华南理工大学学报(自然科学版) ›› 2022, Vol. 50 ›› Issue (9): 109-115.doi: 10.12141/j.issn.1000-565X.210804

所属专题: 2022年机械工程

薄壁深杯形件多工艺复合旋压成形机理研究

徐晓 张川洋 肖刚锋 夏琴香

- 华南理工大学 机械与汽车工程学院,广东 广州 510640

On the Mechanism of Multi-process Compound Spinning for Thin-walled Deep Cup Shaped Parts

XU Xiao ZHANG Chuanyang XIAO Gangfeng XIA Qinxiang

- School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510640,Guangdong,China

摘要:

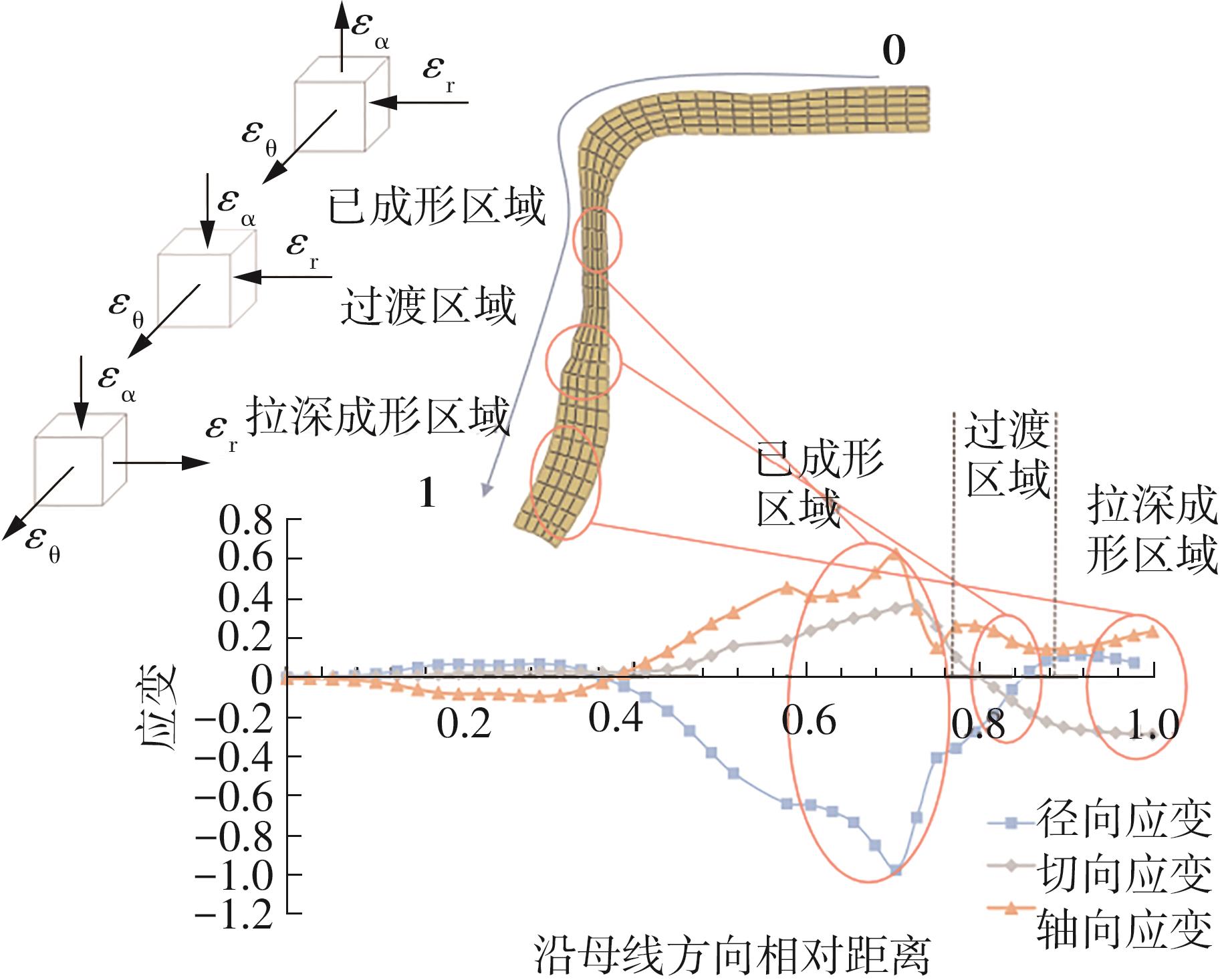

针对传统的薄壁深杯形件成形流程长、效率低、质量控制难的问题,提出采用拉深-流动多工艺复合旋压方法实现此类零件的高效短流程精确制备。基于Abaqus有限元软件建立了SPHC热轧钢薄壁深杯形件拉深-流动多工艺复合旋压成形有限元模型,研究了深杯形件复合旋压成形时的应力应变分布及材料流动行为,揭示了复合旋压的成形机理,结合复合旋压成形试验,验证了有限元模拟的准确性。结果表明:采用多工艺复合旋压工艺可实现深杯形零件的单道次旋压成形,并可获得成形质量良好的薄壁深杯形零件。按照材料变形状况,多工艺复合旋压可分为拉深旋压阶段、流动旋压起始阶段和复合旋压稳定阶段;在流动旋压起始阶段最大等效应变随旋压的进行而急剧上升;在稳定旋压阶段最大等效应变出现在已成形区域,其变形状态为轴向与切向拉伸、径向压缩,而过渡区域为轴向拉伸、径向与切向压缩。流动旋压起始阶段,贴模区域材料向口部的轴向流动随着拉深旋压用与流动旋压用旋轮间的轴向错距量的增大而增大。在复合旋压稳定阶段,坯料与拉深旋压用旋轮接触的外侧区域受三向压应力,而内侧区域受到三向拉应力的作用,坯料与流动旋压用旋轮接触区域受三向压应力作用。为保证旋压成形质量,旋压拉深旋压用旋轮与流动旋压用旋轮之间的轴向错距量应取值大于5.3 mm。

中图分类号: