收稿日期: 2018-10-08

修回日期: 2019-01-14

网络出版日期: 2019-06-01

基金资助

国家科技重大专项(2013ZX04002021)

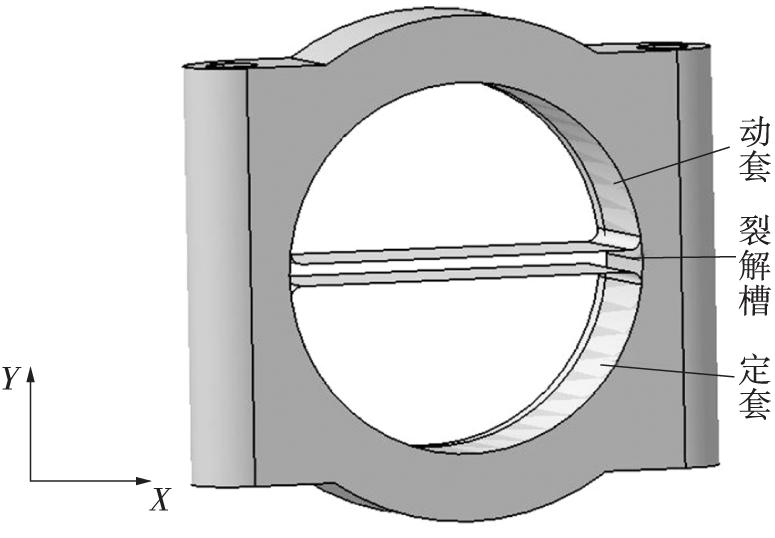

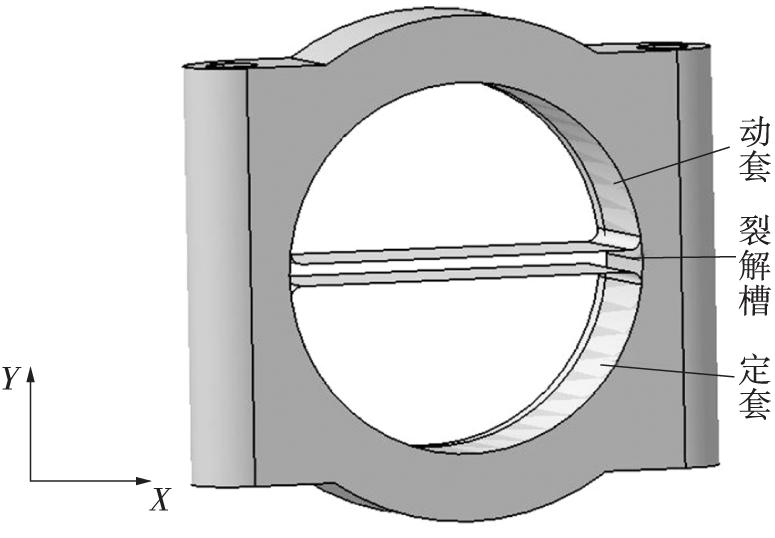

Numerical Analysis of Material Fracture Splitting Performance of Rear Axle's Main Reducer Shell Bearing Seat

Received date: 2018-10-08

Revised date: 2019-01-14

Online published: 2019-06-01

Supported by

Supported by the National Science and Technology Major Project of China(2013ZX04002021)

寇淑清 修亭亭 金文明 赵勇 姚娟 . 后桥主减速器壳体轴承座材料裂解性能数值分析[J]. 华南理工大学学报(自然科学版), 2019 , 47(7) : 121 -127,135 . DOI: 10.12141/j.issn.1000-565X.180495

/

| 〈 |

|

〉 |