收稿日期: 2021-12-01

网络出版日期: 2022-02-25

基金资助

国家自然科学基金资助项目(52075187);广东省自然科学基金资助项目(2022A1515010995);华南理工大学中央高校基本科研业务费专项资金资助项目(2017ZD024)

Study on Cutting Forces and Machining Performance in Turning Stainless Steel with Variable-Length Restricted Contact Tool

Received date: 2021-12-01

Online published: 2022-02-25

Supported by

the National Natural Science Foundation of China(52075187);the Natural Science Foundation of Guangdong Province(2022A1515010995)

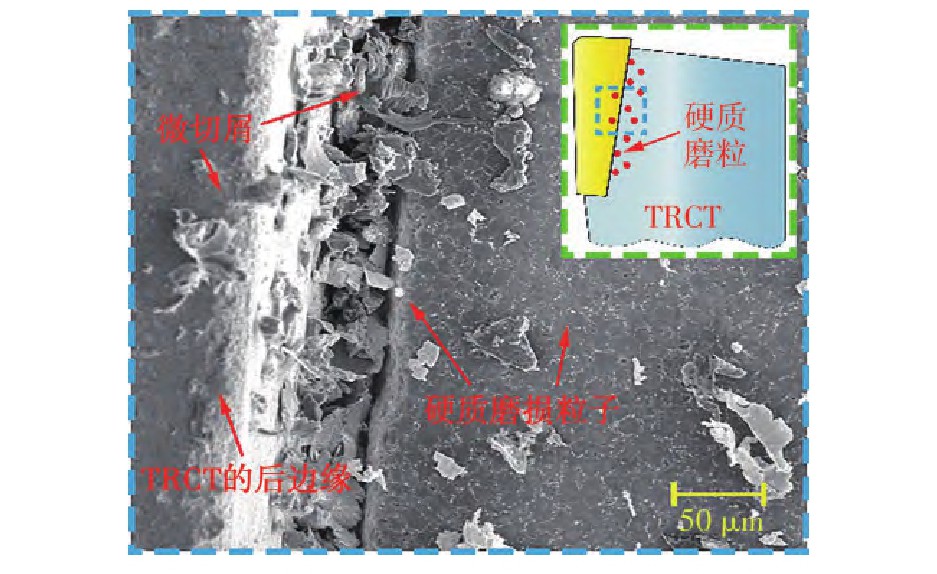

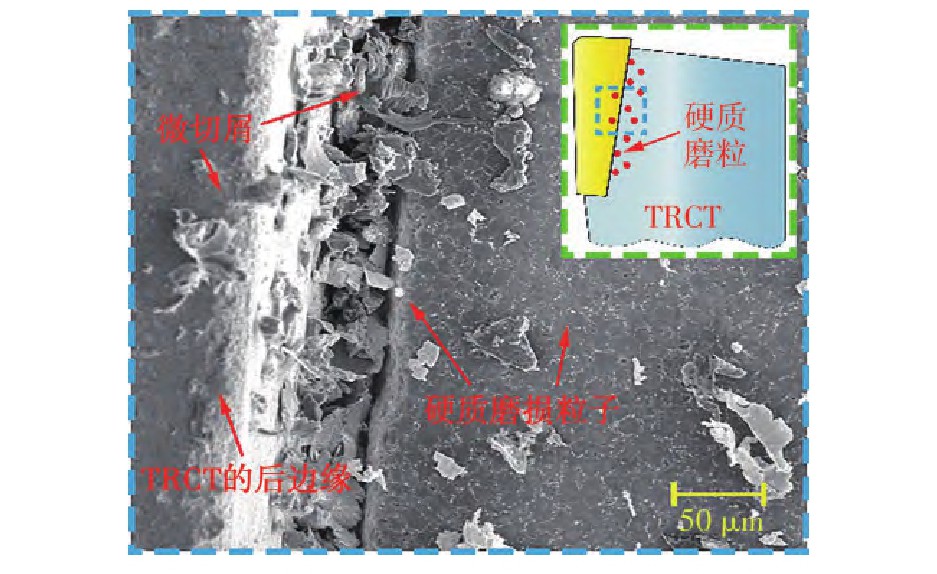

AISI 316L奥氏体不锈钢作为典型的难加工材料,存在着加工效率低和加工过程热-力载荷大的问题。现有关于改善不锈钢加工性能的若干方法,如采用润滑措施、设计刀具表面结构等,均存在明显缺陷,例如,切削液的大量使用不利于环境和人体健康,刀具表面结构的不合理设计反而会加剧刀具磨损。针对现有方法无法很好改善奥氏体不锈钢加工过程热-力载荷大等问题,文中设计了一种新型变接触长度的限制接触刀具,用于加工AISI 316L奥氏体不锈钢,其与传统限制接触刀具相比可以有效减小切削力和摩擦系数。研究中首先基于非等距剪切区模型和切削力学理论,建立了用于预测变限制接触长度的限制接触刀具在车削时的切削力半解析模型;然后,在硬质合金刀具前刀面上通过线切割和微细电火花加工出常规和新设计的限制接触形状(矩形以及梯形限制接触形状),并进行了大量实验用于验证预测模型。结果表明:利用所建立的半解析模型预测出的切削力与实验数据吻合较好;与传统限制接触刀具相比,变限制接触长度的刀具能明显减小切削力。此外,文中还对比分析了传统和变接触长度的限制接触刀具在干切削条件下对切削性能的影响,发现变限制接触长度的刀具比传统限制接触刀具能更有效地降低切削温度和减少刀具磨损。文中研究结果可为切削难加工材料的刀具的设计提供参考。

庞学勤 , 邓文君 , 李松青 . 变接触长度限制接触刀具车削不锈钢时的切削力及切削性能研究[J]. 华南理工大学学报(自然科学版), 2022 , 50(8) : 49 -61 . DOI: 10.12141/j.issn.1000-565X.210741

As a typical difficult-to-machine material, AISI 316L austenitic stainless steel has the problems of low machining efficiency and large thermo-mechanical load during machining. The present methods to improve the machining performance of stainless steel such as adopting lubrication, designing tool surface structure, etc., all exist obvious defects. For example, the extensive use of cutting fluid is detrimental to the environment and human health, and tool wear will be aggravated if the tool surface structure is designed unreasonably. Given that the existing methods fail to well deal with the problems like large thermo-mechanical load during machining austenitic stainless steel, a new restricted contact tool with variable contact length was designed aiming at machining AISI 316L auste-nitic stainless steel. Compared with traditional restricted contact tools, the new tool is superior in reducing cutting force and friction coefficient. This paper first developed a semi-analytical model for turning to predict cutting forces for inconstant restricted contact length based on the non-equidistant shear zone model and the principles of unified cutting mechanics. Then, the conventional and variable-length restricted contact pattern (rectangular and trapezoidal restricted contact pattern) was fabricated on the rake surface of uncoated cemented carbide by the W-EDM and micro-EDM process. Subsequently, extensive experiments were performed to validate the proposed model. Results show that the cutting forces predicted by the proposed semi-analytical model are in good agreement with the experimental values. As compared with conventional restricted contact tools, the developed restricted contact tool can significantly reduce cutting forces. Furthermore, the influences of conventional and developed restricted contact tools on cutting performance were compared and analyzed under dry machining conditions. The restricted contact tool developed in this paper can effectively decrease the cutting temperature and tool wear. This study can provide a basis for designing the cutting tools in machining difficult-to-cut materials.

| 1 | 许峰,杨莉,邓长春,等 .固溶温度对316L奥氏体不锈钢δ铁素体转变的影响[J].稀有金属材料与工程,2021,50(8):2921-2926. |

| 1 | XU Feng, YANG Li, DENG Changchun,et al .Effect of solution temperature on transformation of δ-ferrite in 316L austenitic stainless steel[J].Rare Metal Mate-rials and Engineering,2021,50(8):2921-2926. |

| 2 | 张国平 .不锈钢切削加工[J].现代机械,2013(1):65-67,70. |

| 2 | ZHANG Guoping .Stainless steel cutting[J].Modern Machinery,2013(1):65-67,70. |

| 3 | 刘念聪,吴圣红,谢京良,等 .车削奥氏体不锈钢时冷却参数对刀具振动和表面粗糙度的影响[J].中国机械工程,2021,32(11):1321-1329. |

| 3 | LIU Niancong, WU Shenghong, XIE Jingliang,et al .Effects of cooling parameters on tool vibration and surface roughness in turning austenitic stainless steels[J].China Mechanical Engineering,2021,32(11):1321-1329. |

| 4 | 郭江,王兴宇,赵勇,等 .微织构刀具制备技术及加工性能研究新进展[J].机械工程学报,2021,57(13):172-199. |

| 4 | GUO Jiang, WANG Xingyu, ZHAO Yong,et al .Recent progress on fabrication technologies and machining performance of textured cutting tools[J].Journal of Mechanical Engineering,2021,57(13):172-199. |

| 5 | AHMED Y, PAIVA J M, VELDHUIS S C .Characte-rization and prediction of chip formation dynamics in machining austenitic stainless steel through supply of a high-pressure coolant[J].International Journal of Advanced Manufacturing Technology,2019,102:1671-1688. |

| 6 | MACHADO A R, SILVA L R R DA, DE SOUZA F C R,et al .State of the art of tool texturing in machining[J].Journal of Materials Processing Technology,2021,293:117096/1-23. |

| 7 | KAWASEGI N, OZAKI K, MORITA N,et al .Deve-lopment and machining performance of a textured diamond cutting tool fabricated with a focused ion beam and heat treatment[J].Precision Engineering,2017,47:311-320. |

| 8 | DUAN R, DENG J X, GE D L,et al .An approach to predict derivative-chip formation in derivative cutting of micro-textured tools[J].The International Journal of Advanced Manufacturing Technology,2018,95(1):973-982. |

| 9 | SADIK M, LINDSTR?M B .The effect of restricted contact length on tool performance[J].Journal of Materials Processing Technology,1995,48(1/2/3/4):275-282. |

| 10 | JIANG H W, HE L, YANG X Y,et al .Prediction and experimental research on cutting energy of a new cemented carbide coating micro groove turning tool[J].The International Journal of Advanced Manufacturing Technology,2017,89(5/6/7/8):2335-2343. |

| 11 | ZOU Z F, HE L, JIANG H W,et al .Development and analysis of a low-wear micro-groove tool for turning Inconel 718[J].Wear,2019,420:163-175. |

| 12 | FANG N, JAWAHIR I S .Analytical predictions and experimental validation of cutting force ratio,chip thickness,and chip back flow angle in restricted contact machining using the universal slip-line model[J].International Journal of Machine Tools and Manufacture,2002,42(6):681-694. |

| 13 | WANG B, ZHANG J Y, ZHOU W,et al .Chip inward curl and its influence on dimensional accuracy in groove cutting with a novel restricted contact tool[J].Advances in Mechanical Engineering,2016,8(9):1687814016665745. |

| 14 | ASTAKHOV V P, OSMAN M O M, HAYAJNEH M T .Re-evaluation of the basic mechanics of orthogonal metal cutting:velocity diagram,virtual work equation and upper-bound theorem[J].International Journal of Machine Tools and Manufacture,2001,41?(3):393-418. |

| 15 | BAI W, SUN R L, ROY A,et al .Improved analytical prediction of chip formation in orthogonal cutting of titanium alloy Ti6Al4V[J].International Journal of Mechanical Sciences,2017,133:357-367. |

| 16 | MERCHANT M E .Mechanics of the metal cutting process. II. Plasticity conditions in orthogonal cutting[J].Journal of Applied Physics,1945,16(6):318-324. |

| 17 | WALDORF D J .A simplified model for ploughing forces in turning[J].Journal of Manufacturing Processes,2006,8(2):76-82. |

| 18 | UMBRELLO D, M’SAOUBI R, OUTEIRO J C .The influence of Johnson-Cook material constants on finite element simulation of machining of AISI 316L steel[J].International Journal of Machine Tools and Manufacture,2007,47(3/4):462-470. |

| 19 | DROZDA T, WICK C .Tool and manufacturing engineers handbook:Vol.1,machining[M].Dearborn:Society of Manufacturing Engineers,1983. |

| 20 | LAI Z W, WANG C Y, ZHENG L J,et al .Adaptabi-lity of AlTiN-based coated tools with green cutting technologies in sustainable machining of 316L stainless steel[J].Tribology International,2020,148:106300/1-15. |

| 21 | FATIMA A, MATIVENGA P T .A review of tool-chip contact length models in machining and future direction for improvement[J].Proceedings of the Institution of Mechanical Engineers,Part B:Journal of Engineering Manufacture,2013,227(3):345-356. |

| 22 | ASTAKHOV V P, SHVETS S .The assessment of plastic deformation in metal cutting[J].Journal of Mate-rials Processing Technology,2004,146(2):193-202. |

| 23 | BAHI S, LIST G, SUTTER G .Analysis of adhered contacts and boundary conditions of the secondary shear zone[J].Wear,2015,330:608-617. |

| 24 | KANG Z Y, FU Y H, CHEN Y,et al .Experimental investigation of concave and convex micro-textures for improving anti-adhesion property of cutting tool in dry finish cutting[J].International Journal of Precision Engineering and Manufacturing-Green Technology,2018,5(5):583-591. |

| 25 | YU R, SOMMERS A D, OKAMOTO N C .Effect of a micro-grooved fin surface design on the air-side thermal-hydraulic performance of a plain fin and tube heat exchanger[J].International Journal of Refrigeration,2013,36(3):1078-1089. |

| 26 | SZCZOTKARZ N, MRUGALSKI R, MARUDA R W,et al .Cutting tool wear in turning 316L stainless steel in the conditions of minimized lubrication[J].Tribology International,2021,156:106813. |

| 27 | ZHANG K D, DENG J X, MENG R,et al .Influence of laser substrate pretreatment on anti-adhesive wear properties of WC/Co-based TiAlN coatings against AISI 316 stainless steel[J].International Journal of Refractory Metals and Hard Materials,2016,57:101-114. |

/

| 〈 |

|

〉 |