,冯佳运,等 .SiP器件组装焊点形态预测及其随机振动可靠性仿真研究[J].机械工程学报,2022,58(2):276-283. |

| Zicheng SA, WANG Shang, FENG Jiayun,et al .Simulation of Sip solder joint geometry and random vibration reliability prediction[J].Journal of Mechanical Engineering,2022,58(2):276-283. | |

| 15 | 沙云东,朱付磊,赵奉同,等 .薄壁结构高温随机振动疲劳寿命估算方法[J].振动与冲击,2020,39(2):64-71,85. |

| SHA Yundong, ZHU Fulei, ZHAO Fengtong,et al .Random vibration fatigue estimation of thin plates in high temperature environment[J].Journal of Vibration and Shock,2020,39(2):64-71,85. | |

| 16 | 周金宇,韩文钦,邱睿,等 .结构系统疲劳失效相关机理与可靠性模型[J].机械工程学报,2018,54(16):220-226. |

| ZHOU Jinyu, HAN Wenqin, QIU Rui,et al .Dependence mechanism of fatigue failure and reliability model for structure systems[J].Journal of Mechanical Engineering,2018,54(16):220-226. | |

| 17 | 朱颖,田玉基 .基于区间理论的不确定结构随机疲劳损伤估计方法[J].工程力学,2017,34(8):1-9. |

| ZHU Ying, TIAN Yuji .Study on random fatigue analysis method of uncertainty structure based on interval theory[J].Engineering Mechanics,2017,34(8):1-9. | |

| 18 | DIRLIK T, BENASCIUTTI D .Dirlik and Tovo-Benasciutti spectral methods in vibration fatigue:a review with a historical perspective[J].Metals,2021,11(9):1-21. |

| 19 | BENASCIUTTI D, TOVO R .Spectral methods for lifetime prediction under wide-band stationary random processes[J].International Journal of Fatigue,2005,27(8):867-877. |

| 20 | ZHAO W, BAKER M J .On the probability density function of rainflow stress range for stationary Gaussian processes[J].International Journal of Fatigue,1992,14(2):121-135. |

/

| 〈 |

|

〉 |