华南理工大学学报(自然科学版) ›› 2023, Vol. 51 ›› Issue (2): 27-34.doi: 10.12141/j.issn.1000-565X.220147

所属专题: 2023年机械工程

基于GA-BP神经网络的喷射成形锭坯形貌调控技术

冷晟1 付有为1 马万太1 钱浩1 虞钧鹏1 蒋云泽2 吴尚霖3

- 1.南京航空航天大学 机电学院, 江苏 南京 210016

2.江苏豪然喷射成形合金有限公司, 江苏 镇江 212200

3.中国航天科工南京晨光集团有限责任公司, 江苏 南京 210006

Study on the Morphology Control Technology of Spray Forming Ingot Billets Based on GA-BP Neural Network

LENG Sheng1 FU Youwei1 MA Wantai1 QIAN Hao1 YU Junpeng1 JIANG Yunze2 WU Shanglin3

- 1.College of Mechanical & Electrical Engineering,Nanjing University of Aeronautics and Astronautics,Nanjing 210016,Jiangsu,China

2.Jiangsu HaoRan Spray Forming Alloy Co. Ltd. ,Zhenjiang 212200,Jiangsu,China

3.China Aerospace;Science and Industry Nanjing Chenguang Group Co. ,Ltd. ,Nanjing 210006,Jiangsu,China

摘要:

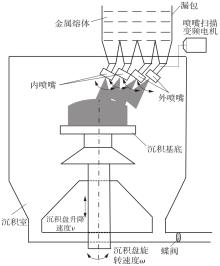

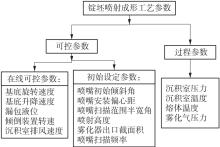

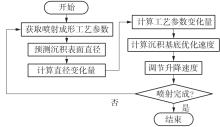

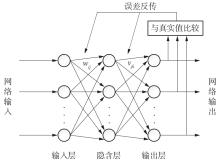

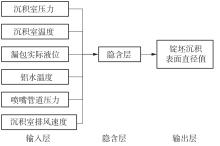

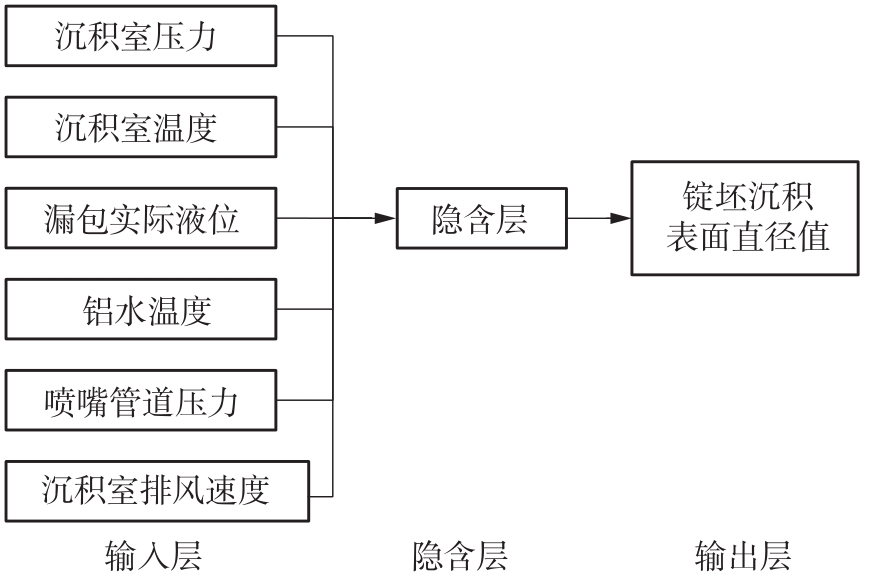

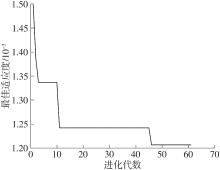

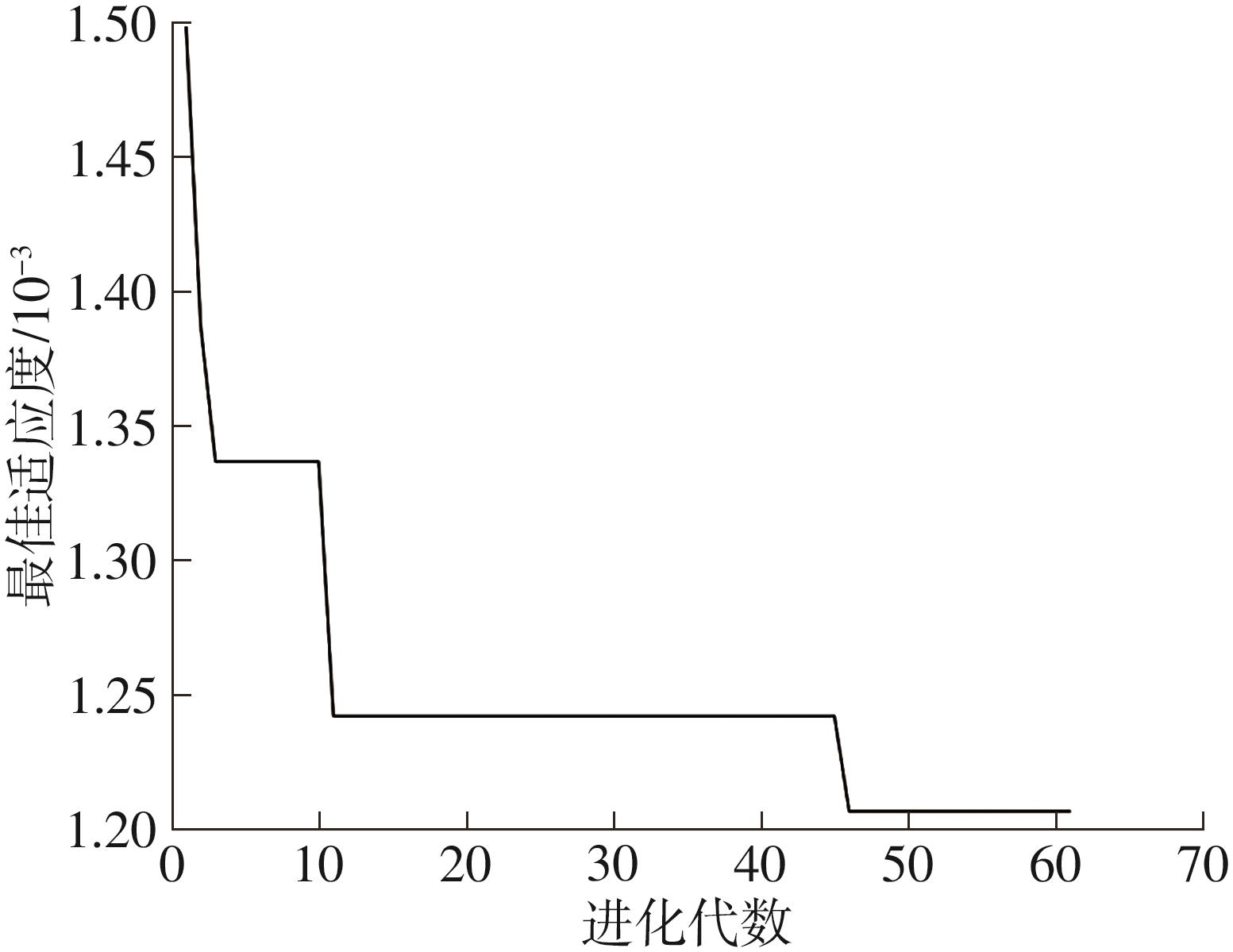

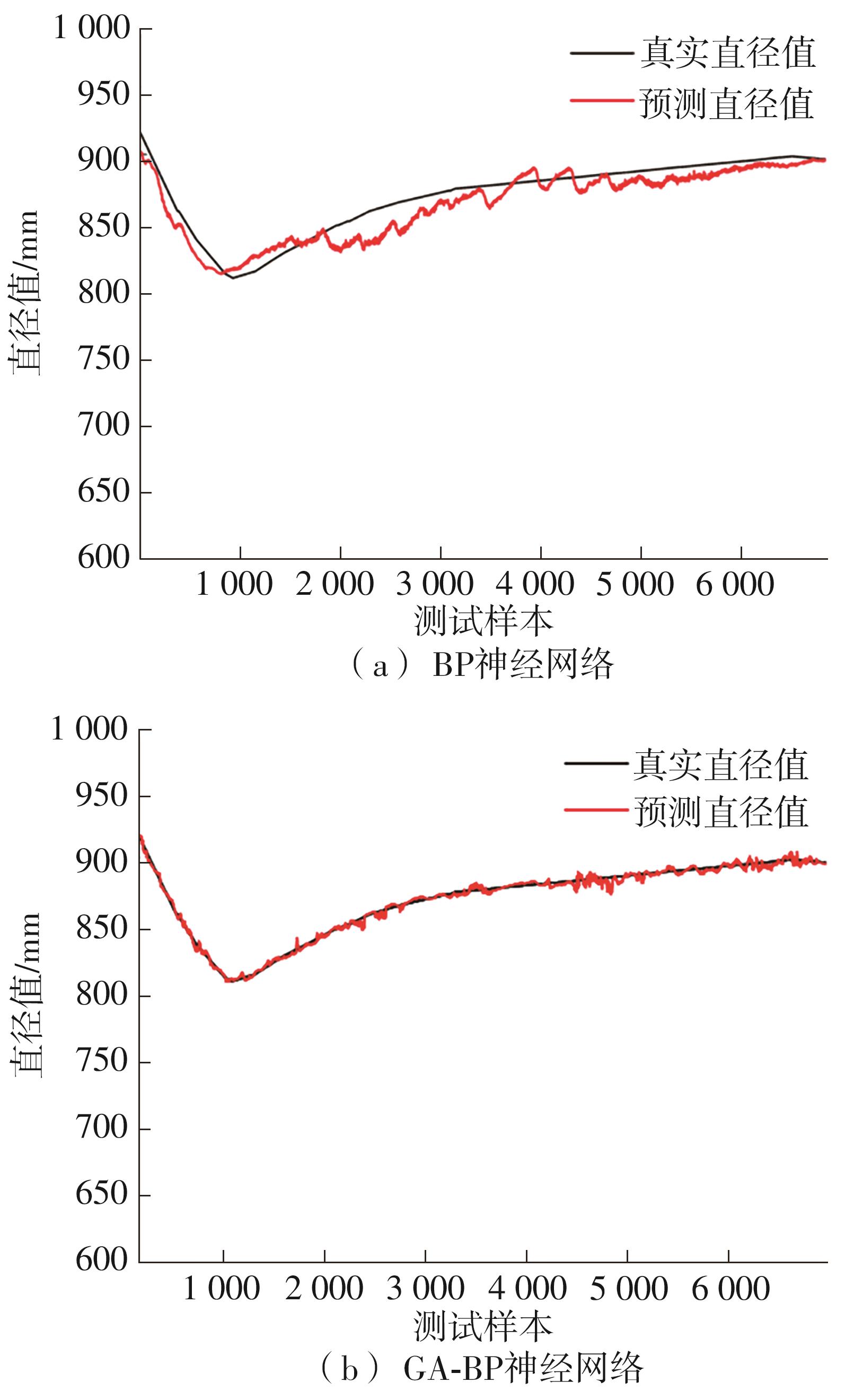

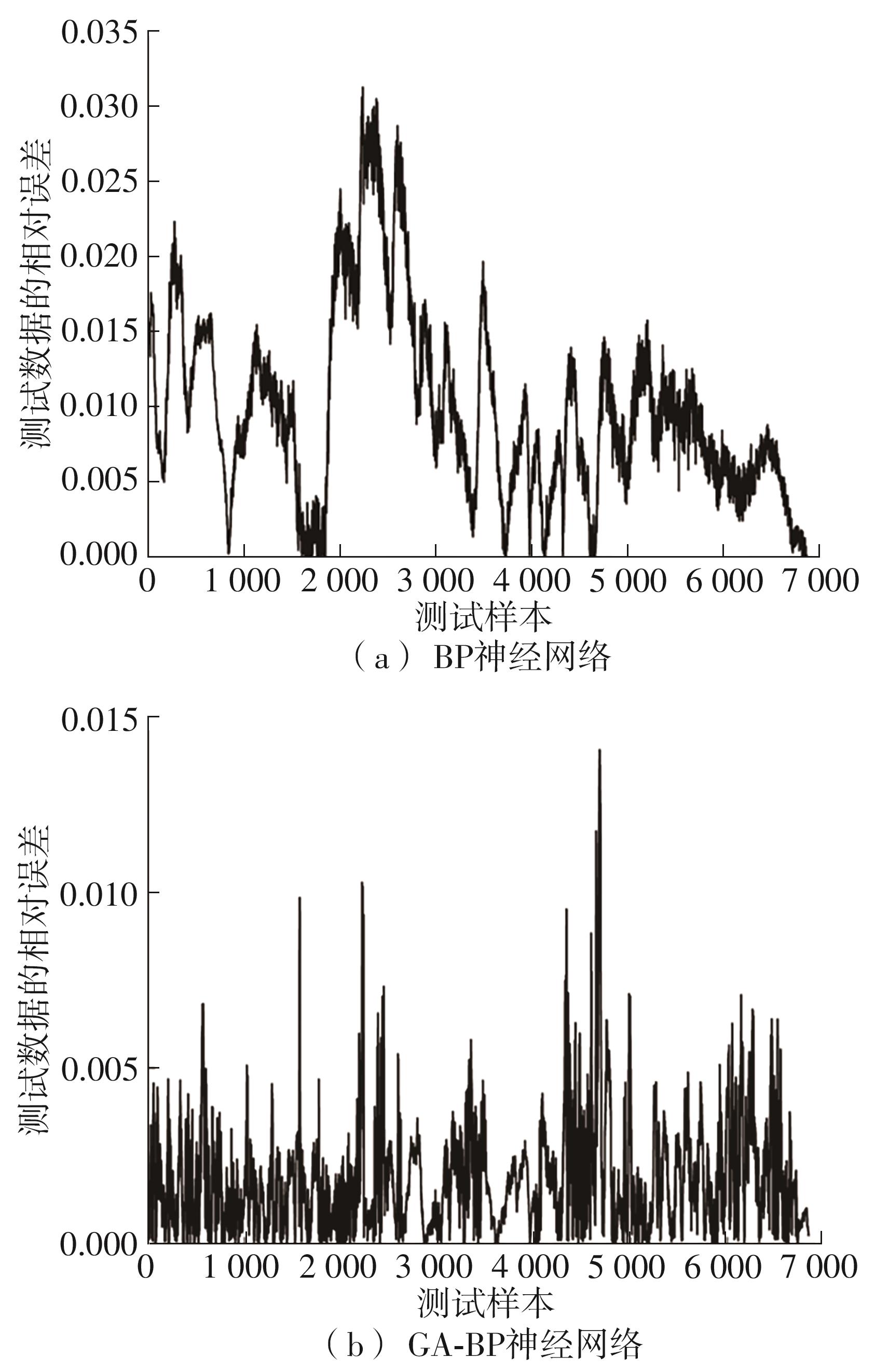

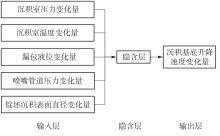

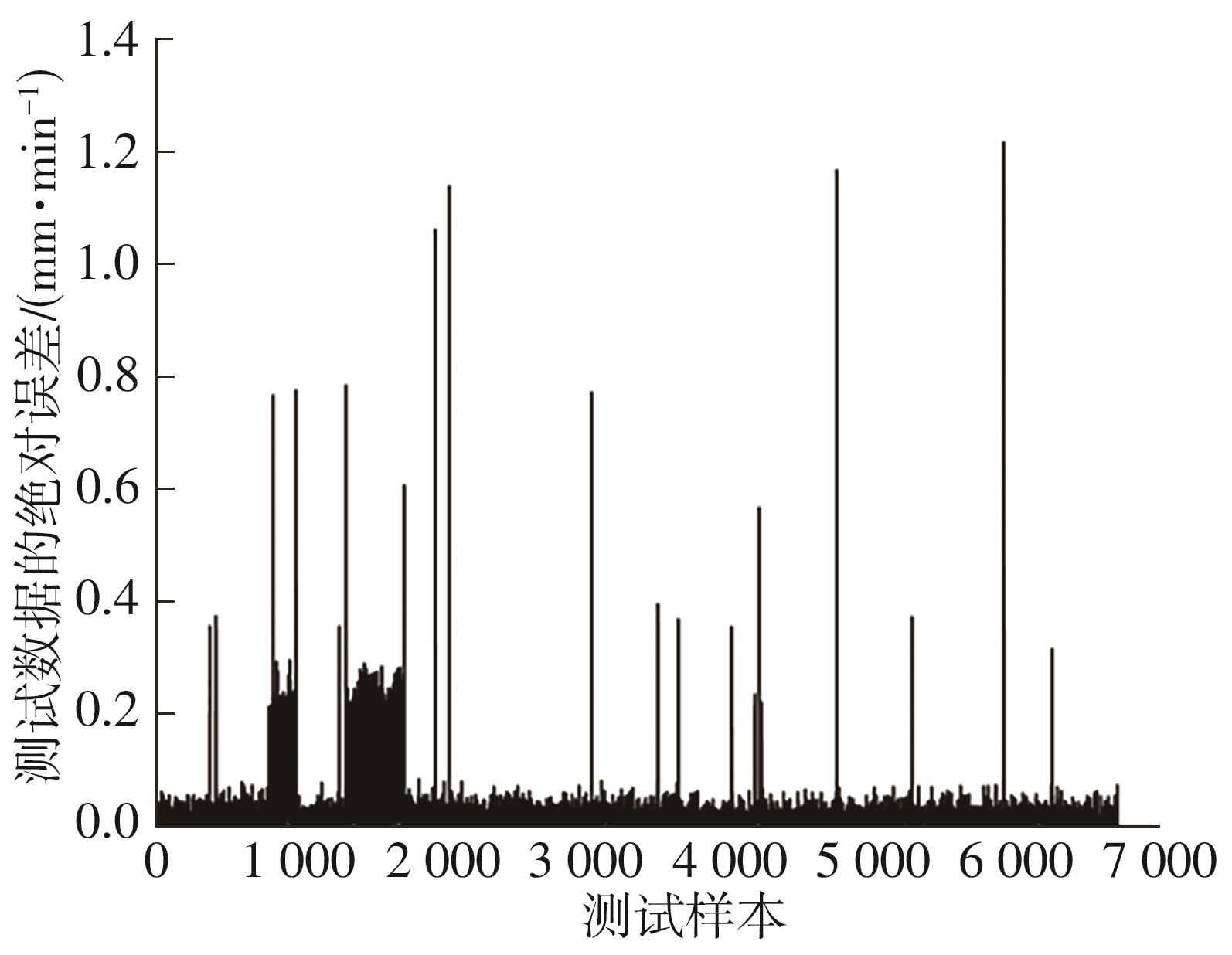

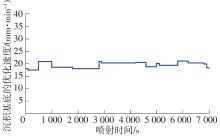

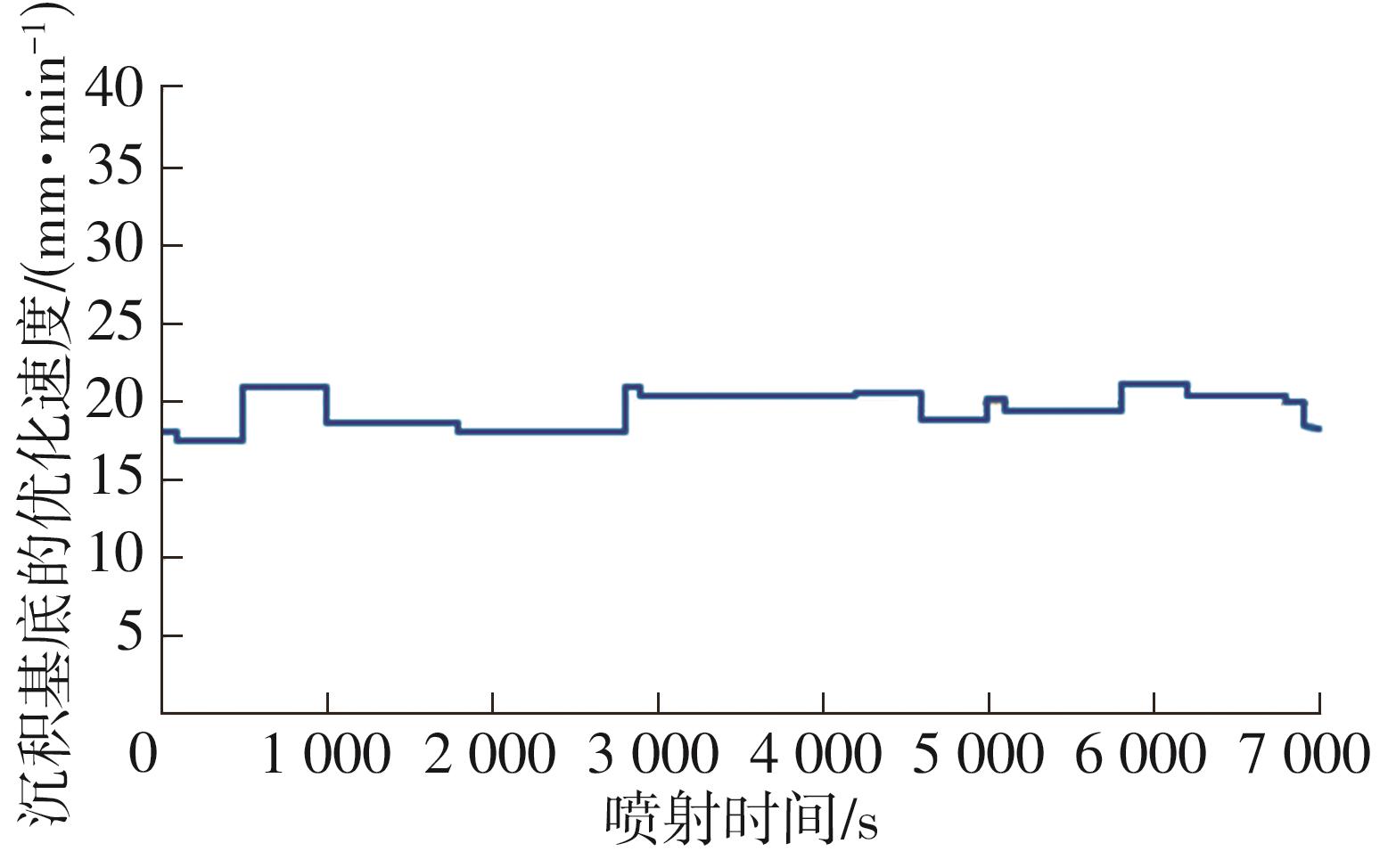

随着现代技术的发展,在汽车和航空航天等领域都在追求材料的轻量化,而材料的高强度高韧性是轻量化的基础。7000系铝合金(Al-Zn-Mg-Cu系铝合金)具有高强度、高硬度、良好的耐腐蚀性能等优点,其中7055铝合金是所有铝合金中强度最高的。喷射成形工艺是7055铝合金常用的制备方法。铝合金锭坯在沉积过程中的稳定生长是喷射成形工艺制备形貌一致、沉积质量均匀的大规格锭坯的基础。受喷射成形过程中众多工艺参数变化的影响,现有的理论模型难以满足实际生产过程中质量控制要求。文中通过所采集的喷射成形过程工艺历史数据与锭坯沉积表面直径的相关性分析,结合BP神经网络与遗传算法,构建锭坯直径的GA-BP神经网络预测模型及生长速度调控模型;根据工艺参数的实时波动,计算直径变化量,作为输入层导入经过训练的速度调节神经网络模型,对沉积基底的升降速度进行优化调控,使得锭坯沉积生长形貌均匀稳定。最后采用该方法对锭坯沉积生长速度调控工艺进行实验分析。结果表明,通过该工艺参数优化方法制备的大规格锭坯直径尺寸偏差在5%以内,验证了生长速度调节的可行性。

中图分类号: