华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (7): 72-80.doi: 10.12141/j.issn.1000-565X.220621

所属专题: 2023年土木建筑工程

低气压对浇筑期泡沫混凝土性能和孔结构的影响

刘鑫1,2 姚云龙1,3 姚梓芮1,3 钱申春4 程涛4 洪宝宁1,3

- 1.河海大学 岩土力学与堤坝工程教育部重点实验室,江苏 南京 210098

2.河海大学 隧道与地下工程研究所,江苏 南京 210098

3.河海大学 岩土工程科学研究所,江苏 南京 210098

4.安徽省公路桥梁工程有限公司,安徽 合肥 230031

Effect of Low Air Pressure on Performance and Pore Structure of Foamed Concrete in Pouring Period

LIU Xin1,2 YAO Yunlong1,3 YAO Zirui1,3 QIAN Shenchun4 CHENG Tao4 HONG Baoning1,3

- 1.Key Laboratory of the Ministry of Education for Geomechanics and Embankment Engineering,Hohai University,Nanjing 210098,Jiangsu,China

2.Tunnel and Underground Engineering Institute,Hohai University,Nanjing 210098,Jiangsu,China

3.Geotechnical Engineering Institute,Hohai University,Nanjing 210098,Jiangsu,China

4.Anhui Road and Bridge Engineering Co. ,Ltd. ,Hefei 230031,Anhui,China

摘要:

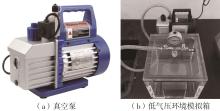

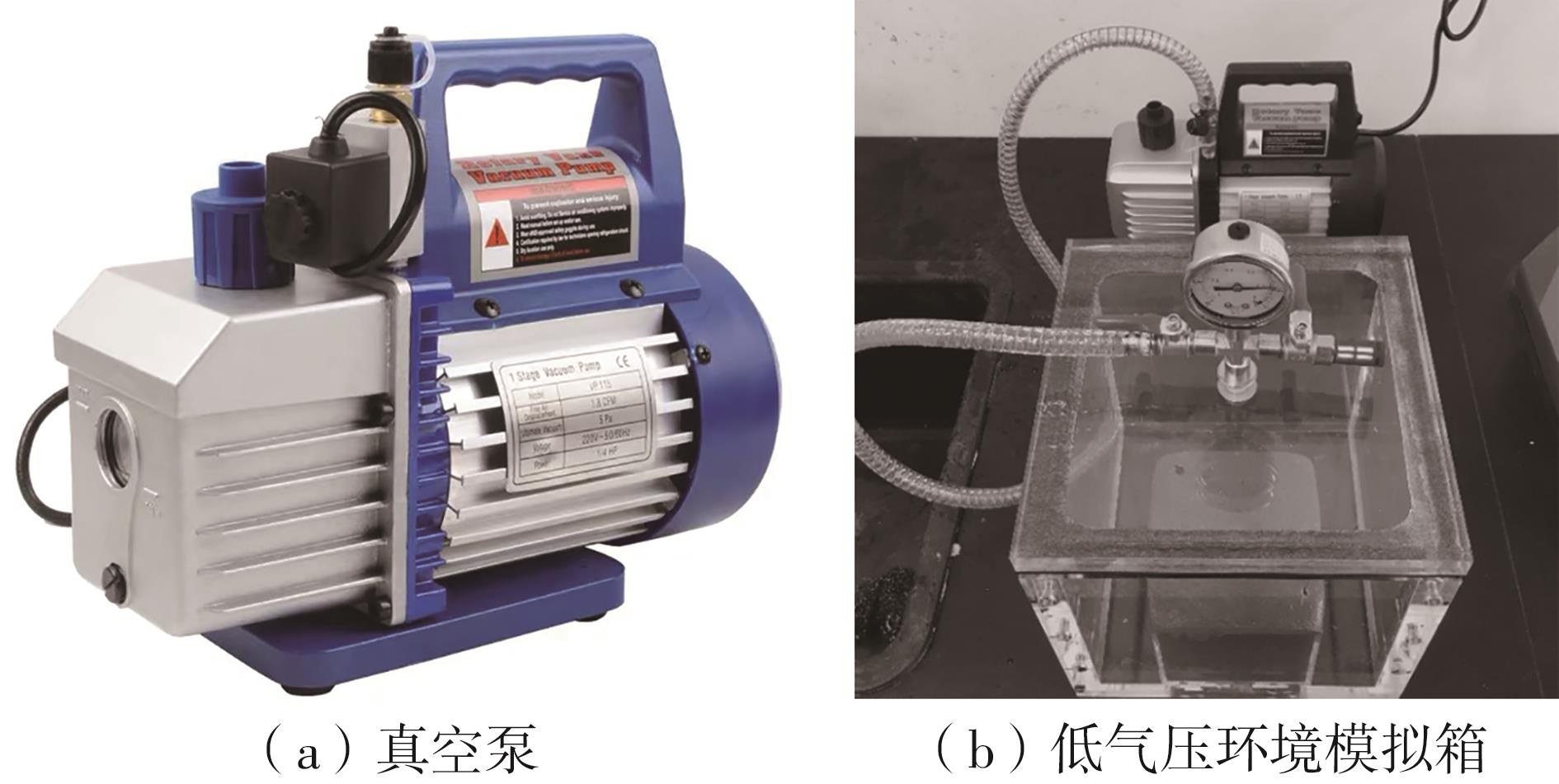

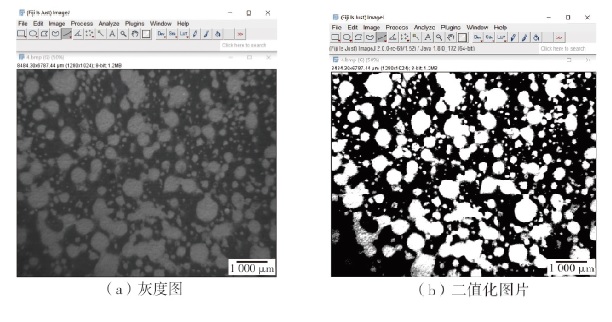

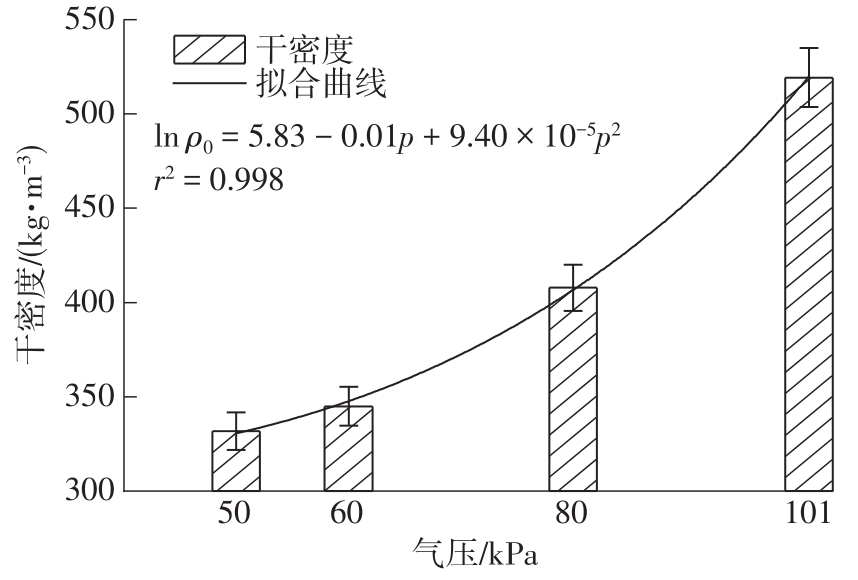

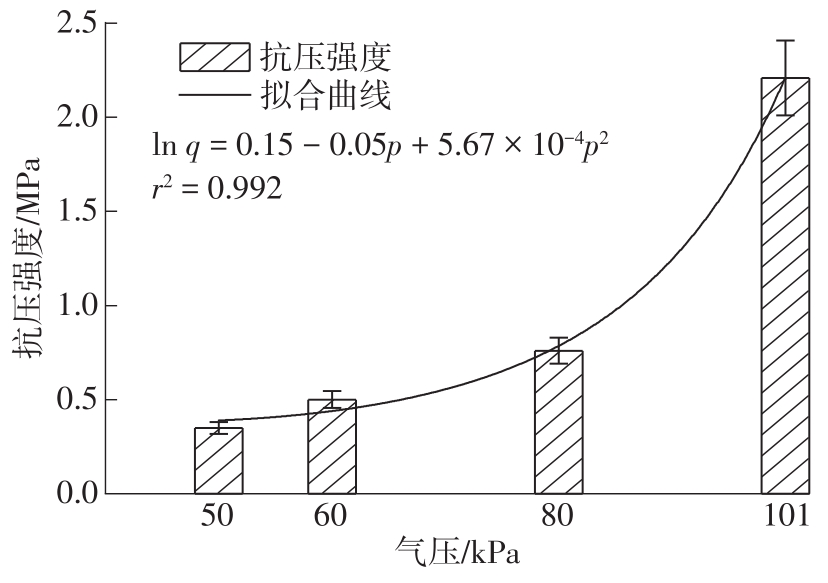

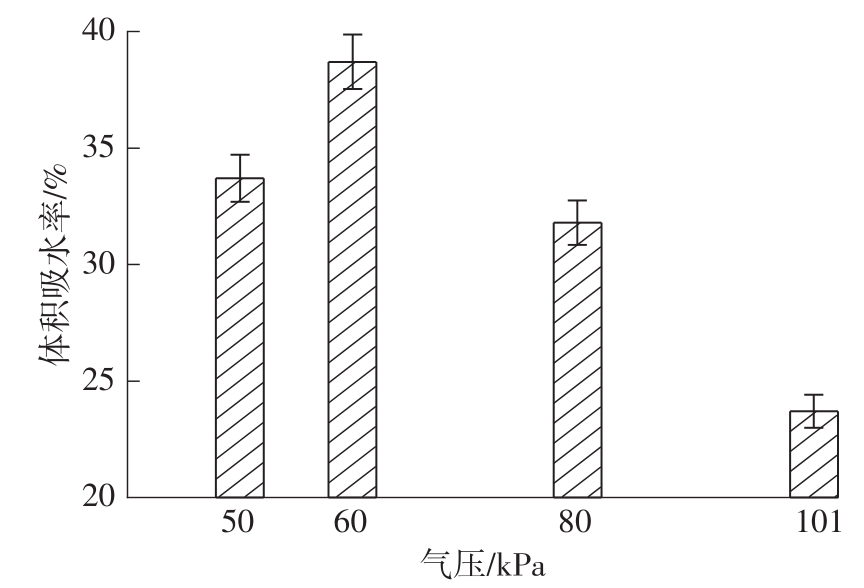

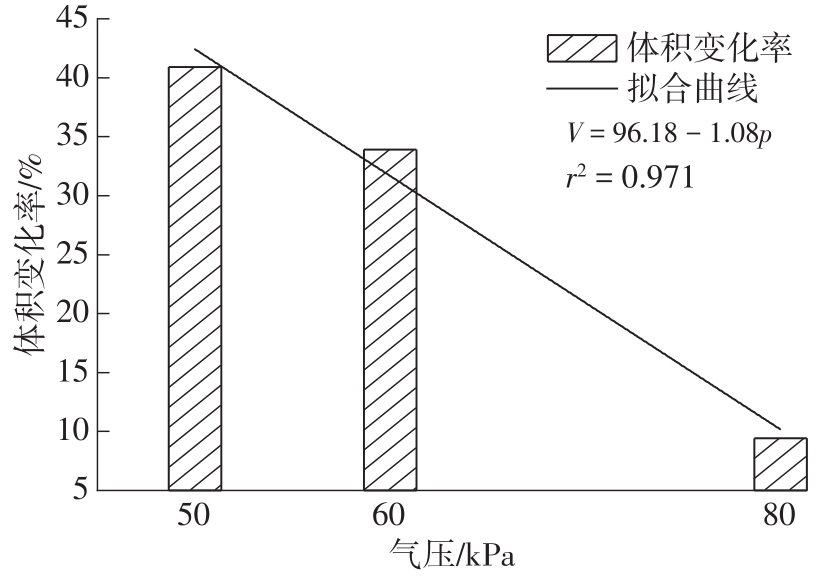

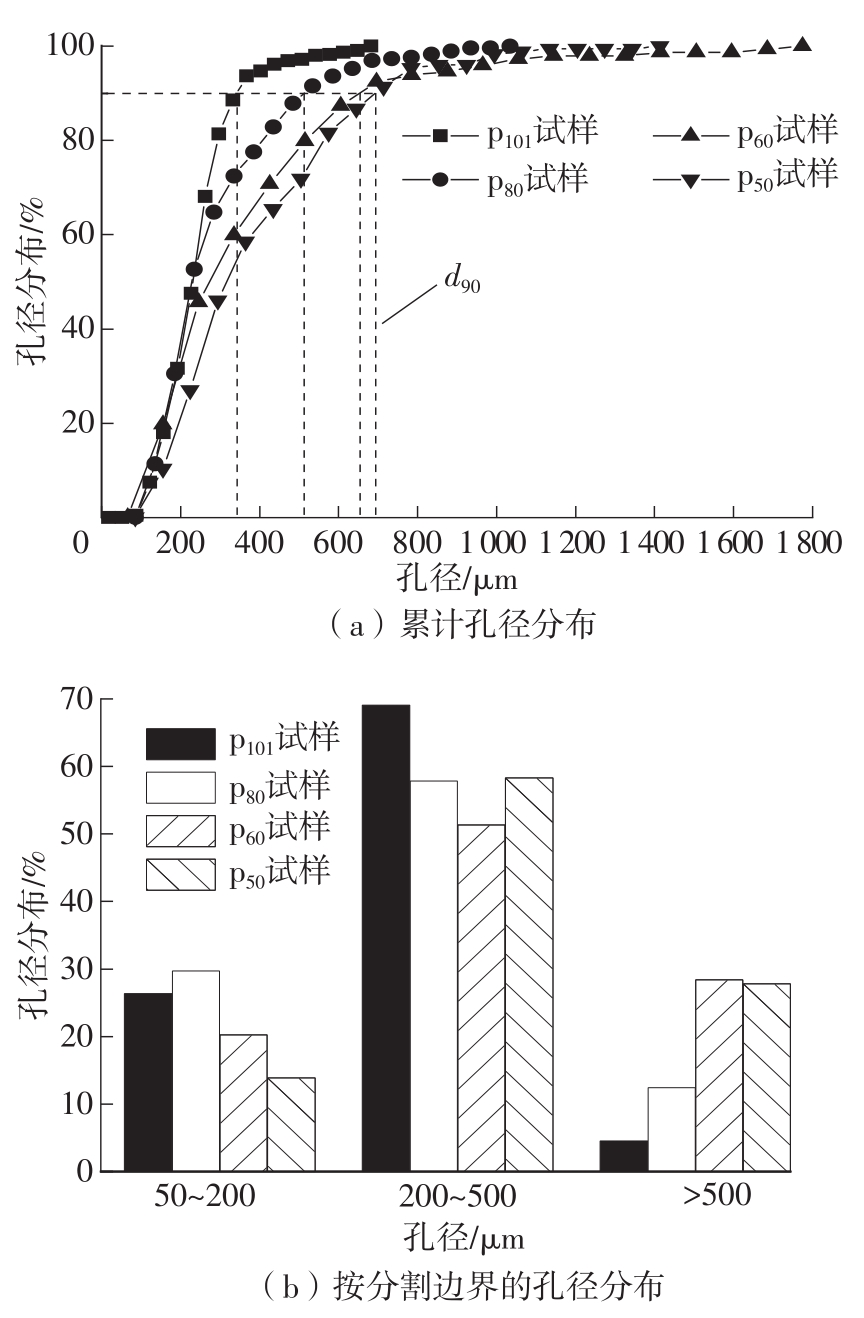

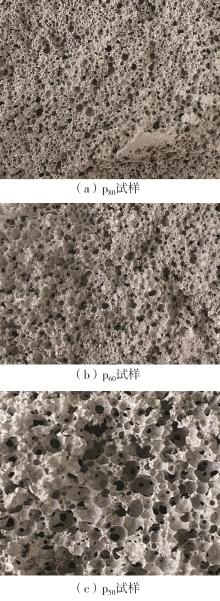

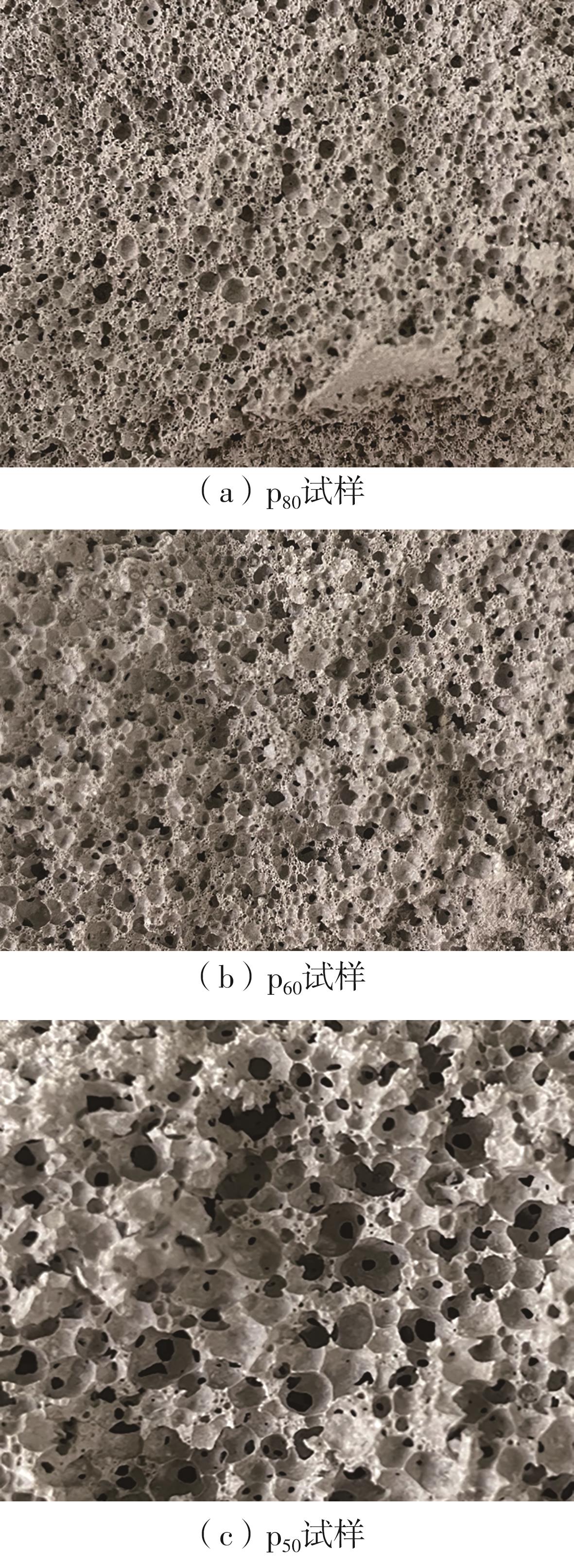

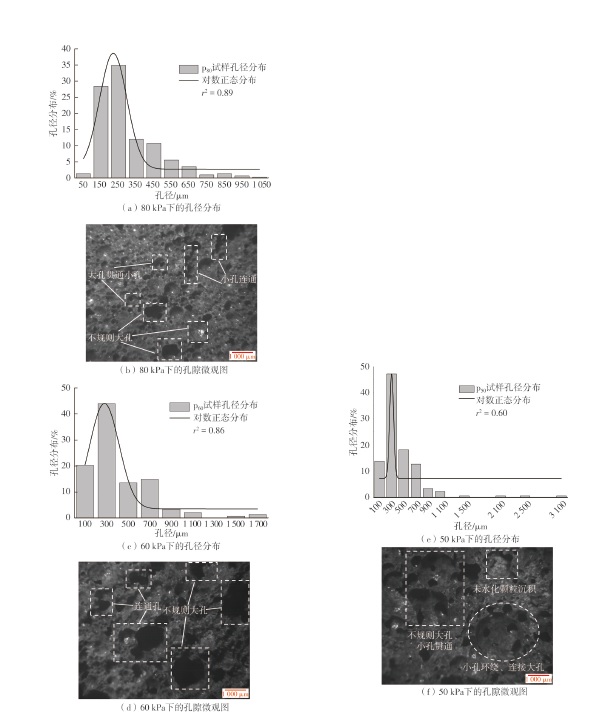

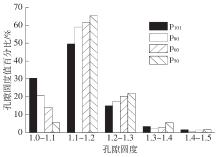

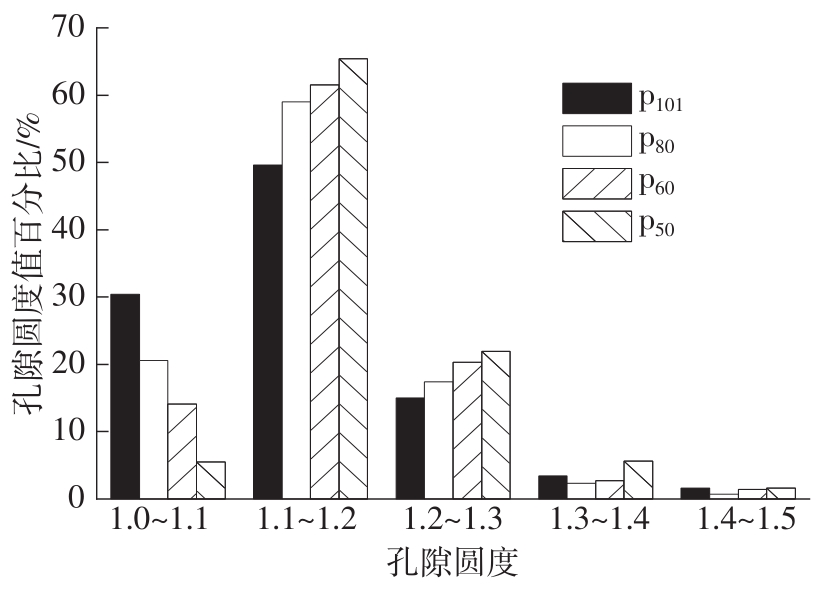

泡沫混凝土具有轻质性、强度可调节性,固化后自立性好,隔热性及耐久性佳,已成功应用在软基换填、地下空洞与溶洞填筑、保温隔热等工程中,尤其是高速公路路堤填筑工程,如道路改扩建、桥背填土、地铁空间上覆减荷等。泡沫混凝土在浇筑至固化成型这段时期内,若受低气压这一不利环境因素的影响,会导致固化成型后泡沫混凝土的性能退化和劣化。然而,目前尚缺少关于泡沫混凝土在浇筑期受低气压影响后的宏观性能和孔结构的研究。为了研究浇筑期泡沫混凝土受低气压影响后的服役性能,文中设计低气压环境模拟箱对比研究了低气压(50、60和80 kPa)下泡沫混凝土的宏观性能和孔结构的演变规律。结果表明:随着浇筑期气压的降低,泡沫混凝土的干密度、抗压强度不断减小,吸水率不断增大,其中50 kPa下泡沫混凝土的干密度为常压(101 kPa)下的63.9%,抗压强度为常压下的15.8%;60 kPa时泡沫混凝土的体积吸水率达到最大值,为38.7%;随着气压降低,泡沫混凝土的等效孔径、孔隙分布分维不断增大,50 kPa下的大孔(直径>500 μm)数量比常压下的增加了24%,不规则大孔和连通孔增多,小孔分布愈加不均匀;在1.0~1.1的孔隙圆度范围内,气孔数量占比随着气压降低而逐渐减小。

中图分类号: